AV45 2

ADAPTIVE ELECTRONICS

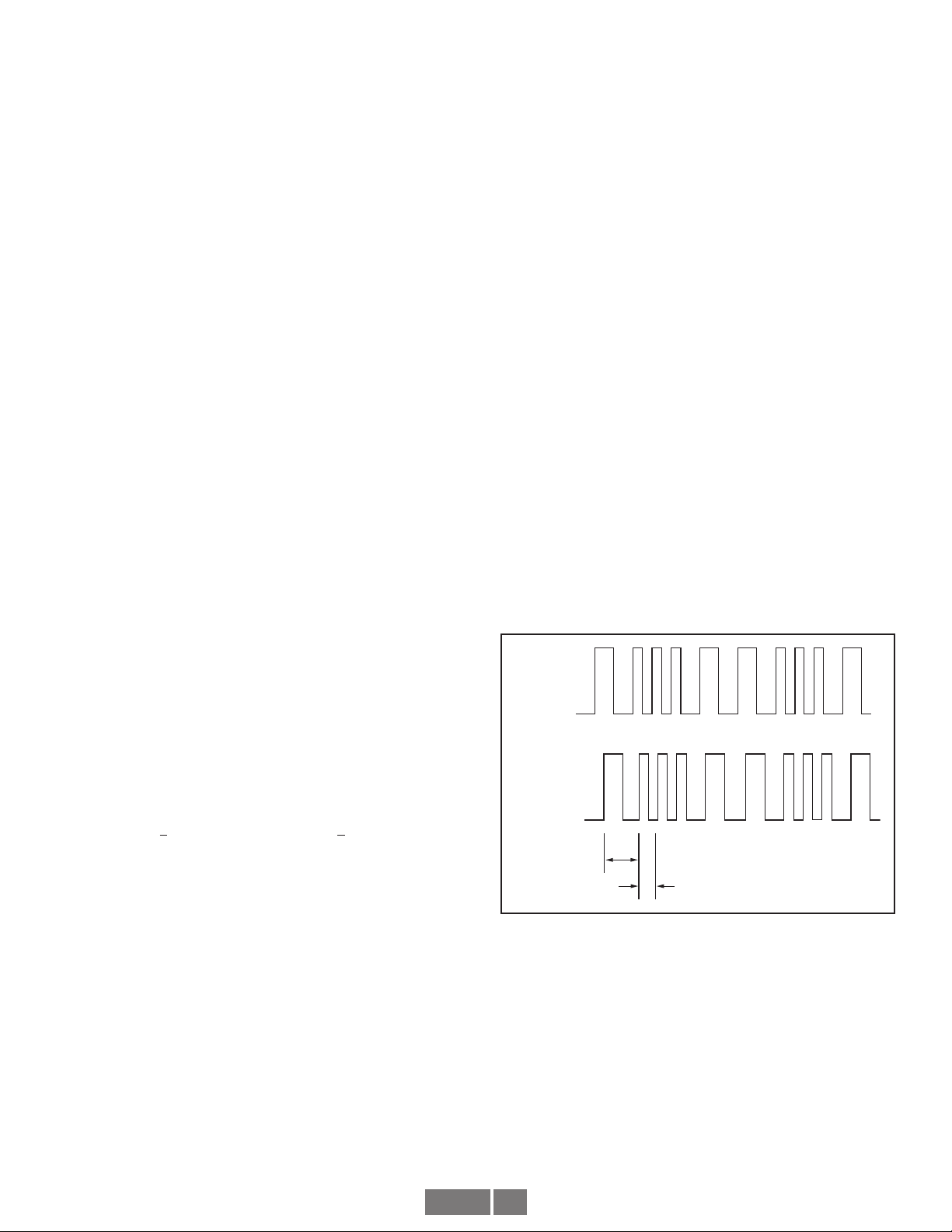

A perfect duty cycle consists of a waveform whose “high” and

“low” conditions are of the same duration (50%/50%). It is possible

over time for the duty cycle and edge separation to change due

to component drift, temperature changes, or mechanical wear.

The Adaptive Electronics extend the life of the AV45 by constantly

monitoring and correcting duty cycle and edge separation over time.

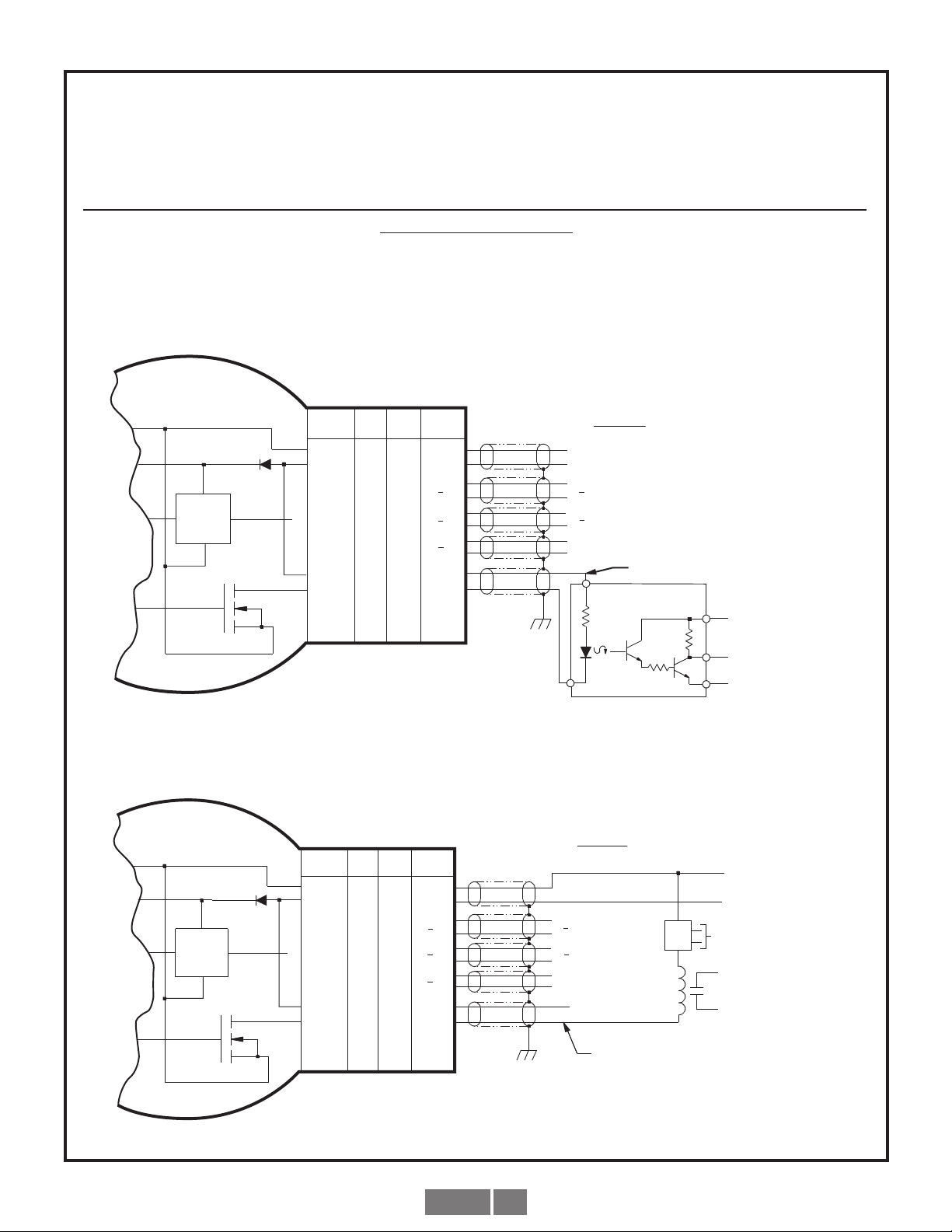

FAULT-CHECK

If the Adaptive Electronics reach their adjustment limit, the LED will

turn red and Fault-Check alarm will notify the drive and operator of

an impending failure. This output can occur before a failure, allowing

steps to be taken to replace the unit before it causes unscheduled

downtime. Fault-Check annunciation is available as an “alarm” output

through the connector.

SAFETY

The AV45 is not considered as a safety device and is not suitable for

connection into a safety system. The mechanical overspeed switch

(option 6xx) is suitable for connection into safety systems.

CAUTION

Do not disassemble mechanical overspeed option. Doing

so may modify the overspeed set point or cause the

switch to malfunction. If the factory seals are not intact

on the overspeed switch, do not use it--return to the

factory for service and calibration.

WARNING

Installation should be performed only by qualified

personnel. Safety precautions must be taken to ensure

machinery cannot rotate and all sources of power are

removed during installation.

INSTALLATION

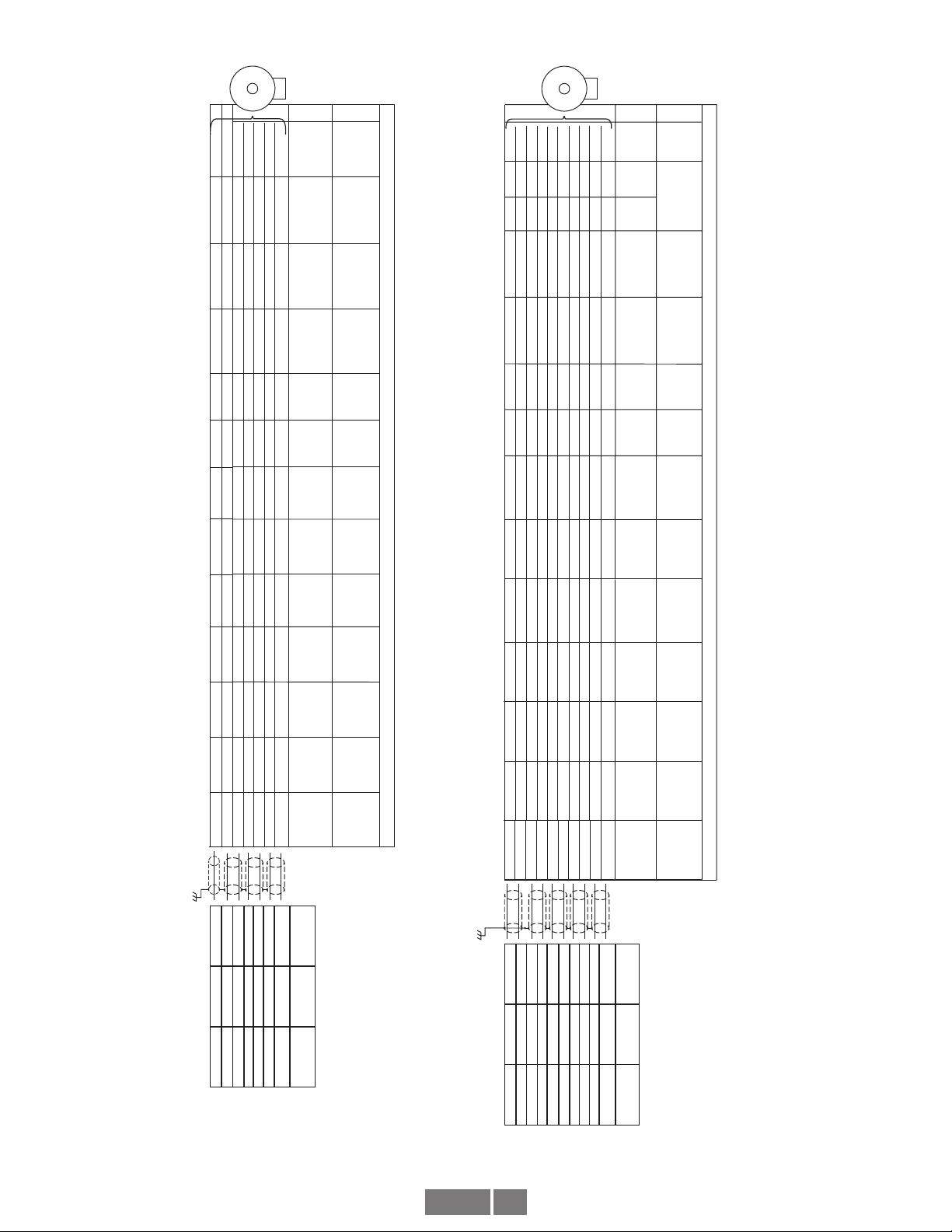

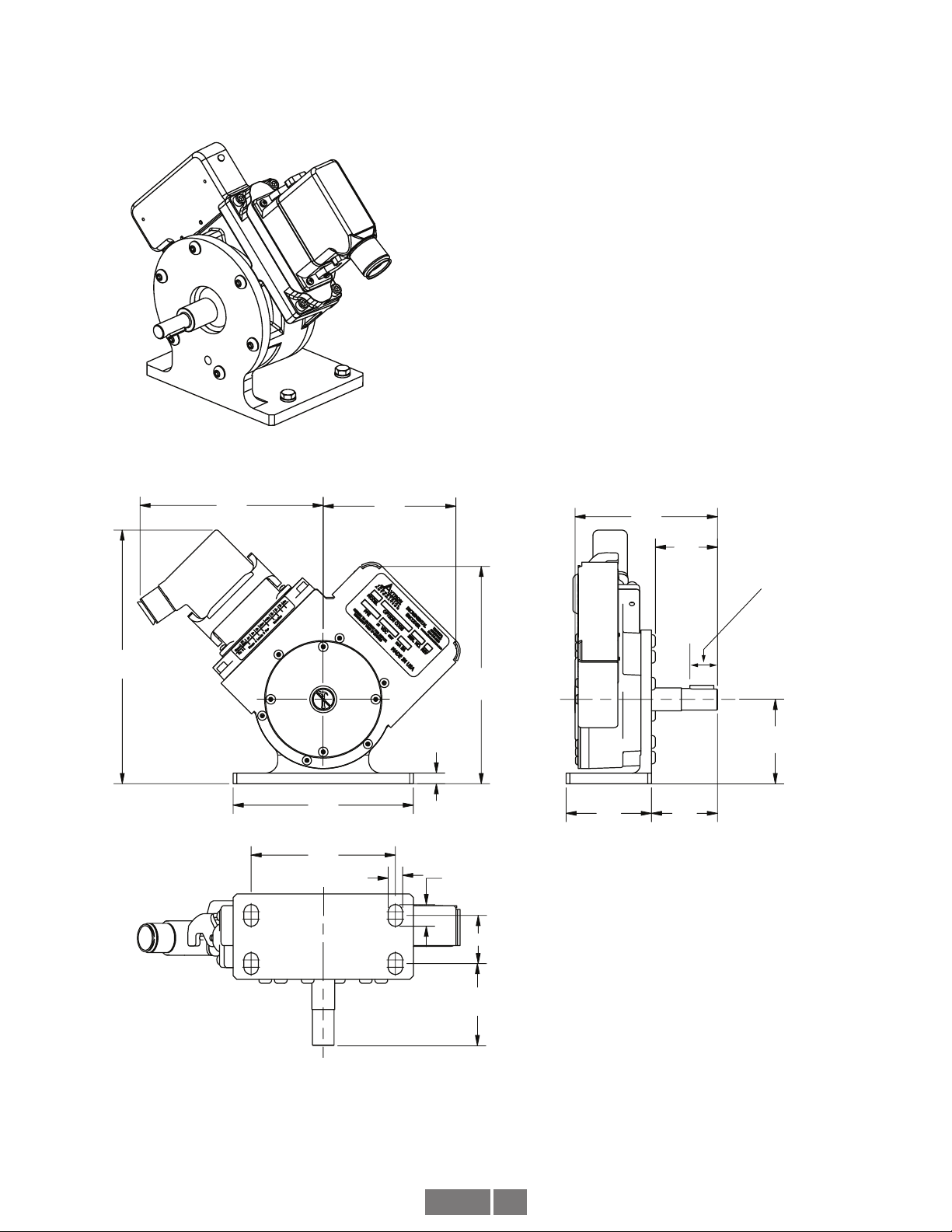

Refer to the back page of these instructions for outline and mounting

dimensions.

Supplied:

AV45 Encoder

Optional:

Foot Mount Kit

Thread Locker (blue)

Not Supplied:

Dial Indicator Gauge

Caliper Gauge

The encoder must be driven by a positive drive rather than a friction

drive. The following means of coupling are acceptable when properly

installed: Direct Coupling.

With a direct drive, use a flexible disc coupling and align the shafts as

accurately as possible. For motors with a pre-aligned flange, it is also

acceptable to use a “spider” or “jaw” coupling type. If a rubber slinger

disc is used, position it on the shaft so it will rotate freely.

CAUTION

Do not force or drive the coupling onto the shaft, or

damage to the bearings may result. The coupling should

slide easily on the shaft. Remove nicks and burrs if

necessary. Consider driving shaft endplay & axial

movement when positioning coupling.

For more details on alignment specifications, measurement

techniques, and special considerations in specifying and installing

drive components, refer to separate installation instructions in the

Avtron PULSE GENERATOR HANDBOOK.

B10 FACE MOUNTING INSTRUCTIONS

1. Apply anti-seize compound [copper], included, to inner

circumference of coupling (both motor and encoder side).

2. Loosen set screws in coupling and apply thread locker to set

screws.

3. Place coupling on motor shaft, inserting to depth per

manufacturer’s instructions.

4. Attach coupling to motor shaft using set screws per

manufacturer’s instructions.

5. Bolt mounting flange (flowerpot) to motor C-Face, using thread

locker with fasteners, included.

6. Slide encoder shaft into other side of coupling. DO NOT FORCE.

Ensure keyway aligns with coupling set screw location.

7. Ensure C-Face on mounting flange matches and aligns with

encoder C-Face precisely.

8. Apply thread locker to hex cap screws.

9. Align bolt holes of encoder and flange, thread in (4) hex cap

screws, using lock washers.

10. Tighten set screws on encoder side of coupling.

FOOT MOUNTING INSTRUCTIONS

Equipment needed for installation

Supplied:

Foot Bracket

(6) M6 Button Hd. Cap Screw

Not Supplied:

M4 Hex Wrench

Dial Indicator

The B10 flange / face is the preferred mounting method for the AV45.

In certain cases, however, it may be necessary to foot-mount this

unit. The optional foot mounting bracket kits, Option 1, 2, or 3, will be

required for standard installations or replacement of foot mounted

Toshiba TS2113N, Hubner HOG & OG, and FG4 units. Read all of the

following instructions and the Avtron PULSE GENERATOR HANDBOOK

prior to beginning any work.

The AV45 performance and life will be directly affected by the

installation. Following this sequence of steps is recommended.

1. Clean and inspect motor/driver shaft. Do not use force to

assemble coupling onto motor/driver shaft. The foot mounting

bracket must be secured to a flat, rigid, vibration free steel or

aluminum base which can be machined to accept the mounting

hardware.

2. Temporarily mount the AV45 to the foot bracket, install the

coupling to the AV45 and driver, and verify that the location is

suitable for installation.

3. If the AV45 encoder, bracket and coupling are suited to the area,

check motor/encoder shaft alignment with a straight edge from

multiple positions around the shaft circumference to verify that it

meets specifications.

4. While maintaining alignment, precisely mark the position of the

foot bracket on its mounting base.

5. Remove the AV45. Transfer punch or layout the mounting hole

pattern as indicated on outline drawing.

6. Machine through holes or tap holes in center of base slots to give

some degree of freedom in final alignment.

7. Reinstall the AV45 with the flexible coupling loosely in place, and

tighten down all mounting hardware. Check motor/encoder shaft

alignment with a straight edge from multiple positions around

the shaft circumference to verify that it meets specifications. Use

thread locker supplied on cap screws which mount AV45 to foot

bracket.

8. Ensure any flat or keyway on the motor and encoder shaft

are aligned with the set screw holes of the flexible coupling.

Apply thread locker to coupling set screws and tighten per

manufacturer’s recommendations.

9. Recheck alignment and tighten all hardware after first several

hours of operation.