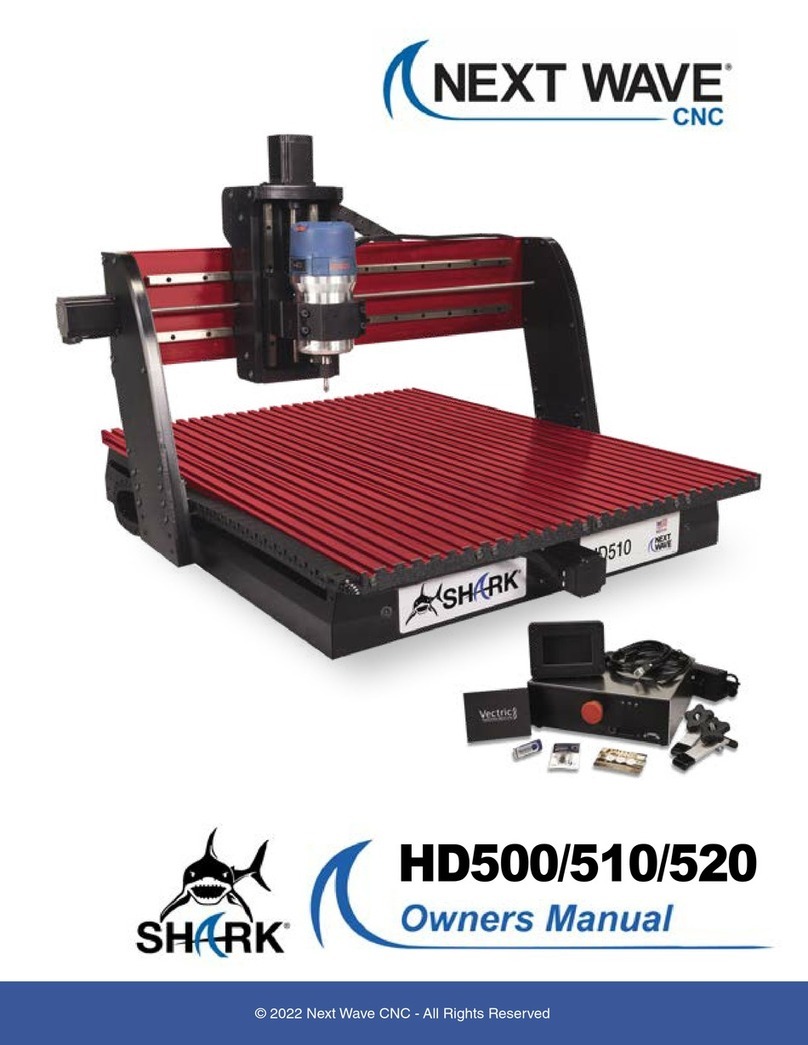

Next Wave CNC SHARK HD500 User manual

SHARK HD500/510/520

User’s Manual

®

2SHARK HD500 Series User’s Manual

Copyright 2020 Next Wave CNC - All Rights Reserved.

SHARK is the registered trademark of Next Wave CNC.

Ready2Control is copyrighted by Next Wave CNC.

Virtual Zero Unlimited is patented by Next Wave CNC.

All other trademarks are the property of their respective owners.

Information in this manual is subject to change without notice.

The most recent version of this manual can be found at

www.NextWaveCNC.com/downloads-links

Next Wave CNC, LLC,

600 W. Boundary St., Perrysburg, Ohio 43551

USA

Main Office Phone (419) 318-4822

3

V. 12/20

To Our Customers ………………………….…………………….… 4

System Requirements ……….………….…………..…..……......... 4

Product Warranty ..….…………….……………………………….… 5

Technical Support …….…………………….……..……………..…. 6

Safety .……….………………………………………..….…………… 7

Machine Assembly ……. ……………………………..….………… 10

Machine Registration …………………………………..….………… 20

VCarve software Installation ………….………..……..….………… 24

VCarve license registration ………….………..………….………… 32

Vectric User Portal account registration ……………..….………… 40

VCarve software version updates …...………..……..…..………… 42

CNC Workflow …..…………………………… ………………..…… 51

Machine Maintenance ………………………..………..….………… 60

Resources ………………………………………..……..…….……… 63

Table of Contents Page

Please read this manual carefully. It provides

important setup and operational information for

your SHARK HD CNC. This manual has been

written with the assumption that you are

experienced with the basic operation of a

computer as well as the technical knowledge

required to safely operate power tools.

4SHARK HD500 Series User’s Manual

To Our Customers

Thank you for purchasing a SHARK HD CNC from Next Wave CNC.

Included with your purchase are software licenses for Ready2Control,

Virtual Zero Unlimited, and VCarve Desktop (with the HD500 and

HD510) or VCarve Pro (with the HD520).

The Ready2Control software runs on your computer and is used to

run your toolpath files and control your SHARK HD CNC. It operates

in a similar way to the LCD Pendant but includes additional machine

control tools. See the Ready2Control User’s Manual for more

information.

Virtual Zero Unlimited allows you to map a curved or uneven

surface using as many reference points as you choose. The program

uses these points to adjust the G-code to conform to the curved or

uneven surface of your material. See the Virtual Zero Unlimited

User’s Manual for more information.

The Vectric VCarve software includes a broad set of CNC project

design and toolpath tools. Design tutorials and software support can

be found at www.vectric.com

System Requirements

All SHARK CNCs use 110v power. Your SHARK HD CNC can be

controlled with the included LCD Control Pendant or the

Ready2Control software.

Ready2Control software can be installed and run on any PC

computer running Windows 10. The computer must also have a USB

output port.

Vectric VCarve will run on most Microsoft Windows based PCs and

does not require any special hardware or graphics card.

NOTE: An Apple computer can be used if it’s running

Microsoft Windows via Parallels or Bootcamp.

Visit Vectric.com for details and exceptions.

5

V. 12/20

Next Wave CNC warrants your new SHARK HD5

series CNC to be free from defects in material

and workmanship for TWO YEARS from the date

of purchase. The warranty applies only to the

original retail purchaser of the SHARK HD5 series

CNC when purchased from an authorized Next

Wave CNC distributor. This warranty covers the

parts and labor to correct the defect. It does not

cover the cost of shipping the machine and/or

parts to Next Wave CNC for evaluation or repair.

Warranty

This warranty does not apply to problems arising from normal wear

and tear, misuse, abuse, negligence, accidents, unauthorized repairs,

alterations, or lack of maintenance. This warranty is void if the SHARK

HD5 CNC or any portion of it is modified without the prior written

permission from Next Wave CNC, or if the machine is located or has

been used outside of the country where the machine was purchased.

Please contact Next Wave CNC to take advantage of this warranty. If

Next Wave CNC determines that your SHARK ® HD5 series CNC is

defective in material or workmanship, Next Wave CNC will at its

expense and upon proof of purchase send replacement parts to the

original retail purchaser necessary to cure the defect. Next Wave

CNC will repair your SHARK HD CNC provided the machine or

affected components are returned to Next Wave CNC, shipping

prepaid, with proof of purchase and within the warranty period.

Next Wave CNC disclaims all other express or implied warranties,

including fitness for a particular purpose. Next Wave CNC shall not be

liable for death, injuries to persons or property, or incidental,

consequential, contingent or special damages arising from the use of

the SHARK HD CNC .

Ready2Control software

Next Wave CNC warrants Ready2Contol and Virtual Zero Unlimited to

perform as intended and will provide customer support to the original

purchaser when purchased from an authorized retail distributor.

Warranty only applies to the current version or the support needed to

update a past version. The cost of the software upgrade (if any) is not

covered by the warranty.

Vectric VCarve software warranty

For details visit: https://www.vectric.com/terms

6SHARK HD500 Series User’s Manual

Serial Number and Software License Information

For easy reference and record keeping, enter your SHARK HD

and Vectric information below. To locate the information, refer

to the pages listed below.

Controller Box Serial Number

(page 21)_______________________________________

LCD Pendant Serial Number

(page 21)_______________________________________

LCD Pendant Unlock Code

(page 22)_______________________________________

Your VCarve User’s Name

(page 35)_______________________________________

VCarve License Code

(page 35)_______________________________________

If you need technical assistance with your SHARK HD

CNC or software, please visit our Support webpage at:

NextWaveCNC.com/support or email Customer Support

at:

Support@NextWaveCNC.com. Please include your

product model number, date of purchase, and other

pertinent information associated with the issue such as

.tap files, VCarve files, screen captures, or photos of your

setup or the problem.

Support Email: support@nextwaveCNC.com

Available: 9 am –5 pm Monday-Friday (Eastern time).

Technical Support

7

V. 12/20

When operating machinery always wear the appropriate ear

and eye protection and follow all safety instructions of the

machine’s owner’s manual and related equipment manuals.

1. Read safety and operating instructions before using your

SHARK CNC.

2. Take time to fully understand how to safely operate your SHARK

CNC.

3. Setup your SHARK CNC following the instructions in this

manual.

4. Always wear appropriate eye and hearing protection when

operating your SHARK CNC and accessories.

5. DO NOT machine metal with your SHARK CNC.

6. Never attempt to adjust the work piece or move the SHARK

while it is running.

7. If needed, use the Cancel or Pause buttons to Stop or Pause

your SHARK CNC during an operation.

8. Never leave your SHARK CNC unattended while it is running.

9. While operating your SHARK CNC, keep a multi-purpose dry

chemical fire extinguisher nearby. It must be rated for both A & C

fires.

10. For added safety and convenience, connect your SHARK CNC

to a 110-115V surge-protected power strip with an on/off switch.

This provides an additional way to turn off the machine in case

of an emergency.

11. Follow all Safety instructions provide with your SHARK CNC and

accessories.

12. Follow all accepted and recommended safety precautions and

practices for woodworking and machining.

Safety

8SHARK HD500 Series User’s Manual

There are four ways that you can immediately stop your SHARK HD

CNC (listed below). Using any of these will immediately stop the

movement of your SHARK HD CNC. They also stop the router if it is

plugged into the Control Box. If you use a Spindle, it can be stop by

pressing the Stop button on the VFD, or if it’s connected to a power

strip, you can turn off the power strip to stop the spindle..

1. The Stop button in the Run screen on the LCD Pendant.

Emergency Stop

2. The Emergency Stop switch on the front of the Control

box

9

V. 12/20

4. The On/Off switch on the surge-protected power strip.

3. The On/Off switch on the back of the Control Box

Emergency Stop (cont.)

10 SHARK HD500 Series User’s Manual

Step 2

Attach the gantry

(see page 13)

Assembly-at-a-glance

ASSEMBLY TIPS

•Use two people to lift the heavy machine base and

gantry parts.

•Lift the machine base by the edges of the aluminum

table or under the front and rear legs.

•During assembly, lift the gantry by the rear beam or

side legs.

•Lift the assembled machine by edges of the aluminum

table or under the front and rear legs.

•DO NOT lift an assembled machine by the side covers

or the gantry.

Step 1

Attach side covers

(see page 12)

Step 3

Attach the cable carrier to the side

of the machine (see page 14)

Machine Assembly

Step 4

Attach the router/spindle mount

and install the router/spindle

(see page 17)

11

V. 12/20

Step 7

Attach power cable to

Control Box.

(see page 19).

Step 6

Attach Pendant to Control Box

(see page 19).

Step 5

Attach motor cables to

back of control box

(see page 18).

IMPORTANT

DO NOT plug in or power up your machine until the motor

and Pendant cables are fully attached.

DO NOT detach or attach motor or Pendant cables when

the Control Box is powered up as this will damage the

electronics and is not covered by the warranty.

MachineAssembly (cont.)

12 SHARK HD500 Series User’s Manual

Step 1a

Rotate side cover sand slide down over the Y-spar.

Step 1b

Attach the side covers with the mounting screws (4 per side). Do not

over-tighten.

Y-spar

Mounting

screws

MachineAssembly (cont.)

Step 1

Attach side covers

13

V. 12/20

MachineAssembly (cont.)

Step 2

Attached Gantry

Attach the gantry to the Y-spar using the included bolts and lock nuts

(6 each side). Do not over-tighten. Attach the gantry using the top six

holes on each leg (as shown above). This is the recommended "low

gantry" position. The bottom two holes can be used if you need to

raise the gantry for additional clearance for tall projects, jigs or

accessories.

Assembly tip –Enlist the help of a neighbor or friend to hold the

gantry in place or add blocks of wood or foam under the gantry beam

to position it during assembly.

14 SHARK HD500 Series User’s Manual

MachineAssembly (cont.)

Step 3a

Use a small tipped screwdriver to gently pry open the latch side of the

crossbars on the cable carrier.

Step 3

Install cable carrier

Step 3b

Loosen the sliding t-nuts that are installed on the cable carrier.

15

V. 12/20

MachineAssembly (cont.)

Step 3c

Remove a few screws from the trim strip at the front left side of the table.

Pull the trim back and slide the t-nuts and the cable carrier into the edge of

the table.

Trim strip

Step 3d

Position the cable carrier inside the left gantry leg.

16 SHARK HD500 Series User’s Manual

MachineAssembly (cont.)

Step 3f

Tighten the screws in the t-nuts to secure the cable carrier to the edge

of the table. Place the cables in the cable carrier and close the

crossbars.

Step 3e

Attach the loose end of the cable carrier to the “Y spar” with the

included bold and nut. (For clarity, the gantry leg is not show in this

picture.

17

V. 12/20

MachineAssembly (cont.)

Step 3g

Re-attached the front trim strip.

Step 4

Install Router/Spindle mount. Loosely attach the mount with the

socket head bolts (included). Insert the router or spindle and tighten

bolts. The height of the router or spindle can be readjusted as

needed for different bits or materials.

An optional 2HP 110v

spindle is available for your

SHARK HD CNC. For

information, contact your

SHARK CNC dealer or visit

www.NextWaveCNC.com

18 SHARK HD500 Series User’s Manual

MachineAssembly (cont.)

Step 5

Attach the motor cables to the back of the control box

Step 5a

Attach the three motor cables and the two homing (RCA) connectors

to the corresponding ports on the back of the control box. The two

round connectors are not specific and can be inserted into either

socket.

Step 5b

Attach the router motor cable and power cables to the back of the

control.

Router power cable Control box power cable

NOTE: If you have the Spindle kit, DO NOT attach the VFD power

cable to the back of the control box. It must be plugged directly into a

wall socket or the power strip.

19

V. 12/20

MachineAssembly (cont.)

Step 6

Attach the pendant cable between the

Pendant and the control box.

Step 7

Plug power cord into the switched surge-protected power strip

to protect your tool and provide another method for shutting

off the machine in case of an emergency.

IMPORTANT –Only plug in and turn on the power AFTER

the all the motor cables have been attached. DO NOT

attach or detach motor cables when the control box is

powered up as this will damage the electronics and is not

covered by the warranty.

20 SHARK HD500 Series User’s Manual

Emergency Switch

Registering your SHARK HD CNC

Step 1

Power up your SHARK HD CNC by turning on both the main power

switch and the Emergency switch. During general use, you only need

to turn off one of these switches to cut power to the machine.

Step 2

Once you power up your SHARK HD CNC, the opening screen will

appear on the pendant. Click Continue.

Main power Switch

IMPORTANT. Always turn off the power switch(s) when connecting or

disconnecting any of the cables. Failure to do so can cause damage to

electrical components and is not covered by the warranty.

Other manuals for SHARK HD500

1

This manual suits for next models

3

Table of contents

Other Next Wave CNC Control System manuals

Popular Control System manuals by other brands

Radionics

Radionics D9124 Operation and installation manual

ECOFOREST

ECOFOREST ecoSMART e-source USER, INSTALLER AND TECHNICAL SERVICE MANUAL

Mi-Light

Mi-Light LS3 User instruction

micro-trak

micro-trak MT-3000 Reference manual

Toshiba

Toshiba TOSDIC-CIE DS Installation and wiring manual

SYR

SYR BA-Filling-Combi 6628 Instructions for use and installation