9

Hot Water Storage Tank with One Coil

BA-ST 9022/9100 - 1FE

INSTALLATION AND OPERATING MANUAL

• The isolated protec ve anode earth conductor must be con-

nected to the steel components of the storage tank (top bot-

tom of the tank). Otherwise, the tank will not be protected

against corrosion.

• In order to eliminate any odour of hydrogen sulphide (caused

by bacteria in the oxygen de cient water), we recommend

observing the periodic cleaning of the tank and replacement

of the anode and, in addi on periodically increase the hot wa-

ter temperature in tank to prevent bacterial growth.

• In the systems with the electric hea ng unit, ensure that the

electrical installa on is properly protected by protec ve cir-

cuit.

• Limit the setpoints of the hea ng medium temperature con-

trollers in the storage tank supply lines to 80 °C in order to

avoid triggering of the thermal cut-o in the electric hea ng

module.

• In order to reduce the possibility of scalding by the water, we

recommended to set the water hea ng temperature in the

storage tank (of both the hea ng unit and the coil) so, that it

does not exceed 60 °C. This will also help to extend the life of

the storage tank.

• Report any malfunc ons in the storage tank opera on to the

authorized service centres. You can nd the complete list of

our authorized service centres at our website.

It is forbidden to:

• ac vate the hea ng medium circuit or electric hea ng

unit if the tank is not lled with water

• use the storage tank, if you nd any malfunc on of the

safety valve

• install any device (such as cut-o and/or check valves,

etc.) between the storage tank and the safety valve (ex-

cept T-pipes)

• make any unauthorized repairs

• stop water leaks from the safety valve

• when hea ng with only the electric unit, the coil circuits

may not be isolated

5. MAINTENANCE

Periodic inspec ons and maintenance are the condi ons of

con nuous opera onal readiness, reliability and a long servi-

ce life of the product.

Maintenance ac vi es include the following:

• rou ne inspec ons and replacement of the protec ve

magnesium anode

• cleaning of the storage tank

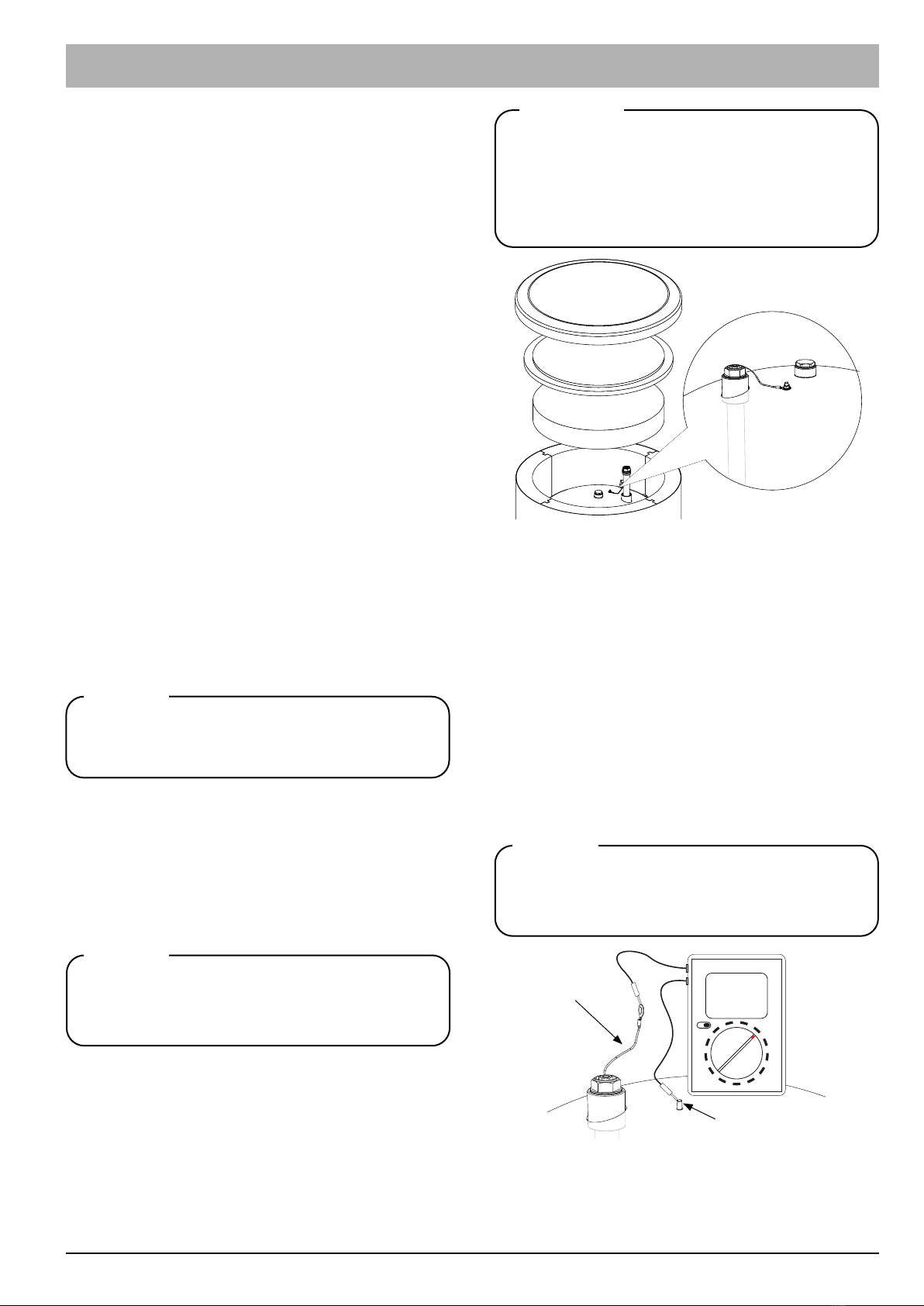

5.1 Inspec on of the Protec ve Magnesium Anode

Storage tanks with one coil of BA-ST Series are, in order to

protect them against corrosion, coated inside with ceramic

enamel and in addi on, protected with isolated protec ve

magnesium anode. The anode corrodes rst under normal

opera on, thus protec ng the storage tank jacket. Therefore,

you have to inspect its condi on from me to me. Corrosion

rate of the protec ve anode is di erent and depends upon

the quality of water in the area. We recommend checking the

protec ve anode condi on once a year in order to ensure

op mum corrosion protec on.

The use of the isolated anode allows you to monitor the

degree of wear of the anode by measuring the intensity

of the protec ng direct current without having to remo-

ve it and empty the tank (interrup ng opera on of the

storage tank). This solu on simplifi es opera on and ad-

di onally contributes to the reliability and long life me.

Informa on

Fig. 10 Insulated protec ve magnesium anode

5.2 Measurement of the Protec ve Magnesium Anode Wear

In order to check the degree of wear of the anode, do the

following (see Fig. 11):

1. Remove the housing cover together with thermal insula on.

2. Disconnect the connec ng conductor (protec ve) from

the storage tank top head.

3. Connect an electric meter (range in mA) between the

protec ve conductor and the M5 threaded pin and me-

asure the intensity of the protec ve direct current.

Intensity of the protec ve direct current should not be lower

than 0.3 mA at full storage tank. If it is too low, remove the

anode and check its wear visually. If the anode is signi cantly

corroded (above 50 % loss), replace it immediately. Connect

the anode protec ve conductor to the tank a er the measu-

rement.

If the current intensity measurements do not indicate

any wear of the anode, its max opera ng me is not

longer than 18 months. The anode should be replaced

a er this me.

CAUTION

PE

M5 pin

0,3 mA

Fig. 11 Measurement of the protec ve direct current intensity

Check the safety valve performance as speci ed by the

valve manufacturer periodically (min. every 14 days) or

before each start-up of the heater a er decommissio-

ning.

CAUTION

Systema c admission of fresh, untreated water to the

hea ng circuit (coil) increases the risk of corrosion inside

the coil.

CAUTION