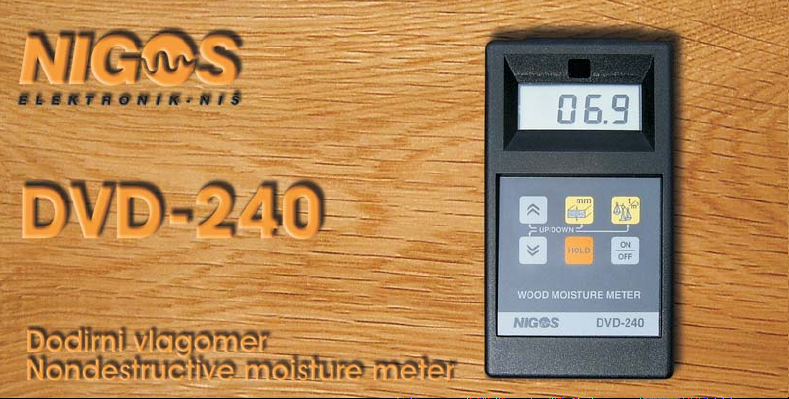

Nigos DVD-240 User manual

1

TABLE OF CONTENTS

1.

2.

3.

4.

5.

5.1

5.2

6.

6.1

6.2

6.3 HOLD

7. MAINTENANCE

8.

8.1 :

QUICK REFERENCE GUIDE

TECHNICAL SPECIFICATION

DESCRIPTION OF MOISTURE METER

TURNING METER ON / OFF AND AUTOCALIBRATION PROCEDURE

DEVICE SET-UP AND ADJUSTMENT FOR MEASUREMENT

9.1 Air temperature and relative humidity measurement procedure

WOOD DENSITY (TYPE) parameter setting

WOOD THICKNESS parameter setting

WOOD MOISTURE CONTENT MEASUREMENT

Timber MC measurement procedure

Veneer MC measurement procedure

function

AND BATTERY REPLACEMENT

APPENDIX

Appendix 1 Additional information regarding wood density and wood moisture content

8.2 Appendix 2: Wood density table

9. AIR TEMPERATURE AND RELATIVE HUMIDITY MEASUREMENT (OPTIONAL)

................................................................................................................... 2

................................................................................................................. 5

...................................................................................................... 6

.......................................................... 8

........................................................................ 10

................................................................................ 10

...................................................................................... 12

....................................................................................... 14

..................................................................................... 16

..................................................................................... 17

........................................................................................................................ 18

............................................................................................ 19

.......................................................................................................................................... 20

.... 20

............................................................................................. 21

................................................ 24

............................................ 25

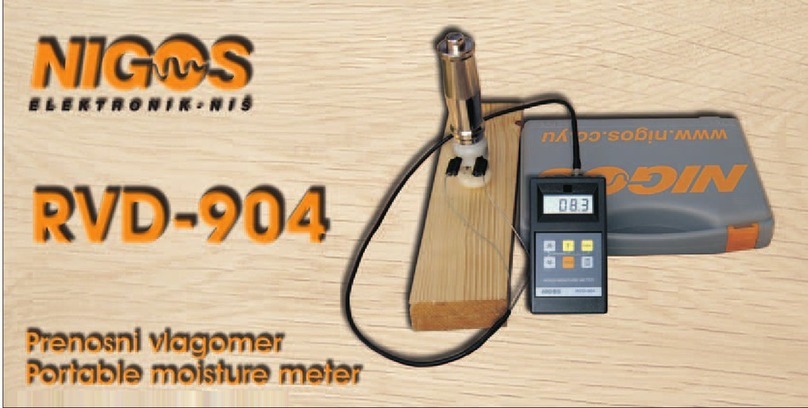

DVD-240

DVD-240

2

1. Turning the meter ON

- Press the button briefly (back side untouched)

- Wait for autocalibration process to end and()

kal

to be displayed

0)0

1. QUICK REFERENCE GUIDE

0ff

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

kal

ON

OFF

ON

OFF

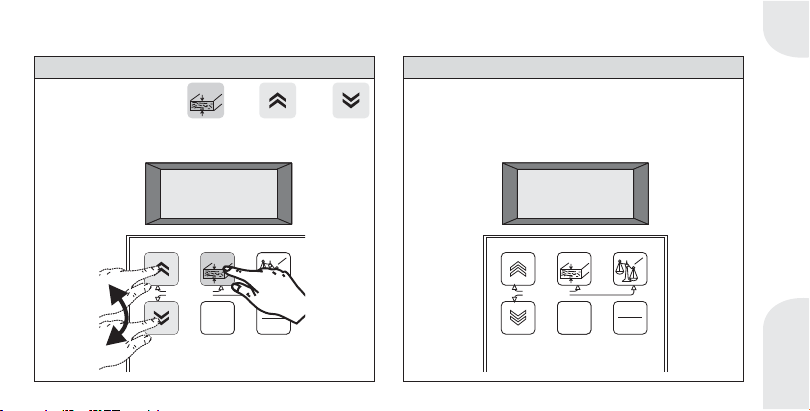

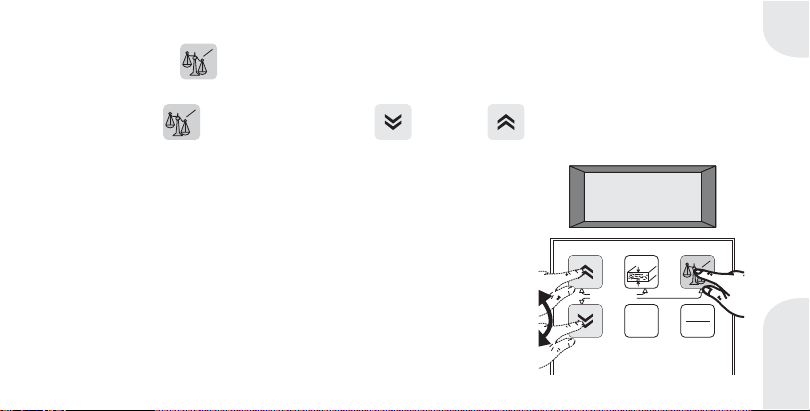

2. Wood density adjustment

- Press and hold button

to adjust timber density (given in t/ )m

3

t

m

3

; use and

)64

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

)64

t

m

3

DVD-240

3

3. Wood thickness adjustment 4. Measurement - moisture content reading

- Gently press the back side of the meter on the flat

and smooth surface of wood sample "along fibers"

- Read the measured value on display (in %MC)

- Repeat the measurement in several points

- Press and hold button ; use and

to adjust wood thickness (given in mm)

mm

2#0

HOLD

ON

OFF

UP/DOWN

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

2#0

mm

)64

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

1%1

HOLD

DVD-240

4

5. Measurement - option HOLD

-

If needed, press briefly button to hold the

measured value displayed for later reading

- Press same button again to continue measuring

-

Press the button briefly

0ff

HOLD

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

0ff

ON

OFF

ON

OFF

6. Turning the meter OFF

HOLD

)64

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

&1

HOLD

DVD-240

2$0

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

DVD-240

5

2. TECHNICAL SPECIFICATION

GENERAL CHARACTERISTICS

Power supply

Operating conditions

Storage

Device dimensions W H

Sensor dimensions (W x H)

Weight

Display

(xxD)

9 V battery, Alkaline or NiCd Aku.

LCD, digital

80 x 140 x 40 (mm)

(mm)

T:550C;RH:590%

0

¸¸

¸¸T:-40 85 C;RH:5 90%

()

(42 x 78)

210 g

0

MEASUREMENT

Measurement resolution

Wood MC measurement range

Wood thickness range

Wood density range

0.1 %

(0.5 40) (mm)

(

(0 100) (%)

0.30 1.10) (t/m )

¸

¸

¸

3

OPEN

DVD-240

2$0

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

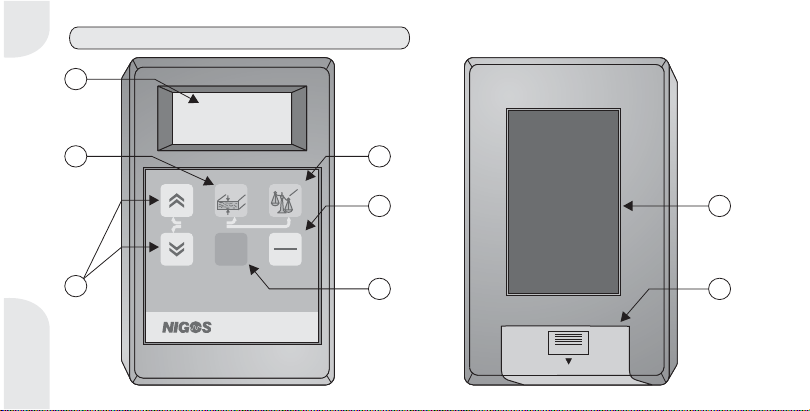

3. DESCRIPTION OF MOISTURE METER

1

4

5

68

7

6

DVD-240

2

3

7

Wood moisture content meter is made for

quick reading of wood moisture by simple pressing

on flat wooden surface.

There is a specially designed sensor plate on the

back side of the meter which measures wood MC

when pressed on the wood surface.

In order to achieve accurate measuring data using

this meter it is required to perform certain procedures

before measurement such as autocalibration and

basic parameter adjustments. Following chapters of

this manual will contain more information th

procedures.

DVD-240

Device is placed in the plastic case with large display

for indication of all measurement data and flat

keyboard for device control.

about ese

DVD-240 FRONT SIDE LAYOUT

LCD DISPLAY

WOOD THICKNESS

UP DOWN

WOOD DENSITY

ON / OFF

HOLD

DVD-240 BACK SIDE LAYOUT

SENSOR PLATE

1. displays:

- Measured moisture content

- Parameter values during set-up

- State and error massages

2. button

3. Buttons and used for increase or

decrease of value of selected parameter

4. button

5. Power button

6. button

7. measures moisture content when

pressed against smooth wood surface

8. Battery compartment

DVD-240

ON

OFF

8

4. TURNING METER ON / OFF AND AUTOCALIBRATION PROCEDURE

Turning the meter ON

It is essentially important to ensure that meter during autocalibration has

such position that sensor plate hangs free in the air, i.e. there is nothing

behind sensor plate blocking it! Do not hold fingers or other objects behind

sensor plate during autocalibration. Existence of any object near sensor

plate during autocalibration procedure can corrupt this process and result

in inaccurate measurement and measuring errors.

is performed with brief pressing on the button . Meter will perform certain additional

functions immediately after powering on. When the button is pressed, message

After a few seconds, when autocalibration procedure is finished, meter will

display: ,

kal

0)0

is displayed for few seconds.

During this time, meter is performing procedure, i.e. series of test-measurements

required for its adaptation to current operating conditions (ambient temperature, air humidity, etc).

which signals that it is ready for measurement or other adjustments.

Autocalibration procedure is performed each time the meter is powered ON,

which ensures reliability of measurement in all declared conditions.

DVD-240 AUTOCALIBRATION

0ff

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

kal

ON

OFF

DVD-240

9

ON

OFF

Turning meter OFF is performed with short pressing on the button .

Display will shortly display message

.

0ff

after which it will turn off.

When it is turned off, the meter does not consume energy from the

battery

If there is any doubt in measuring accuracy and possible error in autocalibration as a cause of false

measurement, autocalibration should be repeated by simple turning off and turning on the meter again.

Meter can detect large calibration errors itself. In this situation, after removing all objects away from back side

of the meter (so it "measures air"), message is displayed.

Ler

0ff

HOLD

ON

OFF

UP/DOWN

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

0ff

ON

OFF

DVD-240

10

5. DEVICE SET-UP AND ADJUSTMENT FOR MEASUREMENT

Correctly performed autocalibration upon powering the meter ON is not enough for accurate measurement.

It is required to set up the meter for specific type (i.e.. density) of timber as well as appropriate thickness of wooden

sample (board or veneer). This step during device set-up must not be forgotten because measured value greatly

depends on this parameter setting.

Once the parameters are set-up, they remain memorized and ready for use for next measurements (if the same

type of timber is tested), but parameter checking is suggested before each use.

Information regarding type of wood for MC measurement is given via for that type of wood.

That is why it is required to determine wood density in as precisely as possible. Wood density is most

commonly given as a table data for specific wood type (specie) when it is absolutely dry (with 0% MC).

Data regarding wood density of specific wood specie can be found in appendix of this manual, but other

reliable sources can be used.

Nondestructive portable moisture meter supports selection of WOOD DENSITY in range to

.

5.1 WOOD DENSITY (TYPE) parameter setting

WOOD DENSITY

DVD-240 0.30

1.10

t/

t/

t/

also

m

m

m

3

3

3

DVD-240

- ;

Press and hold button ( ). Device will display density value (in ) which was last enteredWOOD DENSITY

t/m

3

-

Holding the button pressed, press the buttons ( ) or ( ) to adjust desired value for

density. Long pressing on these buttons will provoke faster change of

parameter in desired direction;

- Release all buttons. After this, device will again display currently measured

wood moisture content.

DOWN UP

t

m

3

t

m

3

)64

HOLD

ON

OFF

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

)53

t

m

3

11

Wood density adjustment is performed in following way:

DVD-240

mm

mm

2#0

HOLD

HOLD

ON

OFF

UP/DOWN

UP/DOWN

mm

t

m

3

WOOD MOISTURE METER

3)0

mm

12

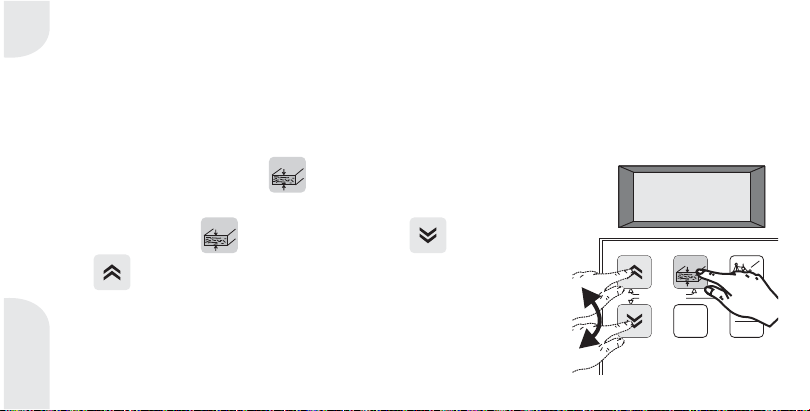

Second essential parameter for correct moisture content measurement is thickness of the wooden sample.

Measured MC value greatly depends on this parameter (especially when thinner samples are used - thinner than

15 mm), so it is required to determine the thickness as precise as possible. Value is entered in and in range

to .

5.2 WOOD THICKNESS parameter setting

mm

0.5 40 mm

- Press and hold pressed button ( ). Device will display

value (in mm) which was entered during last parameter set-up;

WOOD THICKNESS

- Keeping the button pressed, press the buttons ( )

or ( ) to adjust desired value.

DOWN

UP

Long pressing on these

buttons will provoke faster change of parameter in desired direction;

- Release all buttons. After this, device will again display currently measured

wood moisture content.

Thickness parameter setting is performed similar to wood density (type) parameter setting:

DVD-240

13

After these procedures, all needed parameters are loaded in meter's memory.

Once entered, these parameters remain stored in the memory and they are active until next adjustment.

In case there is no need to change these parameters frequently, it is enough just to check these values

before each measurement and proceed with measurement immediately.

DVD-240

14

6.

WOOD MOISTURE CONTENT MEASUREMENT

Wood moisture content measurement is main purpose f this device. Moisture content value is given in

percentage (%) and displayed on LC display.

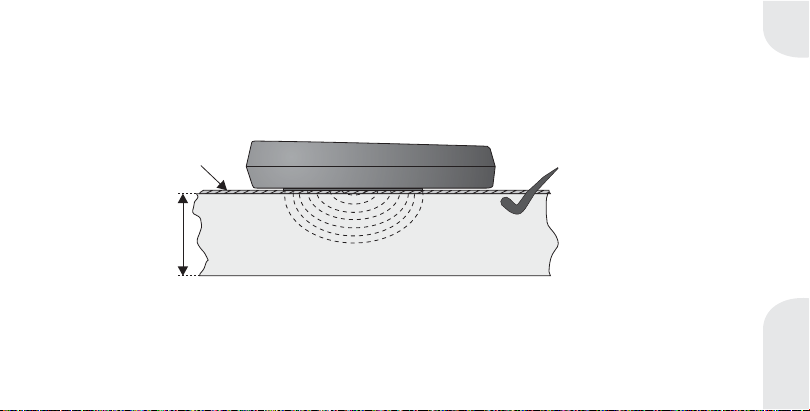

Measurement process is very simple and comes to proper placing

of the meter on the surface of wooden sample and reading of displayed value.

P

-

o

(aside previously described adjustment)

roper placing of the meter on the surface of wooden sample means following:

longer side of sensor plate must be parallel to wood fibers

- wooden sample must be wider than sensor plate and entire surface of sensor plate must be laid on

wooden sample

OPEN

OPEN

DVD-240

15

Complete measurement procedure is performed in following way:

- Before the start of measurement turn the meter ON. Pay attention to autocalibration process which is performed

automatically immediately after powering the meter (chapter 4);

- Check parameter settings for and and correct the values if needed;

- Position the meter on the wooden sample (back side turned to sample), check if it is placed properly, gently press

the meter and take a reading.

It is recommended to take a reading in several points (if conditions allow it) to achieve best possible knowledge

of actual moisture content and its distribution throughout entire wooden sample.

After wood moisture content measurement is finished, turn the meter OFF in order to preserve battery.

WOOD DENSITY WOOD THICKNESS

DVD-240

16

-

-

6.1 Timber MC measurement procedure

For accurate MC measurement in timber boards following must be payed attention to:

Moisture distribution along depth of the board should be uniform (board surface must not be dried due to

exposure to direct sun light or during extensive drying. If necessary, cut the sample in half.

Place the board (sample) on wooden bars to avoid the influence of the ground on the measurement. Thick

piece of polystyrene (styropor) can be used instead of bars.

>50mm

DVD-240

17

Veneer MC measurement is very specific, so it is required to perform following preparation for accurate reading.

- Precisely determine sample thickness, because thickness parameter has great influence for thin samples.

- Place veneer sample on expanded polystyrene layer at least 50 mm thick (polystyrene does not influence

measuring!).

- Powering ON should be performed while meter is placed on the polystyrene layer (without veneer sample

beneath meter). Remove hands aside and avoid moving near the meter during autocalibration procedure.

- It is easure MC of multiple veneer layers (at least 3) with adequate thickness selection.

- In case veneer is already stacked, set the thickness to 40 mm (best is to avoid this kind of measurement).

6.2 Veneer MC measurement procedure

NOTES:

more accurate to m

>50mm

Polystyrene

Veneer

DVD-240

HOLD

HOLD

18

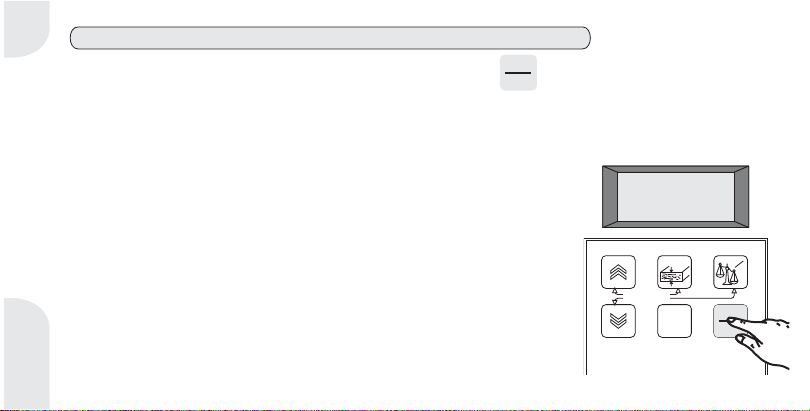

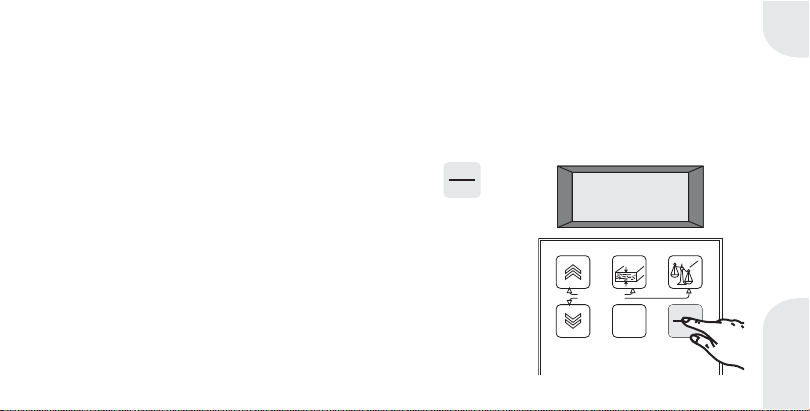

6.3

HOLD

function

HOLDFunction is very useful in cases where timber sample is partially unaccessible, so it is impossible to see the

display directly, but it is possible to reach the sample with the meter.

During measurement, after the meter is positioned properly and measurement conditions are stable, press

button. Meter will now freeze the measured value on the display, so it is readable even after the meter is

removed from the wooden sample.

Turning the "frozen" display OFF is performed in the same way like turning ON, with the press of the button .

DVD-240

7. MAINTENANCE AND BATTERY REPLACEMENT

Portable meter has plastic housing which under normal exploitation conditions provide necessary

mechanical firmness and protection. Rough manipulation, hitting and exposing the meter to extreme conditions

(high temperature, high humidity, offensive chemicals, high mechanical tensions, etc) should be avoided.

Do not open the device and perform unauthorized service because it can damage device and corrupt

measuring accuracy.

Do not place stickers or other materials on sensor plate because it will corrupt measuring accuracy.

Device is supplied by one standard 9V alkaline battery. It is placed inside the housing in separate battery com-

partment which can be accessed from the back side of device. When low battery is detected, "LO BAT" symbol

is displayed in upper left corner of the LC display.

Empty battery should be replaced with new one, same type.

DVD-240

19

kal

mm

t

m

3

1^9

LO BAT

DVD-240

OPEN

Table of contents

Other Nigos Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Spirax Sarco

Spirax Sarco MTI10 Insertion Installation and maintenance instructions

ANDERSON-NEGELE

ANDERSON-NEGELE IZMSA operating manual

Leupold

Leupold GX-3 operating instructions

SPL-Laboratory

SPL-Laboratory Race Meter 2018 user manual

LaserLiner

LaserLiner PowerBright-Laser PBL P5 operating instructions

Drawell

Drawell DW-DI1500 user manual