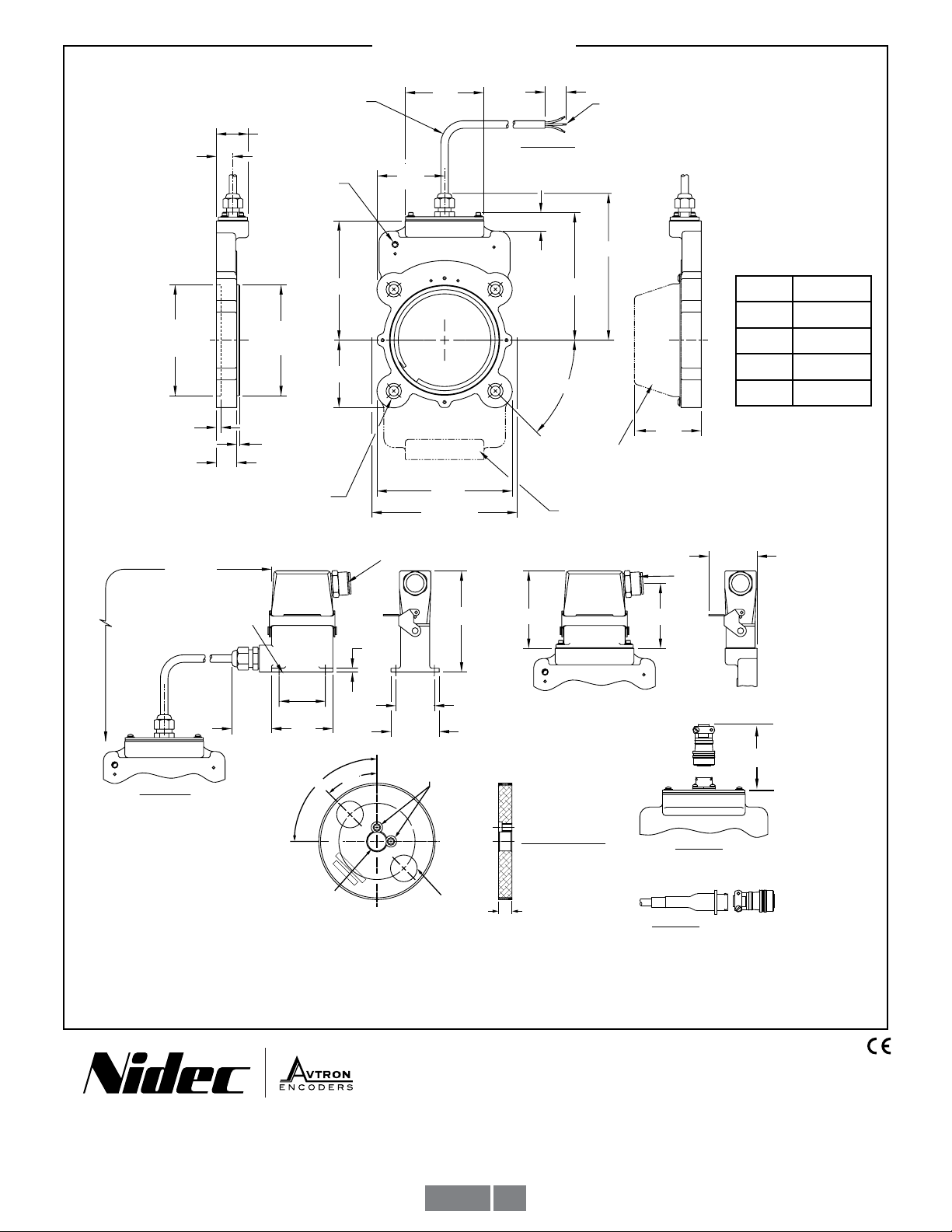

STATOR HOUSING INSTALLATION

The stator housing is attached to the motor using four socket head

cap screws M10 x 0.5 x 20mm long, locating on a 150mm bolt circle.

Longer bolts (not included), are required for sandwich installation

between a motor and a brake. Install the four mounting bolts using

thread locker and torque to approximately 27 to 40 N-m using the

8mm T-handle hex wrench.

VERIFY ROTOR LOCATION

To ensure the rotor is properly located on the shaft: remove the back

cover if factory-preinstalled, and verify that the outer face of the rotor is

at the same depth as the alignment grooves, using a straight edge tool.

(Figure 3)

CAUTION

Do not use silicone sealants or caulk of any kind on the

motor or encoder face; these can cause misalignment

or sensor scraping damage. The AV115 electronics are

fully sealed; water may enter and leave the rotor area

as needed. A drain hole option is available if frequent

moisture buildup is expected.

COVER INSTALLATION

Covers must not interfere with the motor shaft or rotor. The longest

shaft that can be used without interfering is 17.5mm with a standard

flat cover (Cover Style option “F”) and 63.5mm with an extended “pie

pan” cover (Cover Style option “E”). Through shaft covers with seals are

available for other applications (Cover Style option “T”).

EXTENDED COVER MOUNT

(Cover Style option “E”)

The extended cover mounts to the encoder housing using quantity 4

#6-32 x 0.31" screws, lock washers, and thread locker.

THRU SHAFT AND FLAT COVER INSTALLATION

(Cover Style option “T” and “F”)

The housing has a machined step in the outboard face to accept the

cover and a recessed groove for the retaining ring. Insert the cover,

line up ears on cover, smooth side facing out, fully into the machined

step until it seats against shoulder. Using a spiral assembly method,

install the retaining ring by first inserting the squared off end into the

machined groove. Flex the ring and insert it into the groove walking

it around the perimeter (A flat blade screwdriver can be used). Final

position should have the ring fully seated into groove. Remove the

cover by reversing above procedure, starting with the tang end.

V-RING INSTALLATION FOR THRU SHAFT COVERS

(Cover Style option “T”)

For thru shaft covers, verify that the shaft passes completely through

the hole in the cover. Apply a small amount of silicone lubricant to

the cover plate around the thru shaft hole. The V-Ring seal should

compress axially when it is pressed against the clean, smooth face

of the cover plate. See Figure 4 for proper installation and V-Ring

compression.

WIRING

CAUTION

Be sure to remove power before wiring the encoder. Be

sure to ground the cable shield: It can be connected to

case ground at the encoder, or grounded as the receiving

device, but should not be grounded on both ends. See

note below for Danaher/Northstar wiring.

Refer to the wiring diagrams for specific information on each option.

The AV115 can be wired for single phase or two phase, either with

or without complements, with or without markers. For bidirectional

operation, Phase A channel leads phase B channel for clockwise shaft

rotation as viewed from the anti-drive or accessory end of the motor

(AV115 mounting end).

NOTE

Wiring option “G” provides a pinout compatible with

NorthstarTM encoders, with a cable shield connection on

pin 10. Note that this option does not ground the shield;

Avtron still recommends grounding the shield at the

drive end of the cable for all wiring options.

CORRECTIVE ACTION FOR PHASE REVERSAL

1) Remove Power.

2) Exchange wires on cable, either at encoder cable end,

or at speed controller end (but not both).

a) Single Ended 2 Phase Wiring (see wiring diagram)

Exchange A and B at the use end of the wires.

b) Differential 2 Phase Wiring (see wiring diagram)

Exchange either A with A– in the phase A pair OR

B with B– in the phase B pair but NOT both.

3) Apply Power.

4) Verify encoder feedback is correct, using hand rotation

of shaft, or jog mode of the speed controller.

Interconnecting cables specified in the wire selection chart are based

on typical applications. Physical properties of cable such as abrasion,

temperature, tensile strength, solvents, etc., are dictated by the specific

application. General electrical requirements are: stranded copper,

22 through 16 AWG (Industrial EPIC connector type options can use

14 AWG), each wire pair individually shielded with braid or foil with

drain wire, .05 uf of maximum total mutual or direct capacitance,

outer sheath insulator. See specifications for maximum cable length.

Stranded 22 AWG wire should not be used for cable runs greater then

61 meters. If 22 AWG is used with EPIC type connector options the wire

ends should be tinned.

FAULT-CHECK

After power-up and the rotor position is checked by the sensor, the

Fault-Check LED will turn GREEN.

If the adaptive electronics reach their adjustment limit for any reason,

the Fault-Check alarm and LED will notify the drive and operator of an

impending failure. The LED will turn RED if the Adaptive Electronics

reach their adjustment limit. This output occurs before an actual

failure, allowing steps to be taken to replace the unit before it causes

unscheduled downtime. Fault-Check annunciation is available as an

“alarm” output through the connector and as an integral LED.

If there is a wiring error, such as an output being shorted to ground

or +V or another output, the Fault-Check LED will turn ORANGE. The

ORANGE LED may blink intermittently, depending on voltage and

severity of short.

TROUBLESHOOTING

If the drive indicates a loss of encoder/tach fault and the AV115 fault-

check LED is not illuminated, check the encoder power supply. If power

is present, check polarity; one indicator of reversed power supply is

that all outputs will be high at the same time. If the drive indicates

encoder fault, but the LED shows GREEN, then check the wiring

between the drive and the encoder. If the wiring appears correct and

in good shape, test the wiring by replacing the AV115. If the new unit

shows GREEN, and the drive still shows encoder loss/tach fault, then

the wiring is faulty and should be repaired or replaced.

If the alarm output and/or LED indicate a fault (RED):

1. Remove the rear cover, and use the built-in gauge to check the

location of the rotor (see Figure 1). Ensure the label marked “This side

out” is facing away from the motor.

2. Remove the AV115 from the motor. Clean the housing mounting

surface for the AV115 housing. Ensure the AV115 is directly mounted

on the motor, with no sealant, gasketing, or other materials, and is

firmly bolted in place.

If the alarm output and/or LED indicate a fault (RED)

On a properly mounted AV115 and the rotor is properly located, replace

the AV115 sensor.

AV115 3