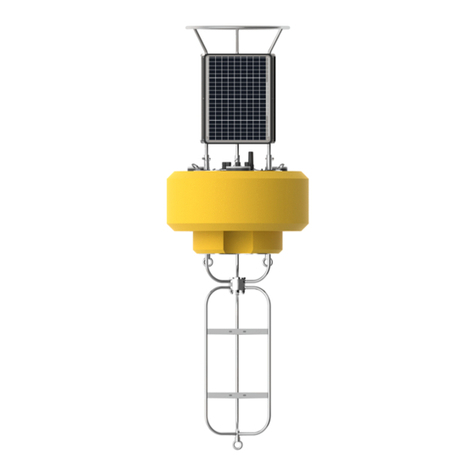

CB-Series Data Buoy Planning & Precautions

Buoy deployments are usually complex operations that involve many elements including

sensors, data loggers, mounting hardware, and mooring equipment. Careful planning and

precautions are essential to the success of a buoy project, not only for system operation

and data collection but also to ensure the safety of project personnel and minimize the risk

of damage to expensive system components. When planning a buoy deployment, be sure

to give careful consideration to the following aspects:

Buoy sizing and power budget

Buoys come in various physical sizes with differing battery and solar charge capacities. A

buoy must be adequately sized to tolerate the site environmental conditions while

providing sufficient power for continuous system operation. A power budget should be

analyzed to ensure the system can meet the demand for sensor measurements and data

transmission.

Buoy ballast

Proper ballast of a buoy is critical to buoy stability when it is deployed in the water. Be sure

to review the ballast weight and stability guide when designing a buoy system. Some

experimentation may be required before final deployment.

Buoy mooring

Mooring systems come in many forms depending on the location, water depth, and

environmental conditions to which a buoy will be exposed. As a starting point, the mooring

data buoys guide provides an overview of common mooring strategies. However, NexSens

does not endorse any particular mooring strategy, and systems should be designed and

executed based on careful consideration and local knowledge of the deployment site.

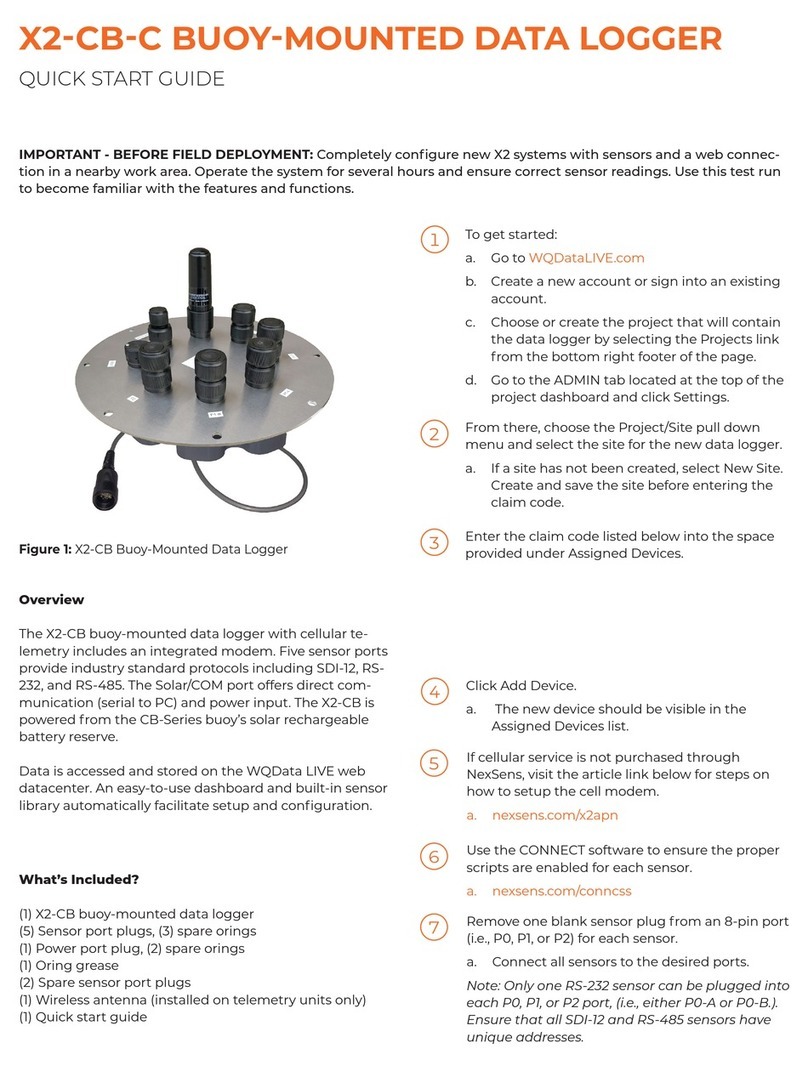

Electrical connections

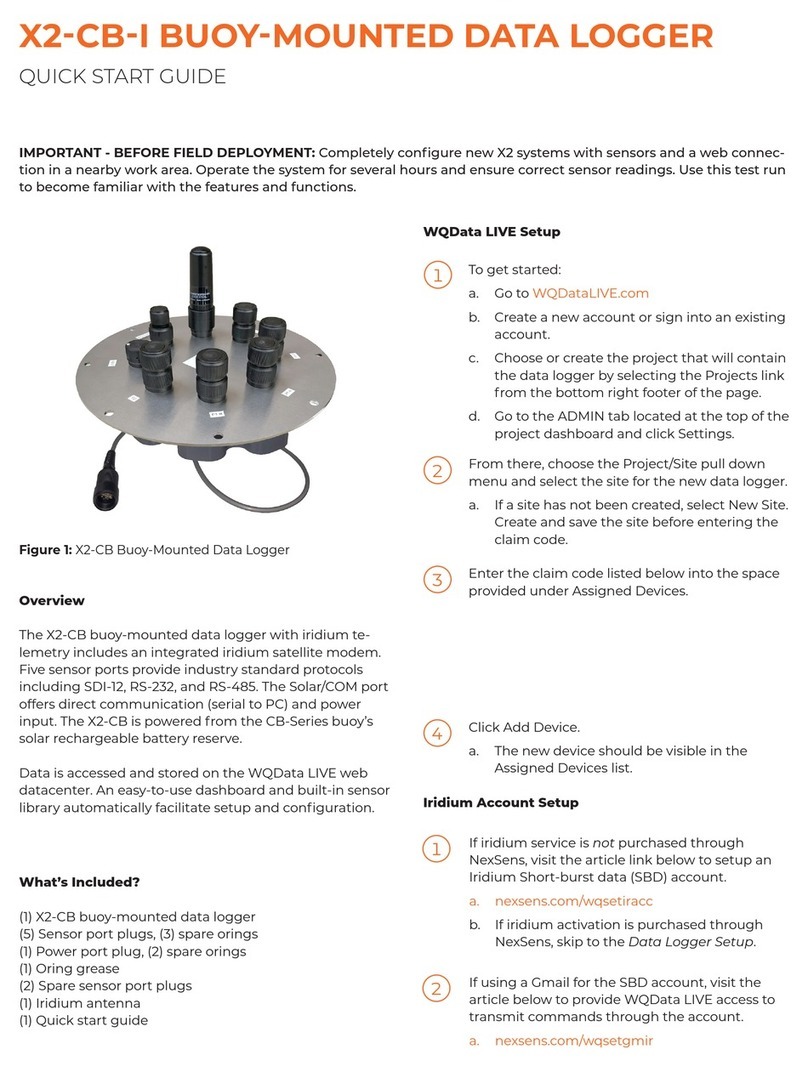

Many NexSens buoy systems utilize UW connectors for connection of power and sensor

cables. Data loggers such as the X2-CB have UW receptacle ports to receive sensor cables

fitted with UW plug connectors. UW connectors provide a double O-ring seal, with one O-

ring inside the receptacle and one around the plug. In order to ensure waterproof

connection, check the following each time a UW connection is made:

1. The O-ring inside the receptacle is present (has not fallen out)

2. The receptacle and plug are clean, dry and free of debris

3. The O-ring on the plug is lightly greased

4. Connection is tight, secure and fully seated

5. Unused receptacle ports are fitted with UW port plugs

Connections may be periodically inspected and maintained with O-ring grease, at a

minimum before each buoy deployment.