8FORM NO. L-20334-C-0404

OPERATION

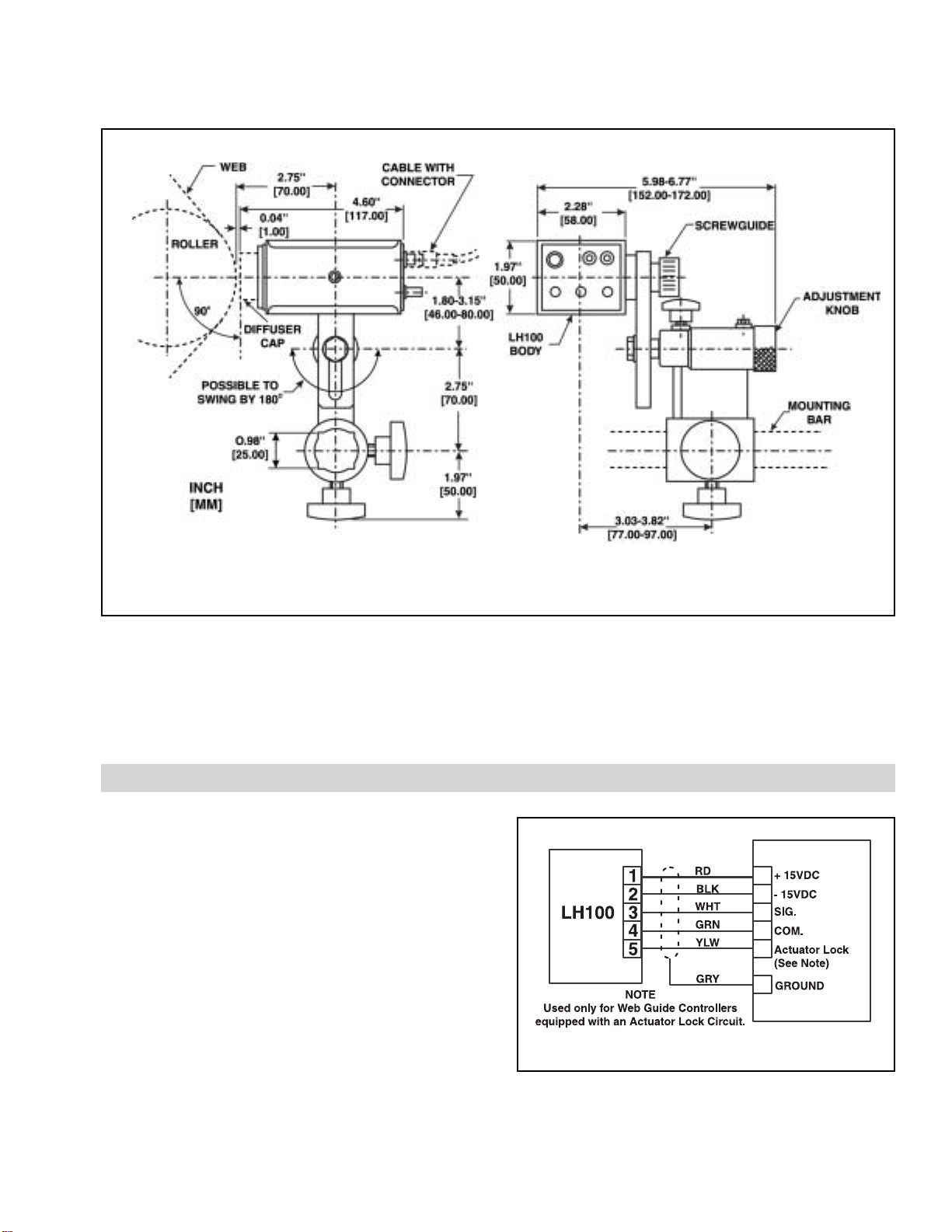

FIGURE10

Left Edge

FIGURE11

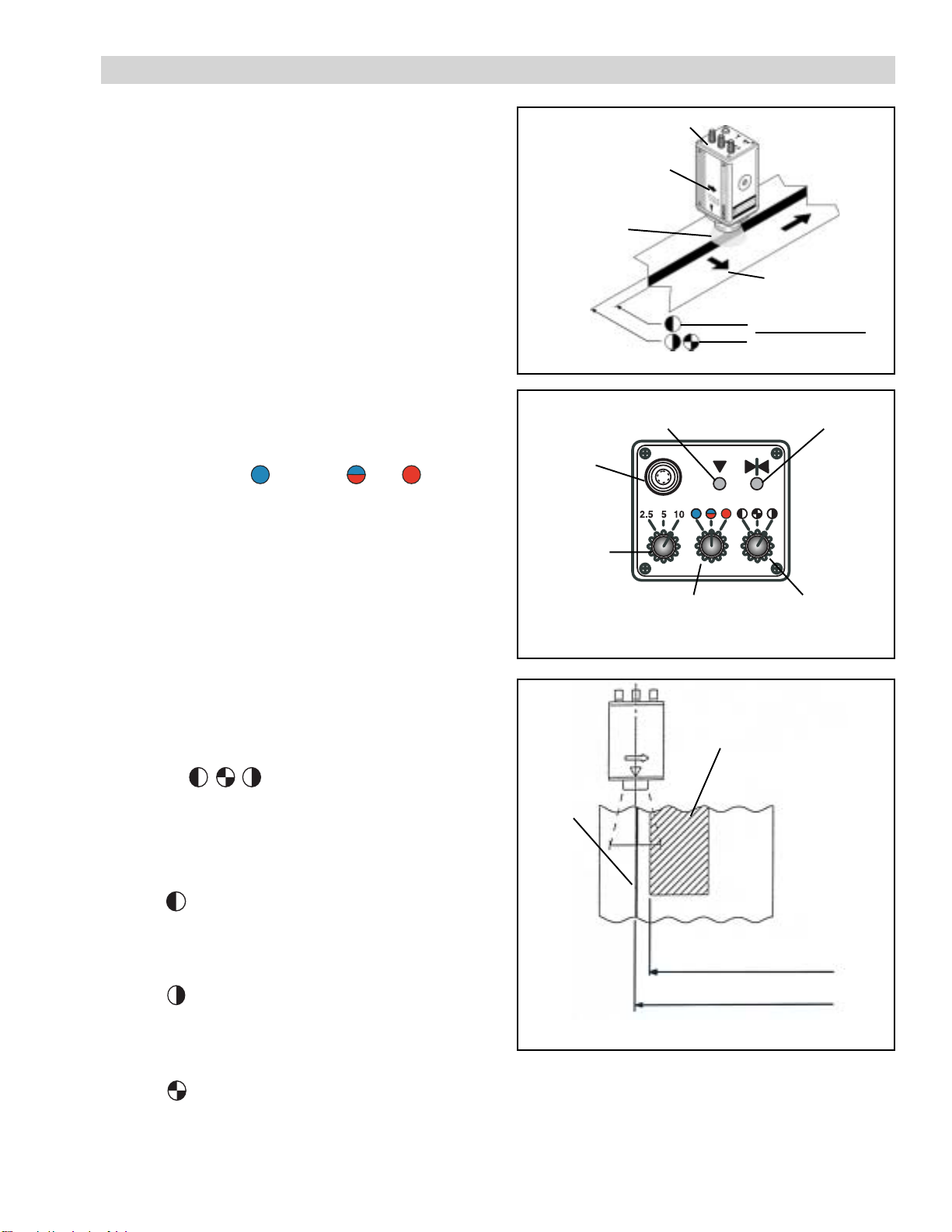

Focal

Display Indicator Center

Display Indicator

Field-of-View

Switch

Color Selector Switch

Contrast

Selector

Switch

Line Follower Head

ScanningDirection

Indicator Arrow

Field of

View

Scanning

Direction

Detection Position

Detection Position

Web

Direction

Right Edge

First Edge

DESCRIPTION

The LH100 scans in the direction of the arrow printed on

its side (See Figure 11). The LH100 looks for a target

edge within its field of view that matches the setting

made with the Field-of-View Switch (See INDICATORS

AND SWITCHES section). When the target edge is not

centered within the field of view, the LH100 will output a

control signal that will vary in proportion to how far the

target edge is away from center. Each setting of the

Field-of-View Switch has a different output voltage

range. The center of the range corresponds to the target

edge being centered within the field of view.

When a target edge moves from center, the output

voltage will change until the edge leaves the field of

view. This output voltage will remain constant until the

target returns to the field of view. This will allow the web

guide to continue steering the target edge back to

center of the field of view. If the Actuator Lock function

is used, then the web guide will maintain its position at

the instant the target edge leaves the field of view until

the target edge returns.

ACTUATOR LOCK FUNCTION

The Actuator Lock Function automatically turns on the

Actuator Lock Output Transistor whenever the Focal

Display Indicator turns off. The following situations will

cause the Focal Display Indicator to turn off: web or line

edge moving outside the field of view, a break in the line

edge, or improper positioning of the LH100.

Use the Actuator Lock output signal for instances where

there are breaks in the target line or edge that will

reappear quickly. This function will prevent the web

guide from moving out of position while waiting for the

line or edge to reappear.

Do not use the Actuator Lock Function for instances

when the edge moves out of the field of view in a

direction perpendicular to web travel and it is desired to

have the web guide controller steer the edge back.

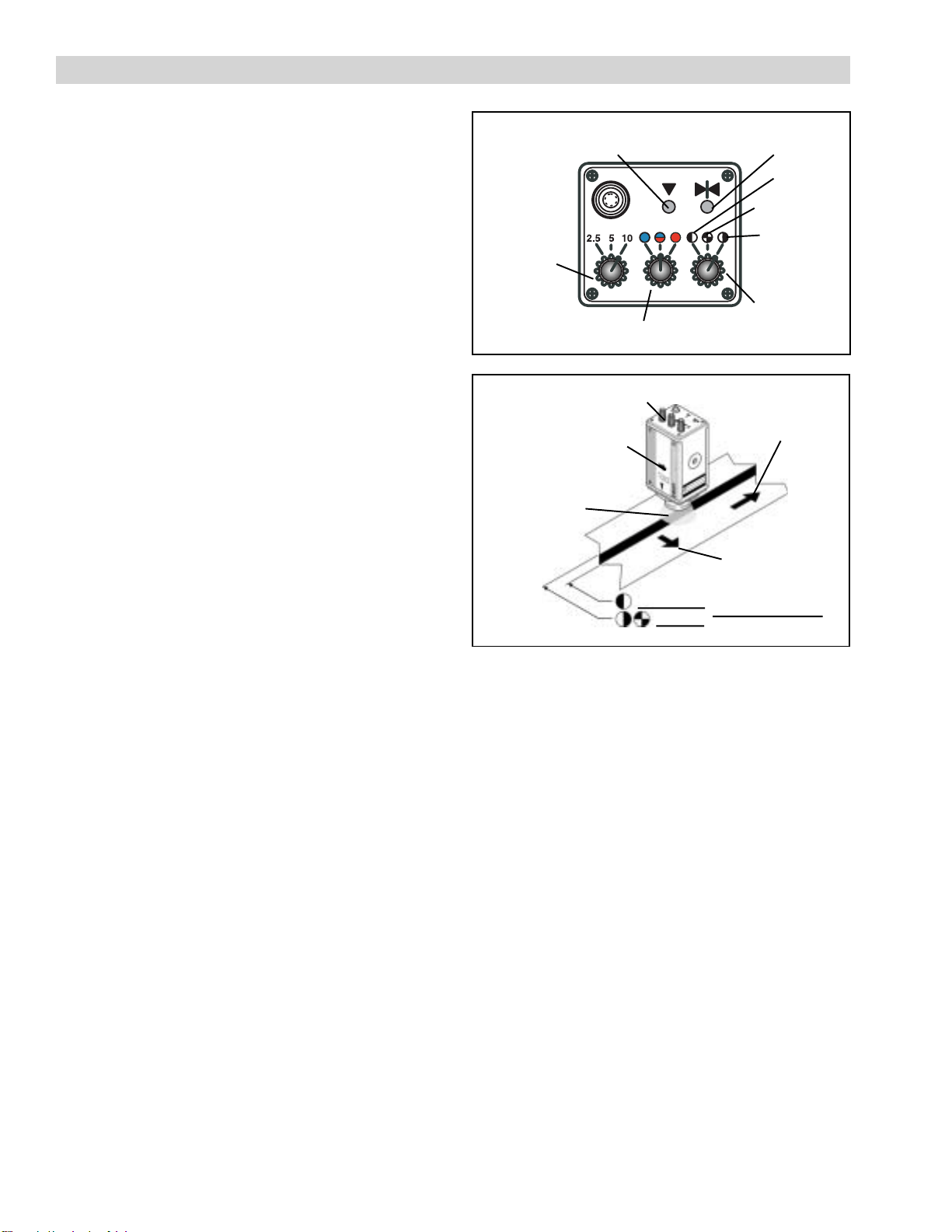

SETUP

1. Set the Field Of View, Color, and Contrast Selector

switches to appropriate positions.

2. Center the LH100 directly over the line or web edge

and adjust the vertical distance of the LH100 to the web

surface until the Focal Display indicator turns on (See

Figures 10 and 11). For highly reflective webs, be sure

the Diffuser Cap is installed and positioned about 1 mm

[0.04 in] above the web for proper focus (See Figure 4).

3. Adjust the lateral position of the LH100 until the

Center Display indicator turns on and indicates the

center of the field of view is aligned with the appropriate

line, pattern or web edge (See Figures 10 and 11).

4. Calibrate the LH100 to the web guide controller by

referring to the controller’s instruction manual.

5. Test the system setup by slowly pulling the web,

causing the line or edge to move within LH100 field of

view. The LH100 output should cause the web guide to

move in the opposite direction of web movement. This

will bring the line/edge back to center.

6. Disable the Actuator Lock Signal and pull the web

edge or line slowly until it leaves the LH100’s field of

view (the focal display indicator turns off). The web guide

should continue to steer, until it reaches an end-of-travel

limit, in an attempt to move the edge or line back to the

center of the field of view.

7. Enable the Actuator Lock Signal and slowly pull the

web edge or line away from the LH100 until it leaves the

LH100’s field of view (the focal display indicator turns

off). The web guide should stop moving once the line or

edge moves beyond the field of view.