SV850 SAFETach™ III Incremental Encoder 4Rev: 001

General electrical requirements are: stranded copper, 22 thru 16 gauge

(Industrial EPIC Connector options can use 14-20 AWG), each wire pair

individually shielded with braid or foil with drain wire, 0.05 uF maximum

total mutual or direct capacitance, outer sheath insulator, 1,000 ft. max.

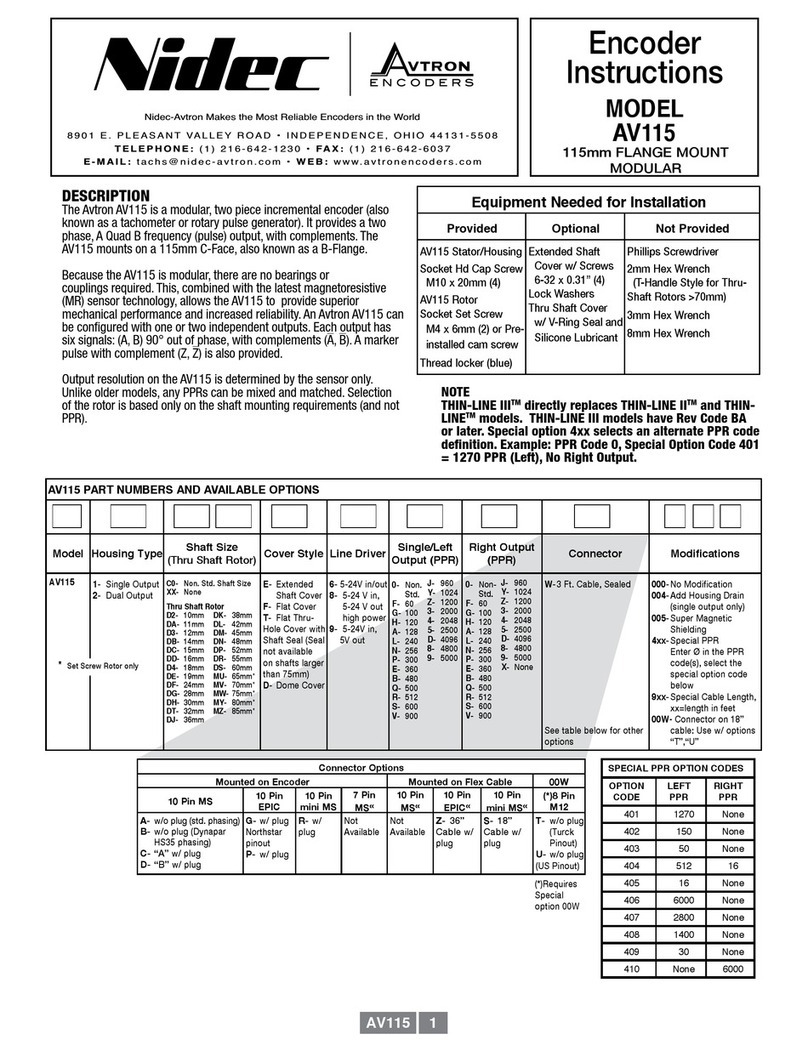

See WIRE SELECTION CHART in Figure 6 for some suggested cables.

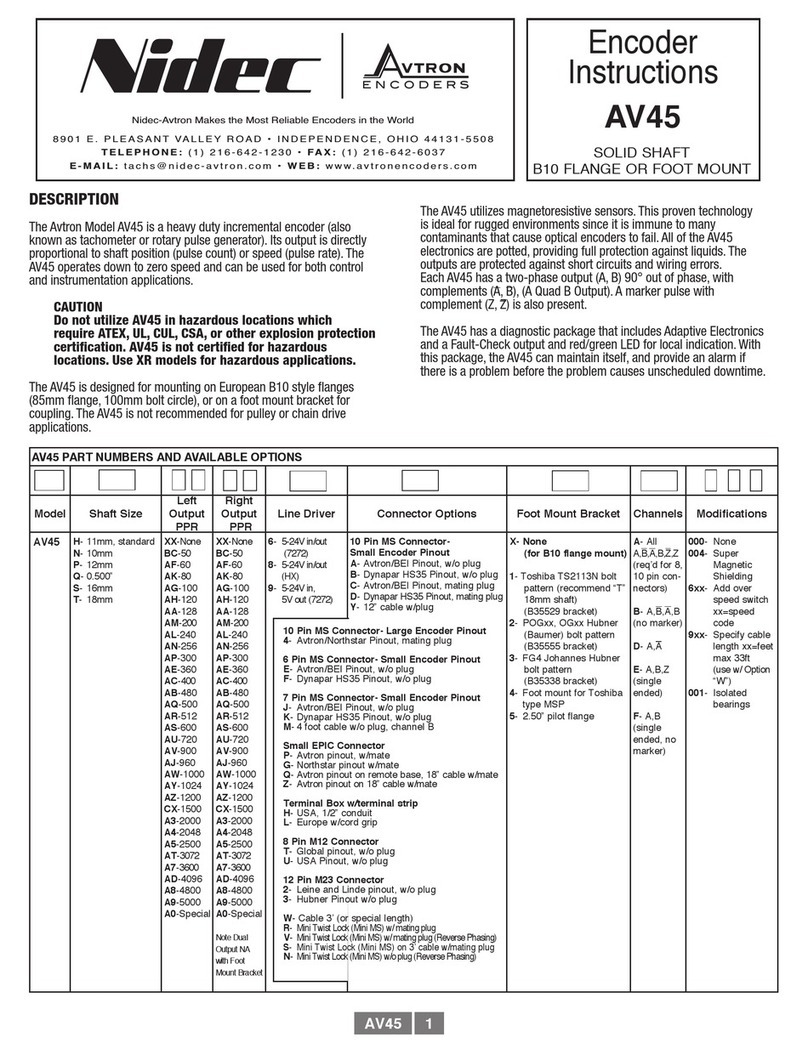

See Figure 7 for examples of alarm output wiring.

NOTE

When using the industrial connector (“G”, “P” options),

the minimum wire size is 20 gage, and 20 gage (only) wire

ends must be tinned with solder before connection at the

screw terminals.

MAINTENANCE

GENERAL

This section describes routine maintenance for the Avtron SV850 Encoder.

For support, contact field service for Avtron Encoders at

216-642-1230. For emergency after hours service contact us at

216-641-8317. The SV850 SAFETach III circuitry includes a diagnostic

package that includes Adaptive Electronics and a Fault-Check output.

ADAPTIVE ELECTRONICS

A perfect duty cycle consists of a waveform whose “high” and “low”

conditions are of the same duration (50%/50%). The SV850 adaptive

electronics extends the life of the SV850 by constantly monitoring and

correcting duty cycle over time.

FAULT-CHECK

After power-up and the rotor position is checked by the sensor, the Fault-

Check LED will turn GREEN.

If the adaptive electronics reach their adjustment limit for any reason,

the Fault-Check alarm and LED will notify the drive and operator of an

impending failure. The LED will turn RED if the Adaptive Electronics reach

their adjustment limit. This output occurs before an actual failure, allowing

steps to be taken to replace the unit before it causes unscheduled

downtime. Fault-Check annunciation is available as an “alarm” output

through the connector and as an integral LED.

TROUBLESHOOTING:

If the drive indicates a loss of encoder/tach fault and the SV850 fault-

check LED is not illuminated, check the encoder power supply. If power

is present, check polarity; one indicator of reversed power supply is that

all outputs will be high at the same time. If the drive indicates encoder

fault, but the LED shows GREEN, then check the wiring between the drive

and the encoder. If the wiring appears correct and in good shape, test

the wiring by replacing the SV5 sensor module. If the new module shows

GREEN, and the drive still shows encoder loss/tach fault, then the wiring is

faulty and should be repaired or replaced.

WARNING

Only use SV5 sensors in SV850 Encoders. Use of other

sensors will not retain the functional safety compliance of

the SV850.

If the alarm output and/or LED indicate a fault (RED):

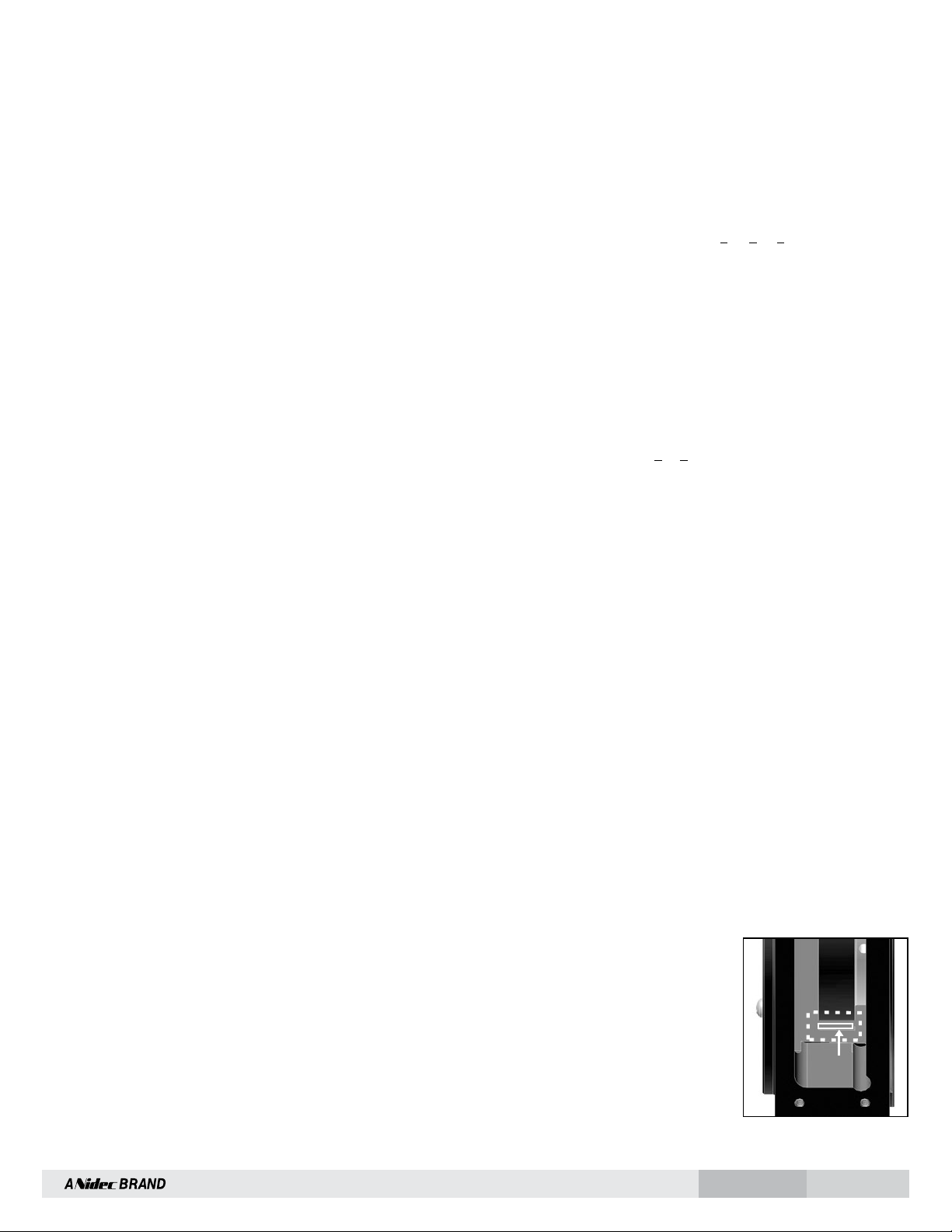

1. Remove a sensor plate or one of the sensors, and use

the built-in gauge to check the location of the rotor (see Figure

2.1). Ensure the label marked “This side out” is facing away

from the motor.

2. Remove the SV5 sensor from the housing. Clean the housing

mounting surface for the SV5 sensor and the SV850 housing.

Ensure the SV5 sensor is directly mounted on the SV850

housing, with no sealant, gasketing, or other materials, and

that it is firmly bolted in place.

If the alarm output and/or LED indicate a fault (RED) on a properly

mounted SV5 sensor and the rotor is properly located, replace the SV5

sensor.

An oscilloscope can also be used to verify proper output of the SV850

encoder at the encoder connector itself and at the drive/controller cabinet.

If the outputs show large variations in the signals at steady speed (jitter

or “accordion effect”, see figure 9), check rotor position. If the rotor

position is correct, the motor or shaft may be highly magnetized. Replace

any magnetized material nearby with non-magnetic material (aluminum,

stainless) (shafts, etc). For GE CD frame motors and similar styles, Avtron

offers non-magnetic stub shafts (included with all “U” style rotor kits).

If variations persist, consider replacing the sensors with super-shielded

models, option -004.

If the alarm output and/or LED indicate a wiring fault (ORANGE):

Remove all output wires/connections (A, A, B, B, Z, Z). The LED should

turn GREEN. If the LED does not turn GREEN, the encoder is not receiving

enough voltage at +V to properly operate. Correct input voltage problem at

power supply or cabling.

If the LED turns GREEN once all outputs are disconnected, reconnect each

output, one at a time, monitoring for ORANGE LED. For partial/resistive

short circuits, the LED may take a few minutes to turn ORANGE. To speed

the troubleshooting process, if possible, spin the encoder while replacing

individual output connections. This may make the ORANGE LED condition

occur faster. Once the shorted output(s) are located, correct the shorting

condition, and the encoder LED should remain GREEN.

If the LED is OFF, but power is being applied to the encoder, check

the output voltage level at A, A,B, B. If all outputs are ON (≈+V), the

connections to +V and COM are reversed. Swap connections between +V

and COM; the LED should turn GREEN.

STATOR HOUSING REMOVAL

To remove the stator housing remove the qty 4 1/2 13 x 3” bolts holding

the housing to the motor.

CAUTION

Take care that the housing does not fall from the pilot and

cause the sensors to crash into the rotor. Damage to the

sensor or rotor could result.

ROTOR REMOVAL

Remove shaft rust and burrs before removing the rotor.

THROUGH-SHAFT AND UNIVERSAL (KA-K9):

Loosen the set or cam screws holding the rotor to the shaft. The cam

screws rotate less than one turn to disengage the shaft. The stub shaft

adapter from the universal (Ux) rotors can be left in place.

NOTE

Do not remove the cam screws from the rotor.

Remove the rotor by hand, taking care not to damage the outer

magnetized ring.

If the rotor cannot be removed by hand, use a gear puller taking care not

to damage the outer magnetized ring.

DO NOT APPLY HEAT TO THE ROTOR. ROTOR ALIGNMENT GROOVE

Figure 2.1

Rotor magnetic strip aligns with groove.