NexSens Technology CB-950 User manual

Table of contents

Other NexSens Technology Data Logger manuals

NexSens Technology

NexSens Technology iSIC-OEM User manual

NexSens Technology

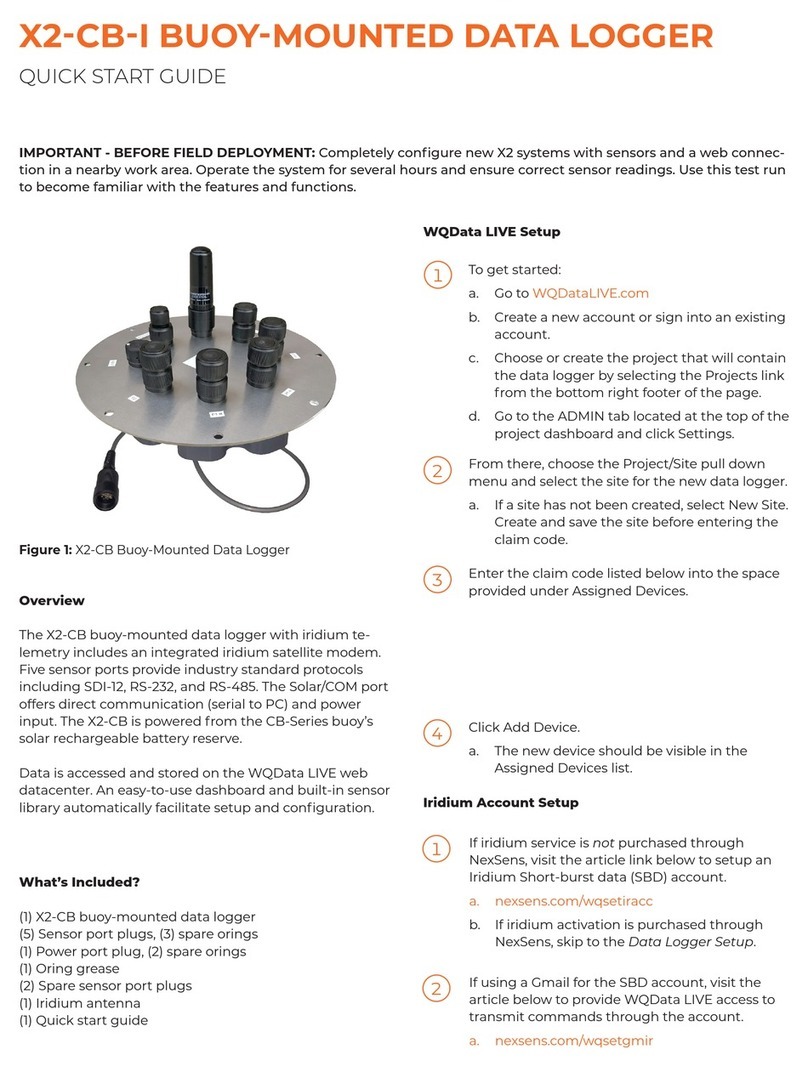

NexSens Technology X2-CB-I User manual

NexSens Technology

NexSens Technology CB-50 User manual

NexSens Technology

NexSens Technology CB-250 User manual

NexSens Technology

NexSens Technology CB-650 User manual

NexSens Technology

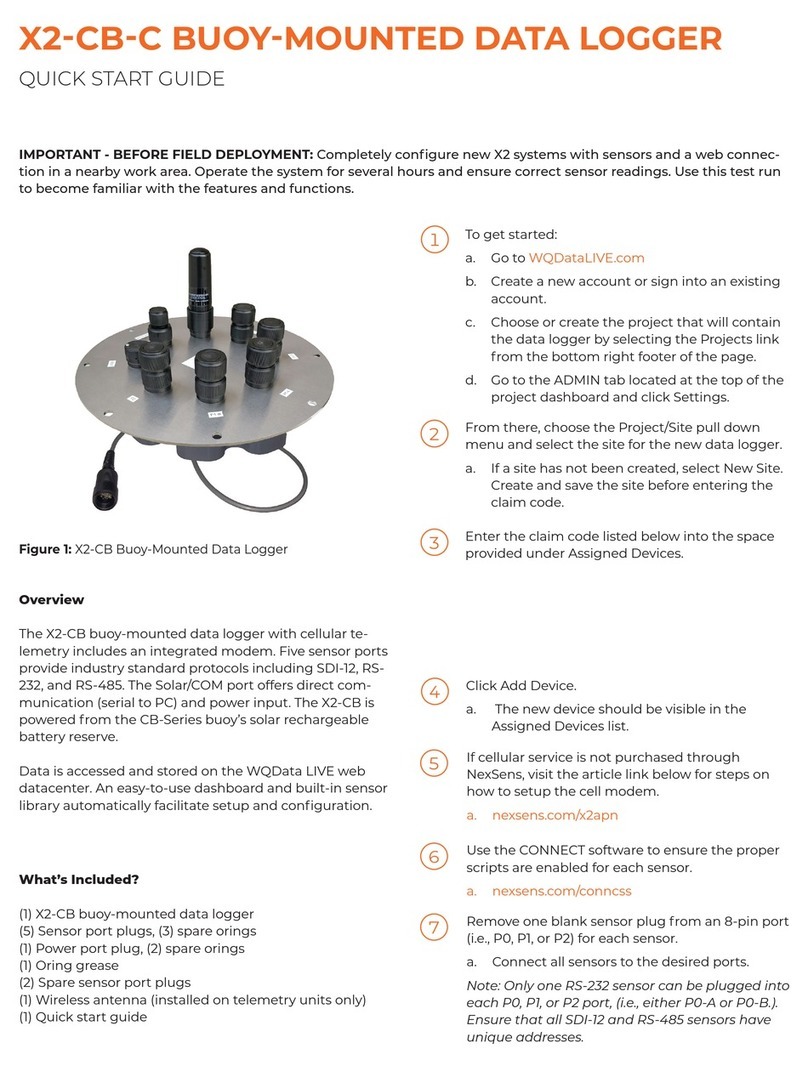

NexSens Technology X2-CB-C User manual

NexSens Technology

NexSens Technology CB-150 User manual

NexSens Technology

NexSens Technology X2-CB User manual

NexSens Technology

NexSens Technology CB-450 User manual

NexSens Technology

NexSens Technology CB-40 User manual

Popular Data Logger manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI Dupline G 3800 0036 quick start guide

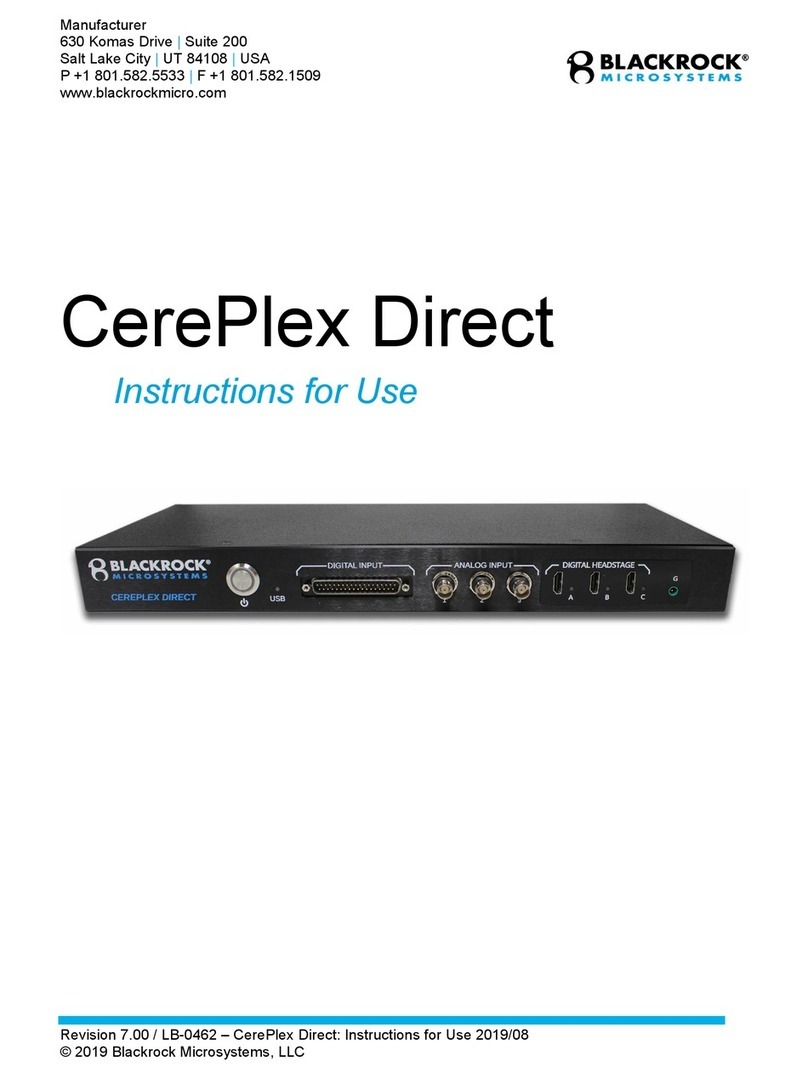

Blackrock Microsystems

Blackrock Microsystems CerePlex Direct Instructions for use

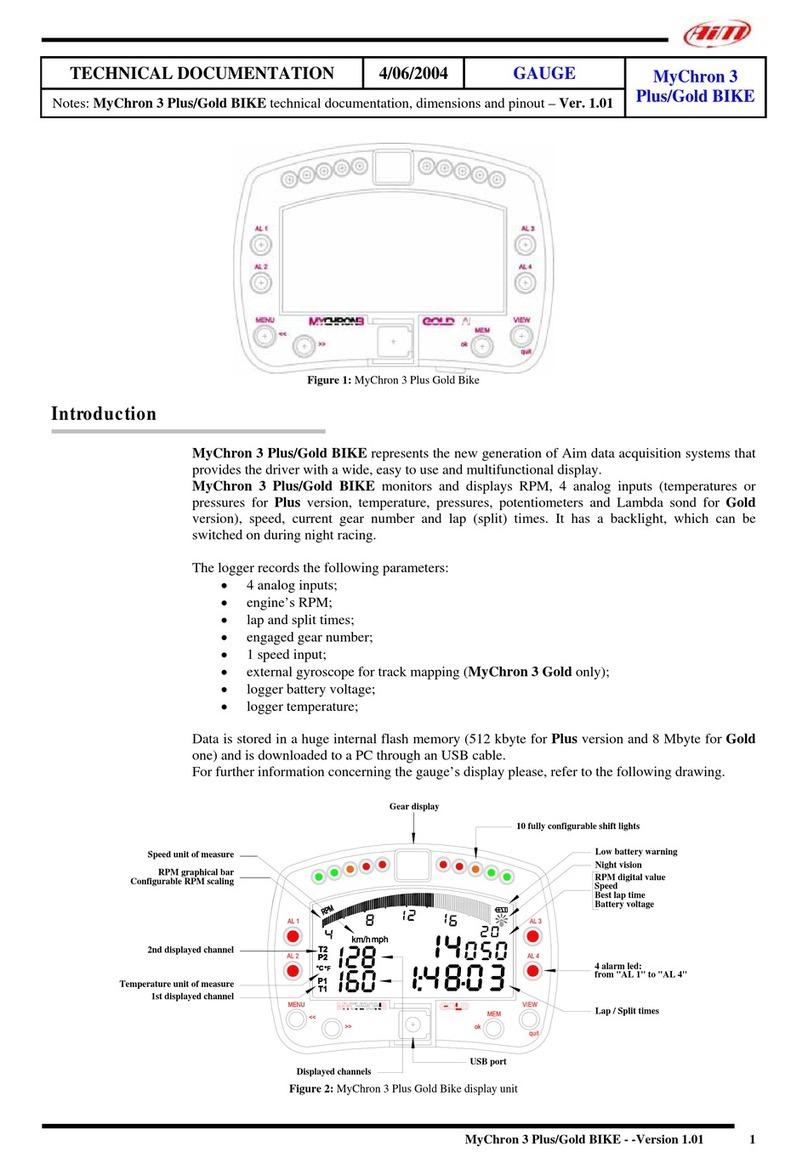

Aim

Aim MyChron 3 Plus/Gold BIKE Technical documentation

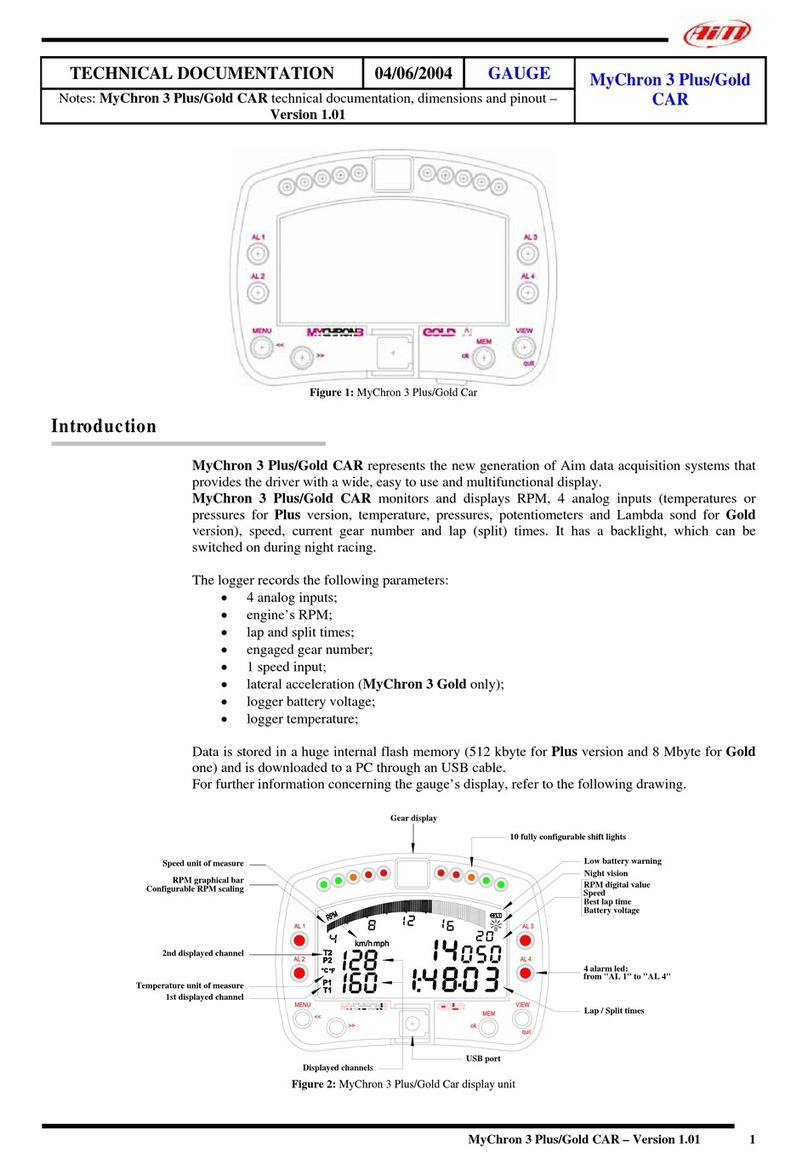

Aim

Aim MyChron 3 Plus/Gold CAR Technical documentation

Chauvin Arnoux

Chauvin Arnoux pel 102 user manual

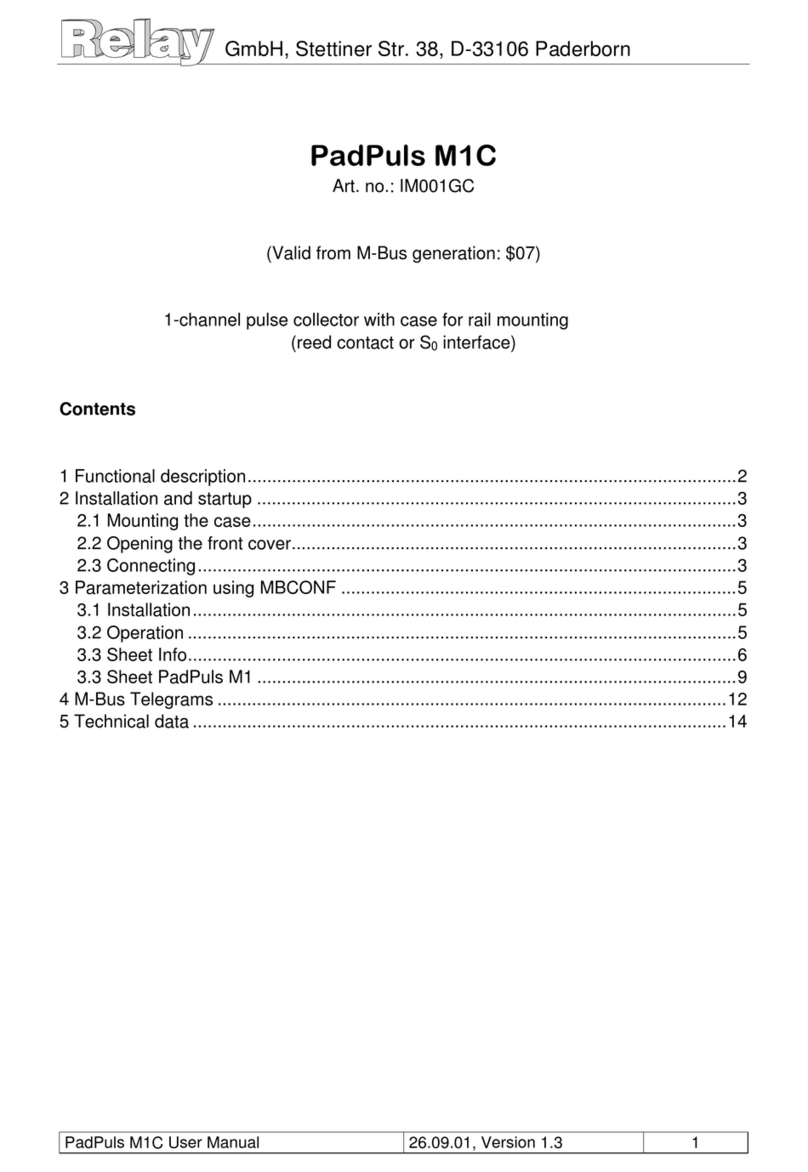

Relay

Relay PadPuls M1C manual

![Lambrecht Ser[LOG] Operator's manual Lambrecht Ser[LOG] Operator's manual](/data/manuals/zq/a/zqaq/sources/lambrecht-ser-log-data-loggers-manual.jpg)