4

Maintenance and service guide - LSPX-FLSPX ZONE 21 - Ex tb – LSES-FLSES ZONE 22 - Ex tc

5725 en - 2020.02 / c

CONTENTS

1 - RECEPTION ................................................................. 5

1.1 - Identication and marking...................................................5

2 - STORAGE ......................................................................6

3 - COMMISSIONING .........................................................6

3.1 - Protocol for lubrication during commissioning ....................6

3.2 - Checking the insulation.......................................................7

4 - INSTALLATION ............................................................ 7

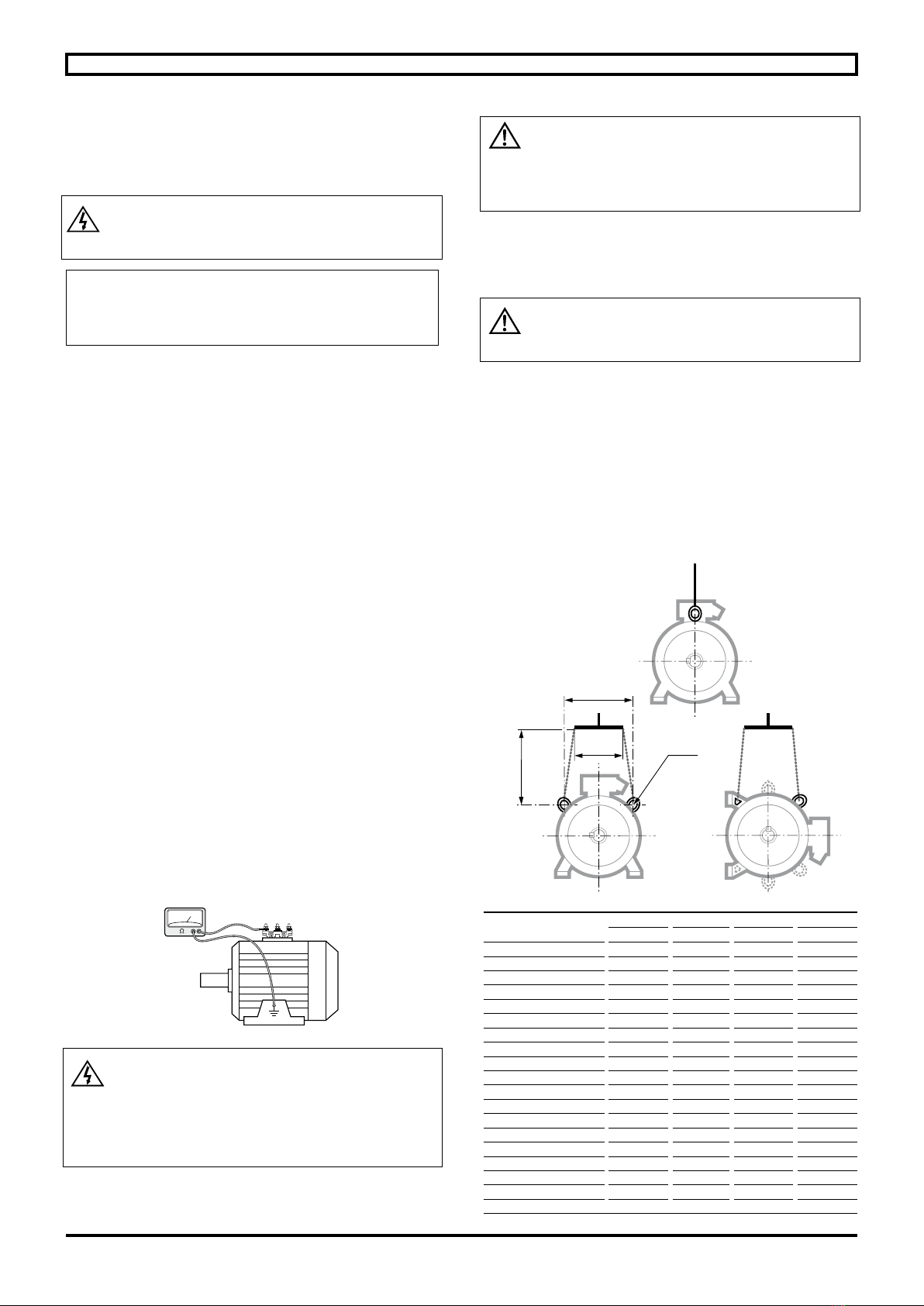

4.1 - Position of the lifting rings ...................................................7

4.2 - Location - ventilation...........................................................8

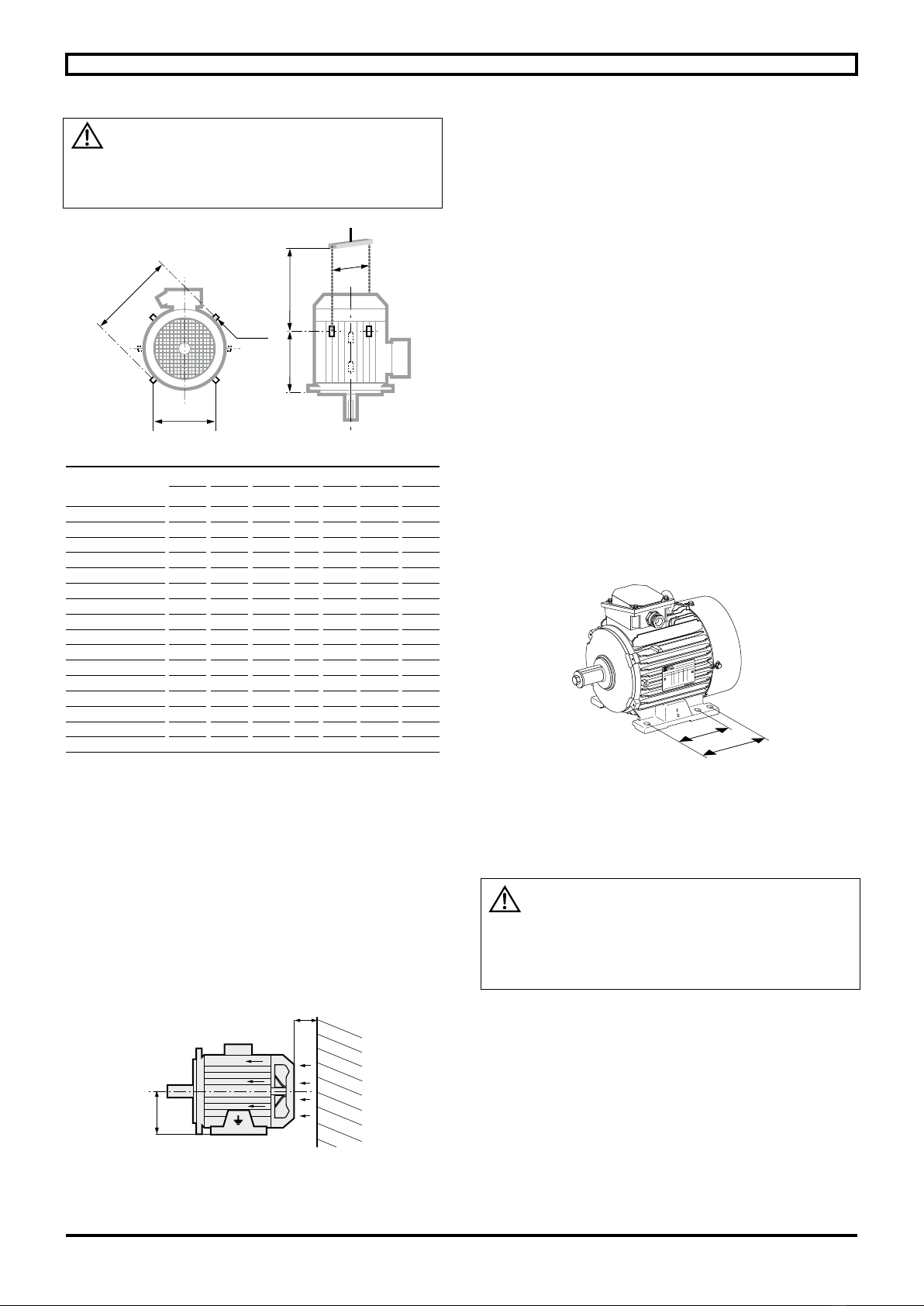

4.3 - Preparation of the xing support .........................................9

4.4 - Coupling ............................................................................ 9

4.5 - Important information to be taken into consideration during

installation.........................................................................................9

5 - ELECTRICAL PARAMETERS - LIMITING VALUES10

5.1 - Limitation of disturbances caused by starting of motors...10

5.2 - Supply voltage..................................................................10

5.3 - Starting time .....................................................................10

5.4 - Supply with frequency inverter..........................................10

6 - USE...............................................................................10

7 - SPECIAL OPERATING CONDITIONS.......................12

7.1 - Variable speed use ...........................................................13

8 - ADJUSTMENT.............................................................16

9 - MAINS CONNECTION ................................................18

9.1 - Terminal box .....................................................................18

9.2 - Connection to the electrical supply ...................................18

9.3 - Terminal block or isolator connection wiring diagram ........19

9.4 - Direction of rotation...........................................................19

9.5 - Earth terminal and earthing...............................................19

9.6 - Connecting the power supply cables to the terminal block 20

9.7 - Indication of cable gland size and type for 400V rated

supply voltage if drillings required without details of hole diameters

being given .....................................................................................21

9.8 - Admissible number and maximum size of

holes for cable glands per “eb” terminal block .................................21

9.9 - Recommended cable temperatures..................................21

10 - MAINTENANCE.........................................................22

10.1 - General...........................................................................22

10.2 - Corrective maintenance: general....................................23

10.3 - Safety rules.....................................................................24

10.4 - Routine maintenance......................................................24

10.5 - Bearing housing maintenance ........................................25

10.6 - IP Leak tightness of motor ..............................................27

10.7 - Group III paints ...............................................................27

10.8 - Troubleshooting guide ....................................................28

10.9 - Recycling........................................................................28

11 - LSPX MOTORS - ZONE 21....................................... 29

11.1 - LSPX 80 to LSPX 160 MP/LR motors .............................29

11.2 - LSPX 160 M/L, LSPX 180 MT/LR motors ...................... 31

11.3 - LSPX 180 L, LSPX 200, LSPX 225 ST/MT/MR motors ...33

11.4 - LSPX 225 MG, LSPX 250 ME,

LSPX 280 SC/MC/MD/SD motors ................................................. 35

12 - FLSPX MOTORS - ZONE 21 .................................... 37

12.1 - FLSPX 80 to FLSPX 132 motors.................................... 37

12.2 - FLSPX 160 and 180 motors........................................... 39

12.3 - FLSPX 200 and 225 MT/MS motors ...............................41

12.4 - FLSPX 225 M to 280 motors...........................................43

12.5 - FLSPX 315 to 355 LD motors .........................................45

13 - LSES AND FLSES MOTORS - ZONE 22..................48

INDEX

Acceptance.......................................................................................5

Adjustments................................................................................... 16

Alarm - early warning ..................................................................... 11

Assembly......................................................................................... 6

Balancing......................................................................................... 9

Bearing housing xing rods or screws: tightening ...........................23

Bearing housings.................................................................... 24 - 25

Belts............................................................................................... 17

Built-in thermal protection ............................................................... 11

Cable gland.....................................................................................18

Cables ............................................................................................20

Capacitors ......................................................................................24

Connection to mains ............................................................... 18 - 20

Connection wiring diagrams............................................................19

Connection .................................................................................... 20

Corrective maintenance..................................................................23

Coupling .......................................................................................... 9

Coupling sleeves ............................................................................16

Digistart ......................................................................................... 12

Direction of rotation.........................................................................19

Draining o condensation water......................................................24

Earth terminal .................................................................................19

Earth....................................................................................... 12 - 19

Europe Directives ....................................................................... 3 - 5

Fan ...................................................................................................8

Frequency inverter......................................................................... 13

Handling ................................................................................. 7 - 8 - 9

Heaters .......................................................................................... 11

Identication .................................................................................... 5

Inertia ywheel................................................................................16

Insulation ......................................................................................... 7

Lifting ring.........................................................................................7

Location........................................................................................... 8

Lubrication - Grease nipples .........................................6 - 24 - 25 - 26

Lubrication............................................................................... 25 - 26

Nameplate ........................................................................................5

Power supply .......................................................................... 10 - 20

Power ............................................................................................ 10

Protections...................................................................................... 11

Pulleys............................................................................................17

Routine maintenance..................................................................... 24

Spare parts .....................................................................................22

Starting ...........................................................................................10

Storage.............................................................................................6

Terminal box.................................................................................. 18

Terminal plate: tightening of nuts.....................................................19

Tolerances ......................................................................................16

Troubleshooting..............................................................................28

INSTALLATION AND MAINTENANCE - LSPX-FLSPX ZONE 21 - Ex tb – LSES-FLSES ZONE 22 - Ex tc