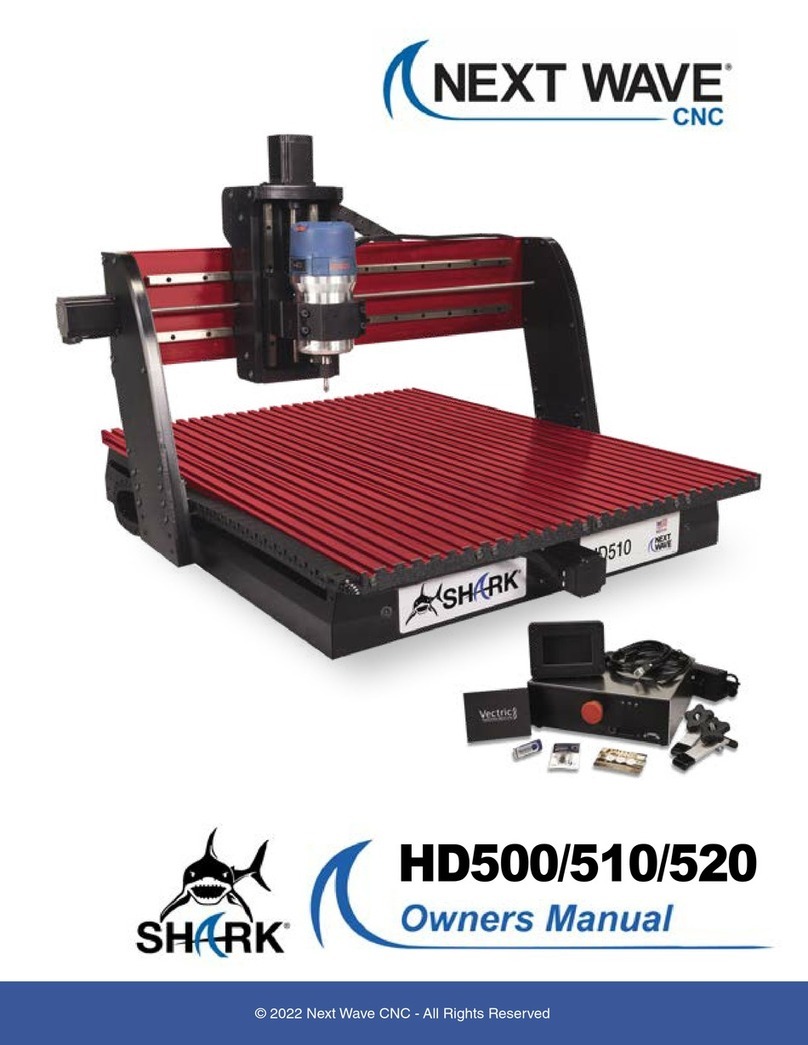

Next Wave CNC SHARK User manual

SHARK 3 HP Spindle kit with speed control

Installation Manual

®

2

Copyright 2021 Next Wave CNC -All Rights Reserved.

CNC SHARK is the registered trademark of Next Wave CNC.

All other trademarks are the property of their respective

owners. Information in this manual is subject to change

without notice. The most recent version of this manual can be

found at www.NextWaveCNC.com/downloads-links

Next Wave CNC, LLC,

600 W. Boundary St.,

Perrysburg, Ohio 43551 USA

Sales (419) 318-4822

Product info email: Info@nextwaveCNC.com

Tech Support email: Support@nextwavecnc.com

3

3HP Spindle Installation Manual

Parts overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

eCool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Spindle installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Coolant hose hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cable installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Priming the plumb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

VCarve Spindle speed setup . . . . . . . . . . . . . . . . . . . . . . . . . 13

Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance/Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 14

Table of Contents

Please read this manual carefully. It provides important setup

and operational information for your SHARK Water-cooled

Spindle. This manual has been written with the assumption

that you are experienced with the basic operation of a

computer, your CNC SHARK as well as the knowledge required

to safely operate power tools.

Page

To use this spindle kit, you must:

Use Control Box and LCD Pendant firmware V.6.0 or

higher. See Page 14 for information on how to identify

and update the firmware.

To use this spindle, you may need to update

the Post Processor in VCarve or Aspire to

Next Wave CNC (inch)(*.tap). It can be downloaded at:

www.nextwavecnc.com/postprocessor

To use this spindle, you must use

VCarve (Desktop or Pro) version 10.5 or higher

or Aspire version 10.5 or higher.

4

Parts Overview

Inverter (VFD) with

spindle interface cable

3HP Spindle Motor (with

ER20 ¼”, ½” collets)

Spindle clamp with

mounting hardware

ER20 Collet

Wrenches

Inline Flow

Indicator

eCool

System

5

eCool Setup

1. Remove the eCool unit from the box. Loosen but don’t

remove the four Phillips head screws attaching the cover

to the aluminum mounting plate. After the four screws are

loosened, remove the cover. Please note that the pump’s

power socket is connected to the cover, so it will need to

remain near the pump.

6

2. Using the slot nuts on the back of the eCool mounting plate,

mount the eCool unit to the upper t-slot on back of Shark gantry.

Tighten the Phillips head bolts to secure the mounting plate to

the gantry. Note: The eCool unit should be mounted to the X-

drive motor end of the gantry ( the right side, when facing the

back of the gantry –see image)

3. Begin opening the cable track with a flathead screwdriver.

Start a few sections in from the right so the water hoses enter

the cable track with out tight bends or kinks.

eCool Setup

7

4. Once the cable track is open, run the hoses through the track. Let

the excess hose run over the top of the sign towards the front of the

machine

Keep your SHARK clean with a

HD SERIES DUST BOOT Part #20170

Available at

www.NextWaveCNC.com

eCool Setup

8

3HP Spindle Installation Manual

6. Loosely attach the spindle mount with the four new mounting

bolts. Tighten the two bolts on the right side. Slide the spindle

into the mount so it is positioned about midway, or a height that

meets your needs, then tighten the two bolts on the left side.

Spindle Installation

5. Loosen the two bolts on the left side of the mount and then remove

your router. Next remove the two bolts on the right side and remove

the mount.

Remove the router mount

Install the spindle mount

9

3HP Spindle Installation Manual

Hose hookup

7. Once the spindle is

secured in the clamp,

attach the hoses from the

cooling system to the

fittings on the top of the

spindle. First remove the

nuts from the fittings on

the spindle and then slide

one onto onto the end of

each hose. Slide the

hoses onto the fittings

and tighten the nuts.

NOTE: The hose with the

flow indicator should be

attached in the location

shown in the image,

which is the supply side.

INTALLATION TIP: Warming and softening the ends of the

hoses with a heat gun makes them easier to install.

10

3HP Spindle Installation Manual

Priming the pump

8. Next fill the coolant reservoir with water or fresh propylene

glycol (RV/Marine Grade) coolant. When the reservoir appears full,

connect the eCool power cord to an active power source. The

pump should turn on and distribute the coolant into the spindle.

Repeat 2-3 times or until the reservoir remains full while powered

on. The flow indicator should be moving when the pump is primed.

When the pump is fully primed, the water level will stay constant.

NOTE: After the pump is primed, the pumps power cord should

be move to the power strip that is attached to the back of the

Shark Control Box. See page 12 for details.

9. Re-attach the eCool enclosure using the 4 screws that were

previously loosened.

11

10. Attach the spindle power cable to the top of the spindle. Now take

the spindle power cord from the inverter (VFD) and plug it into the top

of the spindle. There is a groove on the plug that that matches a tab on

the spindle socket. Make sure these line up when connecting the parts.

Electric cable connections

Alignment tap

Alignment notch

12

12. Attach the Spindle Interface cable to the front of the Control

Box. NOTE: Depending on where the controller is located on the

machine’s table, a power strip with a longer cord may be

required to prevent strain on the various cables. Perform a jog

test around the entire machine to ensure there is no strain.

11. Plug a power strip (not included) into the back of the Shark

controller. Then plug the VFD and eCool power cords into the

power strip. NOTE: For the eCool system and VFD to function

correctly they must be connected to the plug on the back of

the Control box via a power strip or similar multi-plug

connector.

VFD

power

cord

LCD

Pendant

cable

Spindle

Interface

cable

Spindle

power cord

(attach to

spindle)

eCool

power

cord

Plug power strip

into back of Control

Box

Electric cable connections

13

3HP Spindle Installation Manual

13. Set your desired spindle speed in the tool data base for each bit you

use. This speed is saved to your .tap file and is used to automatically turn

on the spindle and adjust its speed. A speed between 16,000 and

22,000 works well for most bits, with lower speeds for large diameter

bits and higher speeds for small diameter bits. DO NOT EXCEED Router

Bit manufacturer’s RPM recommendations

14. You must save your toolpath using

the Next Wave CNC (inch)(*.tap)

post processor (shown at the right).

If you dd not have this post process, it

can be downloaded at:

www.nextwavecnc.com/postprocessor.

VCarve spindle speed setup

15. You may need to update the firmware on your Control Box and LCD

Pendant before using this spindle. If the spindle turns on when you run a

.tap file, then you have the correct firmware. If the spindle fails to turn

on, then you should update the firmware. For information on how to

update your firmware visit www.nextwavecnc.com/firmware.

To use this spindle, you

must use VCarve (Desktop

or Pro) 10.5 or higher or

Aspire 10.5 or higher.

14

3HP Spindle Installation Manual

Maintenance/Troubleshooting

The Flow indicator is not turning

•Is the Control Box turned on?

•Is the digital interface cable securely attached to the front of

the Control Box?

•Is the pump plugged into the power strip on the back of the

Control Box?

•Is the eCool powered on? Look for a blue light in the

reservoir itself.

•Are large bubbles preventing the flow indicator from

turning? Light tap or shake the indicator to dislodge the

large bubbles. Some air or bubbles are OK.

•On rare occasions the water flow may be block by air in the

spindle/. This can be resolved by first disconnecting the

power to the VFD, then remove the spindle (with the hoses

still connected). Next tip the spindle back and forth and

upside down to dislodge the air lock.

Replacing eCool system coolant

•The pump reservoir coolant level should be checked

regularly and replaced every 4-6 months.

•Unplug the eCool power supply from the power strip

connected to the controller.

•With a small bucket or container ready, remove the hose

with the flow indicator (supply side) from the spindle. It will

immediately leak so place it over the bucket

•Plug the eCool power supply into a separate outlet, this will

power the eCool system immediately.

•Let the water drain from the hose into the bucket.

•Once the eCool system is fully drained, follow the

installation steps to re-prime the pump

15

3HP Spindle Installation Manual

Maintenance/Troubleshooting

Spindle not starting

•Is your Shark controller and pendant on the latest firmware?

•Check that all cables are plugged in as specified in the

installation instructions

•Was the correct file selected in the USB screen?

NOTE: If a laser file is selected, the eCool system and

VFD will power off. To correct this, the controller will

need to be restarted to function correctly.

Collet Nut installation issues

•The collet should snap into the spindle’s collet nut with the

long-tapered part of the collet going up into the spindle

away from the collet nut. You should be able to turn the

collet nut over and the collet will hang loosely from it.

•If this is done incorrectly, the collet and collet nut can be

damaged or cross threaded

SHARK 3 HP Spindle kit with speed control

Installation Manual

Version –2021 12 03

Other manuals for SHARK

1

Table of contents

Other Next Wave CNC Control System manuals

Popular Control System manuals by other brands

Radionics

Radionics D9124 Operation and installation manual

ECOFOREST

ECOFOREST ecoSMART e-source USER, INSTALLER AND TECHNICAL SERVICE MANUAL

Mi-Light

Mi-Light LS3 User instruction

micro-trak

micro-trak MT-3000 Reference manual

Toshiba

Toshiba TOSDIC-CIE DS Installation and wiring manual

SYR

SYR BA-Filling-Combi 6628 Instructions for use and installation