5

RECOMMENDATIONS

Installation guide FFB brake motors

5286 en - 2017.09 / c

en

Do not knock the motor (terminal box, cover), the shaft or

the coupling during mounting, do not crush the seal, do not

project beyond the shoulder of the shaft.

Ensure correct brake motor cooling, the air intakes and outlets

must be kept clear.

Check that the loads applied to the motor shaft (especially

the belt tension) are compatible with the values stated in our

technical catalogues.

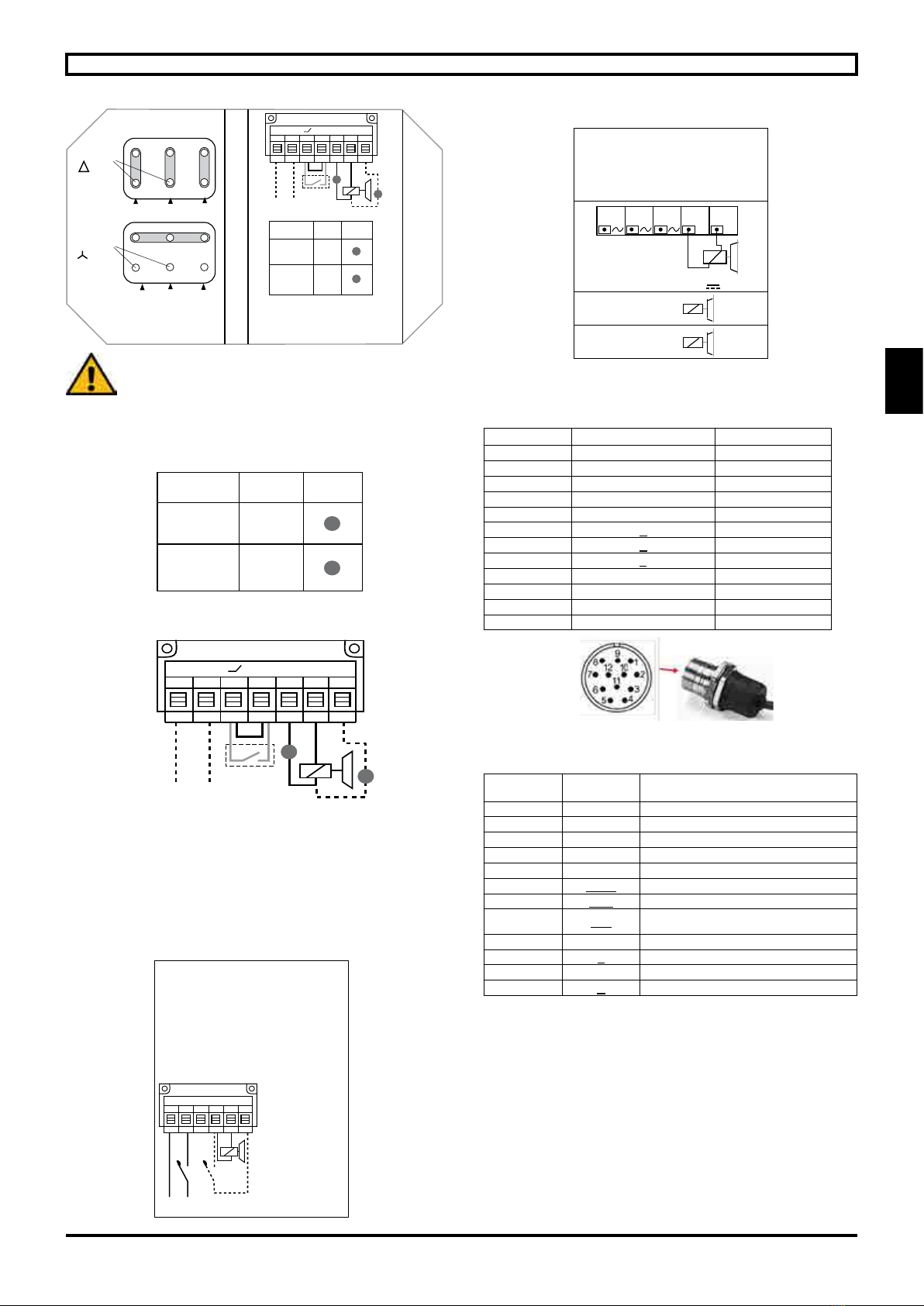

2.2.1 - Brake with options

It is prohibited to drive the extension in

manual rotation and the fan with the

parking brake applied, or the brake

released under load.

- Auto-return hand brake release (DLRA)

For brakes tted with a lever, push it towards the back of the

brake motor.

Whenever the brake has been released, make sure that

it is engaged once any maintenance operations have been

completed.

See dismantling/reassembly procedure in ref.5287 FFB

maintenance.

- (Manual) brake release lock off system (DLM)

For brakes tted with a DLM, proceed in the same way as the

DLRA to release the brake and then turn (clockwise) the DLM

handle in line with the DLRA to lock the brake in the released

position. When the brake is next powered up, it is engaged

automatically and the brake is operational again.

See dismantling/reassembly procedure in ref.5287 FFB

maintenance.

- Remote (electrical) brake release lock off (DMD)

For brakes tted with a DMD, supply the brake coil with

power separately from the motor. Once the brake is released,

supply the electromagnet on the lock control board with

power. Once the locking contactor is engaged, switch off the

brake coil power supply and then that of the control board.

The brake is held in the released position. When the brake is

next powered up, it is engaged automatically and the brake is

operational again.

Whenever the brake has been released, make

sure that it is engaged.

- Release indicator (open/close)

For brakes tted with a release indicator, while the brake is

supplied with power the armature actuates a microswitch

(discrete) xed on the backplate indicating brake release.

When the power is switched off, the microswitch changes

state in order to conrm that the brake is engaged.

- Wear indicator

For brakes tted with a wear indicator, while the brake is

supplied with power the armature actuates a microswitch

(discrete) xed on the yoke. If the brake lining is worn

(+ 0.6 mm) the microswitch is actuated and informs the user

of the need to adjust the air gap or change the brake lining if it

is less than the required minimum (See the “Adjusting the air

gap” procedure in ref.5287 FFB maintenance).

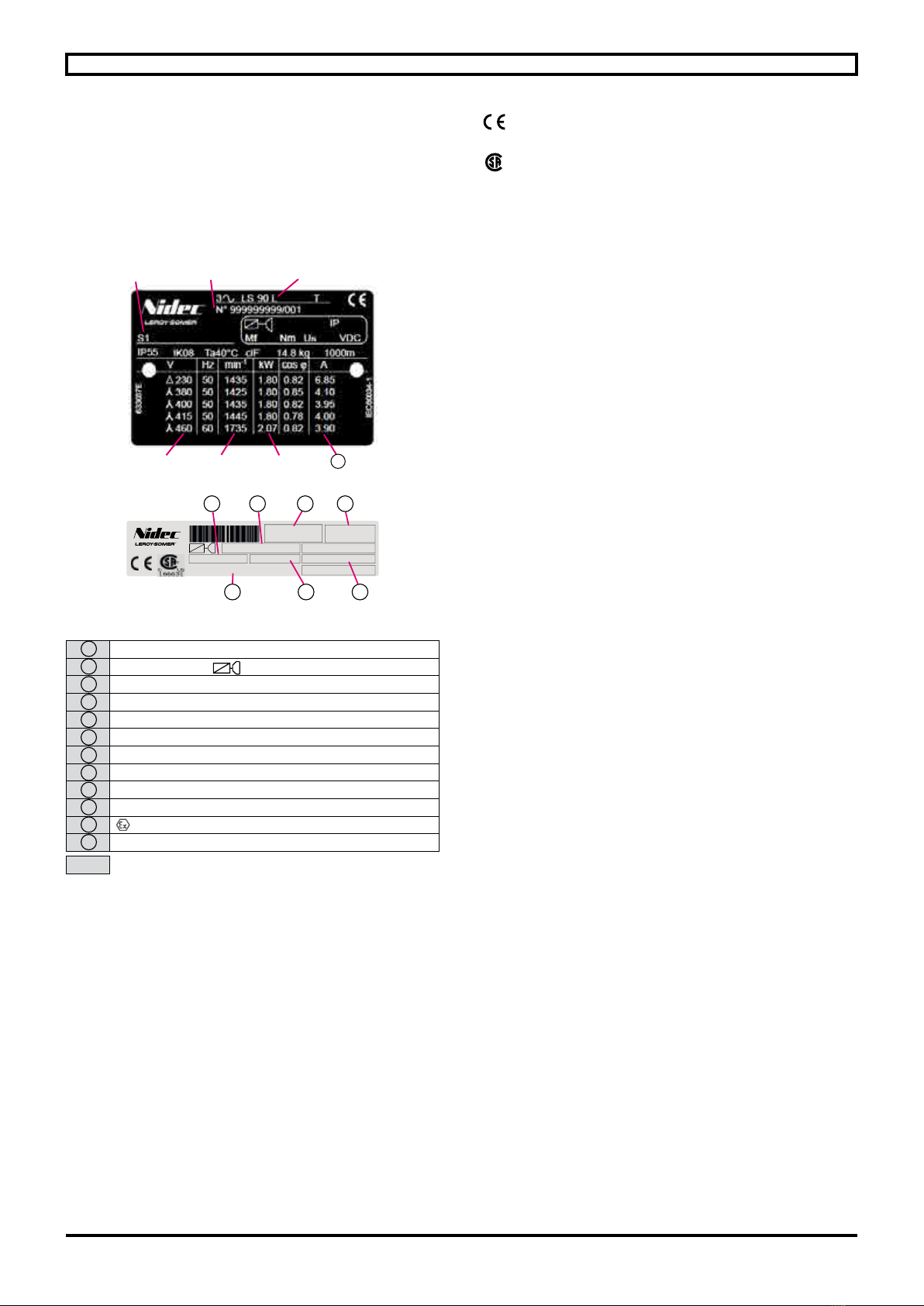

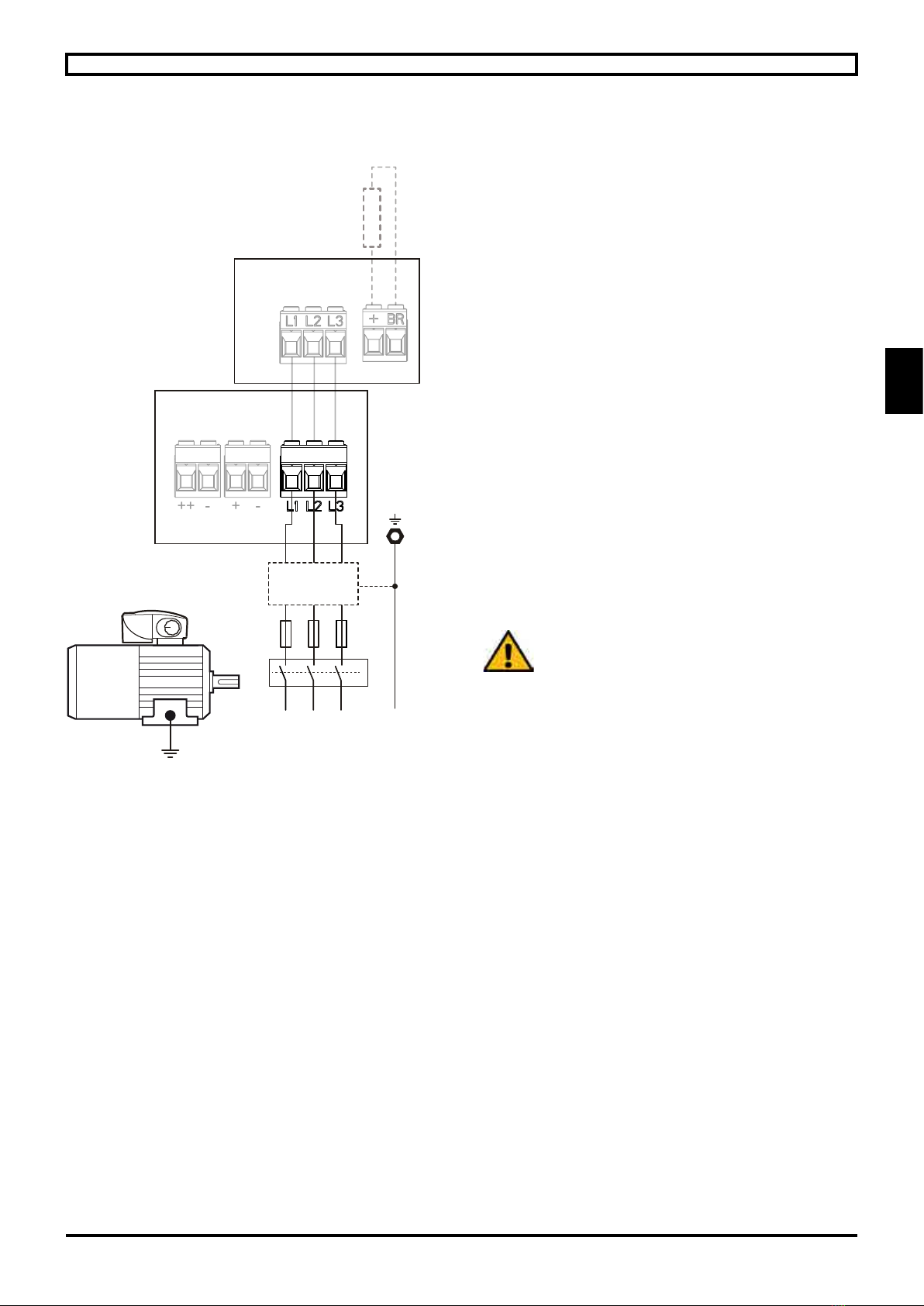

2.3 - Electrical connection

The cables should be connected with the power

off by qualied personnel, in accordance with

good practice, in compliance with the safety

conditions. Choose the protection system and

cables according to the information on the

nameplate (the voltage drop during the starting

phase must be less than 3%).

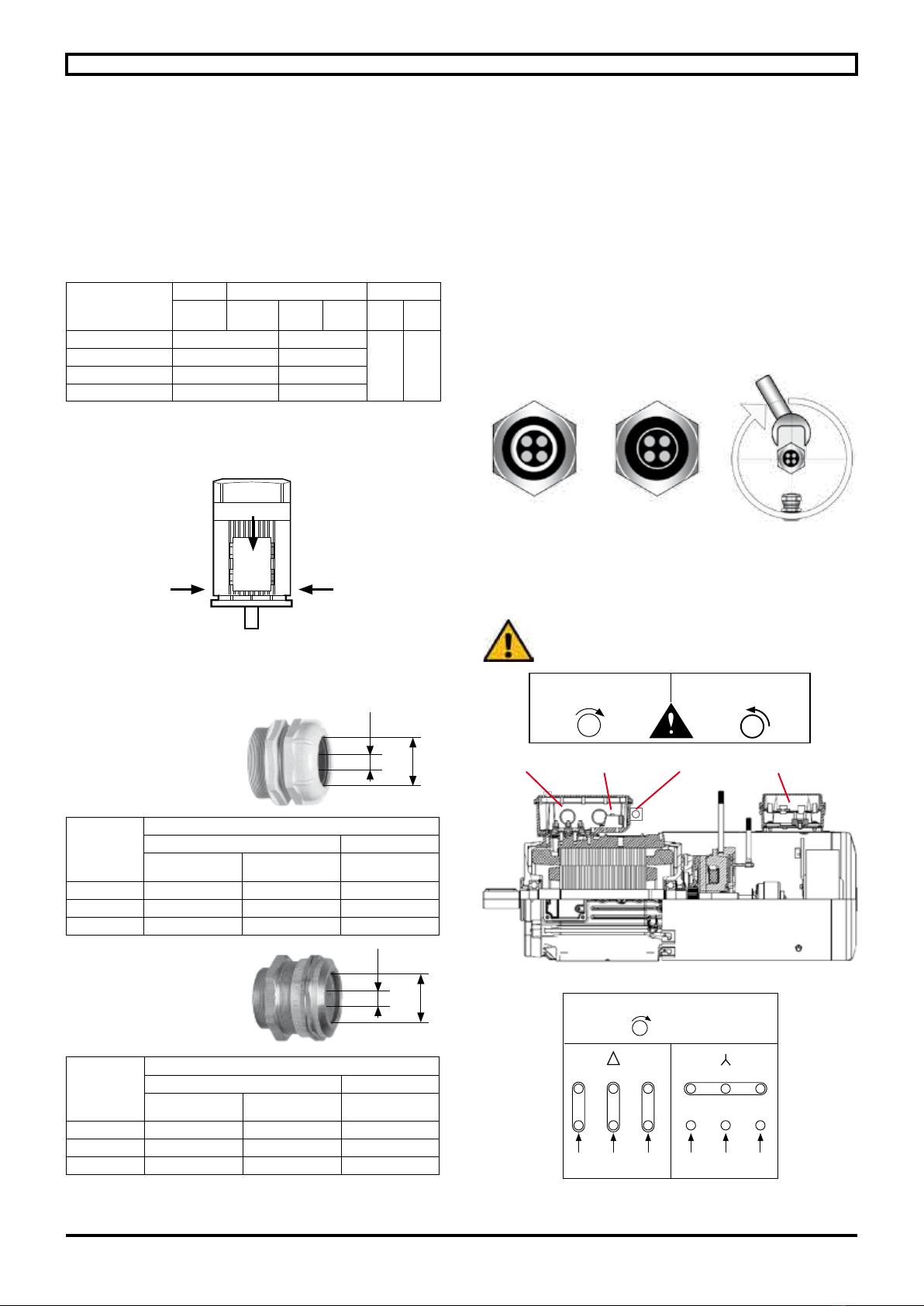

Tighten the terminal lock nuts, connectors and power supply

cables to the torque stated below (N.m):

M4 M5 M6 M8

Steel 1 2.5 4 10

If using cables without connectors, attach calipers.

- Do not place washers or lock nuts between the motor

connections and the connections on the power supply cable.

Connect the thermal protection devices and accessories

(section 3.5).

Ensure that the cable gland is watertight (the cable gland

must always correspond to the diameter of the cable used).

Incorporate a bend where the cable enters the terminal box

to prevent water entering via the cable gland.

Check the motor direction of rotation (section 3.1).

The internal terminal box connections must never be put

under any stress due to the cables connected by the user.

Earthing

It is mandatory to earth the brake motor (in the terminal

box and on the brake), and earthing must be performed in

accordance with current regulations (protection of workers).

Power supply (see wiring diagrams under the terminal box

cover, section 3).

Brake motors with a built-in power supply are connected like

standard motors. They are tted with a DC coil (180 VDC).

The brake is supplied directly from the motor stator

(230/380/400/415/460/480 V) via a brake power supply unit,

rectier mounted in the terminal box.

For motors with different voltages, starting at reduced

voltage or operating at variable voltage or frequency, a

separate brake power supply must be provided. (The same

applies to a 20 VDC coil).

To reduce the brake application response time (mandatory

in Hoisting applications), it is necessary to switch off the

brake DC power supply at the same time as that of the

motor, usually via an auxiliary contact on the motor starting

contactor.