______________________________________________________________________________________________________________

2010-2324CE-G March 2022 Page 3 of 8

EN

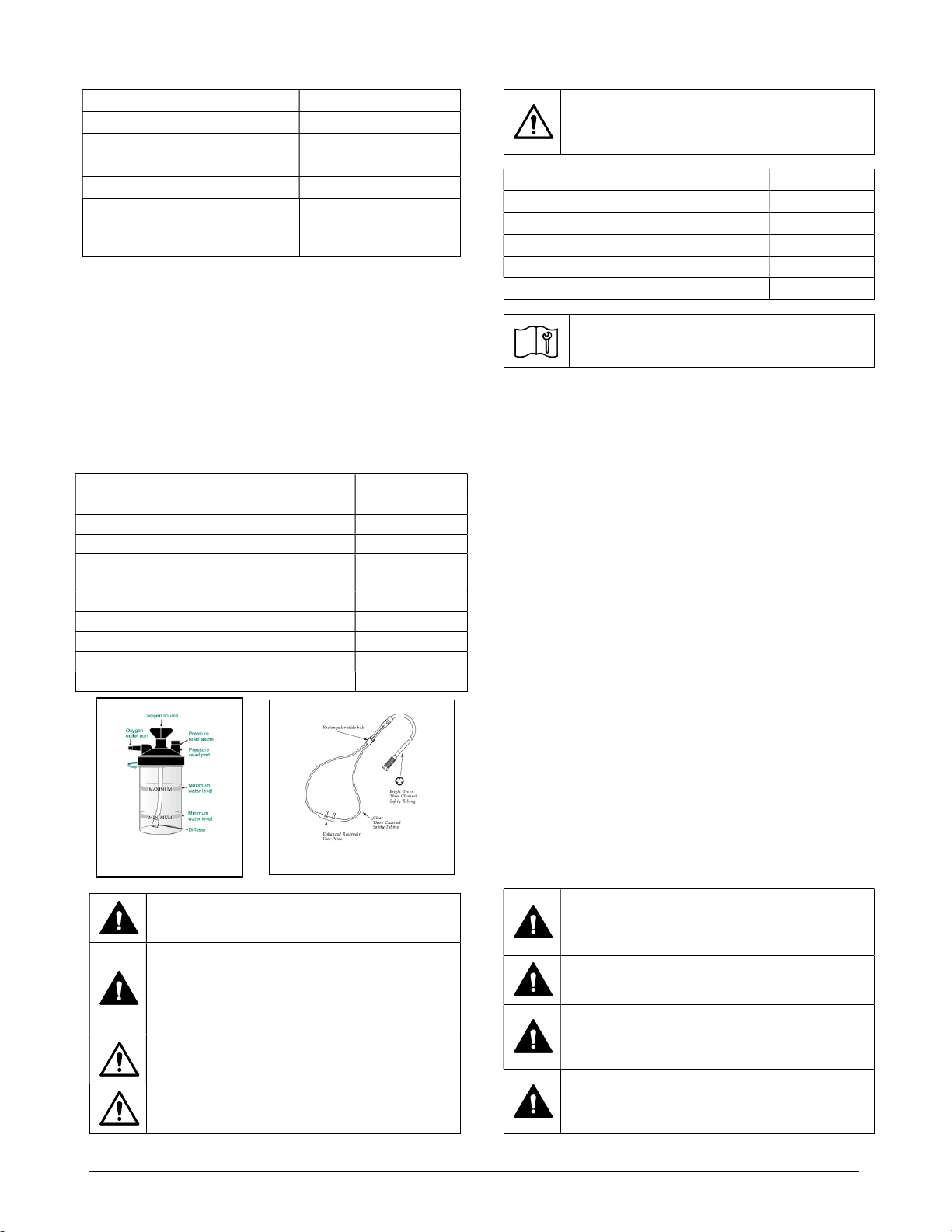

Use the power cord provided.

Check that the electrical characteristics of the power

outlet used match those indicated on the manufacturer’s

plate on the rear panel of the device.

This unit may be equipped with a polarized plug. That is

one blade wider than the other. If it does not fit into the

outlet, reverse the plug. If it still does not fit, contact a

qualified electrician. Do not defeat this safety feature.

2.3 Alarms and Safety Features

The device has an audible alarm to warn the user of

problems. In order that the alarm may be heard, the

maximum distance that the user can move away from it

must be determined to suit the surrounding noise level.

No voltage detection: In the event of a loss of mains

power, an intermittent audible alarm is activated and the

green light turns off.

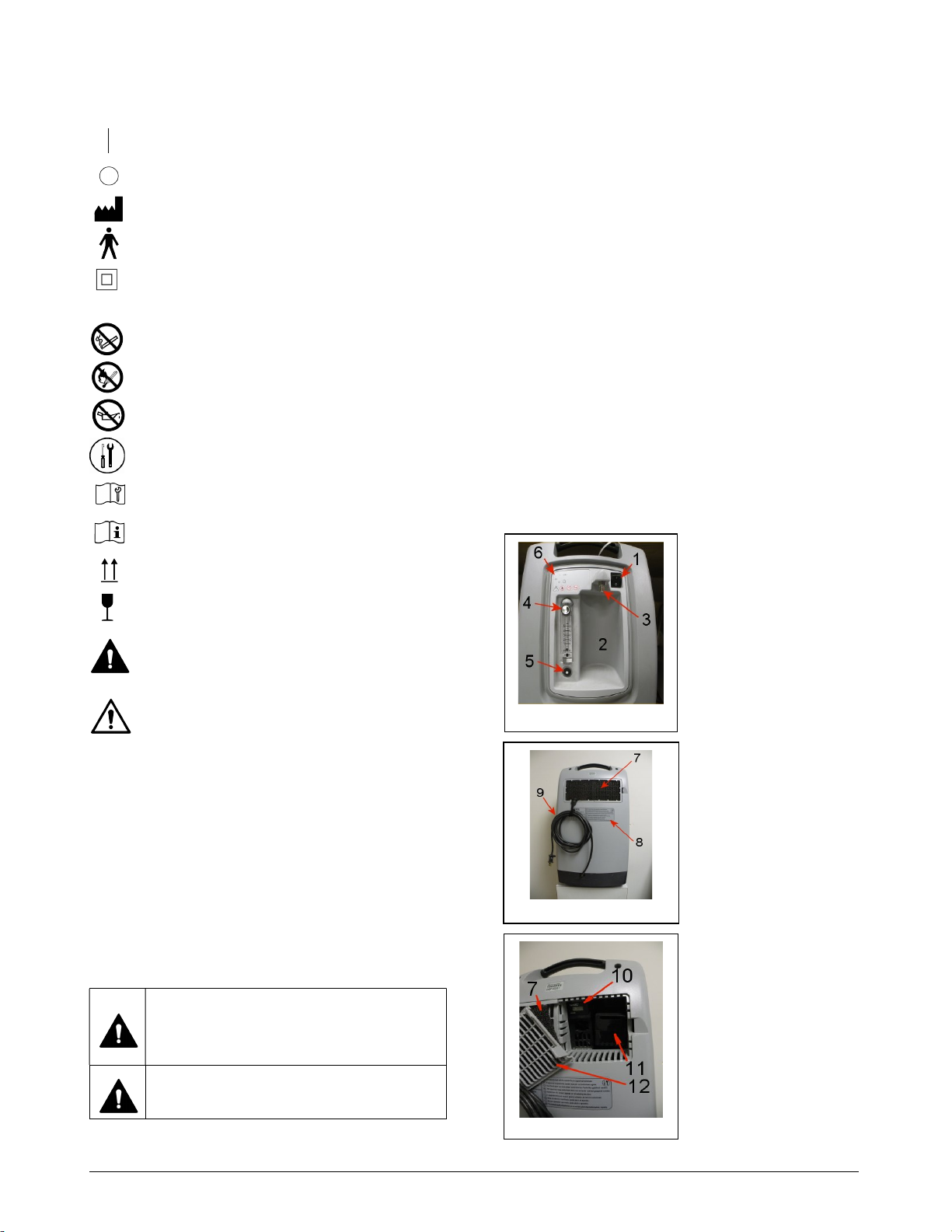

Test alarm by actuating the Power Switch (Fig 1-1) when

the mains cable is not plugged into the power outlet.

Oxygen Concentration Status Indicator: The oxygen

concentration monitor is an electronic module capable of

checking the effective oxygen concentration supplied by

the concentrator. The oxygen monitor measures the

concentration and activates an audible and visual alarm if

it falls below the alarm set point percentage. When the

device is started, the indicator lights (Fig 2-6) located on

the front panel operate as described below.

Green indicator: This light indicates that power is

applied to the concentrator and that it is ready to provide

oxygen enriched air to the patient.

On initial power up, this indicator light will flash green

until the device has reached normal operating conditions.

This should happen within approximately 2 minutes.

Yellow indicator: This light and a continuous audible

alarm will activate when the oxygen concentration level

falls below the set point.

Devices manufactured prior to 2018 included a red indicator light.

No special maintenance is required. The alarm set-point is

factory set and the setting cannot be adjusted.

All OCSI models are set at 85% ± 3%.

Blocked Cannula detection: If supplied, the device has a

Blockage Alarm. A continuous audible alarm and both

indicator lights will be lit immediately in the event the

flow of oxygen to patient becomes blocked.

Malfunction detection: If low pressure occurs due to a

mechanical failure, the indicator light will flash yellow

and a continuous audible alarm will actuate.

If any of the above alarm conditions occur, press the

Power Switch (Fig 1-1) to the “O” (OFF) position.

Call your equipment supplier to service the device.

Thermal safety: The compressor motor is protected by a

thermal switch situated in the stator winding (145 ± 5° C).

One tubeaxial fan cools the compressor compartment and

additional fans cool the heat exchanger coil for the Nuvo

8 and Nuvo 10 models (585, 985, 595, and 1005).

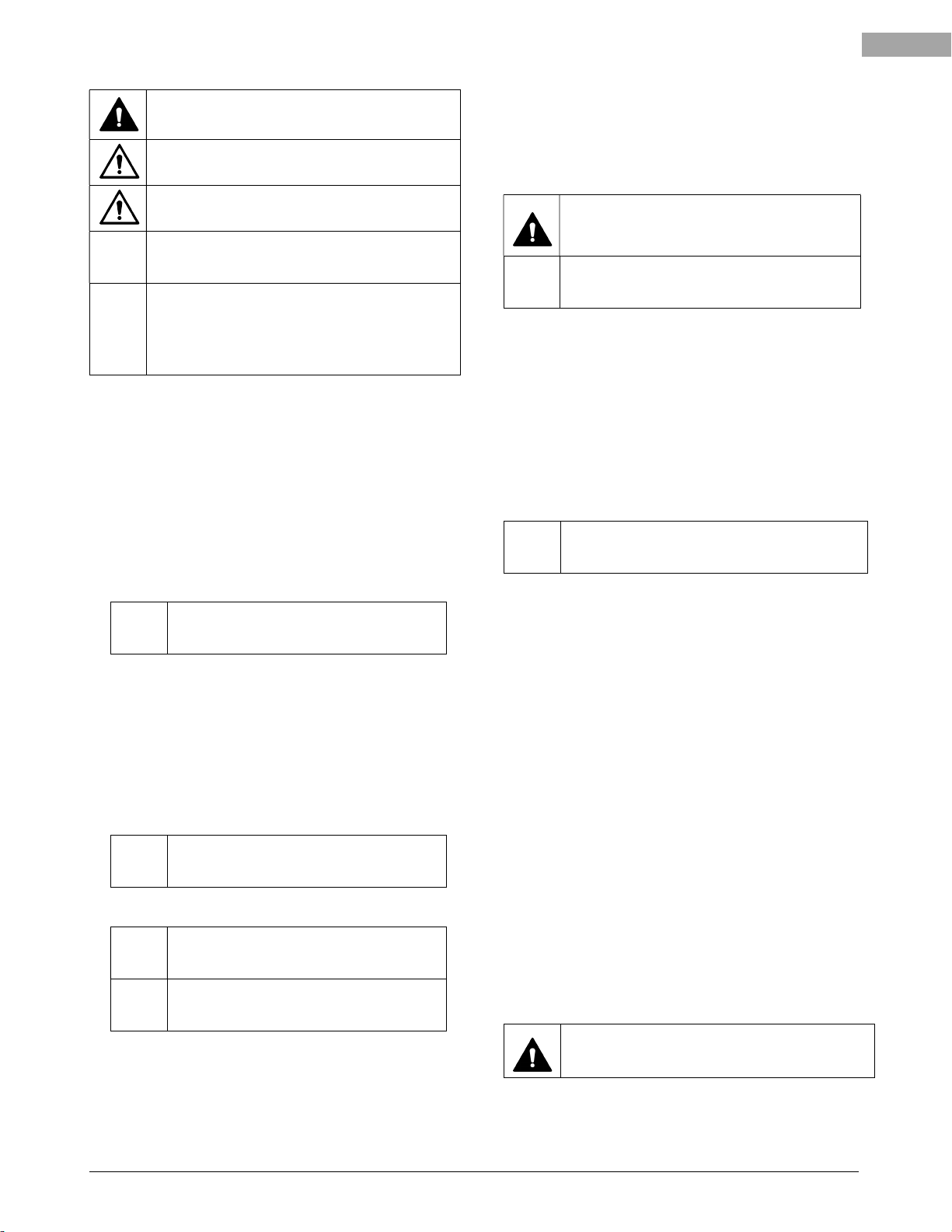

Electrical protection:

A 5A circuit breaker is incorporated into the front

cabinet of all 230V models

A 10A circuit breaker is incorporated into the front

cabinet of all 115V models

Class II devices with insulated casings (EN60601-1 standard)

Safety valve: This is fitted on the compressor outlet and

is calibrated to 3.4 bar (50 psig).

Fire Break: This device is fitted with a metal fire break

at the Oxygen Product Outlet (Fig 1-3). This break will

keep fire from entering the device. See “Accessories and

Spare Parts” (§ 2.5) for fire safe accessories.

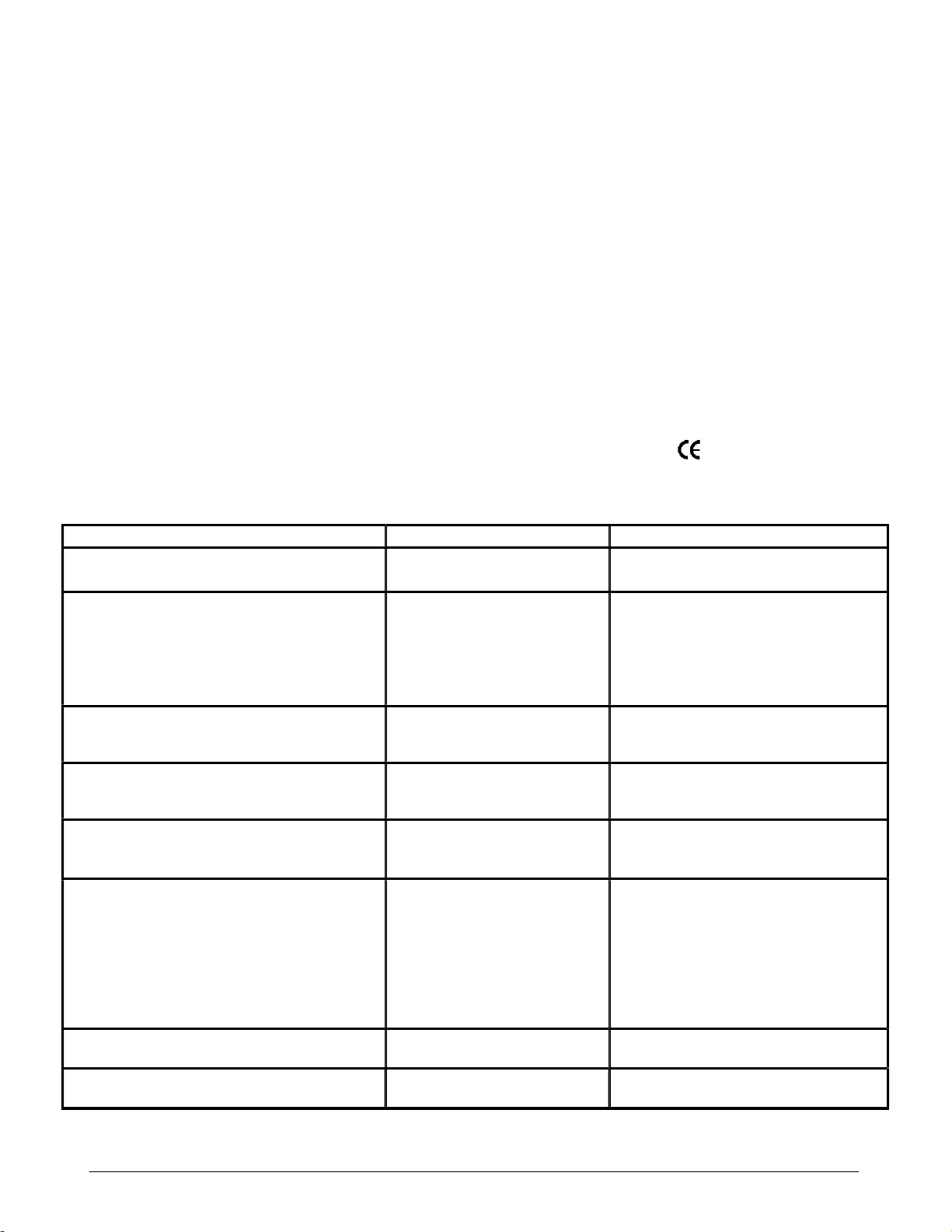

2.4 Device Performance and Specifications

The performance of the device (especially the oxygen

concentration) is quoted at 21°C (70°F) and one

atmosphere. The specifications may change with

temperature and altitude.

Model 505/565 905/965 585 985 595 1005

Description 5lpm

115V

5LPM

230V

8LPM

115V

8LPM

230V

10LPM

115V

10LPM

230V

Frequency 60Hz 50/60Hz 60Hz 50/60Hz 60Hz 50Hz

Average

Power

410

Watts

420

Watts

500

Watts

490

Watts

700

Watts

600

Watts

Protection

Class Class II

Mains

Protection 10A 5A 10A 5A 10A 5A

Average

Oxygen

Content

At 2 LPM

> 90%

At 2 LPM

> 90%

At 2 LPM

> 90%

Average

Oxygen

Content

At 5 LPM

87% to 95.5%

At 8 LPM

87% to 95.5%

At 10 LPM

87% to 95.5%

Liter Flow 1 to 5 LPM 2 to 8 LPM 2 to 10 LPM

Outlet

Pressure 7 Psig 15 Psig 20 Psig

Dimensions

(L x W x H) 394 x 396 x 706 mm (15.5 x 15.6 x 27.8 in.)

Weight 24.5-26 kg (54-58 lbs)*

Noise Level < 58 dBA

* Weight dependent on model and features

In compliance with EN ISO 80601-2-69, the flow supplied is

equal to the flow set on the flowmeter, accurate to within

± 10% or 200 ml/min, whichever is greater.

The variation of the maximum recommended flow does not

exceed ± 10 % of the indicated value when a back pressure

of 6.9 kPa (1 psig) is applied to the output of the device.

Materials in direct or indirect contact with the patient

Concentrator enclosure ABS/Polycarbonate

Printed labels Polycarbonate

Power switch (Fig 1-1) Nylon

Oxygen product outlet (Fig 1-3) SS or Brass

Flow adjustment knob (Fig 1-4) ABS