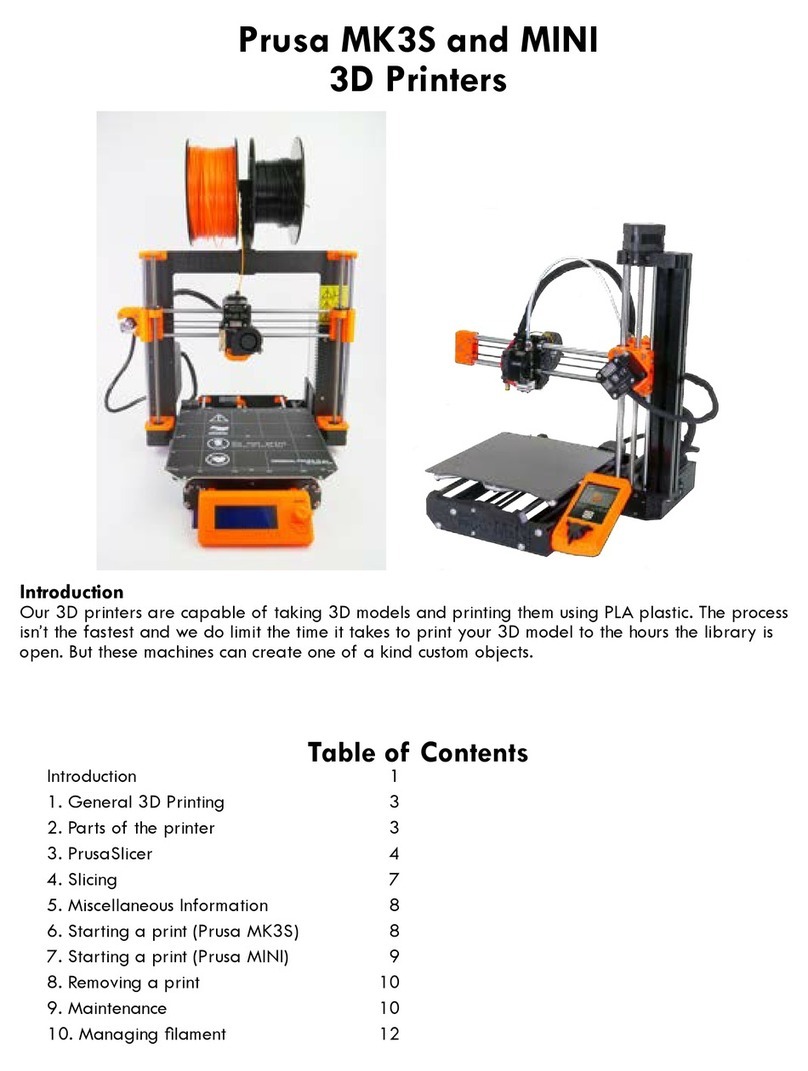

SeeMeCNC DropLit User manual

DropLit Assembly Guide

Welcome to the Assembly Guide for the DropLit 3D printer.

Version 0.50, September 2 th, 2014

Copyright 2014 by Gene Buckle

Licensed as Creative Commons Attribution-ShareAlike 3.0

Questions or corrections should be emailed to geneb@deltasoft.com

Disclaimer text provided by LulzBot

1

DropLit Assembly Guide

READ ME FIRST!

READ THIS MANUAL COMPLETELY BEFORE ASSEMBLING AND POWERING UP

YOUR PRINTER!

Hazards and Warnings

The SeeMeCNC DropLit 3D printer has motorized parts. When the printer is in operation always be

aware of possible hazards.

lectric Shock Hazard

Never open the electronics bay of the printer while the printer is powered on. Before removing

the access door, always power down the printer and unplug the AC line cord.

Fire Hazard

Never place flammable materials or liquids on or near the printer when powered on or in

operation.

Pinch Hazard

When the printer is in operation, take care to never put your fingers in the moving parts,

including the belts, pulleys or gears. Also, tie back long hair or clothing that can get caught in

the moving parts of the printer.

Static Charge

Make sure to ground yourself before touching the printer, especially the electronics.

lectrostatic charges can damage electronic components. To ground yourself, touch a

grounded source.

Age Warning

For users under the age of 18, adult supervision is recommended. Beware of choking hazards

around small children.

2

DropLit Assembly Guide

Table of Contents

READ ME FIRST!.....................................................................................................................................2

0 – Introduction and Acknowledgments....................................................................................................4

1 – Required and Optional Tools And Materials........................................................................................5

2 – Visual Bill of Materials........................................................................................................................6

3 – Getting Started: Building the Front Cover.........................................................................................16

4 – Building the DropLit Chassis.............................................................................................................23

Mounting the Arduino Uno.............................................................................................................23

Assembling the Chassis..................................................................................................................25

Installing the T-Slot Extrusion........................................................................................................34

5 – Assembling the Drive System & Carriage.........................................................................................38

Installing the Stepper Motor...........................................................................................................38

Installing the Carriage.....................................................................................................................43

Installing the Z Axis Drive Rod......................................................................................................50

6 – Things Electronic!..............................................................................................................................53

Installing the Limit Switch.............................................................................................................53

Installing the Power Supply & Power Switch................................................................................56

Wiring & Installing the gShield......................................................................................................60

7 – Final Assembly...................................................................................................................................64

Assembly & Installation of the Mirror Support..............................................................................64

Final Assembly...............................................................................................................................67

3

DropLit Assembly Guide

0 – Introduction and Acknowledg ents

I’d like to welcome you to the DropLit assembly guide!

Please read this entire guide before you begin assembly of your new DropLit! It will help you

avoid any unpleasant surprises and will ensure that you’ve got everything you need BEFORE you need

it! Understand that the photographs in this assembly guide do NOT tell the whole story of each step!

Make sure you read and understand the accompanying text for each step!

A quick note on the Arduino Uno and the gShield. These two devices work in combination to

control the DropLit and are very static sensitive, so please don't take them out of the bags they ship in

until you're ready to install them.

Many thanks to Michael Hackney – he trailblazed the first beta DropLit build and my job would

have been a LOT more difficult without his stellar efforts.

4

DropLit Assembly Guide

1 – Required and Optional Tools And Materials

Before you begin assembly of your DropLit, please make sure you’ve got everything on the

following list of tools and additional materials.

•P1 & P2 sized Phillips screwdrivers

•Small flat tip jeweler's screwdriver

•Standard flat head screwdriver

•5/32” Allen Wrench

•5/16” Wrench

•3/8” Wrench

•Wire strippers

•Wire cutters

•Battery powered screwdriver. If you ever needed an excuse to buy one of these, THIS IS IT.

•Soldering Iron

•Thin Super Glue.

•Waxed lacing cord. This is optional, but you can use this in place of wire ties in pretty much

any application. You can find it here: http://www.skygeek.com/wht-string.html. While

expensive, you'll never really need to buy a wire tie again and it'll likely last you the rest of your

life. :)

•Q-Tips

5

DropLit Assembly Guide

2 – Visual Bill of Materials

Your DropLit kit should contain a wrapped pack of Melamine parts, three bags of parts (two

bags of hardware, one bag of electronic parts) a short section of aluminum extrusion and a power

supply.

The Melamine parts are covered with a special cutting mask that prevents the laser cutting

operation from depositing laser cutting byproducts on the Melamine surface. You'll need to remove all

of this material before beginning construction.

This process is called the Five Stages of Masking Tape.

1. Denial - Oh there's no way I need to scrape all this tape off those parts? Do I?

2. Anger - @#$%@#! This sucks! I've NEVER SEEN SO MUCH TAPE IN

ONE PLACE IN MY LIFE!

3. Bargaining - “Well hi there, Significant Other! Would you PLEASE remove

all this tape for me? PLEASE?”

4. Depression - This tape hates me. *sobs quietly*

5. Acceptance - Well I suppose if I'm ever going to get this thing built, I'd better

get on with it and get all this tape removed...*sigh*

Ok, it's not THAT bad, it just seems like it. It beats having sticky residue all over your nice and

clean Melamine parts. :)

6

Fig. 2-1: DropLit package contents.

DropLit Assembly Guide

For those that aren't sure how to identify the various screw types, Bolt Depot has made available

some excellent references. I would recommend Fastener Basics (http://www.boltdepot.com/fastener-

information/Printable-Tools/Fastener-Basics.pdf) and their Fastener Type Chart

(http://www.boltdepot.com/fastener-information/Type-Chart.aspx).

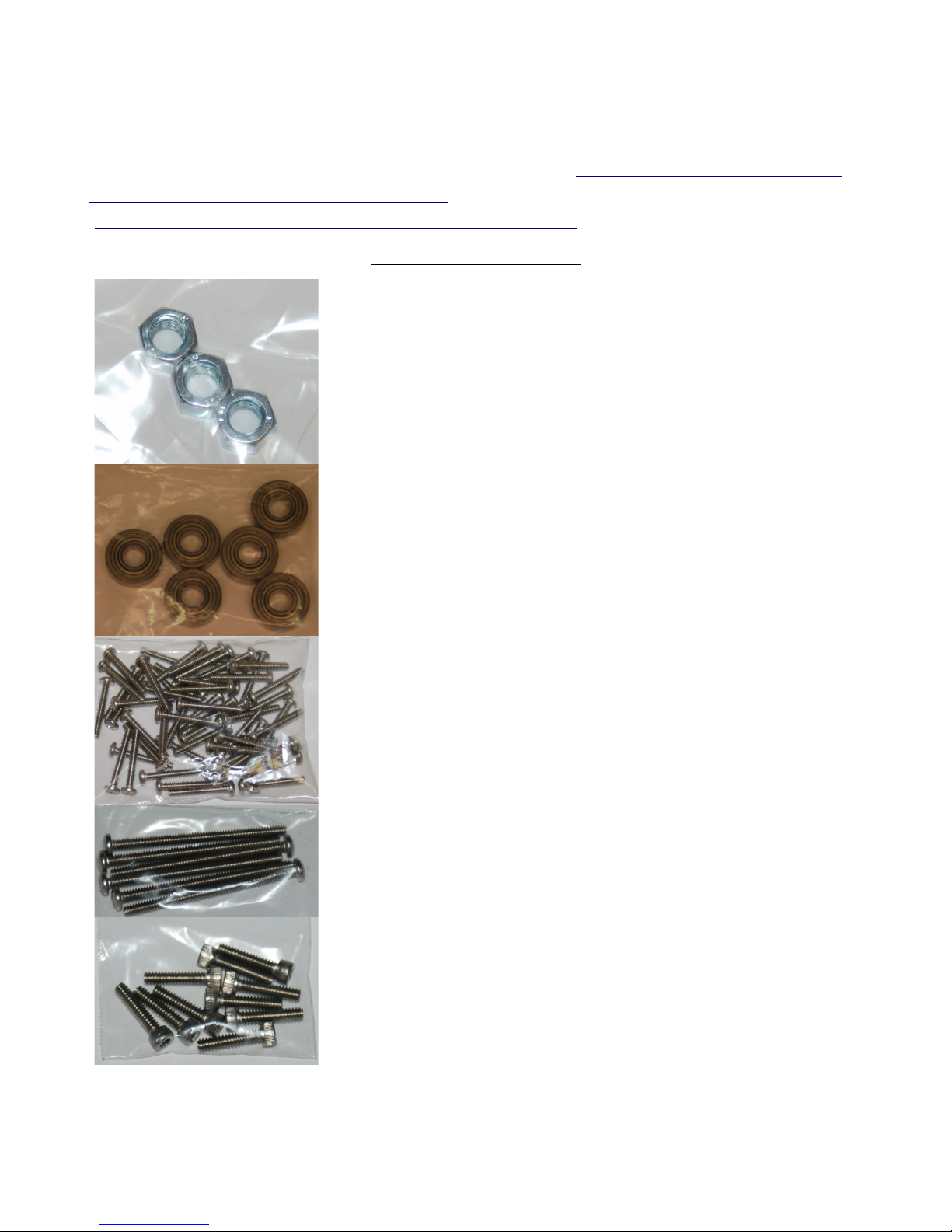

DropLit Hardware Bag #1

(___) (3) M5 Zinc Plated Nut

(___) (6) 1/4” ID x 5/8” OD x .1 6” Ball Bearing (R4ZZ)

(___) (57) #6-32 x 1” Phillips Pan Head Screw 18-8 SS

(___) (6) #6-32 x 2” Phillips Pan Head Screw 18-8 SS

(___) (10) #6-32 x 5/8” Socket Head Cap Screw 18-8 SS

7

DropLit Assembly Guide

(___) (75) #6-32 Nylon Lock Nut SS

Rubber foot pack containing

(___) (4) Leg for 44010 Foot

(___) (4) Rubber Foot (44010)

(___) (4) #10-32 x 5/8” Pan Head Screw (Nylon)

(___) (4) #10-32 Nylon Finish Nut

(___) (4) Plastic Bearing Roller 1/8” ID x 3/8” OD x 0.156” W

(___) (4) #6-32 x 1/2” Slotted Pan Head Screw (Nylon)

(___) (6) 1/4-20 T-Slot Nut

8

DropLit Assembly Guide

(___) (6) 1/4-20 x 1/2” Button Head Cap Screw (SS)

(___) (6) #2-56 x 5/8” Pan Head Screw

(___) (6) #2-56 Finish Nut

(___) (4) M3-.05 x 10mm Phillips Pan Head Screw (SS)

(___) (4) #4 SAE Flat Washer (SS)

(___) (8) #6 x 1/2” Phillips Pan Head Sheet Metal Screw (SS)

DropLit Assembly Guide

(___) (1) .300” OD x .030 wire x 1/2” SS Compression Spring

(___) (2) #10-32 T-Nut

(___) (2) M3-.5 x 6mm Allen Set Screw

(___) (1) 1.5mm Allen Wrench

(___) (4) #10-32 x 3/4” Knurled Thumb Screw (Black Nylon)

10

DropLit Assembly Guide

DropLit Hardware Bag #2

(___) (1) 12”, M5 Threaded Rod

(___) (1) 5mm Shaft Coupler

(___) (1) 15-1/4” T-Slot Extrusion

(___) (1) Build Platform Standoff

(___) (12) R4 Bearing Sleeve

(___) (2) Hinge, 1x1

(___) (1) 75mm x 75mm First Surface Mirror

11

DropLit Assembly Guide

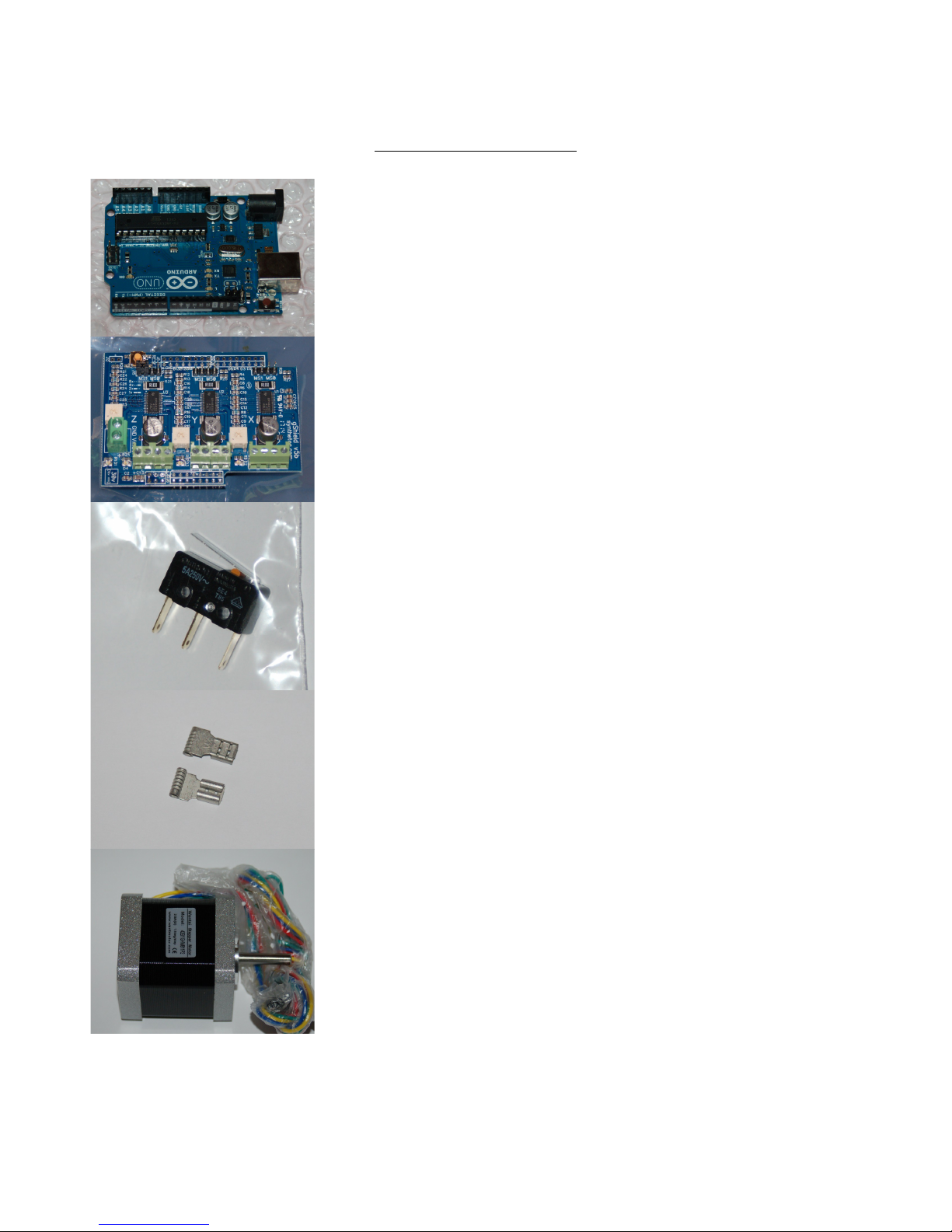

DropLit Electronics Pack

(___) (1) Arduino UNO R3

(___) (1) Gshield 3 Axis Stepper Motor Board

(___) (1) SW143-ND SPDT Micro Switch

(___) (2) Spade Terminal Crimp for Power Switch

(___) (1) NEMA 17 Stepper Motor (4800gcm holding torque)

12

DropLit Assembly Guide

(___) (1) Rocker Switch (Round)

(___) (1) 550W ATX Power Supply (Viotek)

(___) (8) Small Wire Ties

(___) (3ft) 26ga Black & White wire

13

DropLit Assembly Guide

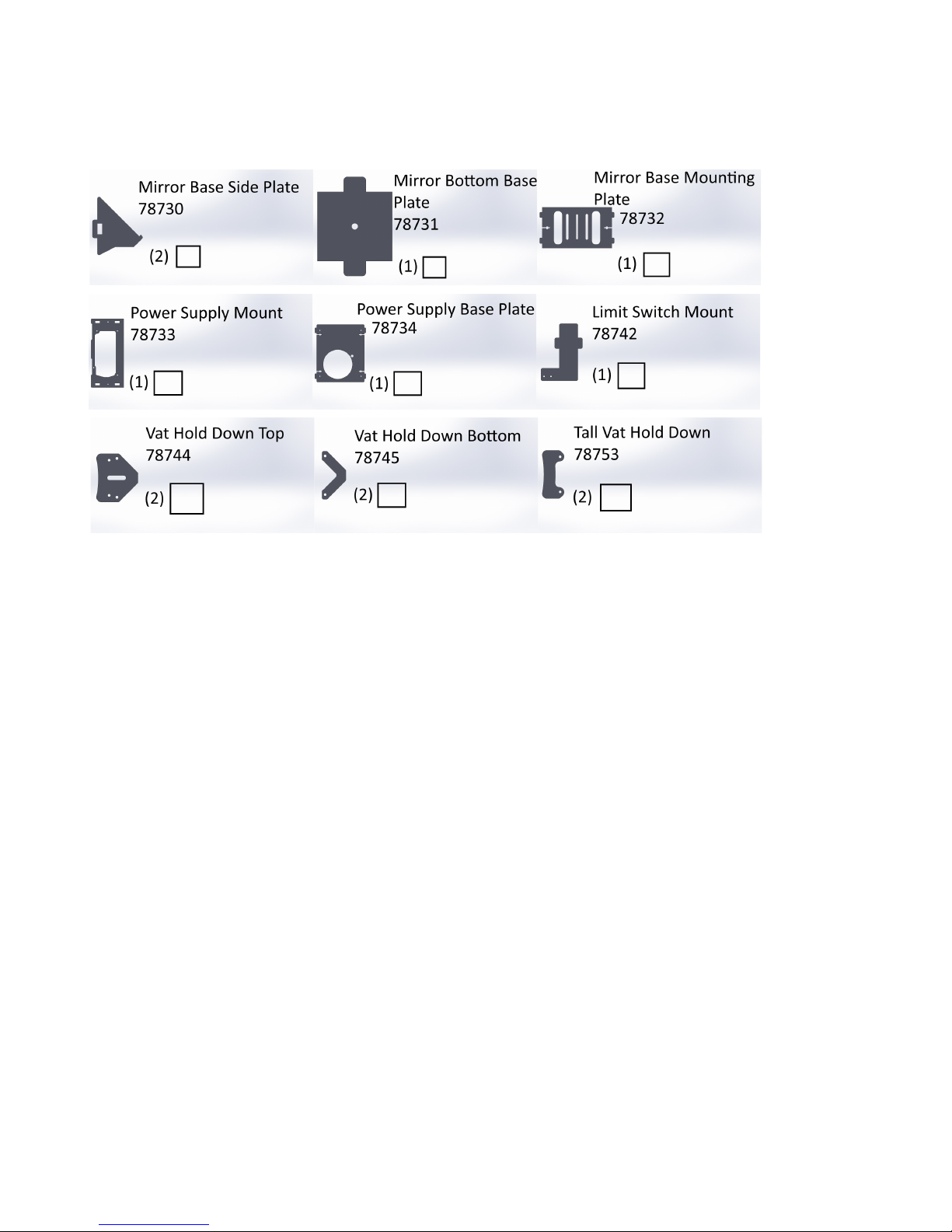

DropLit Acrylic & Melamine Parts

The following parts will be found in the main laser cut parts package. Check off each item as

you locate it. Please contact [email protected]m if you're missing any of these parts.

14

DropLit Assembly Guide

DropLit Acrylic & Melamine Parts – ontinued

15

DropLit Assembly Guide

3 – Getting Started: Building the Front Cover

As discovered by the SeeMeCNC forum user “mhackney”, a good first step in building the

DropLit is to start with the front cover. This is an excellent choice as it gives builders an easy

introduction into the tab & slot construction that all SeeMeCNC 3D printers enjoy.

For this task, you'll need the following components:

The Cover Name Plate is identified by the laser-engraved SeeMeCNC logo as shown:

16

Fig. 3-1: Cover Name Plate

DropLit Assembly Guide

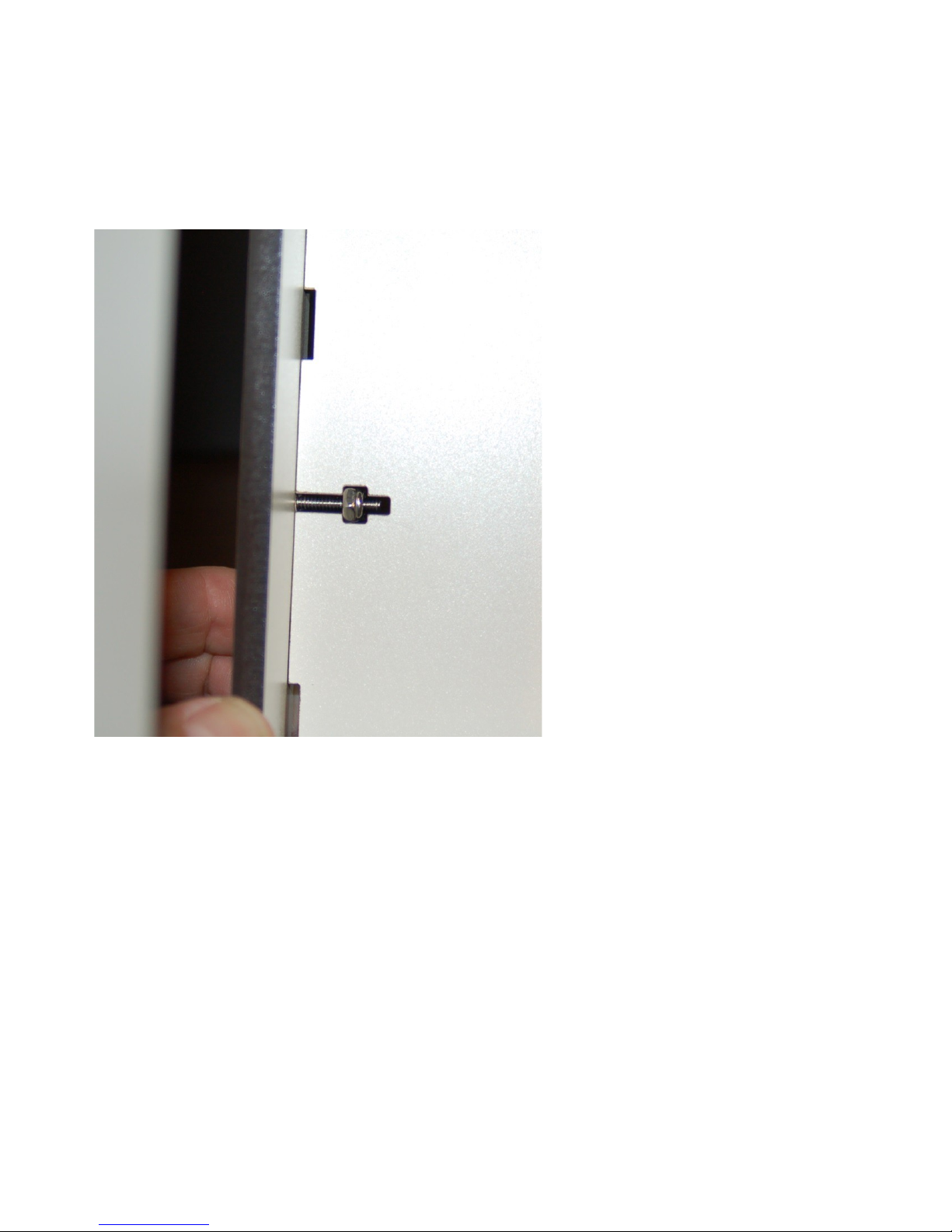

We're going to start the cover assembly by setting three #6-32 nylon lock nuts into the nut

capture pockets on the left “side” of the cover. The left side is identified by the two pair of hinge holes

along the edge of the side panel.

The laser cut nut pockets are designed to fit the nylon

lock nuts snugly. If they're too difficult to press in from one

side, try inserting the nut from the other side of the part.

The laser leaves behind a bit of a beveled “kerf” that is

wider at the top of the cut than at the bottom. This feature

can help insert problematic nuts. If the nut REALLY won't

fit, you can give it a bit of encouragement using a pair of

needle nosed pliers. Just make sure that you're inserting the

nut squarely as shown on the right.

The figures above show what a properly seated nut is going to look like.

17

Fig 3-2: Nut & nut pockets

Fig 3-3: etting the nut.

Fig 3-4: Nut fully seated. Fig. 3-5: Edge-on view.

DropLit Assembly Guide

Go ahead and insert two more of the nuts along the long edge of the cover side as shown below.

Lay the Cover Front flat on the table and align the cover side as shown – there's only one

correct way, where all three screw holes align.

Press the tabs from the side into the slots on the Cover Front and then lay it over on the cover

side so you can insert three #6-32 pan head screws in the mounting holes. Thread the screws finger

tight.

18

Fig. 3-6: First three nuts installed.

Fig. 3-7: Cover side alignment.

Fig. 3-8: etting the mounting screws.

DropLit Assembly Guide

Using your electric screwdriver (You DID buy one, didn't you? If not, you'd better have wrists

of steel because that #2 Philips screwdriver is going to give you one heck of a workout...) carefully

tighten the three screws you just threaded into the nuts.

You want to take care to not over

tighten the screws when installing them.

If you apply too much force, the nut will

start to collapse the base of the nut pocket.

The end result of that is the

structural integrity of the joint is then

compromised and the Melamine can no

longer retain the nut properly.

1

Fig. 3-9: Properly tightened screw.

DropLit Assembly Guide

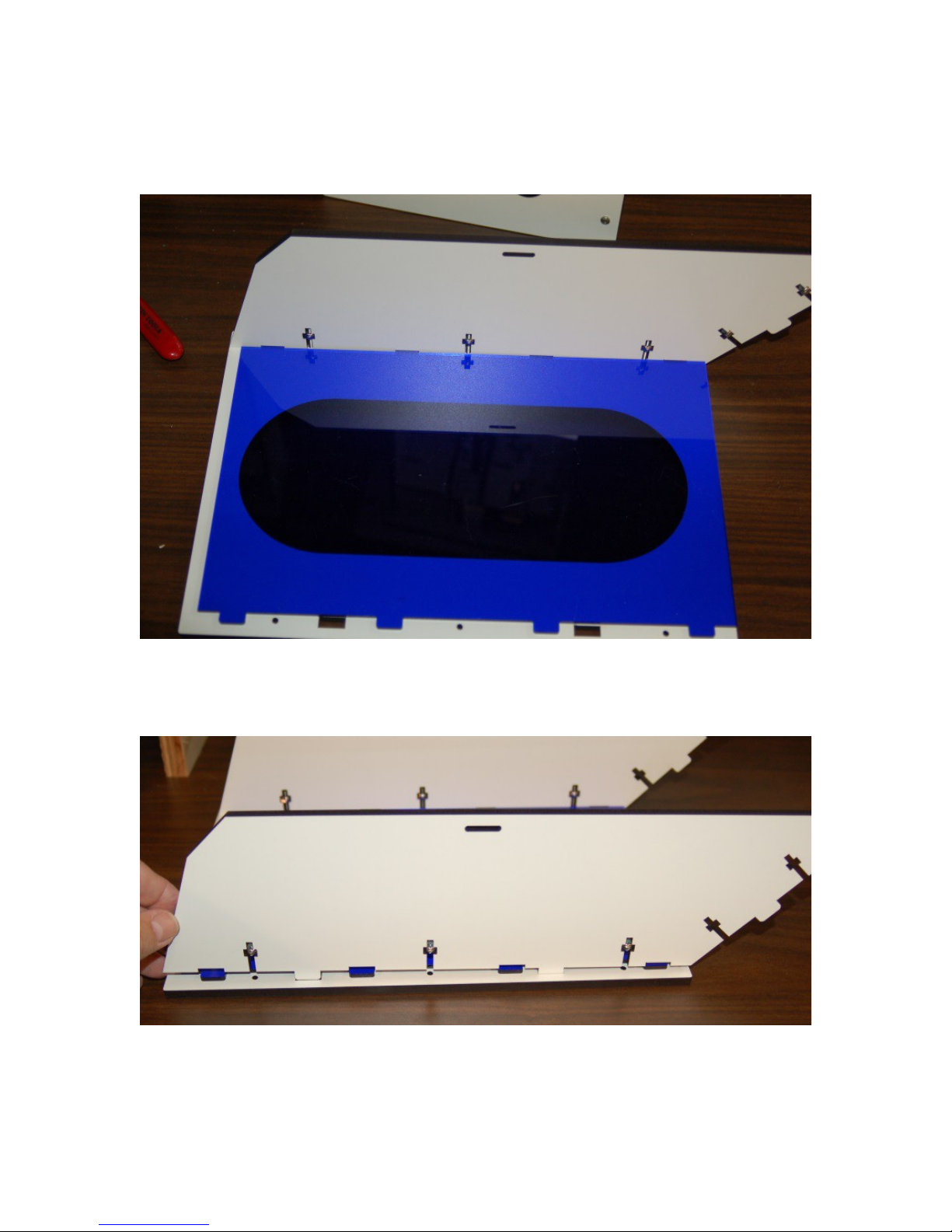

Before we can install the right side of the cover, the acrylic window panel needs to be installed.

Lay the cover down flat and slide the panel into the tabs provided, as shown below.

Now insert three #6-32 nuts into the right cover side and install it using three screws, just as you

did the left side.

20

Fig. 3-10: Window panel installation.

Fig. 3-11: Installing the right cover side.

Table of contents

Other SeeMeCNC 3D Printer manuals

SeeMeCNC

SeeMeCNC Artemis 300 User manual

SeeMeCNC

SeeMeCNC ERIS DELTA User manual

SeeMeCNC

SeeMeCNC Rostock Max User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC rostock max v2.0 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Rostock Max v3 User manual

SeeMeCNC

SeeMeCNC Delta User manual

SeeMeCNC

SeeMeCNC orion delta User manual