3

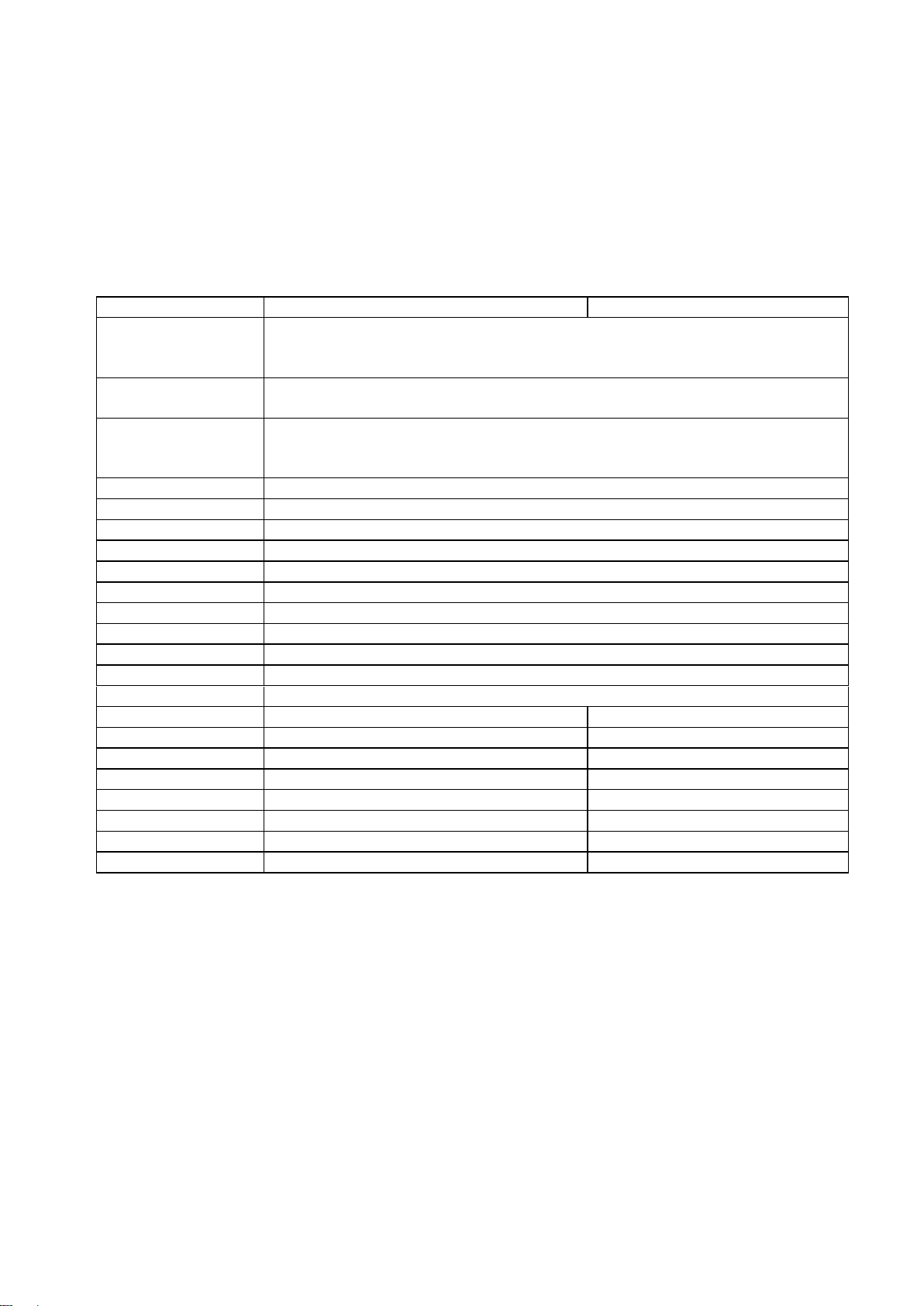

TABLE OF CONTENTS

SECTION 1 ........................................................................................................................................................4

INTRODUCTION................................................................................................................................................4

1.1 USE AND FUNCTION .........................................................................................................................4

SECTION 2 ........................................................................................................................................................5

TECHNICAL SPECIFICATIONS.......................................................................................................................5

2.1 TECHNICAL SPECIFICATIONS TABLE.............................................................................................5

2.2 ACCESSORIES FOR NF 1200/1200R................................................................................................5

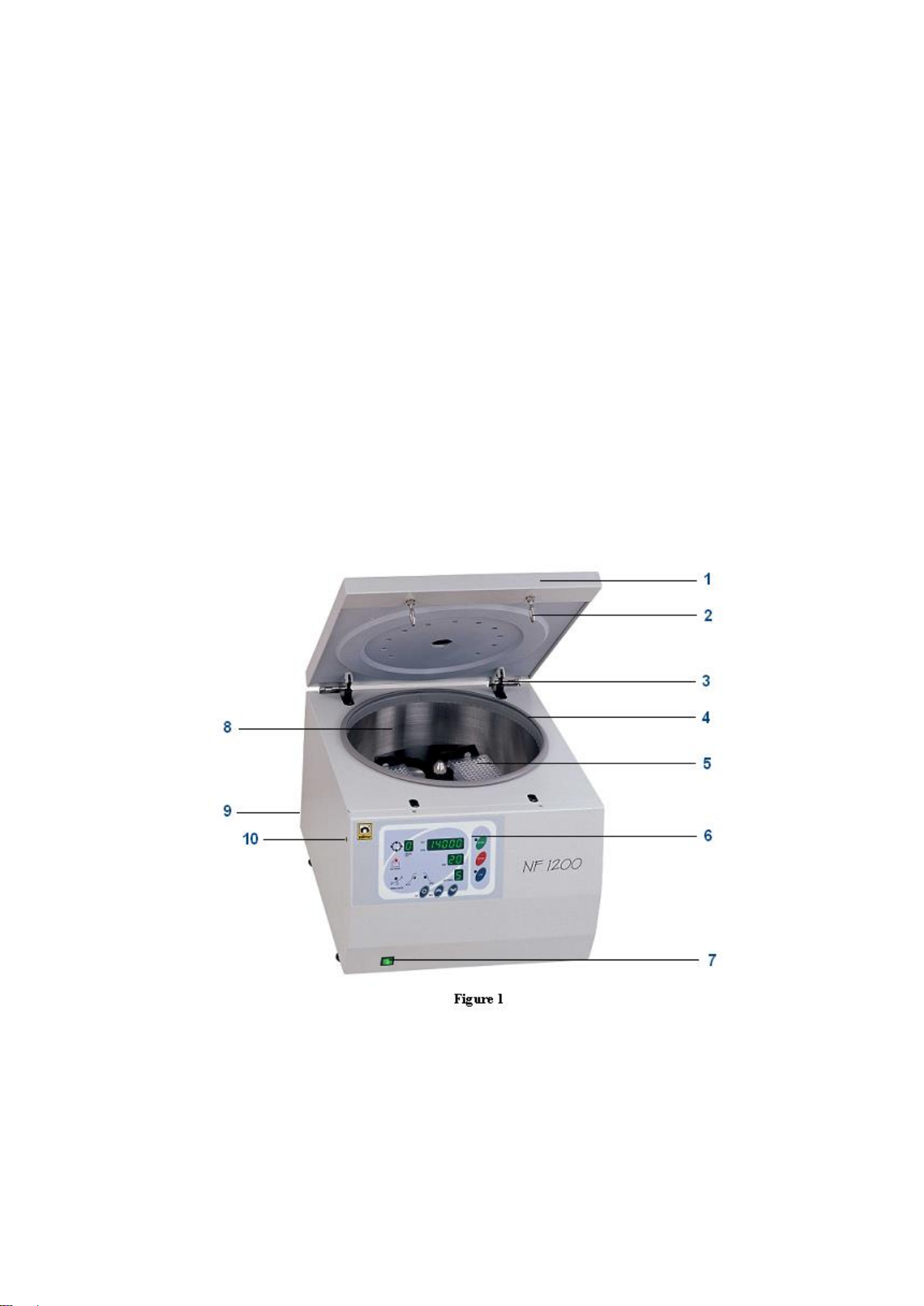

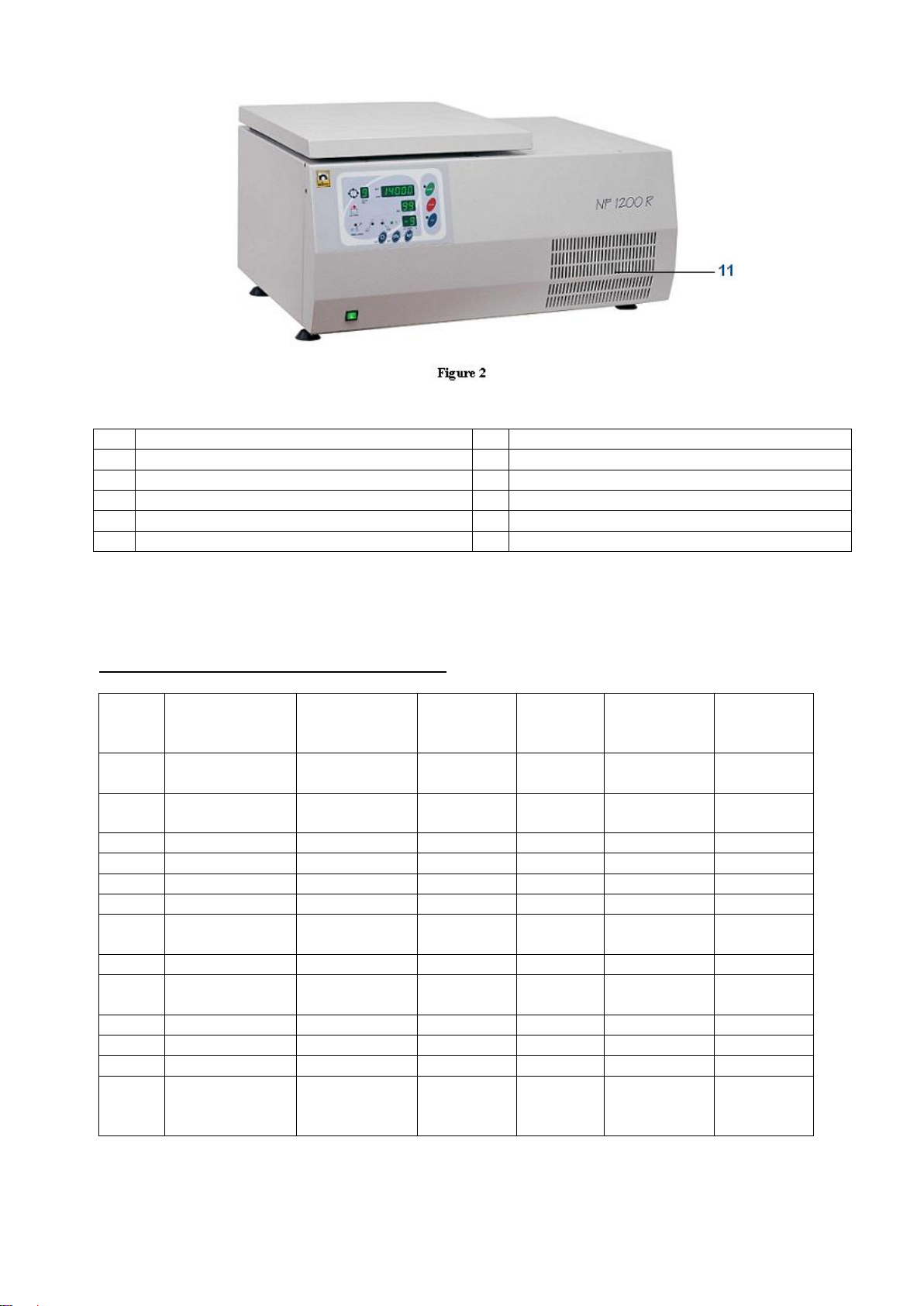

2.3 GENERAL PRESENTATION...............................................................................................................6

2.4 ROTOR SELECTION TABLE ..............................................................................................................7

2.5 PRECAUTIONS AND USAGE LIMITATIONS.....................................................................................8

SECTION 3 ........................................................................................................................................................9

SYMBOLS .........................................................................................................................................................9

SECTION 4 ........................................................................................................................................................9

OPERATING UNIT ............................................................................................................................................9

4.1. OPERATING........................................................................................................................................9

4.2. DISPLAYS AND CONTROL PANEL..................................................................................................10

4.2.1. Introduction to Control Display Panel Components and Functions............................................10

4.3. MAKING ANEW PROGRAM.............................................................................................................11

4.4. RUNNING THE PROGRAM ..............................................................................................................13

4.4.1. SELECTING THE MEMORIZED PROGRAM............................................................................13

4.5. SAFETY INTERLOCK SYSTEM........................................................................................................14

4.6. IMBALANCE DETECTION SYSTEM.................................................................................................14

4.7. MANUAL LID OPENING....................................................................................................................14

SECTION 5 ......................................................................................................................................................15

OPERATING PRINCIPLES.............................................................................................................................15

5.1. PREPARATION OF THE ROTORTO RUN.......................................................................................15

5.2. LOADING...........................................................................................................................................15

5.3. ROTOR INSTALLATION ...................................................................................................................16

5.4. DRIVE SYSTEM................................................................................................................................17

SECTION 6 ......................................................................................................................................................17

CLEANING AND PERIODIC MAINTENANCE ...............................................................................................17

6.1. PERIODIC MAINTENANCE..............................................................................................................17

6.2. STERILIZATION................................................................................................................................17

6.3. CORROSION INFORMATION ..........................................................................................................17

6.3.1. Chemical Corrosion....................................................................................................................18

6.4. STRESS CORROSION............................................................................................................................18

6.5. CLEANING ........................................................................................................................................18

6.6. ELECTRICITY ...................................................................................................................................18

SECTION 7 ......................................................................................................................................................19

DISPOSAL MANAGEMENT CONCEPT.........................................................................................................19

SECTION 8 ......................................................................................................................................................19

TROUBLESHOOTING.....................................................................................................................................19

SECTION 9 ......................................................................................................................................................20

ELECTRICAL CIRCUIT DIAGRAMS..............................................................................................................20

9.1. ELECTRICAL CIRCUIT DIAGRAM OF NF 1200...................................................................................20

9.2. ELECTRICAL CIRCUIT DIAGRAM OF NF 1200R ............................................................................21

SECTION 10 ....................................................................................................................................................22

WARNING LABEL...........................................................................................................................................22