NexSens Technology X2-SDL User manual

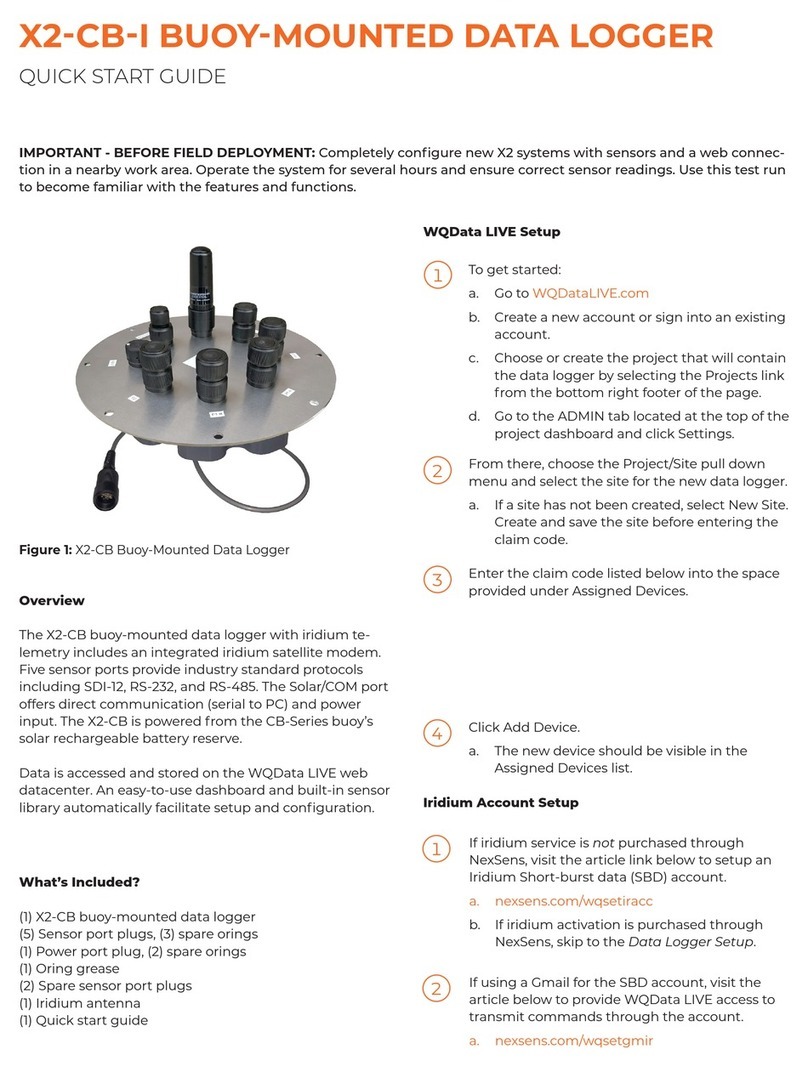

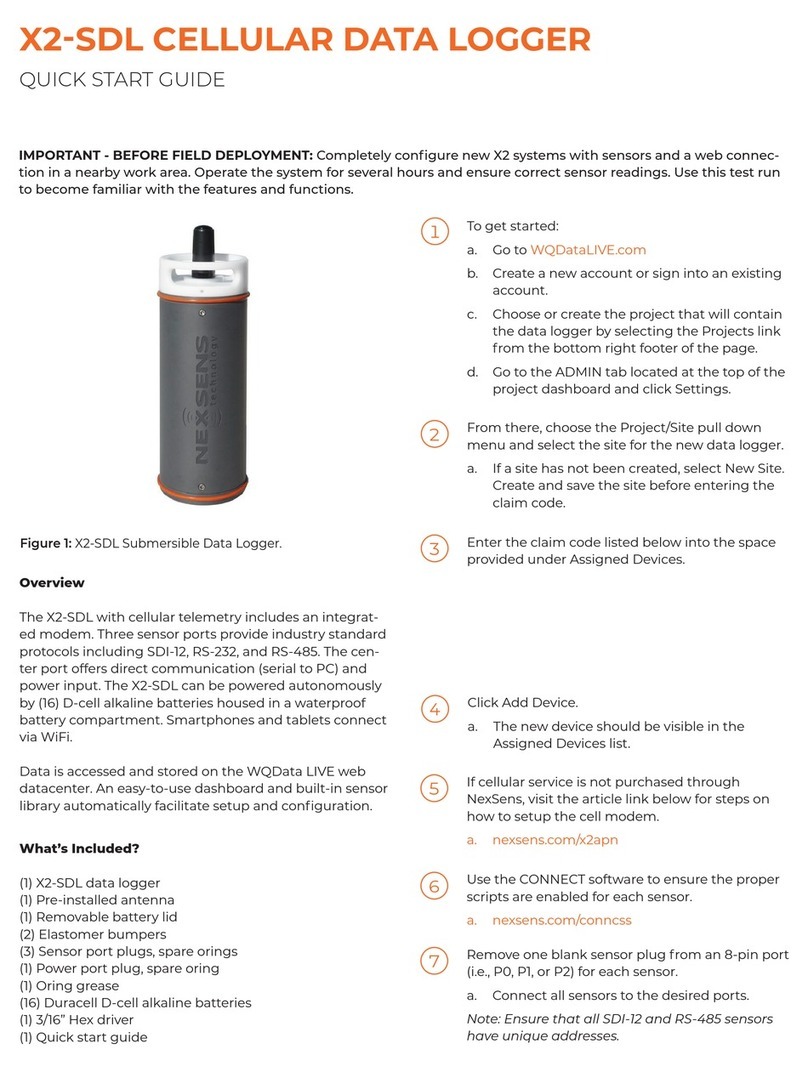

X2-SDL Submersible Data Logger

User Guide

Last Revision: 23 February 2023

Date Generated: 28 February 2023

Copyright © 2023 NexSens Technology, Inc.

Table of Contents

1. General

X2-SDL Body Tag Identification

What depth of submersion is the X2-SDL rated for?

2. System Power

What type of batteries does the X2-SDL take?

Apply Power to the X2-SDL

Basic Requirements

Input Channels

Connector Wiring

Install Batteries in the X2-SDL Data Logger

UW-6 Universal Pinout

Buzzer Indicator

Performing a Measurement System Power Budget

Instructions for Use

Advanced Custom User Entry

Disclaimer

Additional Resources

3. Establish Communication

X2 Data Flow

Wi-Fi

Cellular

Iridium

Radio to Cellular

Radio to PC

Wi-Fi

Configure Network Settings

Cellular

Set up a 4G Cellular Account for an X2 Data Logger

Install a SIM Card

Set an APN on an X2 Data Logger Using CONNECT

Iridium

Setup Gmail Account to Allow WQData LIVE Access (Iridium)

Setup Iridium (SBD) Data Account

Setup Iridium Logger Through CONNECT

Iridium Transmission Delay

Radio

Set Up a NexSens Radio Network

4

4

6

7

7

8

8

8

9

10

12

14

15

15

20

20

21

22

22

22

23

24

25

26

27

27

30

30

31

34

42

42

46

49

52

54

54

2

4. Connect Sensors

X2 Supported Sensors

Tier 1 Sensors

Tier 2 Sensors

Tier 3 Sensors

CONNECT Software

UW Connectors

UW-8 Sensor Port Pinout

UW-8 Plug Pinout

X2 Sensor Detection

When Sensor Detections Occur

Important Considerations

Setup in WQData LIVE

Creating a WQData LIVE Project

Adding a Data Logger to a WQData LIVE Project

Changing Sensor Log Intervals

Changing Data Logger Transmission Interval

Run Remote Sensor Detection

X2 Logger Diagnostic Readings

X2 Meta Parameter Descriptions

5. Troubleshooting and Maintenance

Sensor(s) Not Found During X2 Auto-Detection

At what voltage should batteries be replaced?

Cycle Power

X2-SDL O-ring Maintenance

X2-SDL Storage Requirements

6. Warranty

7. Service Request

Service Request

61

61

61

63

64

65

66

66

67

68

68

68

69

69

71

74

75

76

78

78

82

82

83

84

85

87

88

89

89

3

1. General

X2-SDL Body Tag Identification

Each X2-SDL and SDL-V2 data logger has a body tag number etched into the long housing tube contained

between the antenna and sensor bulkheads.

This number is incorporated into the default name of the device on WQData LIVE and will often be requested by

a technical support specialist in the event remote troubleshooting is required or if NexSens-supplied data

services require activation or cancellation.

X2-SDL body tag is listed on the long enclosure tube opposite the NexSens logo.

X2-SDL body tag marking 1715.

4

X2-SDL default device name.

Note all SDLs will have a ‘3’

entered in front of the Body

Tag display value.

5

What depth of submersion is the X2-SDL rated for?

The X2-SDL is rated for submersion up to 200ft (~60m).

Note that the SDL-CAP accessory is required to fully submerge cellular or radio models containing an external

antenna. The antenna port of Wi-Fi only models is epoxied closed and may be completely submerged using the

standard battery lid.

6

2. System Power

What type of batteries does the X2-SDL take?

The X2-SDL requires (16) D-Cell Duracell1 Alkaline batteries.

1D-cell batteries from other manufacturers may have sub-flush negative terminals which can result in poor

contact and may affect the consistency of power supplied to the X2-SDL logger.

7

Apply Power to the X2-SDL

The X2-SDL has flexible power input choices that provide several options in terms of type and number of power

sources.

Basic Requirements

5-24 VDC [+/-10%] (Reverse polarity protected)

Current Draw (Typical @ 12VDC): Low power sleep: 350uA; Logger Active: 35mA; Wi-Fi Transmitting:

43mA; Cellular Transmitting: 300mA

Peak Current: 500mA @ 12V for 1 second

Input Channels

The X2-SDL is equipped with two separate power input channels. The X2-SDL pulls power from the highest

priority channel that has a voltage within the specified range. If one of the sources falls outside the range, the

next highest priority channel will automatically take over without an interruption in supply.

From highest to lowest priority, the channel order is as follows.

Primary

Backup

This multi-input design allows users to connect redundant power sources in order to mitigate the likelihood of

system power loss.

Typical Application

Frequently, X2-SDL systems are run off of (16) internal D-Cell Alkaline batteries. The following article describes

the process for installing these batteries properly before deployment.

Install Batteries In an X2-SDL Data Logger

X2-SDL Data Logger

8

Connector Wiring

Power may be applied to the X2-SDL via the UW-6 receptacle port by a UW-USB-485P for connection to a PC,

or from a customized solar power kit. Most applications; however, rely on the internal D-Cell Alkaline batteries

during deployment.

X2-SDL UW6 Power Port Pinout

Pin Number X2 Wire Color Signal

1 Green Host RS-485A

2 Blue Host RS-485B

3 White Backup Power Input

4 Black Ground

5 — —

6 Red Primary Power Input

UW-6 Pin Numbering

9

Install Batteries in the X2-SDL Data Logger

The battery compartment of the X2-SDL data logger accommodates (16) D-Cell Alkaline batteries for system

power. These batteries should be replaced once the reported secondary power falls to 8V to avoid data

collection interruption.

1. Locate the white battery lid at the top of the X2-SDL.

2. Rotate the lid counter-clockwise to remove it.

a. Note: Due to the double O-ring lid seal this will take significant effort to loosen.

b. The 3/16″ ball-point hex driver included in the X2-SDL maintenance kit can be inserted into either of the

two recesses in the lid to provide extra leverage.

Remove the white battery lid.

10

3. Note the polarity labels affixed to the inside of each battery tube prior to inserting fresh D-cell batteries.

4. Thread the battery lid back on to the top bulkhead of the X2-SDL.

5. Rotate the lid clockwise and tighten securely using the hex driver.

a. Once the large washer at the bottom of the white battery lid makes contact with the battery terminals,

power will be applied to the X2-SDL and a buzzer will sound once confirming it is running.

Insert (16) D-cell batteries.

11

UW-6 Universal Pinout

The schematics and table below details the 6-pin plug and receptacle universal pinout for all 6-pin NexSens

cables excluding the 6-pin AC adapter.

Figure 1: NexSens UW-6 receptacle pinout Figure 2: NexSens UW-6 plug pinout

Figure 3: X2-CBMC/SDLMC MCIL-6-FS 6-pin power

port Figure 4: NexSens MCIL-6 plug pinout

12

Universal Pinout

Note: For instruments shown below, all signals in the table refer to their 6-pin receptacle port.

Plug Pin Receptacle Pin Wire Color G2-Series Signal X2 Signal X2-CB Buoy Solar Signal**

1 6 Red Ext. Power Input Main Power Input X2 PCB Power In

2 5 Yellow — Secondary Pwr Input* Unregulated Solar In

3 4 Black Ground Ground Ground

4 3 White — Backup Power Input Internal Buoy Bat.

5 2 Blue RS-485 B RS-485 B RS-485 B

6 1 Green RS-485 A RS-485 A RS-485 A

*X2-SDL’s purchased after

August 2021 do not include

secondary power.

**Wire colors for the X2-

CB/X2-CBMC follow the UW-6

Bulk Pinout

iSIC-V2 X2 X2-CB**

G2-RAIN X2-SDL* X2-CBMC**

G2-EXO X2-SDLMC

13

Buzzer Indicator

X2-SDL & X2-CB data loggers are equipped with an onboard buzzer to provide audible system status feedback

to the user.

X2-SDL/X2-CB Buzzer Indicator Status Lookup

Event Beep Type Status

When power is applied Short beep System boot successful

During telemetry connection Two short beeps Connection successfully established

During telemetry connection Three short beeps No signal/connection failed

During Sensor Detection 3 second beep WQData LIVE setup completed

successfully

14

Performing a Measurement System Power Budget

Analyzing a measurement system power budget is a useful practice to help ensure that a proposed system

design will meet the monitoring objectives and reliably deliver data. To aid with this, NexSens has developed a

power budget tool which can quickly estimate the expected power performance of systems using the most

common NexSens buoy platforms, data logger configurations, and commonly integrated NexSens and third-party

sensors for deployment locations throughout the world.

The power budget tool is frequently updated with site locations, sensor types and other information. Contact a

NexSens applications engineer to request an up-to-date copy:

Contact NexSens

Instructions for Use

1. Begin by entering the company and/or project name and date in the top section. It is recommended to save

the file with a unique identifier before proceeding past this point.

2. Proceed to enter basic information about the system – equipment type (logger and hardware), telemetry

option (if any), sample and transmit intervals, and extra battery if used.

a. The example below shows a CB-950 data buoy with X2 data logger and CB-A05-3 battery pack with (3)

28 A-hr batteries. The system will sample every 20 minutes and transmit all data every 60 minutes and

has no additional batteries connected (as is normal on buoy-based systems).

3. Proceed to select the sensors to be connected to the system from the predefined sensor list (drop-down

menu in Sensor column). Select the quantity of each sensor type and whether they will use full power,

switch power or internal power.

a. The example below shows an Airmar 200WX-IPX7 weather station, NexSens T-Node FR temperature

string with 10 nodes, Nortek Signature 1000 current profiler, and a YSI EXO3 sonde all on switch

power.

Project information header.

Enter system information.

15

Select sensors from drop-down list.

16

b. While the pre-populated sensor list is fairly extensive and frequently updated, there may be cases

where a sensor is not listed. In such cases, it is possible to enter up to four devices manually by

selecting Custom 1/2/3/4 from the drop-down list.

Custom sensor entry.

17

c. Once selected, proceed to the Custom User Entry tab of the spreadsheet. Navigate to the Sensor

Details section and fill in the prompted information either using data from the device manufacturer or

measured data during device testing.

Custom sensor data entry.

18

d. Note that some instrument types have a number of different configurations which may affect power

performance. The predefined sensors in the drop-down list are set up based on a typical configuration

and information provided by the manufacturer or NexSens bench testing where applicable. These

therefore represent a best approximation based on available information. However, these may also be

edited manually in the Sensor Details section of the Power Budget Calculation tab if more precise

information is available.

4. Once all sensor information is entered, select a deployment location from the drop-down list. The predefined

list contains locations throughout the world, and it is normally sufficient to select the closest possible

location provided that the latitude and general climate conditions are similar. However, if an appropriate

location does not appear to be available, it is recommended to contact NexSens as new locations can

normally be added quickly upon request.

5. Select which months of the year the system is expected to be deployed. In many cases, all months will be

selected, and December will be the limiting month for sites in the northern hemisphere. However, this option

is given because, particularly for data buoy systems, some applications require only seasonal or short-term

deployment.

6. Having entered all equipment information and deployment site conditions, the Results section will now

display the calculated results.

Select deployment location.

Select months of active deployment.

Calculated results display.

19

a. Reserve Days refers to how long the system could operate if starting with near 100% battery charge

during an extended period without solar charging, or how long a system without any solar charging can

be expected to operate. For solar-charged systems, a rule of thumb is to target at least two weeks (14

days) of reserve power.

b. Panels Available refers to how many individual panels are available in a solar array. CB-Series buoys

normally have three panels on the solar tower. Since these are oriented such that all three cannot

receive sunlight simultaneously, this is accounted for in the power budget by efficiency factors built into

the calculation. It is therefore not necessary to change this value.

c. Panels Required refers to the calculated result for solar charge capacity needed to support the given

configuration. It must be less than the Panels Available in order for the system to support the

application as defined.

d. Sufficient Power provides a yes/no answer for whether the selected hardware, logging and transmit

configuration is supportable. If it is not, it displays how many additional panels would theoretically be

required. Adjustments can be made to the system design until a viable result is achieved.

Advanced Custom User Entry

Because flexibility for use with user-supplied loggers, batteries, sensors and other electronics is a basic design

principle of NexSens CB-Series data buoys, the power budget calculator also facilitates user entry of data for all

components.

Besides just the Custom sensor data entry noted in step 3 above, the Custom User Entry tab supports input of

user-supplied data loggers, solar panels, telemetry systems and battery packs, as well as solar insolation for the

exact deployment location.

These fields can be activated by selecting the Custom entry option for equipment type, telemetry type, extra

battery, sensors, and/or deployment location as illustrated below.

Disclaimer

The NexSens power budget calculator is intended as a helping tool for correct system design. It integrates

efficiency factors and other conservative estimates of power consumption in order to provide a best possible

approximation of system power performance and viability. However, real-world conditions may vary, and field

testing is the only way to ensure that a system will perform adequately. NexSens does not assume liability for

any system that does not perform in accordance with power budget estimates.

Custom user entry options.

20

Other manuals for X2-SDL

1

Table of contents

Other NexSens Technology Data Logger manuals

NexSens Technology

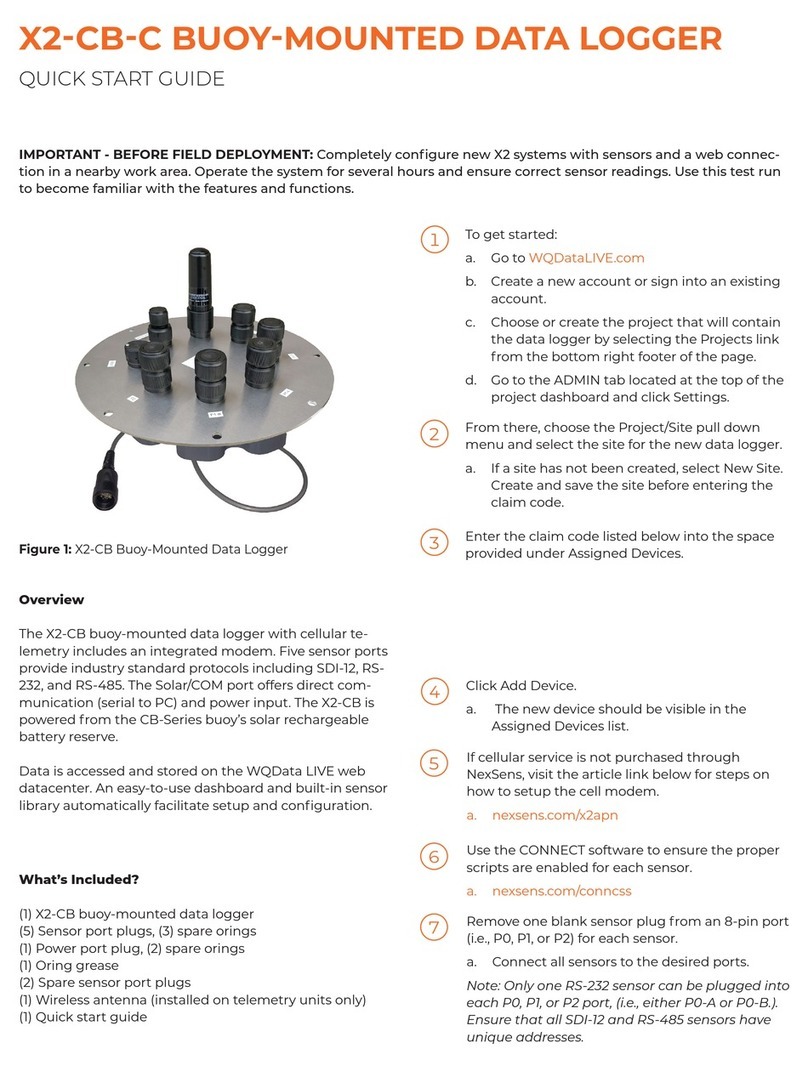

NexSens Technology X2-CB-C User manual

NexSens Technology

NexSens Technology CB-25 User manual

NexSens Technology

NexSens Technology CB-50 User manual

NexSens Technology

NexSens Technology CB-650 User manual

NexSens Technology

NexSens Technology CB-40 User manual

NexSens Technology

NexSens Technology CB-150 User manual

NexSens Technology

NexSens Technology iSIC-OEM User manual

NexSens Technology

NexSens Technology X2 User manual

NexSens Technology

NexSens Technology X2-CB User manual

NexSens Technology

NexSens Technology CB-250 User manual