Nexa3D NXE400 User manual

NXE400.OM_EN.2.6

NXE400 Operation Manual

NXE400.OM_EN.2.6 3© Copyright 2020 Nexa3D

Contents

1. Overview4

1.1. Safety Warnings .......................................................................................................................4

1.2. Technical Specifications ...........................................................................................................5

1.3. Certifications ............................................................................................................................6

1.4. Product Elements .....................................................................................................................7

2. User Resources............................................................................................................... 12

2.1. Software .................................................................................................................................12

2.2. Instructions For Use ...............................................................................................................12

2.3. Unboxing & Setup...................................................................................................................12

3. NXE400 Systems............................................................................................................. 17

3.1. Light Engine............................................................................................................................17

3.2. Resin System...........................................................................................................................17

3.3. Z-Axis ......................................................................................................................................18

4. Post Processing .............................................................................................................. 19

4.1. Washing..................................................................................................................................19

4.2. Curing .....................................................................................................................................19

4.3. Support Removal....................................................................................................................19

NXE400.OM_EN.2.6 4© Copyright 2020 Nexa3D

1. Overview

1.1. Safety Warnings

Danger: Read this operation manual prior to using the NXE400 printer.

Failure to do so can result in injury or death.

Caution: Do not modify the NXE400 without factory authorization.

Modifications to the NXE400, including the override of safety features or

interlocks, can result in damage to the printer or injury to operators.

Unauthorized modifications invalidate your warranty.

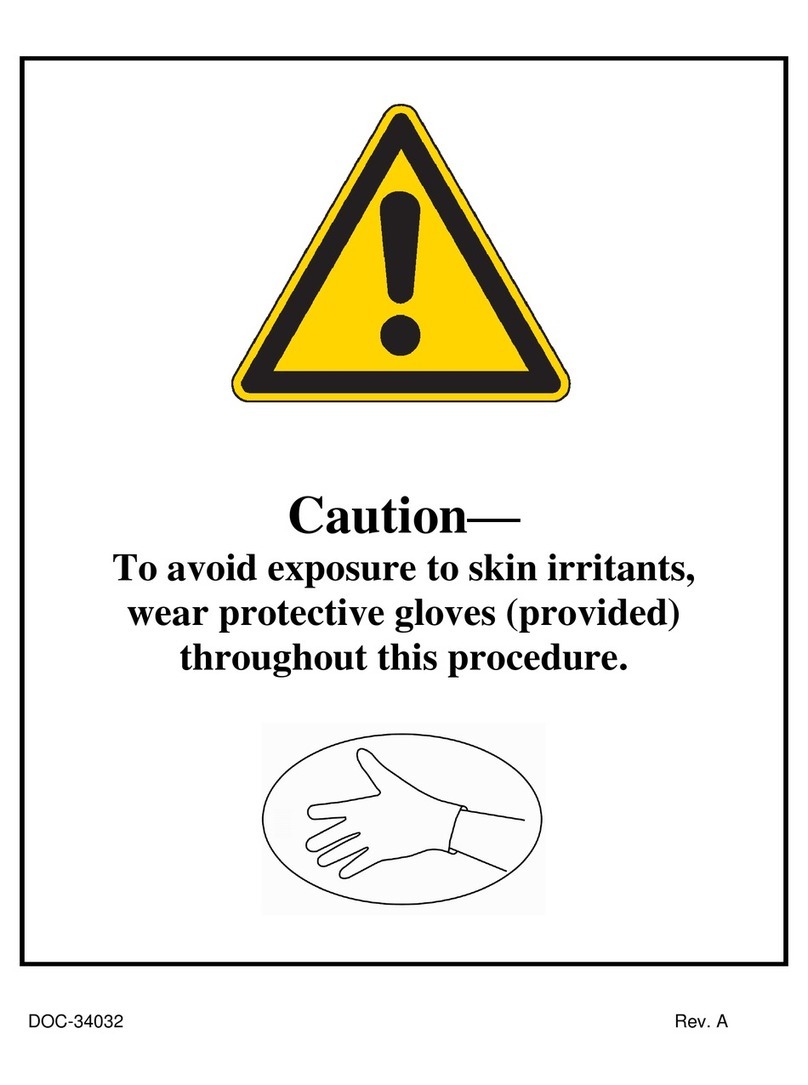

Caution: Use appropriate protective equipment when handling resin and

solvents, including cut & abrasion resistant gloves, safety goggles, smock,

and vapor respirator if recommended by SDS of resin or solvent.

Caution: The NXE400 light engine emits UV-A radiation which can damage

eyes or skin with prolonged exposure. Use protective glasses rated for 99.9%

UVA protection when working around the NXE400 or post-cure equipment.

Warning: It is the user responsibility to verify suitability of material and

process for application requirements. In no case shall Nexa3D be liable for

loss, death, or injury caused by products produced on Nexa3D printers or

with Nexa3D materials. Nexa3D expressly disclaims any implied or explicit

warranty of fitness for any particular usage.

Warning: Immediately clean spilled resin from the printer, or it may cure

and cause surface damage when removed. Most surfaces may be cleaned

with IPA or other similar solvents (Yellow Magic 7, Window Cleaner, xClean).

NXE400.OM_EN.2.6 5© Copyright 2020 Nexa3D

1.2. Technical Specifications

Printing Technology

Continuous LSPc

Light Source

Structured Light Matrix

Build Volume

275 x 155 x 400mm (10.8 x 6.1 x 15.7 inch)

XY Resolution

76.5 μm(4K)

Z Resolution

50/100/200 microns

Interface

7” Touchscreen

Input File Format

.stl, .3mf

Materials

xGPP-Blue, xGPP-Transparent, xGPP-Grey, xABS-

HT-Orange, 3843-ABS-Black, xCE-Black, xMED412

Weight

160kg (350lb)

Dimensions

710 x 710 x 1675 mm (28 x 28 x 66 inch)

Crated Weight

250 kg (550lb)

Crated Dimensions

990 x 990 x 1905mm (39 x 39 x 75 inch)

Electrical Requirements

US: 100-130V, 8A, NEMA 15-5R

EU: 200-240V, 4A, CEE7/7 (Schuko)

Connectivity

WiFi, USB, Ethernet

Operating Environment

Air temperature between 20-25˚C (60-80˚F) and

RH below 70%

NXE400.OM_EN.2.6 6© Copyright 2020 Nexa3D

1.3. Certifications

NXE400.OM_EN.2.6 7© Copyright 2020 Nexa3D

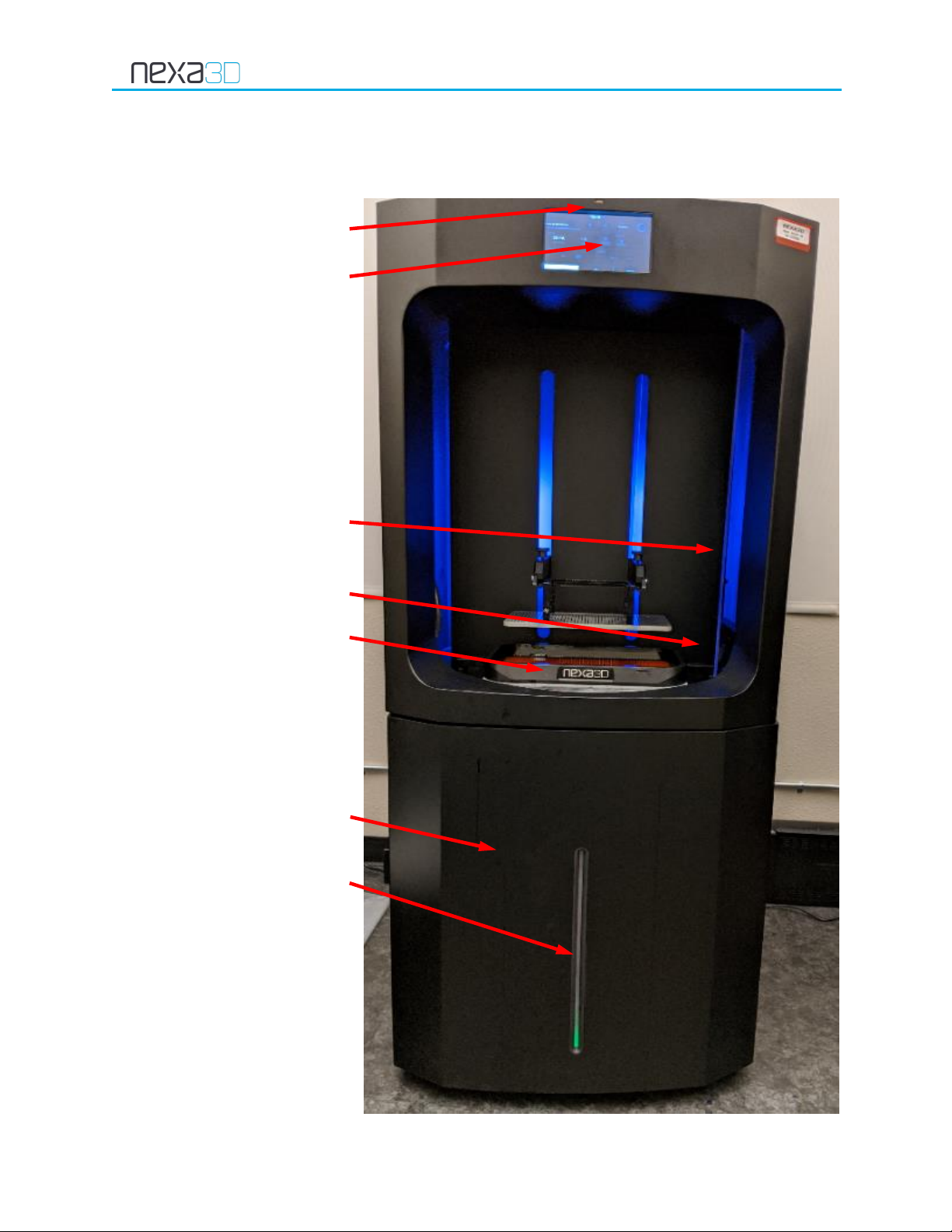

1.4. Product Elements

1.4.1 NXE400

USB

Touchscreen

Transparent Door

Camera

Vat

Lower Door

Progress Bar

NXE400.OM_EN.2.6 8© Copyright 2020 Nexa3D

Buildplate

Thumbscrews

Build-plate

Vat Clamps

Vat

Membrane

Door Track

Nozzl e Holder

Elevator Arms

Resin Vacuum Nozzle

Vat

NXE400.OM_EN.2.6 9© Copyright 2020 Nexa3D

Light Engine

Resin Pump

Computer Reset

Carboy Container

LE Filter

Rear Filter Panel

Main Power Switch

NXE400.OM_EN.2.6 10 © Copyright 2020 Nexa3D

1.4.2 Shipped Separate

Accessory Kit

An accessory kit is included to facilitate post processing and adjustments to the printer.

Plastic Bin –for cleaning build plate and

small parts

Plastic Drip Tray –prevent resin from

dripping when removing build plate

Nitrile Gloves –protect hands from irritation

Safety Glasses –protect eyes

Flush-cut Snips –support removal

Plastic Squeege –direct resin towards

pickup nozzle

Funnel and Filters –filter used resin

Steel flexible putty knife –removing residue

from build plate

Steel picks –cleaning residue from slots in

build plate

Allen Wrenches for removing shipping

bracket and leveling build plate

Caps –for resin hoses when disconnected

Membranes

5pk Membranes

Build Plate

Build Plate

NXE400.OM_EN.2.6 11 © Copyright 2020 Nexa3D

Resin Container

5L Carboy Container w/ tube kit

Vat

Aluminum Vat

Resin Cartridge

Resin Cartridge

NXE400.OM_EN.2.6 12 © Copyright 2020 Nexa3D

2. User Resources

2.1. Software

Software required to operate NXE400 may be found at nexa3d.com/downloads.

MagicsPrint for Nexa3d with .bpprof file of parameter settings and NexaX with .nxr file with

parameter settings are both required for file preparation.

2.2. Instructions For Use

Usage instructions and training may be found at the Nexa3d service center,

nexa3d.atlassian.net/servicedesk/customer/portal/2

Prior to scheduling installation, review and sign the site preparation requirements.

2.3. Unboxing & Setup

No tools are needed to unpack the NXE400. If the printer will be relocated, remove all resin,

secure the z-stage and use original packaging.

Unlatch the front panel/ramp and place

as shown in the picture. Line up the holes

and place bolts (found in a plastic bag

inside the crate) to secure the ramp

before unloading.

NXE400.OM_EN.2.6 13 © Copyright 2020 Nexa3D

Unscrew and remove the three bracing

boards

Remove the hatch door on the back of the

crate

Raise the foot pads by turning the orange

nuts

Roll the NXE400 down the ramp to the

desired location.

Remove the plastic wrap from the printer

and discard.

NXE400.OM_EN.2.6 14 © Copyright 2020 Nexa3D

Prior to plugging in the unit, remove tape

securing the doors and resin vacuum

nozzle. Place the nozzle in the magnetic

cradle on the inside wall of the printer.

Install the carboy container, using the lid

with tube-insert assembly.

Remove the red bracket securing the

elevator on the Z-stage

Drop the feet of the printer and adjust

height until a bubble-level on the glass of

the light engine shows horizontal

NXE400.OM_EN.2.6 15 © Copyright 2020 Nexa3D

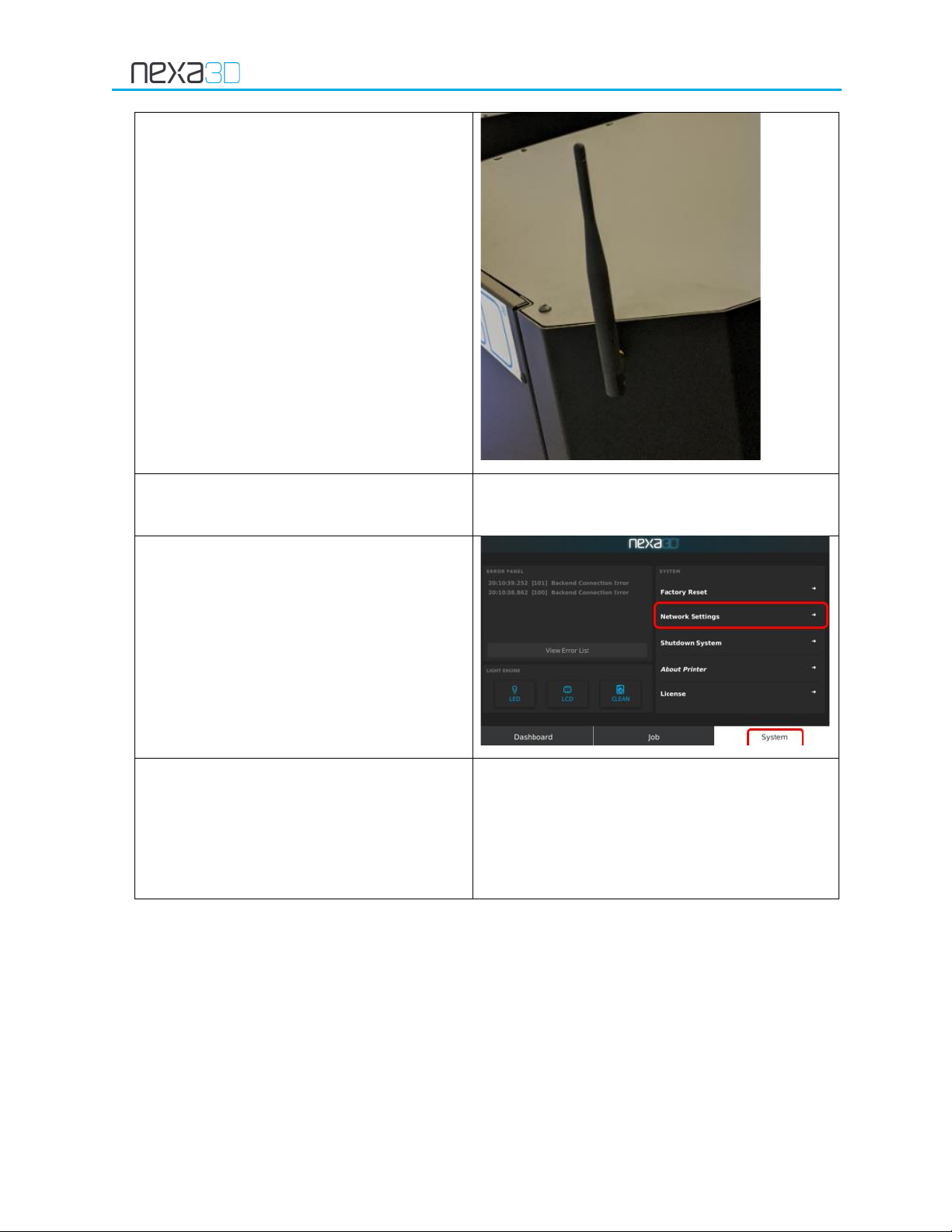

Screw in the WiFi antenna taped to the

side of the printer chassis

Plug in the power cord and turn on the

power switch on the back of the machine

Navigate in the touchscreen to System >

Network Settings menu and connect to

the network if desired

The build plate was aligned with the light

engine at the factory, however it should

be checked after shipping. Follow the

instructions online at the Service Center

to check if adjustment is required

NXE400.OM_EN.2.6 16 © Copyright 2020 Nexa3D

Install the build platform and secure with

2 thumb screws

Wipe the top surface of the light engine

clean, install a membrane with screws

facing down, then the vat on top of the

membrane and close the vat clamps to fix

it in position

NXE400.OM_EN.2.6 17 © Copyright 2020 Nexa3D

3. NXE400 Systems

3.1. Light Engine

Maintaining the NXE400 light engine is critical to get best printer performance.

There is a protective film on the top surface of the light engine. Keep it clean and free of

streaks. It may be cleaned with xClean, isopropyl alcohol, or glass cleaner. Don’t use sharp

objects or abrasive materials to clean it. Keep the build plate clean of burrs and the resin

free of cured shards of resin. Detailed care and maintenance enstructions may be found

online.

The LCD is delecate and should be protected from damage. Don’t drop objects on the light

engine top surface to avoid cracking the glass. Remove the build plate before turning off the

printer to avoid it falling on the light engine. Don’t apply pressure to the edges of the LCD to

avoid damage to the data conducters.

The light engine will become ineffective if dust is allowed to build up. Always keep a filter

installed and change 3-6 months depending on air quality.

After removing resin and membrane, run the cleaning job from the System screen to inspect

the light engine for damage (dead zones, contamination). Keep the door closed or use

protetive eyewear. It should look like this:

3.2. Resin System

The NXE400 membrane is separate from the vat. Never load resin in the printer if the

membrane and vat are not installed and the clamps are not secured. Failure to do so may

result in a resin leak. The o-ring face seal must be in place to ensure resin seal, and must be

replaced if damaged.

Warning, Spill Risk: Never unlock the vat clamps with resin in the vat. Drain

resin prior to unlocking the vat.

Use the black tray provided when removing a build to prevent dripping resin on the printer.

If resin is dripped on the printer, clean it immediately with Isopropyl Alcohol or xClean.

NXE400.OM_EN.2.6 18 © Copyright 2020 Nexa3D

The membrane must be replaced if damaged. Filter the resin removed from the printer and

run the cleaning print job (full exposure layer) after failed builds. Peel off the cured layer and

remove before running a new job.

Pumps and hoses must be free of air to pump efficiently. Replace hoses if cracks develop.

Tighten the connectors until fully seated.

The section of hose in the pump must be pulled taught before closing the pump, and must

be worked-in before using to avoid stalling the pump motor.

3.3. Z-Axis

The z-axis has a resistance feature to protect the light engine from damage. It must be

disengaged and allowed 5 seconds to self-calibrate before moving by hand, or the resistance

will be excessive. Remove the build plate before disengaging for best results.

Note: Membrane Handling Precautions.

•Only handle membranes by the frame, avoid touching membrane

•Keep resin off light-engine side of membrane, clean light engine

before installing

•Membrane can easily be punctured, keep away from sharp objects

•Avoid contact with any surface other than the light engine - keep

membranes in the resealable bag when not in use.

•If need to change different type of resin. Clean the resin side only

using a lint free wipe moistened with IPA.

•To prevent membrane damage:

oCheck build plates for cured resin or burrs before use

oFilter resin or run Clean cycle after any failed build.

•Inspect membrane between builds by dragging a rubber or silicone

spatula across the surface. Replace as necessary. You may need to

drain resin to under 1cm depth to allow visual inspection in wake of

the spatula movement.

NXE400.OM_EN.2.6 19 © Copyright 2020 Nexa3D

4. Post Processing

4.1. Washing

Parts must be cleaned of uncured resin after printing. Nexa3D recommends washing parts

with xClean or Isoporpyl Alcohol. Washing should be done immediately following printing for

best results.

Wash in a bath using gentle agitation for 5-10 minutes total. Consult local jurisdiction to

determine requirements for safety and disposal in your area.

If parts remain tacky after washing, the solvent may need to be refreshed. Use 2 baths of

progressive cleanliness will help ensure final bath has limited resin contamination. If using

xClean, rinse in water for up to 1 min. In case of 3843-ABS-Black and xMED412, don’t rinse in

water –allow to air dry or rinse in IPA.

Danger: Most cleaning solvents are flammable. Don’t use near open flame

and ensure adequate ventilation and spill containment measures are are in

place.

4.2. Curing

To achieve advertised mechanical properties curing is required in a UV chamber with

>2.5mW/cm2 of UV light in the 405-365nm spectrum. Duration may need to be extended for

thicker section parts. If warping occurs during cure, then cure attached to buildplate and/or

at room temperature.

xGPP-Blue, xGPP-Grey,

xGPP-Transparent,

xMED412

30-60 minutes

Room Temperature

xABS-HT-Orange, xCE-

Black, xCE-White

30-60 minutes

60°-80°C

3843-ABS-Black

30-60 minutes

30°C

4.3. Support Removal

Supports may be broken off by hand or with snips, then sanded down to improve finish if

desired. They may be removed before or after washing and curing. Progressivly sanding with

220 and 400 grit paper works well. Mineral oil is recommended for wet sanding and cleaning

excess dust.

Table of contents

Other Nexa3D 3D Printer manuals

Popular 3D Printer manuals by other brands

Dremel

Dremel 3D40 Idea Builder instructions

3D Systems

3D Systems Duraform ProX PA Original instructions

SINTERIT

SINTERIT Lisa X Translation of the original user manual

Tinkerine Studio

Tinkerine Studio Ditto Pro Setup & operation manual

3DKreator

3DKreator Kreator Motion user manual

Dremel

Dremel DigiLab 3D45 manual