2010-8401CE Rev C

6May 2011

MARK 5 Nuvo LITE Serial No. ______________

Date rst used: ___________________________

Maintained by: ___________________________

_________________________________________

Your distributor: _________________________

Address : ________________________________

_________________________________________

Telephone : ______________________________

PREVENTIVE MAINTENANCE:

a. Wash cabinet lter weekly.

b. Inspect inlet air lter at each patient visit.

Replace lter every 2 years, or more often

depending on environment.

c. Check oxygen concentration every 15,000 hours or

3 years to verify the continuing OCSI function.

The manufacturer’s instructions for the preventive

maintenance of the devices are de ned in the

maintenance manual. Check with your service

provider for any updates to recommended schedules.

The work must be carried out by suitably trained

technicians certi ed by the manufacturer.

Use original spare parts only (see Pg. 7).

Uponrequest,thesuppliercanprovidecircuitdiagrams,

sparepartslists,technicaldetailsoranyotherinformation

of use to quali ed technical personnel for parts of the

devicewhicharedesignatedasbeingthemanufacturer’s

responsibility or by the manufacturer as repairable.

Medical Device Regulations require users and

service providers to report to the manufacturer any

incident that could, if repeated, result in injury to

any person.

IV.8. Method for disposing of waste

AllwastefromtheMARK5NuvoLITE (patient circuit, lter,

etc.) must be disposed of using the methods appropriate to

the civil authority of the location where disposed.

IV.9. Method for disposing of the device

In order to preserve the environment, the concentrator must

only be disposed of using the appropriate methods. All ma-

terials of construction are recycleable.

Furthermore, as part of the marking (directive 93/42/EEC),

the serial number of the device disposed of must be sent to

the Nidek Medical technical service department if the unit

has the marking.

Accuracy of ow supplied:

In compliance with the ISO 8359 standard, the ow supplied

is equal to the ow set on the owvalve, accurate to within ±

10 % or 200 ml/min, whichever is the larger of the two.

Oxygen Concentration:

• at 2 l/min: >90%. .

• at 5 l/min: 90%. (+6.5%/-3%)

(Values at 21oC and at one atmosphere pressure).

Maximum recommended ow: 5 l/min.

The variation of the maximum recommended ow does not

exceed ± 10 % of the indicated value when a back pressure

of 7 kPa (1 psig) is applied to the output of the device. The

maximum outlet pressure is 50 kPa (7 psig).

Electrical power supply:

115 V Units 230 V Units

Frequency: 60Hz 50 & 60Hz

Average Power: 330W(avg) 300 W(avg)

Protection Class: Class II Class II

Mains Protection: 10A 5A

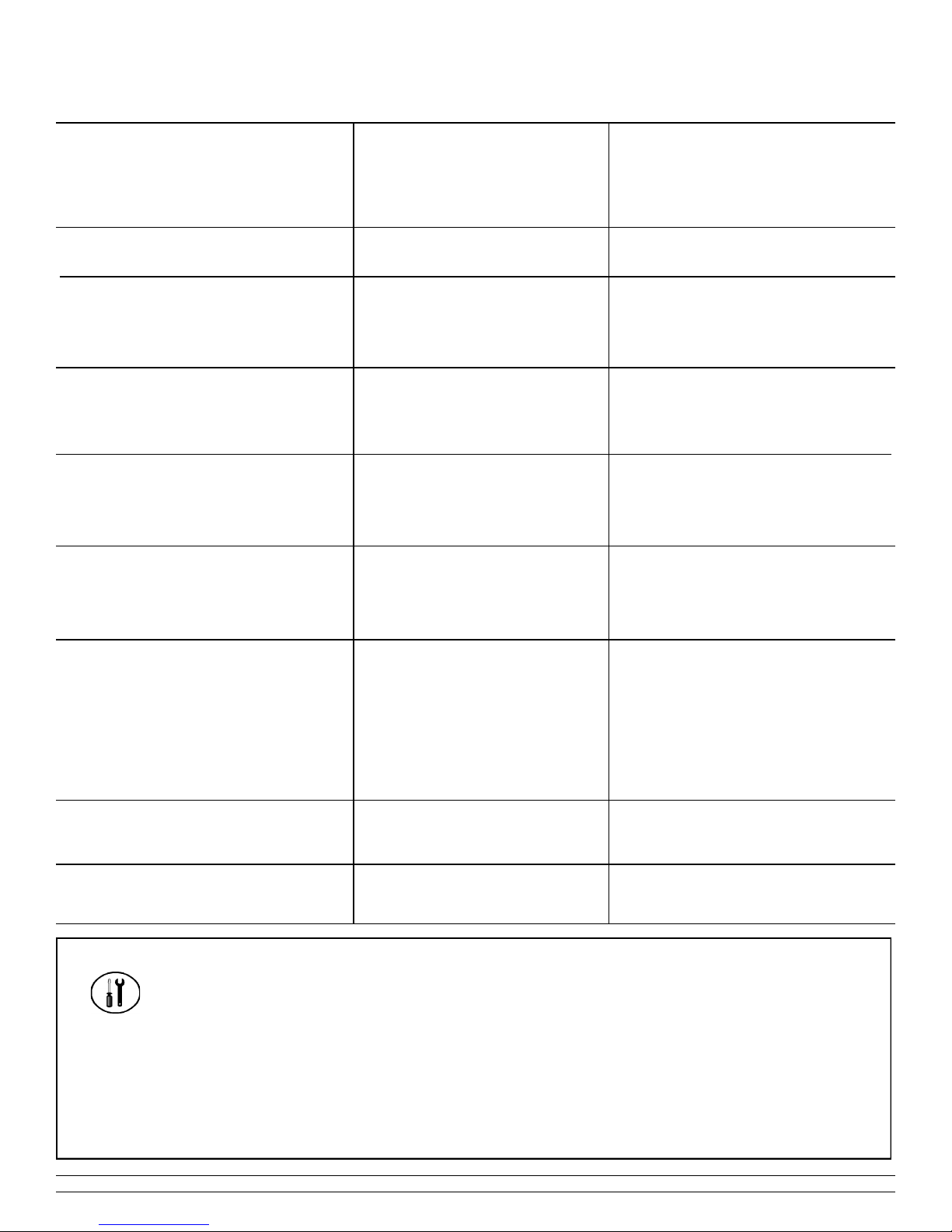

Filters:

At the rear of the device: a cabinet air lter.

At the compressor input: an inlet air lter, 5 µm, located

behind the cabinet air lter.

Before the oxygen outlet: a nal product lter, < 0.3 µm.

(technician only).

Air circulation:

A tubeaxial fan cools the compressor compartment.

Environmental limit conditions:

The performances of the device (especially the oxygen

concentration)arequotedat21oC(70oF)andoneatmosphere.

They may change with temperature and altitude. For further

information, please consult the maintenance manual.

• The device must be stored, transported and used in the

vertical position only.

• Ambienttemperatureofbetween5oCand 40oC(40oFto

104oF) operation.

• Storage temperature from -20oC to 60oC (-4oF to 160oF).

• Relative humidity of between 15 % and 95 % operation

and storage, both non-condensing.

• Altitude(21oC): Up to 2,286m (7,500ft) without degra

dation; Consult your equipment provider for further in

formation regarding 2,286m to 4000m (7,500 to

13000ft).

• Complies with EN60601-1 standard; spilling of a glass

of water.

IV. 7. Standards

ISO 8359:1996 Oxygen concentrators for medical use.

EN60601-1[UL60601-1:2003],CAN/CSA-C22.2No.601.1-

M90 w/A1&A2: Electrical Safety- Medical Devices.

EN60601-1-2:2001 Electromagnetic Compatibility