Nieco MPB73 User manual

Other Nieco Broiler manuals

Nieco

Nieco BroilVection JF74 Electric User manual

Nieco

Nieco BroilVection JF62 Electric User manual

Nieco

Nieco BroilVection JF91 User manual

Nieco

Nieco Flexi-Chef System 615E User manual

Nieco

Nieco 952G User manual

Nieco

Nieco BroilVection JF94 Electric User manual

Nieco

Nieco 9025 User manual

Nieco

Nieco BroilVection JF61 User manual

Nieco

Nieco N724 FT User manual

Nieco

Nieco N2500 User manual

Nieco

Nieco N824 User manual

Nieco

Nieco MV 62 Series User manual

Nieco

Nieco MV74 Electric User manual

Nieco

Nieco JF93G Gas BroilVection User manual

Nieco

Nieco FH94 Electric User manual

Nieco

Nieco 732 User manual

Nieco

Nieco BroilVection JF91 Gas User manual

Nieco

Nieco 824E User manual

Nieco

Nieco MPB94 User manual

Nieco

Nieco JF94E User manual

Popular Broiler manuals by other brands

Wolf

Wolf FS-HB Specifications

Omcan

Omcan CE-CN-0552-B instruction manual

Lang

Lang CLB-1L-L Installation, operation, maintenance, & troubleshooting

Avantco Equipment

Avantco Equipment 177SAL17M user manual

Lang

Lang CLB-1-E Installation, operation, maintenance, & troubleshooting

Anvil

Anvil CBR9012 Specifications

Magikitch'n

Magikitch'n LPG-30 Use and care instructions

Blodgett

Blodgett BSB-36 owner's manual

Magikitch'n

Magikitch'n LPAGA Use and care instructions

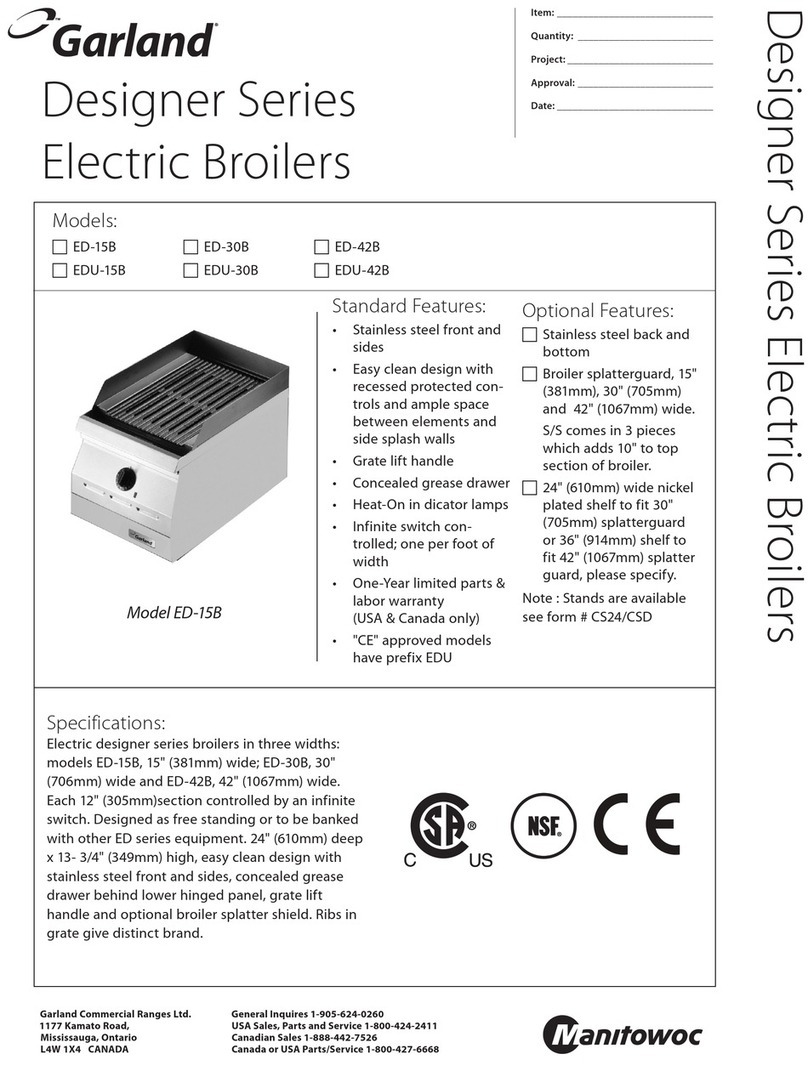

Garland

Garland ED-15B Information sheet

SERV-WARE

SERV-WARE SGSB-36 Service, installation and care manual

ITW Food Equipment Group

ITW Food Equipment Group Vulcan VACB25 Replacement parts catalog