9

ASSEMBLY AND COMMISSIONING RECOMMENDATIONS

LSHRM - FLSHRM - PLSHRM - Permanent Magnet Assisted Reluctance motors

5411 en - 2019.04 / b

3 - ASSEMBLY AND COMMISSIONING

RECOMMENDATIONS

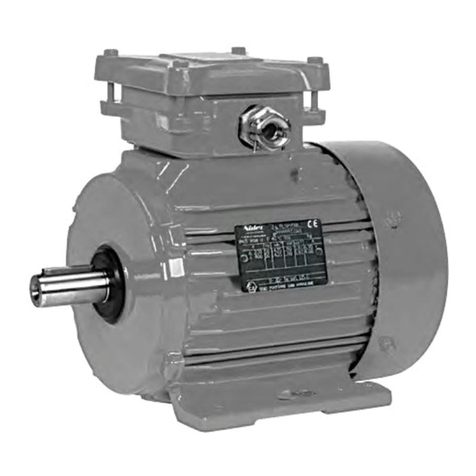

In all cases, compatibility of the motor and its

environment must be guaranteed before its

installation and also throughout its life.

Electric motors are industrial products.

They must therefore be installed by

qualied, experienced and authorised personnel.

The safety of people, animals and property must be

ensured when tting the motors into machines

(please refer to current standards).

3.1 - Checking the insulation

This check is essential if the motor has been stored for

longer than 6 months or if it has been kept in a damp

atmosphere.

This measurement must be carried out using a meg-

ohmmeter at 500 volts DC (do not use a magnetoelectric

system). It is better to carry out an initial test at 30 or 50

volts and if the insulation is greater than 1 megohm,

carry out a second test at 500 volts DC for 60 seconds,

between the winding and ground (on U then V then W).

The insulation value must be at least 10 megohms in

cold state.

If this value cannot be achieved, or routinely if the motor

might have been splashed with water or salt spray, or

kept for a long period in a very humid place, or if it is

covered with condensation, the motor should be dried

using the optional space heaters if the motor has them

(see section 3.4.3).

Do not apply the megohmmeter to the terminals

of the temperature sensors as this can damage

them.

For any insulation or high voltage test, it is

advisable to connect the temperature sensors and/

or accessories to ground.

Caution: If the high voltage test, carried out

at the factory before dispatch, needs to be

repeated, this should be performed at half

the standard voltage, i.e.:

1/2 (2 U + 1000 V). Check that the capacitive

effect resulting from the high voltage test

is eliminated before connecting the

terminals to ground.

3.2 - Location - ventilation

The motor must be installed in a ventilated place, with

clearance for the air inlet and outlet.

Obstruction (clogging) – even accidental – of the venti-

lation circuit has an adverse effect on motor operation.

With drip-proof motors, do not obstruct the air inlet with

a coupling guard, provide a perforated plate.

It is also necessary to check that the hot air is not being

recycled. If it is, pipes must be provided for the intake of

cold air and expulsion of hot air, in order to prevent an

abnormal increase in motor temperature.

In this case, if the air is not circulated by an auxiliary fan,

the dimensions of the pipes must be such that the pres-

sure losses are negligible compared to those of the

motor.

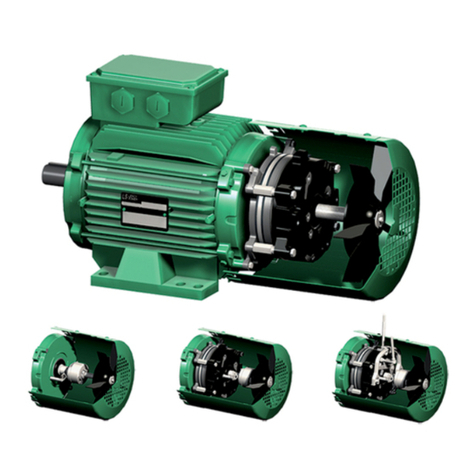

3.2.1 - Enclosed motors

Our motors are cooled in accordance with method

IC 411 (standard IEC 60034-6) i.e. “machine cooled by

its surface, using the ambient uid (air) owing along the

machine”.

The fan at the non-drive end cools the motor. Air is

sucked in through the grille of a fan cover (which pro-

vides protection against the risk of direct contact with the

fan in accordance with standard IEC 60034-5) and

blown along the housing ns to ensure the thermal equi-

librium of the motor in any direction of rotation.

Before starting the motor, it is advisable to

check the insulation between the phases and

earth, and between phases.