NexSens Technology CB-450 User manual

CB-450 Data Buoy

User Guide

Last Revision: 20 October 2022

Date Generated: 7 December 2022

Copyright © 2022 NexSens Technology, Inc.

Table of Contents

1. General

CB-450 Data Buoy Overview

Key Components and Definitions

Key Specifications

CB-Series Data Buoy Planning & Precautions

2. Buoy Assembly

Using NexSens Electronics in CB-Series Data Buoys

Data Loggers

Battery Packs

Installing User-Supplied Electronics in CB-Series Data Buoys

Common Accessories

Securing Data Well Plate

CB-PTL Bulkhead Connector Assembly Installation

Connector Types

UW-6 Power Bulkhead Connector Assembly Wiring

UW6-BULK Pinout

Wiring Options

M550 Beacon for CB-Series Data Buoys

Installation

Operation

CB-Series Data Buoy Instrument Cage Installation

CB-CCA Anti-Rotation Collar

Use of Sacrificial Anodes on CB-Series Data Buoys

CB-Series Data Buoy Instrument Mounts

Topside Mounts

Subsurface Mounts

3. Deployment

CB-Series Data Buoy Ballast Weight & Stability

Top-Side Weight

Ballast Weight

Buoy Ballast Weights

Mooring Data Buoys

Buoy Ballast

Mooring Eye Lifting

Data Buoy Mooring Types

CB-Series Data Buoy Deployment Tips

NexSens CB-Series Data Buoys

4

4

4

6

7

9

9

9

10

11

11

12

13

13

14

14

15

16

16

17

18

19

20

21

21

21

23

23

24

25

26

27

27

27

27

33

33

2

Connecting Mooring Hardware

Deployment

Single-Point Mooring Deployment

Two-Point and Three-Point Mooring Deployment

Planning a Medium-Deep Water Mooring for Small Data Buoys

Mooring Line Length Calculation

Chains for Controlled Movement vs. Ballast Weight

System Maintenance

Mooring Hardware Materials

Deployment

4. Troubleshooting and Maintenance

General Data Buoy Maintenance

Verify Battery Voltage of a CB-Series Buoy

Replace a Battery in a CB-Series Data Buoy

Battery Removal

New Battery Installation

Test a CB-Series Buoy Solar Tower

Data Buoy Storage Requirements

5. Warranty

6. Service Request

NexSens Return Authorization

33

34

35

36

37

37

41

43

43

44

47

47

49

50

50

52

56

58

60

61

61

3

1. General

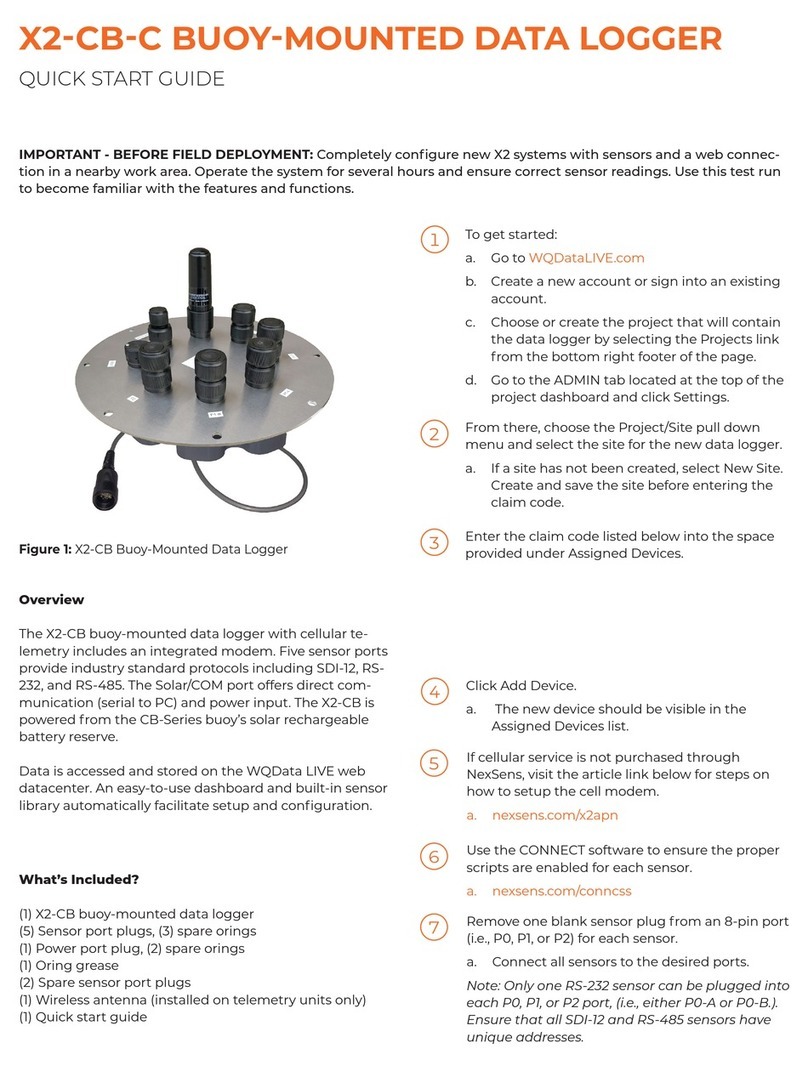

CB-450 Data Buoy Overview

The CB-450 data buoy is ideally suited for dredge turbidity monitoring, temperature profiling, dissolved

oxygen monitoring, limnology research, and weather monitoring on inland lakes and protected coastal

areas. Like all solar-powered NexSens CB-Series data buoys, it is a highly customizable platform that

may be configured with NexSens or user-supplied electronics. It supports a wide variety of topside and

subsurface sensors and measurement instruments.

Key Components and Definitions

Buoy Hull – Constructed of cross-linked polyethylene foam with a durable polymer outer layer and

rugged stainless steel frame providing a net buoyancy of 450 lb (204 kg). Three 4” passthrough holes

with female NPT bottom threads allow for quick connection of instrument deployment pipes and custom

sensor mounts.

Data Well – The waterproof compartment located in the center of the buoy hull for placement of system

electronics such as batteries and data loggers. On the CB-450 model, the data well has a 10.3” (26.2

cm) diameter and 19.5″ (49.5 cm) height.

For complete NexSens systems, the data well is fitted with CB-A01-2 or CB-A05 battery harnesses and

the X2-CB data logger, which includes five sensor ports with waterproof UW connectors supporting

common standards such as SDI-12, RS-232 and RS-485. Waterproof sensor connection is achieved by

factory installation of fully-sealed UW connectors onto sensor cables.

CB-450 data buoy.

4

For users supplying their own electronics, the CB-450 is delivered as an open platform with empty data

well or with battery only. A data well top plate can be supplied in one of three ways:

1. A standard CB-PTL Pass Through Lid for passing of instrument cables through gland fittings

2. A CB-PTL lid with UW8-BULK sensor bulkhead cable assemblies

3. A blank lid with only UW6-BULK power cable assembly and vent that users may drill their own

holes and install connectors into

Solar Tower – Three 15W solar panels on the solar tower capture sunlight from any direction and

charge batteries located inside the data well. The tower also supports the mounting of an M550 solar

marine light for nighttime visibility. Aside from regular cleaning to ensure solar panels are unobstructed

from receiving maximum sunlight, there is little to no maintenance required. However, solar assemblies

may be function tested if any performance issue is suspected by placing in the sun and measuring

output on the UW-6 (6-pin) port plug.

Buoy data well and pass-

through holes. Data well top plate.

CB-450 solar tower.

5

Buoy Frame – The skeleton of the buoy is comprised of 316 stainless steel with topside lifting eyes and

subsurface mooring eyes for single and multi-point moorings. The frame supports attachment of an

instrument cage for secure connection of subsurface sensors and additional ballast weight for stability.

Key Specifications

The key specifications of the CB-450 buoy are given below:

Hull Outer Diameter: 34.0” (86.4cm)

Hull Height: 20.0” (50.8cm)

Data Well Inner Diameter: 10.3” (26.2cm)

Data Well Height: 19.5″ (49.5cm)

Pass-Through Hole Diameter: 4.0″ (10.2cm)

Tower Height: 20.0” (50.80cm)

Solar Panels: 3x 15-watts

Weight: 130 lb (59kg)

Net Buoyancy: 450 lb (204kg)

Hull Material: Cross-linked polyethylene foam with polyurea coating & stainless steel deck

Hardware Material: 316 stainless steel

Mooring Attachments: 3x 3/4” eyenuts

CB-450 buoy frame with

instrument cage installed.

6

CB-Series Data Buoy Planning & Precautions

Buoy deployments are usually complex operations that involve many elements including sensors, data

loggers, mounting hardware and mooring equipment. Careful planning is essential to the success of a

buoy project, not only for system operation and data collection but also to ensure the project personnel’s

safety and minimize the risk of damage to expensive system components. When planning a buoy

deployment, be sure to give careful consideration to the following aspects:

Buoy sizing and power budget – Buoys come in various physical sizes with differing batteries and

solar charging capacities. A buoy must be adequately sized to tolerate the site environmental conditions

while providing sufficient power for continuous system operation. A power budget should be calculated

to ensure the system can meet the demand for sensor measurements and data transmission.

Buoy ballast – Proper ballast of a buoy is critical to buoy stability when it is deployed in the water. Be

sure to review the ballast weight and stability guide when designing a buoy system. Some

experimentation may be required before final deployment.

Buoy mooring – Mooring systems come in many forms depending on the location, water depth, and

environmental conditions to which a buoy will be exposed. As a starting point, the mooring data buoys

guide provides an overview of common mooring strategies. However, NexSens does not endorse any

particular mooring strategy, and systems should be designed and executed based on careful

consideration and local knowledge of the deployment site.

Electrical connections – Many NexSens buoy systems utilize UW connectors for connection of power

and sensor cables. Data loggers such as the X2-CB have UW receptacle ports to receive sensor cables

fitted with UW plug connectors. UW connectors provide a double O-ring seal, with one O-ring inside the

receptacle and one around the plug. In order to ensure waterproof connection, check the following each

time a UW connection is made:

1. The O-ring inside the receptacle is present (has not fallen out)

2. The receptacle and plug are clean, dry and free of debris

3. The O-ring on the plug is lightly greased

4. Connection is tight, secure and fully seated

5. Unused receptacle ports are fitted with UW port plugs

Connections may be periodically inspected and maintained with O-ring grease, at a minimum before

each buoy deployment.

CB-Series data buoys contain a waterproof data well constructed of stainless steel where batteries are

mounted. Whenever installing or maintaining battery systems, use caution to avoid short-circuiting of

battery poles to the metal walls of the data well. Gloves and tools with rubber grips are recommended,

and any exposed connections should always be covered with electrical tape or other suitable coverings.

Safe deployment – Above all else, safety is the most critical consideration to take during the planning of

a buoy deployment. Any time a buoy system is deployed, there are countless hazards, including, but not

7

limited to, working on/near water and lifting of heavy equipment. Important factors to consider for

personnel safety are:

Use of safety equipment (i.e., life jackets, gloves, steel toed boots, etc.,)

Proper lifting and mooring techniques

Awareness of on-site and surrounding weather conditions and advisories

Despite careful planning, unforeseen situations are always still a possibility. Buoy deployments are an

at-risk operation, and the user assumes liability for any injury or damages that may occur.

8

2. Buoy Assembly

Using NexSens Electronics in CB-Series Data Buoys

Although users may provide their own electrical components including data loggers, modems and

batteries, many CB-Series data buoys are delivered as complete, plug-and-play system packages with a

NexSens data logger as the central component of the system.

Data Loggers

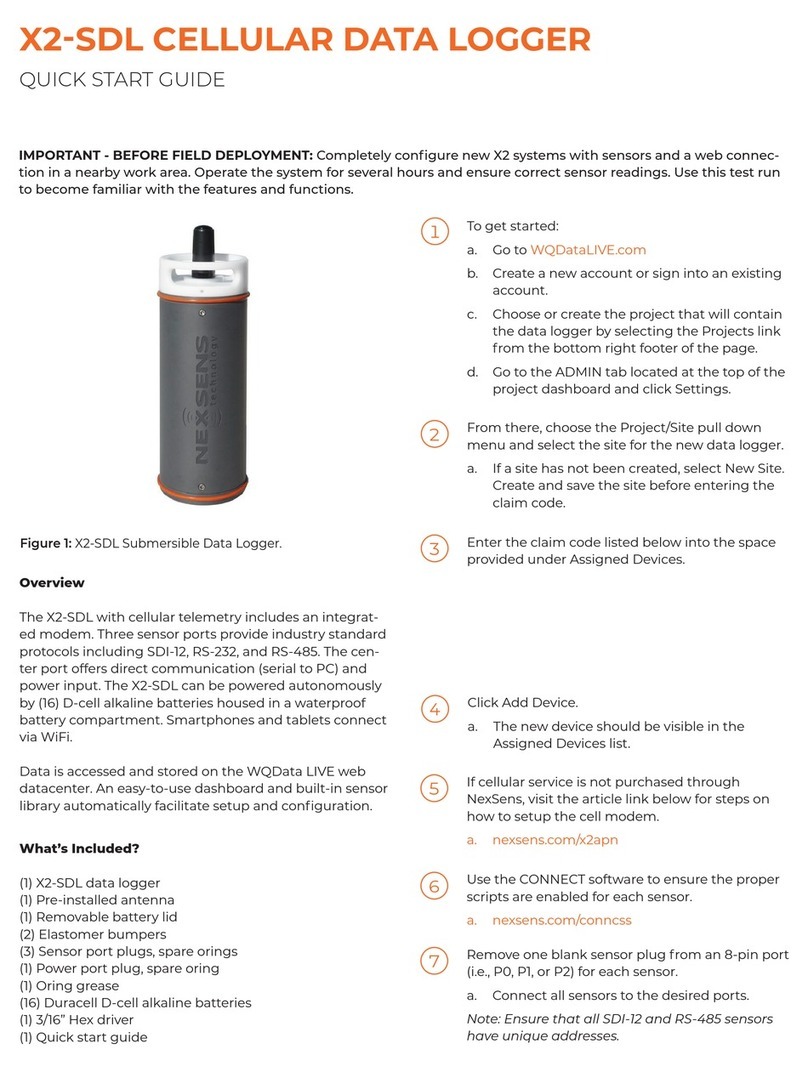

NexSens offers four different data logging systems for buoy deployment, all of which are based on the

central processing unit of the X2 environmental data logger:

1. X2-SDL Submersible Data Logger – fully submersible unit designed for standalone operation or

installed in the CB-50 platform

2. X2-SDLMC Submersible Data Logger – fully submersible unit with topside wet-mate sensor

connectors for standalone operation or installed in the CB-25 platform

3. X2-CB Buoy-Mounted Data Logger – waterproof, lid-mounted package for integration on CB-

Series data buoys with data well and solar charging (model CB-150 and larger)

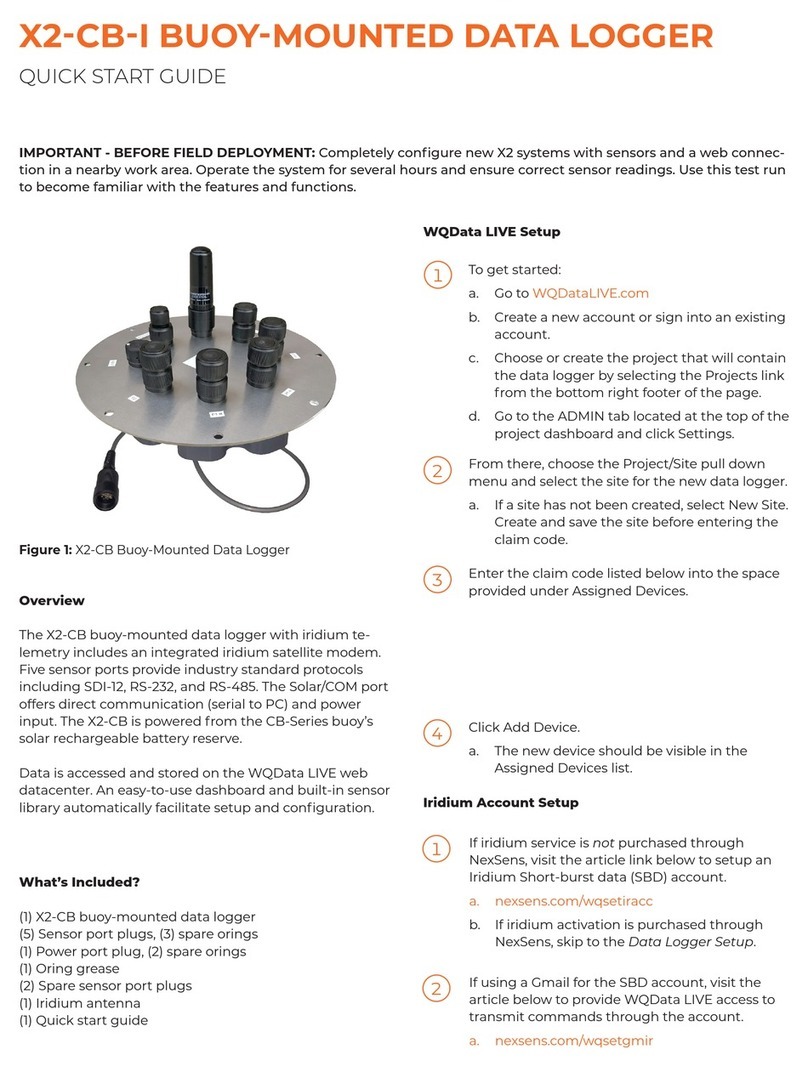

4. X2-CBMC Buoy-Mounted Data Logger – lid-mounted package with wet-mate connectors for use

on CB-Series data buoys in challenging environments such as offshore, typical on model CB-650

and larger

Reference the Data Loggers section of the NexSens Knowledge Base for resources including Quick

Start and User Guides to install, configure and operate NexSens data loggers with CB-Series data

buoys. Data logger user guides include detailed instructions on interfacing with sensors and setting up

transmission of data to the WQData LIVE web datacenter.

X2-SDL data logger. X2-SDLMC data logger. X2-CB data logger. X2-CBMC data logger.

9

Battery Packs

X2-SDL and X2-SDLMC data loggers rely on internal batteries to supply power. X2-CB and X2-CBMC

data loggers are designed for use on CB-Series data buoys with solar charging (model CB-150 and

larger). These buoys have a data well for installation of battery packs, and the data logger serves as the

top plate to provide a waterproof seal on the data well.

NexSens offers two standard types of battery harnesses, which include sealed lead acid (SLA) batteries,

solar regulator, mounting bracket and data logger connection cable pigtail (UW-6 connector):

1. CB-A01-2 – contains two 8.5 A-hr batteries (CB-150 only)

2. CB-A05-x – contains one to four 28 A-Hr batteries (depending on buoy capacity – see table below)

The following table shows what battery harness models each CB-Series data buoy model has capacity

for in the data well. However, what model is selected should be based on a complete power budget

analysis that includes system power demand, solar charge capacity (panel size) and available sunlight

based on deployment location to aid in determining how much reserve battery power is needed.

CB-A01-2 CB-A05-1 CB-A05-2 CB-A05-3 CB-A05-4

CB-150 x x

CB-250 x x

CB-450 x x

CB-650 x x x

CB-950 x x x

CB-1250 x x x x

NexSens battery harnesses are typically shipped pre-installed in CB-Series data buoys. However, in

cases where batteries need to be installed or replaced, detailed instructions can be found here.

10

Installing User-Supplied Electronics in CB-Series Data Buoys

NexSens CB-Series data buoys are flexible platforms that allow for use with both NexSens and user-

supplied electronics. For those wishing to integrate their electronics, including batteries, data loggers,

and modems, several accessories are available to facilitate installation inside the watertight data well

located in the center of the buoy.

Common Accessories

Battery mounts – While user-supplied electronics systems may receive power from NexSens-issued

CB-A01-2 and CB-A05-x battery harnesses, users may also supply and install their battery and solar

regulator systems in the data well. The bottom of the data well has two welded standoffs for connection

of battery mount posts, and hardware for securing user-supplied batteries, including mounting posts,

brackets, and foam inserts. Consult a NexSens Applications Engineer for available parts.

Data well plates – Buoys may be delivered with various data well top plate options:

CB-PTL pass-through lid with gland fittings for running user-supplied flying lead cables into the data

well, also compatible with bulkhead cable assemblies

Blank plate with only screw holes for users to drill custom hole patterns

No plate, user may machine custom plate using screw hole pattern from NexSens

In most cases, the CB-PTL is delivered with the buoy as it offers both flexibility and ease of use.

CB-PTL pass through lid.

11

Bulkhead cable assemblies – Ports on a CB-PTL may be interchanged with bulkhead cable

assemblies for power, RF signals and sensor data cables. The following options are available:

UW6-BULK – 6-pin power cables for connection of batteries, solar panels and regulator

RF-BULK – N-style female to SMA male RF cable assembly for use with modems placed inside

data well

UW-BULK – 8-pin sensor receptacle for use with sensor cables with factory-installed UW plug

connector; allows for external waterproof connection of user-supplied sensors

Instructions for installation and use of these bulkhead connector cables is available here.

Securing Data Well Plate

Any time the data well plate will be resealed, first verify that the large O-ring is in good condition, clear

of debris, and lightly greased. Align the plate with the bolt holes on the buoy and place the provided

bolts with lock washer. Tighten incrementally using a 9/16″ socket wrench in a cross-pattern as shown

below (2-3 passes recommended) to ensure even load distribution and proper seal of the data well.

UW6-BULK power cable

assembly.

RF-BULK antenna cable

assembly.

UW-BULK sensor cable

assembly.

Tighten bolts in a cross-pattern to seal properly.

12

CB-PTL Bulkhead Connector Assembly Installation

NexSens CB-Series buoy data wells capped with CB-PTL pass through lids may optionally have UW

plug ports replaced with bulkhead cable connector assemblies.

Connector Types

The CB-PTL comes standard with a UW-6 power bulkhead cable assembly (UW6-BULK) pre-installed.

Wiring instructions for connection of this cable to user-supplied electronics are available here.

The RF bulkhead connector assembly (RF-BULK) allows 3rd party modems to be integrated inside CB-

Series buoy data wells capped with CB-PTL pass through lids or blank lids with user-drilled holes. It

consists of an N-style female connector integrated on the bulkhead for external antenna connection, and

1m pigtail cable with SMA male connector for connection to a modem placed inside the watertight data

well. Installation instructions for an RF-BULK cable assembly can be found here.

UW sensor bulkhead connector assemblies (UW-BULK) allow for pluggable, watertight connection of

sensor cables to user-supplied electronics in the data well. Sensor cables must have a factory-installed

UW connector for connection to the UW-BULK bulkhead receptacle. Installation instructions for a UW-

BULK cable assembly can be found here.

13

UW-6 Power Bulkhead Connector Assembly Wiring

CB-Series Buoys without NexSens integrated electronics will ship with a solar tower and pass-through

plate outfitted with a UW-6 power bulkhead connector (UW6-BULK) port. Information regarding the port

pinout and different options for wiring power to user-supplied electronics is supplied below. For

installation instructions, follow the guide here.

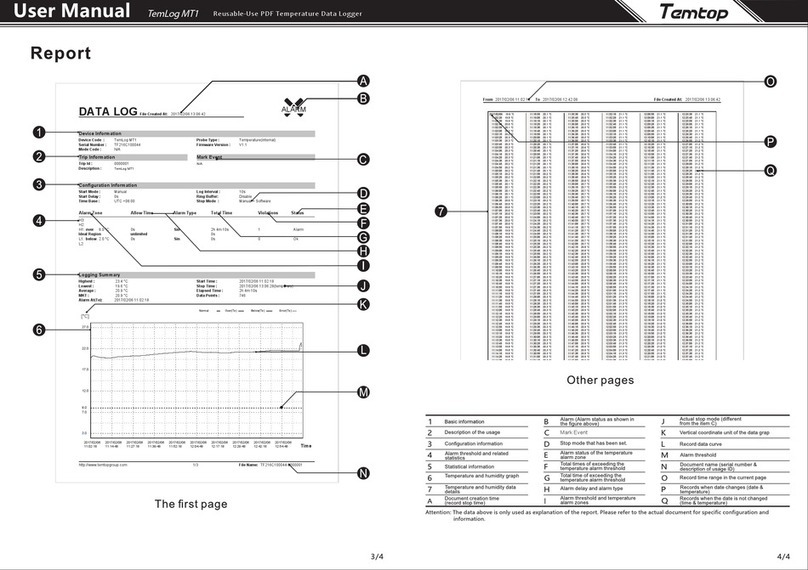

UW6-BULK Pinout

The diagram and table below show the pinout of the UW-BULK cable assembly.

NexSens UW6-BULK power cable

assembly.

UW6-BULK pinout.

14

UW6-Bulk Pin # Molex Wire Color¹ Flying Lead Wire Color² Notes

1 – –

2 – –

3 Red – Solar Connector Jumps to Pin 6

4 Black Black

5 Yellow –

6 Orange Red Solar Connector Jumps to Pin 3

¹Molex connector is designed to interface with a NexSens CB-A01-2 or CB-A05-x battery harness. If this

accessory was not ordered, connector can be cut off to wire to user-supplied components.

²The Red and Black flying lead wires are intended to supply power to user-supplied electronics.

Wiring Options

Solar Charged Battery [most commonly used]

If power to the buoy electronics is to be maintained by a solar-charged battery and the buoy was not

delivered with a CB-A05-x or CB-A01-2 battery harness, a solar regulator and battery must be sourced

locally.

Molex Wire Solar Regulator Connection Battery Terminal Connection

Yellow Solar + –

Black Common/GND Negative (GND)

Orange Battery + –

Red – Positive (V+)

The internal jumper inside the solar panel connector disconnects battery power from on-board

electronics when the solar panel plug is removed from the UW6-BULK port. This simplifies system

storage as the data well does not need to be opened to manually disconnect the battery.

Battery ONLY

If solar charging is not required for the application, a user may source a standalone battery to supply

power to on-board electronics. The following wiring will direct battery power to the Red and Black flying

lead wires of the UW6-BULK.

Molex Wire Battery Terminal Connection

Orange Positive (V+)

Black Negative (GND)

Solar Panel ONLY

If the unregulated solar panel output is solely required to power instrumentation, connect:

Molex Wire Electronics Connection

Yellow V+

Black GND

15

M550 Beacon for CB-Series Data Buoys

The NexSens M550 Solar Marine Light is a common accessory added to NexSens CB-Series data

buoys up to and including the CB-450. Depending on the configuration, it has a 1-3 nautical mile range

and is normally delivered with flange mount hardware, yellow color and default 15 flash/minute pattern

(Model M550-F-Y).

Installation

While it typically comes pre-installed, the M550 can easily be removed and/or installed by the user.

Reference the M550 Installation Instructions for guidance with the standard flange mount version. The

pole mount option can be similarly fixed to the buoy top plate using the provided hardware and one of

the pre-drilled holes on the top plate.

M550 Solar Marine Light.

M550 pole mount option. Mounted to top plate.

16

CB-Series Data Buoy Instrument Cage Installation

The instrument cage attaches to the bottom of CB-Series buoys for water sensor deployments while

simultaneously lowering the center of gravity and increasing stability.

Model number CAGE is 39″ (99 cm) in length and is normally used with the CB-50, CB-150, CB-250 and

CB-450 buoys. It is an optional accessory for the CB-50 and comes standard with the others.

Model number CAGE-L is 44″ (112 cm) in length and has a wider profile. It comes standard with CB-

650, CB-950 and CB-1250 buoys.

The cage is a critical component of the ballast weight of a data buoy and provides a mounting location

for additional ballast weight to be added as needed.

Attachment to the internal frame of a data buoy is simple using the provided hardware.

1. Use the provided bolt, lock washer and castle nut to attach the cage to the buoy frame.

Model CAGE instrument cage. Model CAGE-L instrument cage.

Bolt installation and cage connection.

18

2. Tighten firmly with a pair of 1-1/8” wrenches such that the lock washer is flattened and the bolt hole

is aligned with a notch on the castle nut.

3. Place the cotter pin through the bolt hole and bend the long leg of the pin.

CB-CCA Anti-Rotation Collar

The single bolt connection is sufficient for small buoys in calm waters. However, a CB-CCA Buoy Cage

Anti-Rotation Collar may be used for added security in rough waters or when suspending sensor strings

from the cage. It is included standard and should always be used with buoy models CB-650 and larger

that come with the CAGE-L. For installation instructions, see the CB-CCA installation guide.

Secured cage.

Cotter pin with bent leg for security.

CB-CCA collar.

19

Use of Sacrificial Anodes on CB-Series Data Buoys

Sacrificial zinc anodes are recommended for use on CB-Series data buoys any time they will be used in

saltwater environments. This helps to prevent corrosion on the stainless steel frame, as zinc is a more

active metal that will be consumed while protecting the stainless steel.

Anodes sourced from NexSens are sized specifically for installation onto buoy frames and instrument

cages using a pair of screws provided with the anode. They will typically need to be replaced

approximately every 6 months, though this may vary depending on factors such as the temperature and

salinity of the saltwater environment. Buoys should be regularly inspected and anodes replaced any

time it appears they will be consumed before the next scheduled maintenance. It is often a good idea to

have two anodes installed onto a buoy – one on the frame and one on the cage – and replace them

intermittently to ensure that there is always sufficient protection for the stainless steel. Anode

replacement will require a 4-mm Allen wrench to remove the pair of screws connecting the two anode

halves.

Zinc is chosen for the anode material because it is a readily-available metal with a lower reduction

potential (-0.76V) than the steel of the buoy frame. This offers the steel what is known as cathodic

protection, where oxidation reactions are transferred away from the steel to the zinc when placed in

highly ionic environments such as saltwater in the case of a buoy. The zinc is slowly consumed by the

process, hence the term sacrificial anode.

In theory, other materials besides zinc can be used as the anode as long as they rank lower on the

reduction potential scale than the stainless steel. Generally speaking, the larger the difference between

the metals on the scale, the faster the rate of the oxidation-reduction reaction. Materials with lower

reduction potential than zinc may therefore be consumed more rapidly and require more frequent

changes. Regardless of anode material chosen, frequent inspection and replacement of anodes as

needed can extend the life of a data buoy significantly in saltwater.

Sacrificial anodes are normally not necessary for buoys used in freshwater except in special

circumstances. It is therefore generally recommended only to order anodes with buoys intended for use

in brackish or saltwater.

Sacrificial zinc anodes.

20

Table of contents

Other NexSens Technology Data Logger manuals

NexSens Technology

NexSens Technology X2-SDL User manual

NexSens Technology

NexSens Technology CB-250 User manual

NexSens Technology

NexSens Technology CB-40 User manual

NexSens Technology

NexSens Technology CB-50 User manual

NexSens Technology

NexSens Technology iSIC-OEM User manual

NexSens Technology

NexSens Technology X2-CB-I User manual

NexSens Technology

NexSens Technology X2-CB-C User manual

NexSens Technology

NexSens Technology CB-150 User manual

NexSens Technology

NexSens Technology CB-25 User manual

NexSens Technology

NexSens Technology X2-CB User manual