Control

FIGHTER 1210

For Home Owners

6

The indoor temperature depends on several factors.

During the hot season, solar radiation and heat given

off by people and equipment are sufficient to keep the

house warm. When it gets colder outside, the heating

system must be started. The colder it is outside, the

warmer radiators and floor heating system must be.

This adjustment takes place automatically, since the

FIGHTER 1210 is equipped with a control computer

for optimal, safe operation. However, the heat pump

must first be given the correct basic setting.

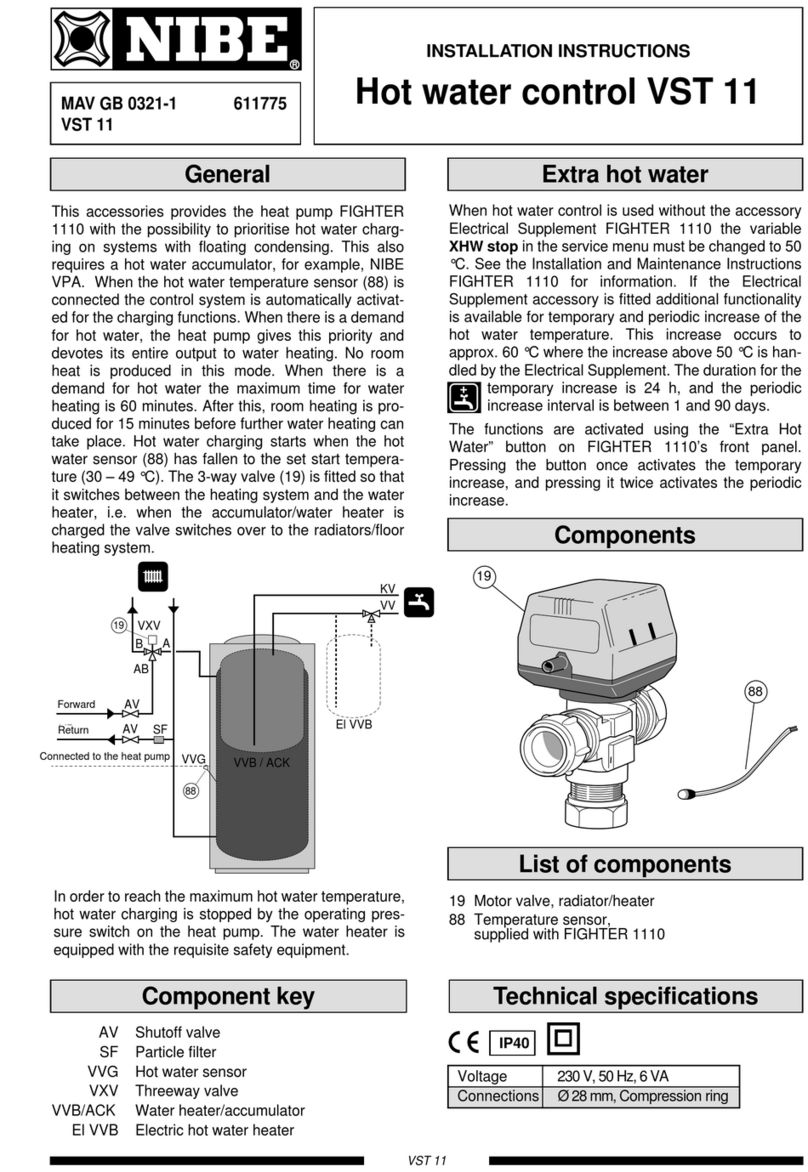

Control of the heat production is performed based on

the floating condensing principle, i.e. the temperature

level needed for heating at a specific outdoor temper-

ature is produced guided by collected values from the

outdoor and flow sensors. As an option, room sensors

can also be used to compensate for variations in room

temperature. Hot water production is given priority and

controlled by means of temperature sensors in the

water heater and an operating pressostat.

For general information and more reliable control of

the function there are also sensors for incoming and

outgoing brine temperatures (collector). If required, a

minimum limit can be set for the outgoing brine tem-

perature (for example, with a groundwater system).

General

Examples of basic data selection:

1. House with low temperature* radiator systems

Markaryd = Area 10 (5). Select curve 10 on the

display and -2 on the Increase/reduce heat knob.

2. House with floor heating** installed in a

concrete floor structure

Markaryd = Area 10 (5). Select curve 5 on the dis-

play and -1 on the Increase/reduce heat knob.

3. House with floor heating** installed in a timber

floor structure

Markaryd = Area 10 (5). Select curve 8 (10-2=8)

on the display and -1 on the Increase/reduce heat

knob.

*A low temperature radiator system refers to a sys-

tem where the flow temperature needs to be 55 °C

on the coldest day.

** Floor heating can be dimensioned very differently.

Examples 2 and 3 above refer to a system where

the flow temperature needs to be approximately

35 - 40 °C resp 45 - 50 °C on the coldest day.

The values stated on the map (see the next page)

apply for the Curve slope.

The first value applies for low temperature *radiator

systems. The Increase/reduce heat knob is set to -2.

The value in brackets refers to floor heating systems**

installed in concrete floor structures. When the system

is installed in a timber floor structure you can use the

number before the brackets, but this value must be

reduced by two units. In these cases Increase/reduce

heat is set to -1.

The map values are usually a good starting point and

concern an approximate room temperature of 20°C.

The values can be adjusted later if necessary.

Basic values for the automatic

heating control system

Setting takes place by programming the

Curve slope, see the section Available information

and settings on the display, and by setting the Heating

curve offset using the Increase/reduce heat knob on

the panel.

If you do not know the correct settings use the basic

data from the map opposite.

If the required room temperature is not obtained, read-

justment may be necessary.

NOTE! Wait one day between settings so that the tem-

peratures have time to stabilise.

Readjusting the setting.

Cold weather conditions

If the room temperature is too low, increase the val-

ue for the heating curve by one step.

If the room temperature is too high, reduce the val-

ue for the heating curve by one step.

Warm weather conditions

If the room temperature is too low, turn the

Increase/reduce heat

knob one step clockwise.

If the room temperature is too high, turn the

Increase/reduce heat

knob one step anticlockwise.

Changing the room temperature manually.

If you want to temporarily or permanently increase or

lower the indoor temperature in relation to the previ-

ous heat setting, turn the Increase/reduce heat

knob

clockwise or anticlockwise. One scale marking corre-

sponds to a change of about one degree in the room

temperature.

NOTE! An increase in the room temperature may be

inhibited by the radiator or floor heating thermostats, if

so these must be turned up.

Setting, heat

Changing the room

temperature