Nexperia NBM5100 User manual

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

1. Introduction

The NBM5100x and NBM7100x are battery booster integrated circuits intended to expand the

lifetime and current capability of a coin cell battery like CR2032 and Lithium Thionyl batteries.

This manual gives a quick start of the NBM5100x and NBM7100x evaluation boards usage

together with the PC application or standalone.

The NBM5100x, NBM7100x evaluation board is fully assembled, containing all necessary

components to evaluate the performance and behavior of these battery boosters.

In total 4 variants of the evaluation board are available:

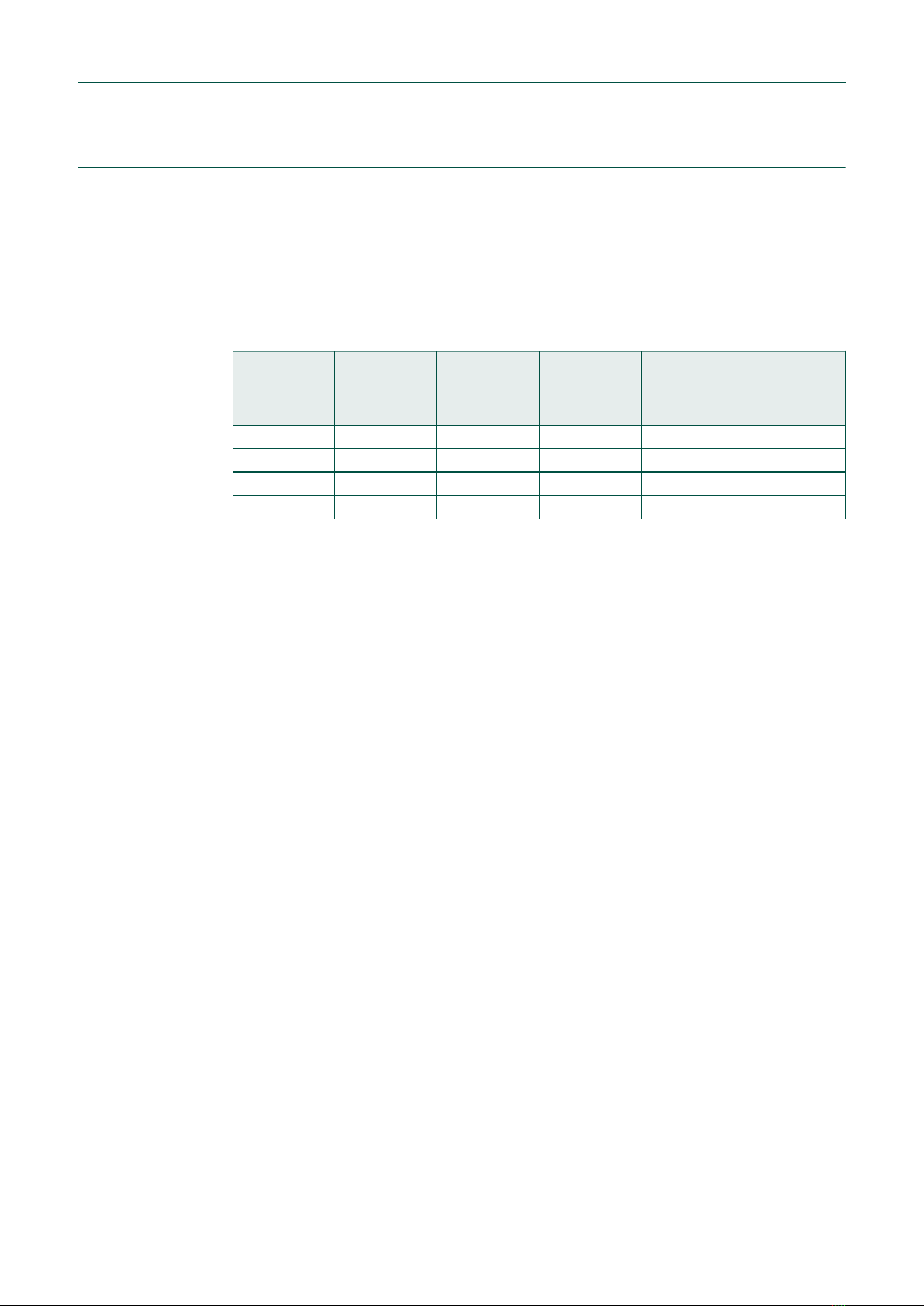

Table 1. Evaluation board variants

Evaluation

board variant

Bus interface Auto start

mode

Storage

Cap Charge

Balance

Function

Max Storage

Cap Voltage

Max Load

Current

NBM7100A I²C + - 11 V 200 mA

NBM5100A I²C + + 5.5 V 150 mA

NBM7100B SPI - - 11 V 200 mA

NBM5100B SPI - + 5.5 V 150 mA

All variants use the same PCB design and expose a USB to SPI/USB to I²C interface to allow

control of the Battery booster from a PC application.

2. Hardware description

The Evaluation Board enables evaluation of the Battery Booster products by controlling them from

a PC or connection to a board under development. The NBM5100x, NBM7100x evaluation kit is

fully assembled, containing apart from a CR2032 battery cell all necessary components to evaluate

the performance and behavior of the battery boosters before applying them in an application. The

top area of the PCB contains an USB to I²C and USB to SPI converter and a level shifter circuit for

controlling the Evaluation board with a PC GUI application. The following sections give a detailed

overview of the module and available test pins for observing the behavior.

2.1. Storage capacitor

By default, one storage capacitor is mounted for the NBM7100x series. For the NBM5100x two

(balanced) super capacitors are mounted in series. The size of these capacitors depends on the

amount of energy needed to supply the load. For demonstration purposes 1000 µF capacitors

are placed on the NBM7100x board and 470 mF for the NBM5100x board. Both boards offer the

possibility to mount leaded (super-) capacitors. It is also possible to connect a custom storage

capacitor to connector J6.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 2 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

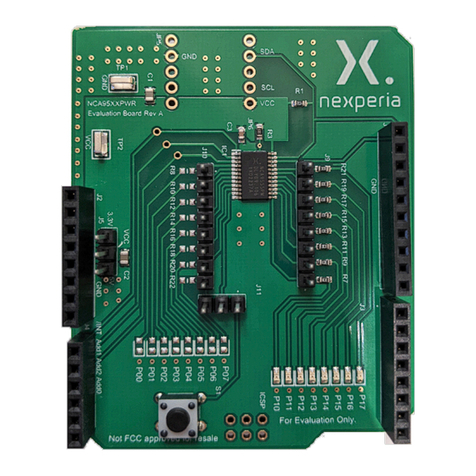

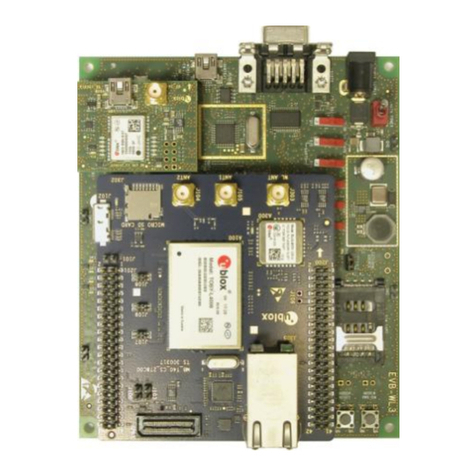

2.2. Breakout board

Fig. 1. Breakout DIL converter board

The Evaluation board also includes a DIL converter board, which can be broken from the Main

PCB. Removing it from the main board will not impact the operation of it, as the board is electrically

not connected to it. This enables an easy evaluation of the product in an application prototype or

on a breadboard. An inductor was not included on the board and has to be connected externally to

allow evaluation of different inductors. The Pin numbers on the TOP side silkscreen directly map to

the pin numbers of the battery booster IC.

2.3. Jumper description

Fig. 2. Top view

Fig. 3. Bottom view

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 3 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Table 2. Evaluation board variants

Jumper

name

PCB

side

Position Description

1-2 (Left) Selects 7-bit I²C address 0x2e

2-3 (Right) Selects 7-bit I²C address 0x2f

JP1 Top

Open Mandatory position for NBM5100B and NBM7100B (SPI variants)

1-2 (top) Selects PC (FTDI) to drive the Load matrix.JP2 Top

2-3 (bot) Selects NBM RDY signal to drive the Load matrix.

Closed Connects the Battery positive pole and the external power supply

input to the supply input to Battery supply of NBM.

JP3 Top

Open External J2 supply input is not connected.

JP4 Bottom Closed Mandatory position to ground TST pin. Don’t open this jumper.

JP5 Top Open Disconnect Balance pin from capacitors.

Closed Connect Balance pin to center pin of series capacitors. Mandatory

for NBM5100A & NBM5100B board in their default configuration.

JP6 Top Open Don’t bypass low side capacitor. This is required for NBM5100A /

NBM5100B boards which have 2 capacitors in series.

Closed Mandatory position for NBM7100A and NBM7100B variants to

connect the negative pin of the storage capacitor to ground.

Open Disconnect on board capacitor.JP7 Top

Closed Connect on board storage capacitor(s) to CAP pin of NBM.

The intention of this pin it to give the ability to measure the

charging current.

JP8 Top Close Default position. Connects the on board inductor to NBM. The

Jumper can be used to measure the coil current. Default should

be closed, when removed the IC will not operate correctly.

Open Disconnect VDHs (sense) line from VDH output.JP9 Bottom

Close Default position. Connects VDHs to VDH output.

JP10 Top Open Connects VDH output of NBM to connector J7 and can be used to

measure the load current.

Close Disconnects VDH output from JP7. Useful to disconnect all loads

from Battery booster.

P12 Top Option to connect an external load which can be controlled over

the Load Matrix and on-board FET. Remove R24 to use this

feature, in case the load is high ohmic.

Pin header JP2 and J9 (Load Matrix)

The Load Matrix is a circuit (see Fig. 4) to simulate load current pulses for evaluation purposes.

Multiple loads in form of resistors are present in the load matrix. An additional LED is present to

show a visual representation of a capacitor loading. The loads are switched with Transistors. Using

a Jumper bank the source of the load signal, but also the load current can be set.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 4 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Fig. 4. Load matrix circuit

As visible from above picture the center pin row of the 6x3 pin header connects to the FET gate

pins for load actuation. The left side connects to SMB connector J8 for external load triggering.

The right side connects depending on Jumper JP2 setting either to the FTDI for actuation of a load

pulse from the PC GUI application (future GUI extension, JP2 position 1-2) or to the NBM RDY pin

(JP2 position 2-3).

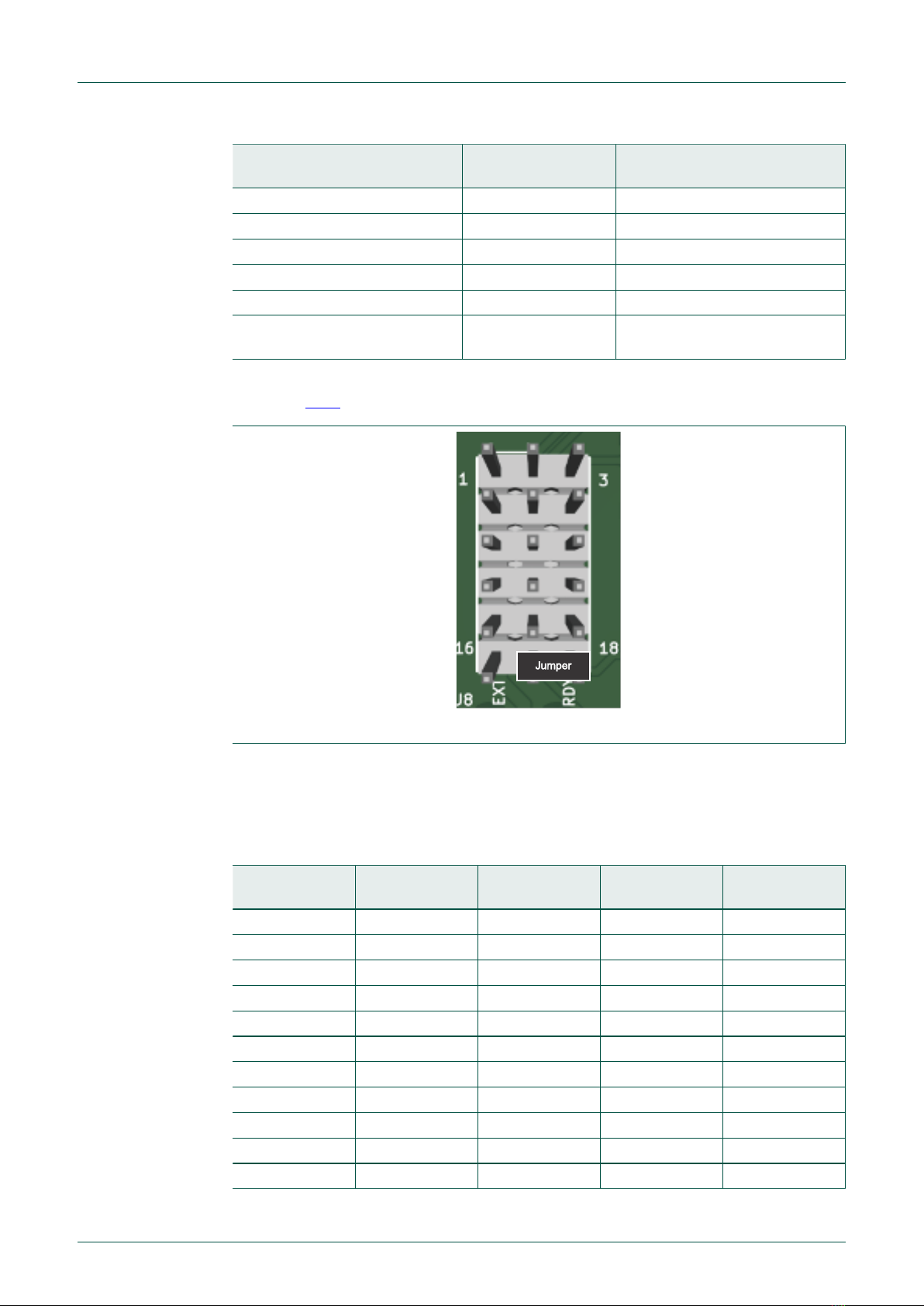

Fig. 5. Load matrix Jumper pins

Multiple jumpers can be placed at the same time to add up the individual currents.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 5 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Table 3. Evaluation board variants

Row

(enumerated from top to bottom)

Approximate current

(VDP = 3.6 V)

Comment

1 1 mA -

2 10 mA -

3 20 mA -

4 50 mA -

5 100 mA -

6 200 mA This selection supplies a high

power LED

Example jumper placement to select 200 mA LED as current sink driven by the NBM ready signal

is shown in Fig. 6.

Fig. 6. Jumper placement to select 200 mA LED

Delivery state jumper settings

When the boards get delivered, they use different jumper settings. Below table summarizes the

default jumper setting.

Table 4. Delivery state jumper settings

Jumper NBM5100A

Default position

NBM5100B

Default position

NBM7100A

Default position

NBM7100B

Default position

JP1 0x2E open 0x2E open

JP2 2-3 2-3 2-3 2-3

JP3 closed closed closed closed

JP4 closed closed closed closed

JP5 closed closed open open

JP6 open open closed closed

JP7 closed closed closed closed

JP8 closed closed closed closed

JP9 closed closed closed closed

JP10 closed closed closed closed

JP12 open open open open

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 6 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

2.4. Connector description

Fig. 7. Connector description

Pin header J1 (Digital TP)

This jumper block makes all digital IO signals available. Depending on the Battery booster type, the

pins have different usages.

Pin header J4 (SPI)

Table 5. Pin header J4 (SPI)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

NBM5100A

NBM7100A

NBM5100B

NBM7100B

SDI = START pin

for auto mode

SDI = SPI MOSI

pin

GND GND

CSN = I²C

address select

CSN = SPI chip

select pin

GND GND

RDY = ready signal (output) GND GND

SDA = I²C data SDA = SPI MISO GND GND

SCL = I²C clock SCL = SPI SCLK GND GND

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 7 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Pin header J3 (I²C)

Table 6. Pin header J3 (I²C)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

GND

SDA = I²C data SDA = SPI MISO

VDP = VDP voltage output from NBM

(the intention is to provide an IO voltage level reference)

SCL = I²C clock SCL = SPI SCLK

Pin Header J7 (Output)

Table 7. Pin Header J7 (Output)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

OUT = VDH output voltage from NBM. (ensure jumper JP10 is

placed)

GND

VDHs = VDH sense signal to NBM. Default-wise it is connected

to the OUT pin using solder-jumper JP9

Pin Header J6 (External capacitor)

Use this pin header to connect an external capacitor. An external capacitor can be used in parallel

to the mounted one. In case only an external capacitor should be used, it is required to desolder

the mounted capacitor.

Table 8. Pin Header J6 (External capacitor)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

- = GND

+ = Positive capacitor terminal

SMB connector J8 (Load)

The Load connector can be used to connect an external function generator (or microcontroller) to

create a timed load pulse for product evaluation. The center pin of the connector connects to the

left side pins of the J9 load selector pin header. The input impedance is high-ohmic.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 8 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Table 9. SMB connector J8 (Load)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

SMB male connector

SMB connector J5 (Start)

The Start connector can be used to connect an external function generator to generate a Start

pulse to the battery booster IC (evaluation of autonomous mode). The input impedance is 100 kΩ.

Table 10. SMB connector J5 (Start)

NBM5100A

NBM7100A

NBM5100B

NBM7100B

SMB male connector

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 9 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

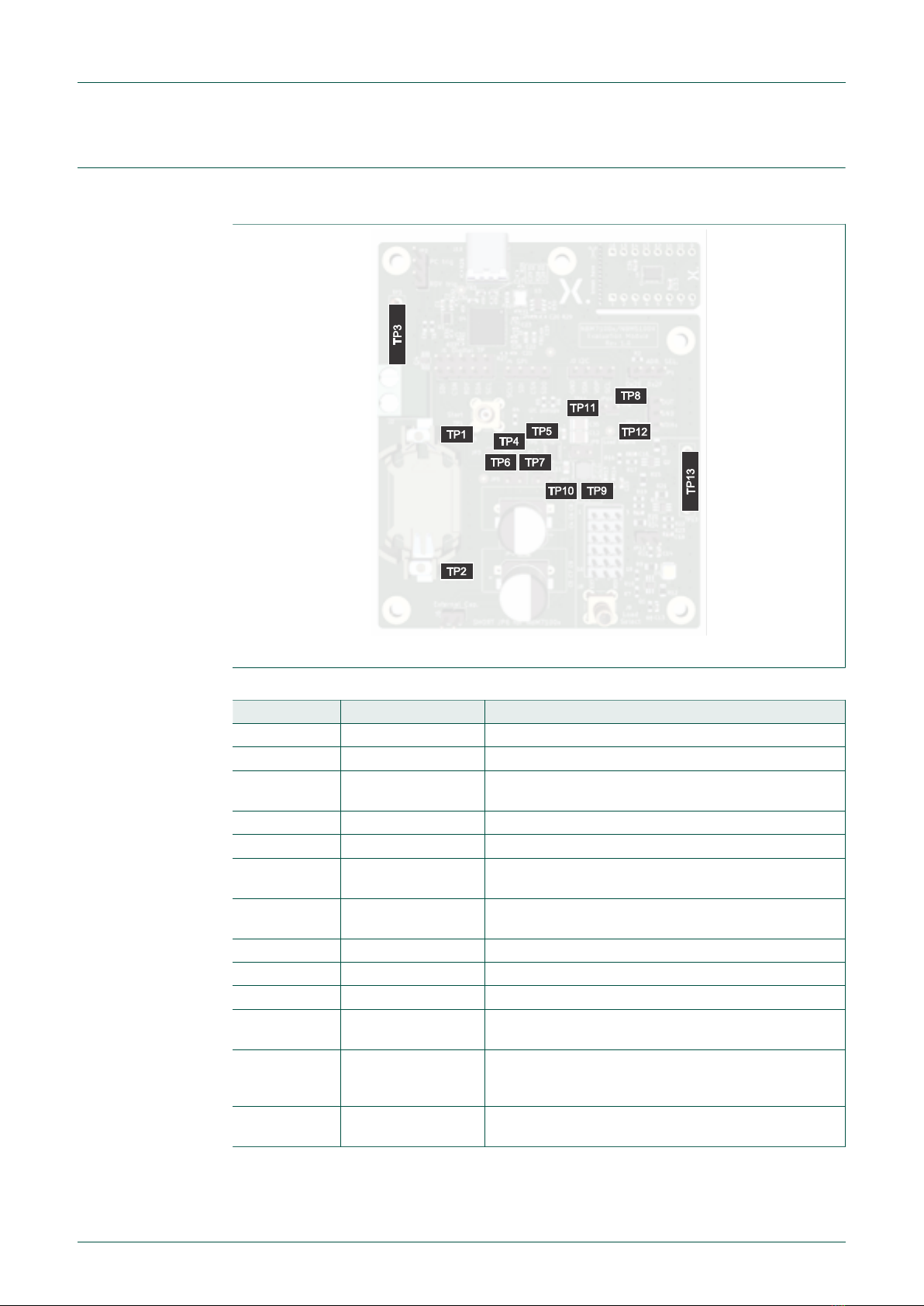

3. Test points

Many test points are provided to observe waveforms or voltage levels of the Battery booster. A

description of the test point location and connection is listed below.

Fig. 8. Test points

Table 11. Pin header J4 (SPI)

Test pin name Connected to Description

TP1 External Supply + pin Measure point for input supply voltage

TP2 GND

TP3 GND Ground bar. Use to connect an oscilloscope probe

ground lead.

TP4 VBT VBT voltage going to VBT pin of NBM.

TP5 TST Do not use.

TP6 BAL Balance pin measurement point. Useful for NBM5100 to

measure capacitor voltage of each capacitor.

TP7 CAP Capacitor positive terminal, connected to CAP pin of

NBM.

TP8 VDP Connected to VDP pin of NBM.

TP9 LX1 LX1 inductor pin.

TP10 LX2 LX2 inductor pin.

TP11 Pin 2: VDH

Pin 1: GND

Measurement point for VDH output in case Jumper J10

is open.

TP12 VDHs VDH Sense input. In case solder Jumper JP9 is opened,

it can be used to inject an externally supplied sense

signal.

TP13 GND Ground bar. Use to connect an oscilloscope probe

ground lead

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 10 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

4. Using the Evaluation board with PC

Below steps are assuming as precondition, that the board is in default jumper setting state. Insert a

CR2032 Battery into the coin cell holder or supply externally 3 V to the supply connector J2. Next

connect the Evaluation board to the PC. When connecting it the first time a driver will be installed

automatically by windows. This can take a few minutes. Windows will confirm once the driver is

installed. In case you want to doublecheck if the driver got correctly installed, open the Windows

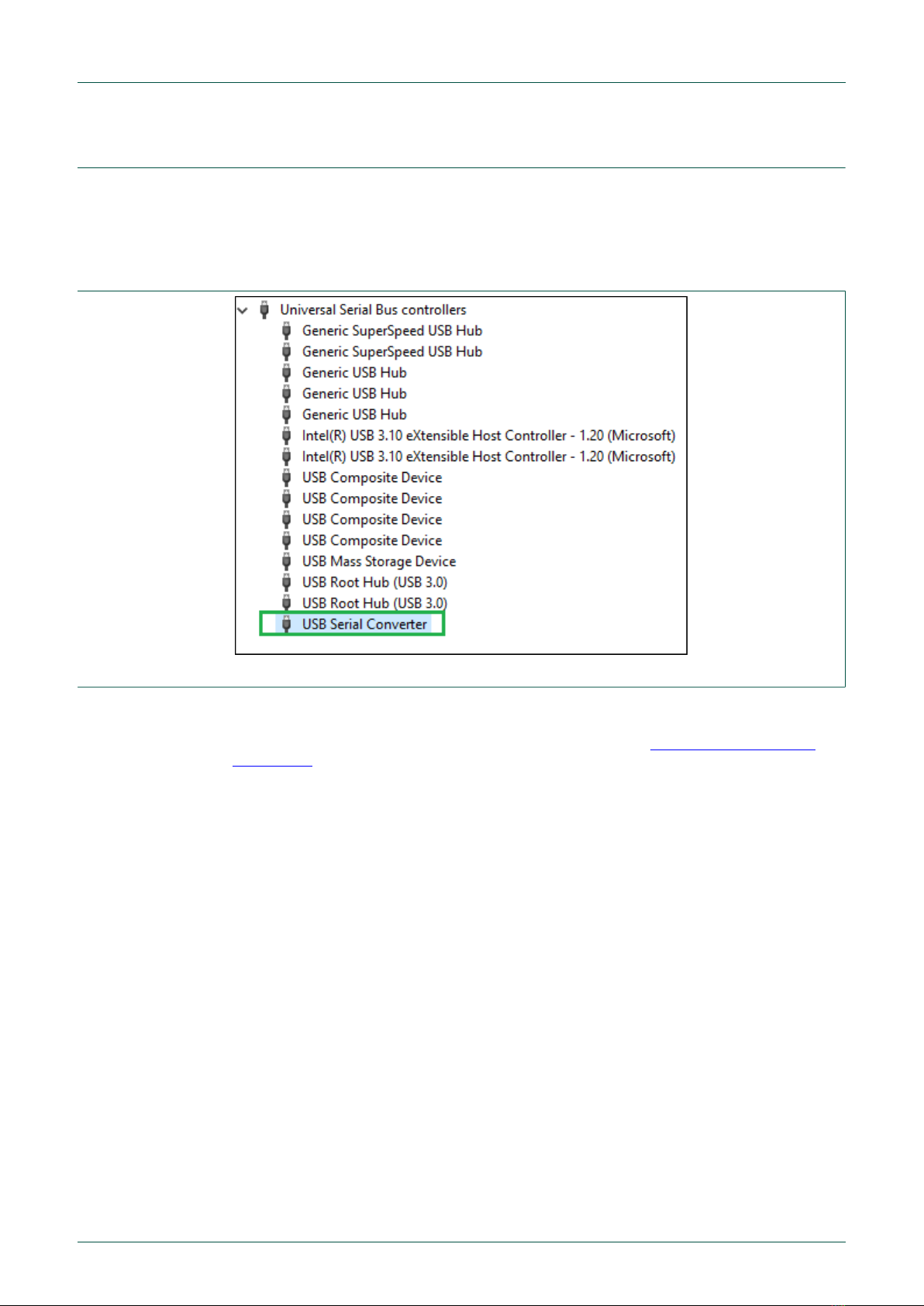

device manager and check for the presence of the device:

Fig. 9. Windows device manager USB controllers

Now the device is ready to be used with the GUI application. The automatic driver installation is

a one-time action. Following connections over USB don’t require waiting time. In case the Driver

does not install automatically, it can be download from this website: https://ftdichip.com/drivers/

d2xx-drivers/ and installed manually. The GUI is delivered as a .zip archive, which needs to be

extracted. It can be placed at any location of your PC harddrive. No installation is required. The

GUI itself can be started by doubleclicking the .exe file. After starting the GUI, the main screen

content is expected to look like this:

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 11 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Fig. 10. Battery manager Evaluation and Rundown Tool GUI

The status bar indicates, if the Battery booster managed to connect to the Evaluation module and

which kind of Interface (I²C Address 0x2e/0x2f or SPI) was identified.

Fig. 11. Battery manager Status bar

Testing continuous mode

Click on the Continuous mode button:

After that it can be observed that the charge cycle count, stored charge and actual v_cap voltage

increases. The V_cap voltage show the voltage across the storage capacitor(s). The voltage can

be observed with an oscilloscope or multimeter on TP7 of the board too.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 12 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

The VDP output voltage is in this state still the battery supply voltage. The Battery booster is in

charged state, but not generating its supply from the storage capacitor. To turn on consumption

from the storage capacitor the active mode has to be turned on by clicking the “Force active state”

button:

By clicking the “force active state button” the charge state changes to the ready state. Output

power will now be supplied from the storage capacitor. Forcing the active state during charging

is called override mode and can be useful if instant power needs to be available. Forcing the

active state is normally done when the device indicates that the storage capacitor is fully charged,

indicated by a high ready signal. A load to the output voltage connector J7 can be connected or

enable a load in the load matrix. Now you can observe in the GUI V_cap field, but also e.g. on an

oscilloscope the storage capacitor voltage decreasing, because the energy is consumed from it.

Care should be taken that you don’t keep the active state on too long, cause the V_cap voltage can

drop below its minimum limit. Disable the force active state for that reason after some time. The

storage cap will charge again afterwards.

Troubleshooting

In case the Evaluation board is not powered from battery or external supply, it will be visible from

the status bar:

Fig. 12. Battery manager Status bar

Check, if the Battery booster is powered correctly. E.g. the CR2032 could be empty or the external

supply is not passing through because Jumper J2 is not placed. In case the USB to SPI/I²C device

was not found it is also indicated:

Fig. 13. Battery manager Status bar

Check, if the Device driver got correctly installed and the USB cable is plugged into the board &

PC.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 13 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

5. Using the Evaluation board stand alone

I²C or SPI control from external Microcontroller

It is also possible to control the Battery booster IC using an off-board microcontroller or external

SPI/I²C master. To be able to use this mode, ensure that the USB connector is not plugged in. Only

supply VBAT by inserting a CR2032 coin battery or by supplying it from an external power source.

Two Control options are available:

1. Jumper J4 makes SPI pins available for wiring to an external SPI master. This option is

available for NBM5100B and NBM7100B variants of the boards.

2. Jumper J3 makes I²C pins available for control from an external I²C master. Use this option for

NBM5100A and NBM7100A boards. Pull-up resistors for SDA and SCL lines to VDP are placed

on board already (1 kΩ resistors R5 and R6).

When connecting an external master, make sure, that you IO levels of this master follow the VDP

voltage. The VDP pin of Jumper J3 can be used to supply an external board and ensure correct IO

levels.

Auto mode

The autonomous mode of NBM5100A and NBM7100A allows a simple evaluation of Battery

booster. This mode is not supported by NBM5100B or NBM7100B, because they don’t have a start

input pin. Place a CR2032 coin cell battery in the BT1 battery holder, make sure that the jumper

between pin 17 and 18 of the load matrix (J9) is placed. Apply a high active start pulse with a width

of about 10 µs (min 10 µs, max 150 µs) on the start SMB connector (J4). The charge cycle of the

storage capacitor will start and when the device exits the charge state, the white LED will turn on

until the storage capacitor is depleted.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 14 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

6. Schematic

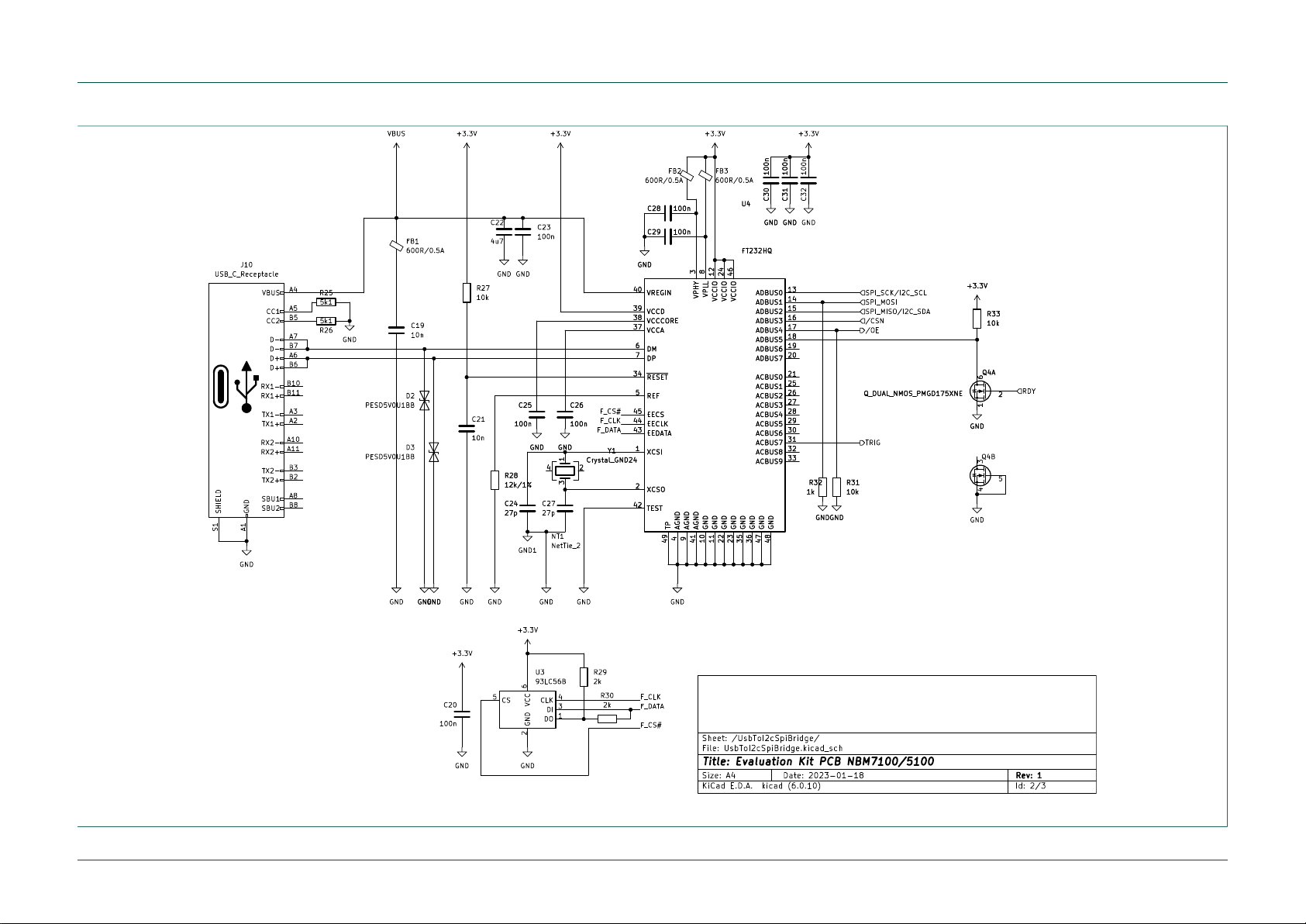

Fig. 14. Schematic (1 of 3)

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 15 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

Fig. 15. Schematic (2 of 3)

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 16 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

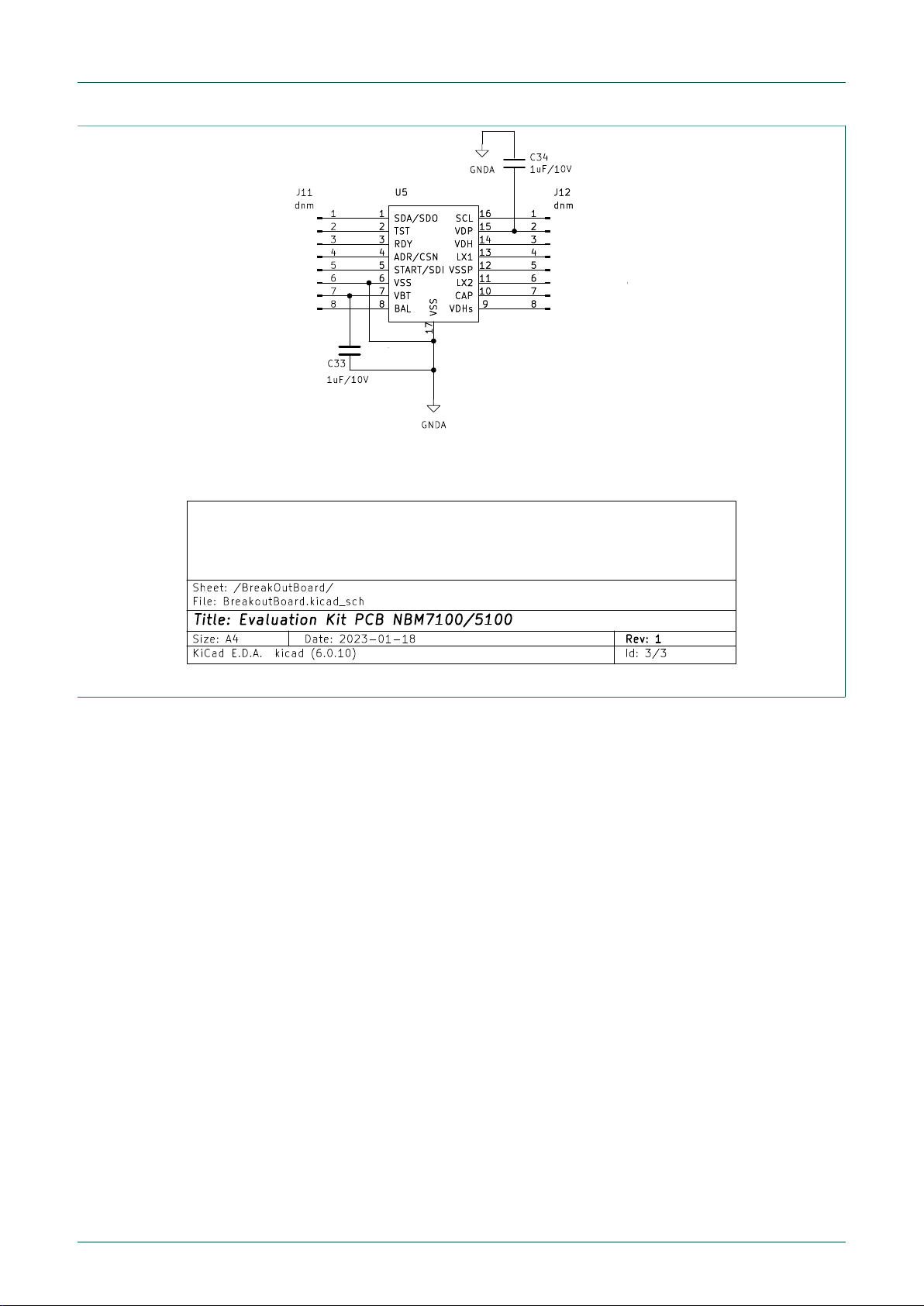

Fig. 16. Schematic (3 of 3)

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 17 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

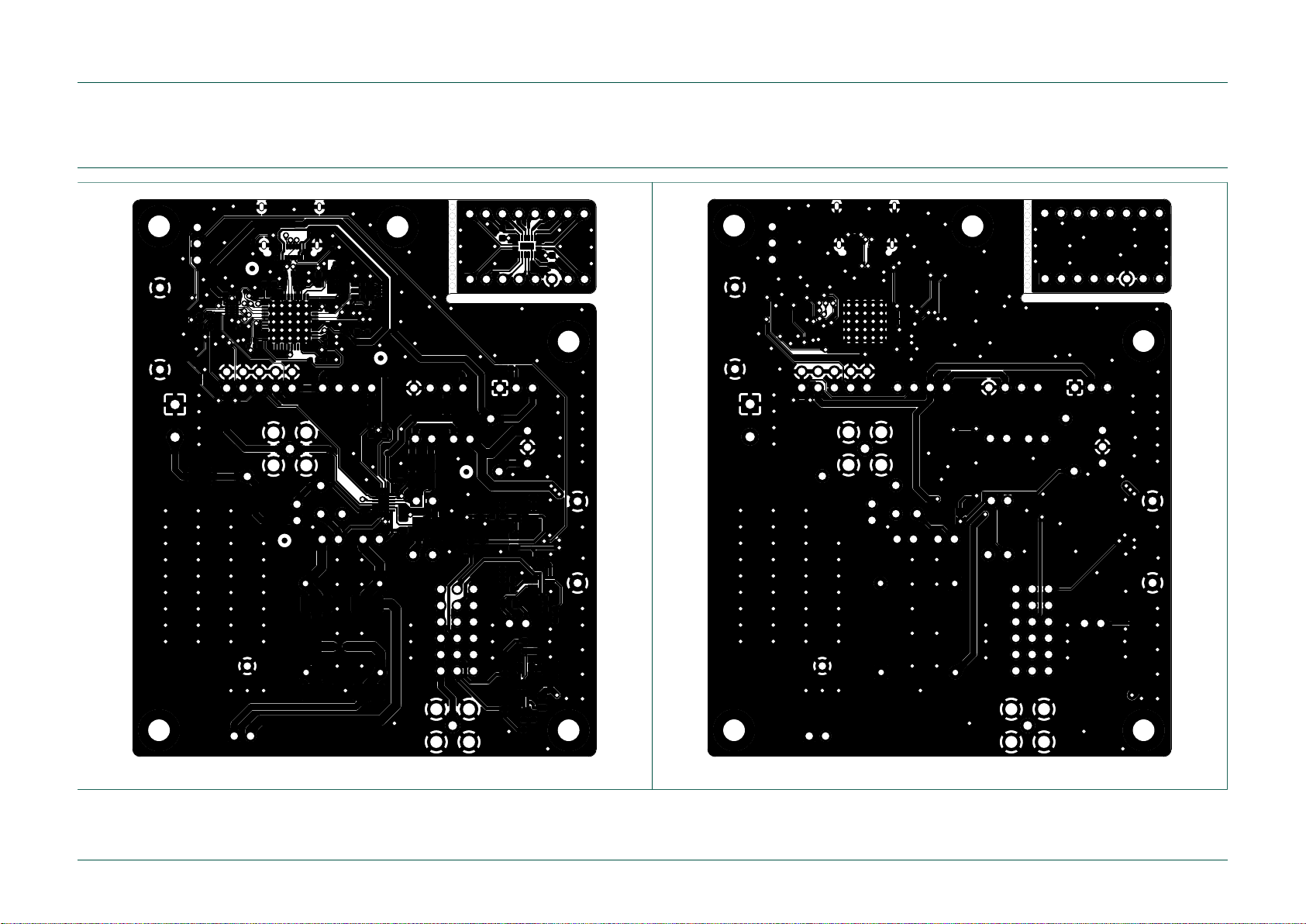

7. Board layout

Fig. 17. Top Side Layer Fig. 18. Bottom Side Layer

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 18 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

8. Revision history

Table 12. Revision history

Revision

number

Date Description

UM90022 v.1 20230711 Initial version

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 19 / 21

Nexperia UM90022

NBM5100; NBM7100 Evaluation board module

9. Legal information

Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. Nexperia does not give any representations or

warranties as to the accuracy or completeness of information included herein

and shall have no liability for the consequences of use of such information.

Disclaimers

Limited warranty and liability — Information in this document is believed

to be accurate and reliable. However, Nexperia does not give any

representations or warranties, expressed or implied, as to the accuracy

or completeness of such information and shall have no liability for the

consequences of use of such information. Nexperia takes no responsibility

for the content in this document if provided by an information source outside

of Nexperia.

In no event shall Nexperia be liable for any indirect, incidental, punitive,

special or consequential damages (including - without limitation - lost

profits, lost savings, business interruption, costs related to the removal

or replacement of any products or rework charges) whether or not such

damages are based on tort (including negligence), warranty, breach of

contract or any other legal theory.

Notwithstanding any damages that customer might incur for any reason

whatsoever, Nexperia’s aggregate and cumulative liability towards customer

for the products described herein shall be limited in accordance with the

Terms and conditions of commercial sale of Nexperia.

Right to make changes — Nexperia reserves the right to make changes

to information published in this document, including without limitation

specifications and product descriptions, at any time and without notice. This

document supersedes and replaces all information supplied prior to the

publication hereof.

Suitability for use — Nexperia products are not designed, authorized or

warranted to be suitable for use in life support, life-critical or safety-critical

systems or equipment, nor in applications where failure or malfunction

of an Nexperia product can reasonably be expected to result in personal

injury, death or severe property or environmental damage. Nexperia and its

suppliers accept no liability for inclusion and/or use of Nexperia products in

such equipment or applications and therefore such inclusion and/or use is at

the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. Nexperia makes no representation

or warranty that such applications will be suitable for the specified use

without further testing or modification.

Customers are responsible for the design and operation of their applications

and products using Nexperia products, and Nexperia accepts no liability for

any assistance with applications or customer product design. It is customer’s

sole responsibility to determine whether the Nexperia product is suitable

and fit for the customer’s applications and products planned, as well as

for the planned application and use of customer’s third party customer(s).

Customers should provide appropriate design and operating safeguards to

minimize the risks associated with their applications and products.

Nexperia does not accept any liability related to any default, damage, costs

or problem which is based on any weakness or default in the customer’s

applications or products, or the application or use by customer’s third party

customer(s). Customer is responsible for doing all necessary testing for the

customer’s applications and products using Nexperia products in order to

avoid a default of the applications and the products or of the application or

use by customer’s third party customer(s). Nexperia does not accept any

liability in this respect.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from competent authorities.

Translations — A non-English (translated) version of a document is for

reference only. The English version shall prevail in case of any discrepancy

between the translated and English versions.

Trademarks

Notice: All referenced brands, product names, service names and

trademarks are the property of their respective owners.

UM90022 All information provided in this document is subject to legal disclaimers. © Nexperia B.V. 2023. All rights reserved

user manual Rev. 1 — 11 July 2023 20 / 21

This manual suits for next models

5

Table of contents

Other Nexperia Motherboard manuals