9Bu er tank with coil

UKVS 20-300/1000

4. CONNECTION AND START-UP

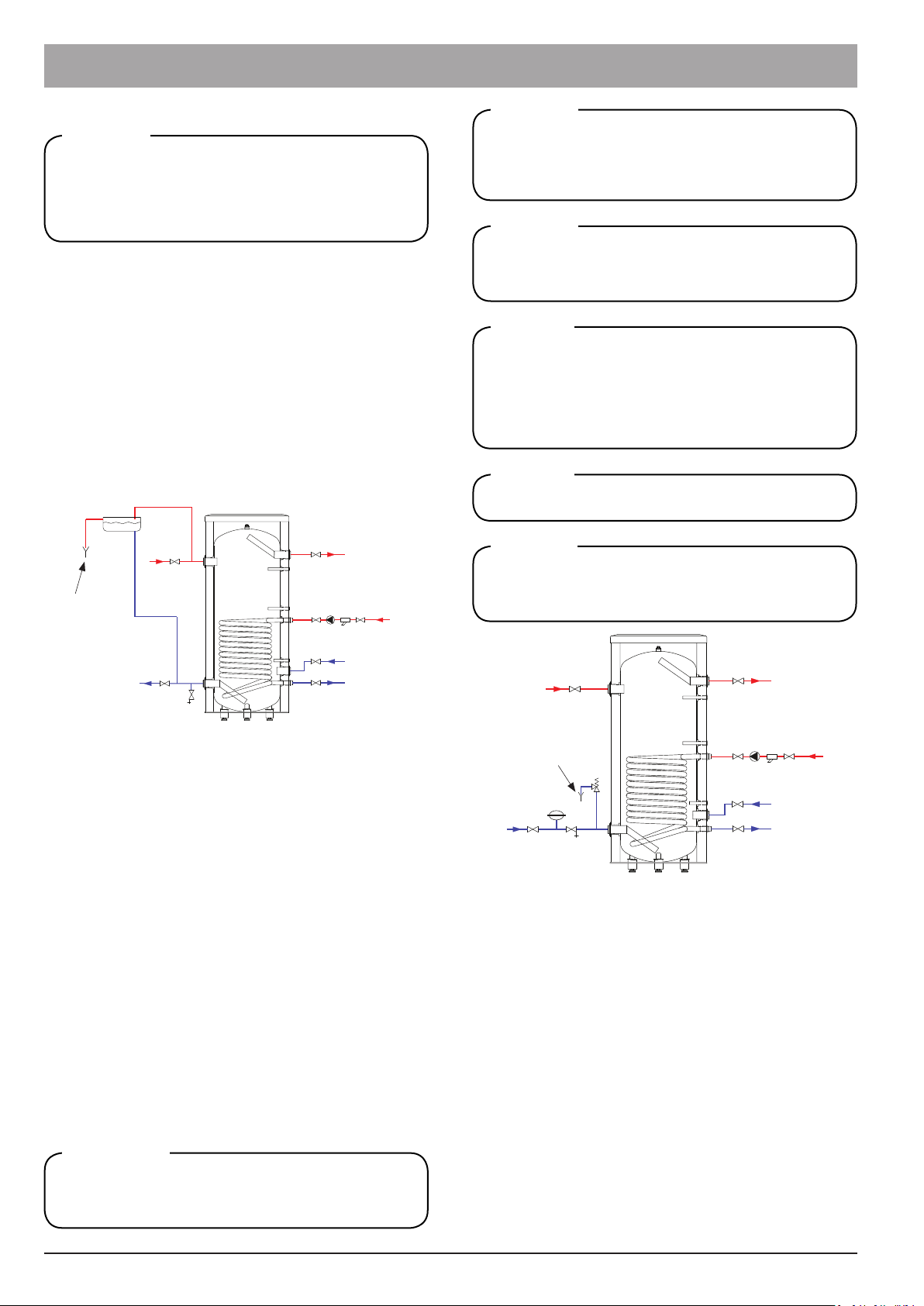

4.1 Connec on

1. Connect the supply line from the heat source (4)

2. Connect the return line to the heat source (10 in UKVS

20-300/500, or 11 in UKVS 20-750/1000)

3. Connect the hea ng system supply line (3)

4. Connect the return line from the hea ng system (9 in

UKVS 20-300/500, or 12 in UKVS 20-750/1000)

5. Connect the coil supply line, (7) in UKVS 20-300/500, or

(8) in UKVS 20-750/1000, and the return line from the

coil to the connector pipe (11) in UKVS 20-300/500, or

(10) in UKVS 20-750/1000.

6. Install the required temperature sensors (5)

7. If necessary, connect the electric hea ng unit to the con-

nector pipe (15) in UKVS 20-300/500, or (16) in UKVS 20-

750/1000.

4.2 Start-Up

A er connec ng all components of the C/H system, do

the following:

1. Fill up the C/H system with the hea ng medium

2. Check ghtness of all connec ons

3. A er checking for ghtness, insulate the pipelines to-

gether with the tank ngs thoroughly

4. Fill up the C/H system with the hea ng medium and vent

the system

A er the installa on and levelling the tank, follow the proce-

dure below (for the connector pipe numbers, refer to Fig. 3,

4, 5 and 6):

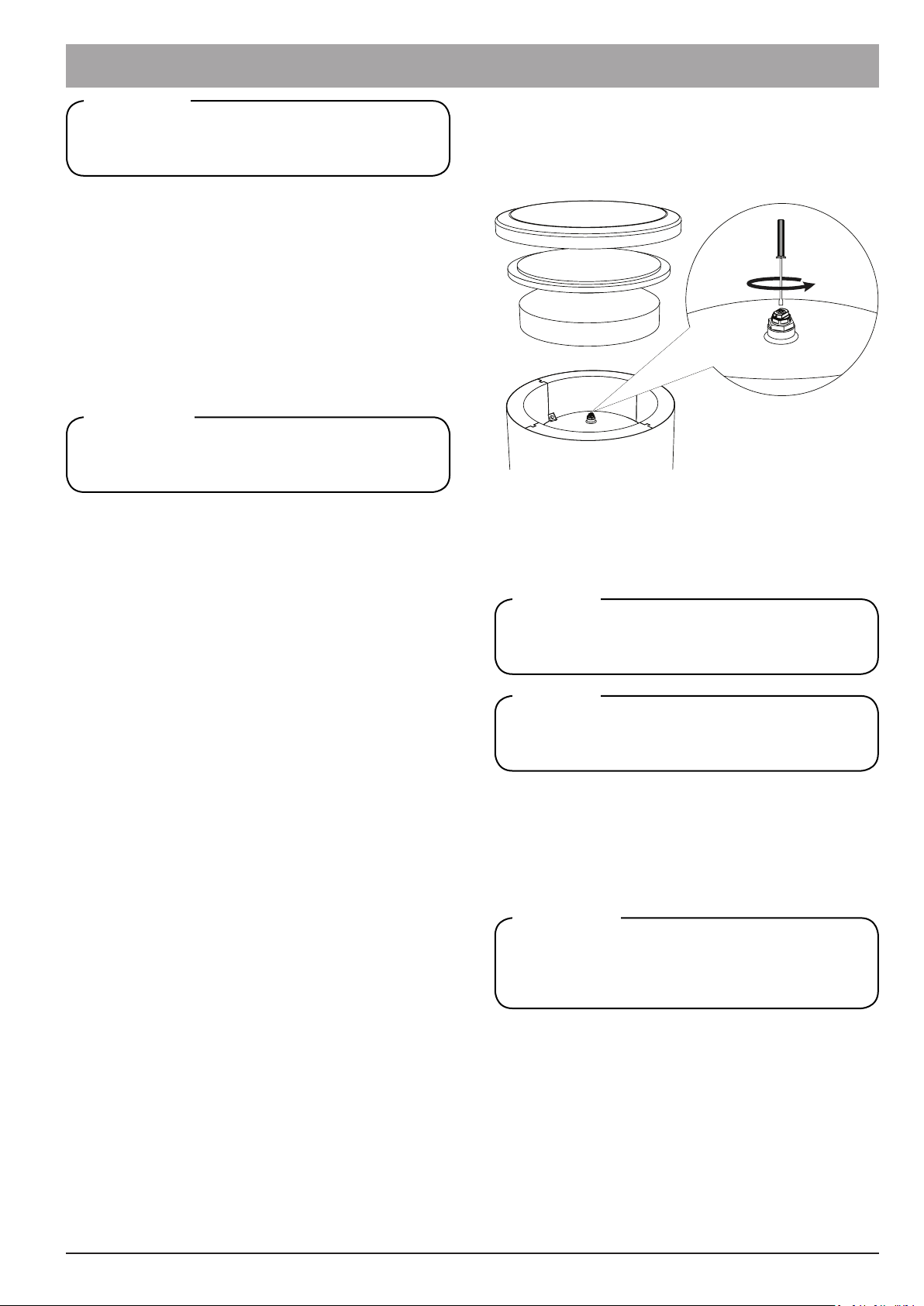

Filling and ven ng the bu er tank:

You can ll the bu er tank directly from the C/H system or

through the tank drain valve. Vent the tank and the C/H sys-

tem a er lling them. Vent the unit through the vent installed

in the top head of the tank (see Fig. 11.)

Fig. 11Ven ng the bu er tank

The coil can operate with almost any central hea ng system

or other heat source such as solar panels, heat pumps, etc.

However, when installing the coil, a en on should be paid to

the fact that the max pressure in the supply system may not

exceed the max opera ng pressure of the coil and that the

temperature of the hea ng medium in the system may not

exceed the allowable coil opera ng temperature. For the allo-

wable coil opera ng temperatures, see Table 1 Technical data.

Connec ng the Coil

The lower return connec ons to the hea ng source and

from the hea ng system can be connected in opposite

confi gura on.

Informa on

We recommend connec ng the tank connector pipes

with the system lines by means of unions to allow discon-

nec on of the tank, if required.

Informa on

Ensure that the en re C/H system is lled with the he-

a ng medium before hea ng the system up for the rst

me or a er a longer break in its opera on.

CAUTION

4.3 Thermal Insula on of the System

In order to minimize thermal energy losses, insulate all con-

nector pipes, pipelines and temperature sensor covers tho-

roughly a er the installa on of the unit and performance of

the leak proof test. For this purpose, use thermal insula on

of correctly selected thickness and thermal insula on para-

meters.

Lack of thermal insula on, its incorrect thickness or in-

sula on made of inadequate materials will cause decre-

ase of thermal insula on proper es of the unit and the

system.

Informa on

A er comple on of the above steps, the system is ready for

opera on. You can use the facility hea ng system a er star-

ng up the heat source and reaching the required temperatu-

re of the hea ng medium.

Switch OFF the hea ng units and wait un l the he-

a ng medium cools down completely in the C/H system

before ven ng the buff er tank.

CAUTION

4.4 Frost Protec on

If you plan to interrupt opera on of the unit and there is a risk

of freezing the hea ng medium in the tank, drain the tank and

the en re hea ng system associated with it completely.

INSTALLATION AND OPERATING MANUAL