Nigos DVD-241 User manual

ON

OFF

PAR

BAT) 96%

‘ ‘ ‘

12

4

-

- Device will turn off automatically after selected

idle time

To turn the meter off, press the button

6. Turning the meter OFF

2

1. Turning the meter ON

- Press the button briefly to turn it on

- Model of the meter and battery status is shown

- After autocalibration is completed, device starts

to display measured MC (in %)

1. QUICK REFERENCE GUIDE

ON

OFF

PAR

MC 00% .

‘ ‘ ‘

ON

OFF

PAR

MC 118% .

‘ ‘ ‘ ‘ ‘

ON

OFF

PAR

MC 00% .

‘ ‘ ‘ ‘

ON

OFF

PAR

2. Wood density adjustment

- Press once the button (see image) briefly

-

density (given in t/ )

Use buttons and to adjust wood

3

m

ON

OFF

PAR

065 t/m3.

‘ ‘ ‘

ON

OFF

ON

OFF

ON

OFF

ON

OFF

PAR

5. Measurement - ALARM function

- In case that measured MC is higher than certain

setpoint, alarm will be triggered

- Device will inform the user with sound alarm and

blinking display that measured MC is too high

5

2. DVD-241/DVD-340/MCD-50TECHNICAL SPECIFICATION OF MOISTURE METERS

GENERAL CHARACTERISTICS

3. DESCRIPTION OF MOISTURE METER

DVD-241/MCD-50/DVD-340 DVD-241/MCD-50 DVD-340

67

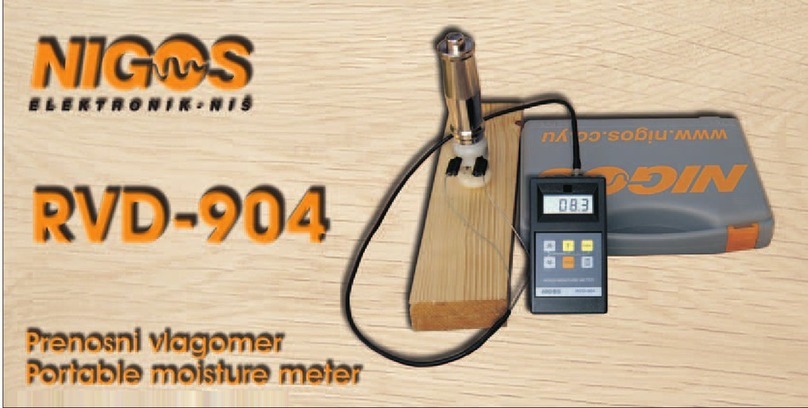

Contact MC meters DVD-241, DVD-340 and MCD-50

are made for quick reading of wood moisture by simple

pressing on flat wooden surface (nondestructive).

There is specially designed contact plate on back side

of DVD-241 and MCD-50 that the meter use to read MC

in the sample when it is pressed against it. DVD-340 use

three contact plates at the front part for this purpose.

- DVD-241 is suitable for fast checking of MC in stack

- DVD-340 is suitable for hard to access samples and

small dimension samples

- MCD-50 is suitable for on-field MC check in rough

samples. It is least sensitive to surface moisture.

Although MC meters measure full range of moisture

content (0-100%), only MC up to 30% is considered

to be accurate.

MC values above 30% are approximate and only show

that wood sample is wet (contains free water).

DEVICE

1. L:

- Measured moisture content

- Parameter values during set-up

- Messages for user

2. Buttons UP and DOWN are used for increase

or decrease of value of selected parameter

3. Button PAR is used for parameter selection

4. Power ON / OFF button

DEVICE BACK SIDE LAYOUT

5/6. CONTACT PLATE measures moisture

content when pressed against smooth

wood surface

7. Battery compartment

FRONT SIDE LAYOUT

CD DISPLAY displays

8

4. TURNING METER ON / OFF AND AUTOCALIBRATION

9

Turning meter OFF is performed with short pressing on the button .

.

Device will turn off automatically after selected idle time.

When it is turned off, the meter does not consume energy from the

battery

Autocalibration procedure is performed each time the meter is powered ON, which ensures reliability

of measurement in all declared conditions.

If there is any doubt in either measuring accuracy or possible error in autocalibration as a cause of false

measurement, autocalibration should be repeated by simple turning off and turning on the meter again.

10

5. DEVICE SET-UP AND ADJUSTMENT FOR MEASUREMENT

5.1

Information regarding type of wood for MC measurement is given via WOOD DENSITY for that type of

wood. That is why it is required to determine wood density in t/ as precisely as possible. Wood density

is most commonly given as a table data for specific wood type (specie) when it is absolutely dry.

Data regarding wood density of specific wood specie can be found in appendix of this manual, but

other reliable sources can also be used. Portable moisture meters DVD-241, DVD-340 and MCD-50

support selection of WOOD DENSITY in range 0.20 t/ to 1.10 t/ .

- Meter must be in basic measurement mode ( )

- Press the button once (see image)

- Use buttons and to set wood density (in t/ )

- Press the button to advance to next parameter setting

(wood thickness)

WOOD DENSITY parameter setting

3

m

3 3

m m

MC %

3

m

Wood density adjustment is performed in following way:

11

3

3. Wood thickness adjustment 4. Measurement

-

surface of the wood sample

- Read the measured value on display (in %MC)

- Repeat the measurement in several points

Gently press contact plate on the flat, smooth

ON

OFF

PAR

250 mm .

‘ ‘ ‘ ‘ ‘

ON

OFF

PAR

MC 126% .

‘ ‘ ‘ ‘ ‘

ON

OFF

PAR

MC 432% .

‘ ‘ ‘ ‘ ‘

Power supply

Consumption

Continuous operating time

Display

Operating conditions

Storage

Device dimensions (W x H x D)

Sensor dimensions (W x H)

Weight

Battery 9V, alkaline or rechargeable

3mA (DVD-241/340), 6mA (MCD-50)

up to 200h (DVD-241/340), up to 100h (MCD-50)

LCD, digital

60 x 120 x 28 (DVD-241/MCD-50); (60 x 150 x 28 (DVD-340) (mm)

(mm) (DVD-241/MCD-50)

0

T: 5 50 C; RH: 5 ¸ 90%

0

T: - 40 ¸ 85 C; RH: 5 ¸ 90%

( ) )

(48 x 75)

140 g

¸

MEASUREMENT

Measurement resolution

Wood MC measurement range

Wood thickness range

Wood density range

0.1%

( ) (values above 30% should be considered informative!)

(DVD-241/340); (MCD-50) (mm)

(

(DVD-241/340); 0.5% (MCD-50)

(0 ¸ 100) %

2 ¸ 30 10 ¸ 50

3

0.20 ¸ 1.10) (t/m )

-

adjust wood thickness (given in mm)

- Dots in the upper part of display also provide

thickness information (1 dot per each 5mm)

Press again , then use and to

PAR

Turning the meter ON is performed with brief pressing on the button .

will briefly display model and then battery status. During this time, device will automatically perform

It is essentially important to ensure that meter during autocalibration has such position that contact

plate hangs free in the air, i.e. there is nothing behind contact plate blocking it!

Do not hold fingers or other objects behind contact plate during

autocalibration. Existence of any object near contact plate during

autocalibration procedure can corrupt this process and results in

inaccurate measurement and measuring errors.

After a few seconds, when autocalibration procedure is finished, meter

will display: ,

Upon power-up, device

AUTOCALIBRATION procedure, i.e. series of test-measurements required for its adaptation to current

operating conditions (ambient temperature, air humidity, etc).

MC 0.0% which signals that it is ready for measurement

or other adjustments.

ON

OFF

PAR

065 t/m3.

‘ ‘ ‘

PAR

PAR

5.2

Second essential parameter for correct moisture content measurement is thickness of the wooden sample.

Measured MC value greatly depends on this parameter (especially when thin samples are used - thinner

than 15 mm), so it is required to determine the thickness as precise as possible. Value is entered in mm and

in range 2 to 40 mm for meters DVD-241 and DVD-340 while MCD-50 have range from 10 to 50 mm.

Thickness parameter setting is performed similar to wood density parameter setting:

- Press the button again (see image)

- Use buttons and to set wood thickness (in mm)

- Press the button to return to basic measurement mode

(display shows )

After these procedures, all needed parameters are loaded in

meter's memory. Once entered, these parameters remain stored

in the memory and they are active until next adjustment. In case

there is no need to change these parameters frequently, it is

enough just to check these values before each measurement

and proceed with measurement immediately.

WOOD THICKNESS parameter setting

MC %

PAR

PAR

ON

OFF

PAR

250 mm .

‘ ‘ ‘ ‘ ‘

WOOD MOISTURE METER

DVD-241

ON

OFF

PAR

MC 126% .

‘ ‘ ‘ ‘ ‘

1

3

247

TABLE OF CONTENTS

5

6

1

1.

2. TECHNICAL SPECIFICATION OF MOISTURE METERS DVD-241/DVD-340/MCD-50

3. DESCRIPTION OF MOISTURE METER

4. TURNING METER ON / OFF AND AUTOCALIBRATION PROCEDURE

5. DEVICE SET-UP AND ADJUSTMENT FOR MEASUREMENT

5.1 WOOD DENSITY parameter setting

5.2 WOOD THICKNESS parameter setting

5.3 Additional settings

6. WOOD MOISTURE CONTENT MEASUREMENT

6.1 Timber MC measurement procedure

6.2 Veneer MC measurement procedure

7. USER CALIBRATION OF DEVICE AND RESET TO FACTORY CALIBRATION

7.1 Reset to factory calibration

7.2 User calibration of the meter

8. APPENDIX

8.1 Appendix 1: Additional information regarding wood density and wood MC

8.2 Appendix 2: Wood density table

QUICK REFERENCE GUIDE ..............................................................................................................

.............................. 5

................................................................................................. 6

..................................................... 8

................................................................... 10

..................................................................................... 10

................................................................................. 11

............................................................................................................. 12

................................................................................... 13

................................................................................ 15

................................................................................ 16

............................................ 17

............................................................................................... 18

............................................................................................. 19

.................................................................................................................................... 20

.................... 20

....................................................................................... 21

2

24

DVD-241 / DVD-340 / MCD-50

Nondestructive hand held MC meter

NIGOS-elektronik

Borislava Nikolica - Serjoze 12, 18000 Nis, Serbia

Tel/fax: +381 18 / 211-212, 217-468

Internet: http://www.nigos.rs

E-mail: office@nigos.rs

12 13

6. WOOD MOISTURE CONTENT MEASUREMENT

in percentage (%) and displayed on LC display.

Measurement process itself is very simple procedure and comes to (aside previously described adjustment)

proper placing of the meter on the surface of wooden sample and reading of displayed value.

Complete procedure is as follows:

- Turn the meter on before taking the measurement. Wait until autocalibration is finished and meter is ready

(see chapter 4).

- Check the value of parameters that are adjustable (THICKNESS and DENSITY) and if necessary change

their values to correct ones

- Place contact plates on wood sample and ensure proper position, gently press the device against the

sample and read the measured value

It is recommended to check moisture of the sample at several points in case that conditions allow it in

order to achieve better information about moisture content and its distribution in the wooden sample.

Turn the meter off after use in order to preserve battery.

Wood moisture content measurement is main purpose of this device. Moisture content value (MC) is given

14

16

18

15

17

19

20

8. APPENDIX

8.1 Appendix 1: Additional information regarding wood density and wood moisture content

Wood density is given for wood specie (type) in absolutely dry condition and is expressed in t/ or

g/c . It is calculated as weight of absolutely dry wooden sample divided by its volume.

This density is often given as constant value for specific wood type from specific climate and it

represents important data for wood moisture content measurement.

Wood moisture content for a given sample of wood is defined as the weight of water in wood expressed

as a percentage of the weight of wood fibrous material (which is the weight of the absolutely dry

sample). The moisture content is calculated by the following equation:

u (%) = (m - m ) / m x100

o o

u

where:

u (%) - equals wood moisture content (MC)

m - equals weight of wet sample

u

m - equals weight of absolutely dry sample

o

i.e., wood moisture content (MC) in wooden sample equals weight of existent moisture content in

sample divided with weight of absolutely dry (same) sample and multiplied by 100.

3

m

3

m

21

8.2 Appendix 2: Wood density table

22 23

6.1

For accurate MC measurement in timber boards the attention must be payed to:

- Moisture distribution along depth of the board should be uniform (board surface must not be overdried

due to exposure to direct sun light or during extensive drying. If necessary, cut the sample in half.

- Place the board (sample) on wooden bars to avoid the influence of the ground on the measurement. Thick

piece of polystyrene (styropor) can be used instead of bars.

Timber MC measurement procedure

> 50 mm

6.2

Veneer MC measurement is very specific, so it is required to perform following preparation:

- Precisely determine sample thickness. Thickness parameter has great influence for thin samples.

- Place veneer sample on expanded polystyrene layer at least 50 mm thick (polystyrene does not

influence measurement!).

NOTES:

- Use only models DVD-241 and DVD-340 to measure MC in veneer.

- Model MCD-50 is not suitable for veneer MC measurement!

- It is more accurate to measure MC of multiple veneer layers (at least 3) while setting total thickness.

- In case veneer is already stacked, set the thickness to 40 mm (best avoid this kind of measurement)

Veneer MC measurement procedure

> 50 mm

Polystyrene

Veneer

5.3 Additional settings

There are several additional settings which are available at separate menu. To access this menu, device

must be in basic measurement mode. Press and hold button and then briefly press button

(see image). Use button to list the items in menu and buttons and to adjust the value

of selected parameter. Battery status is shown first ( ) followed by measured temperature

( ). These are informational data which can not be changed.

Following parameters are changeable:

- Value of moisture content that will trigger ( ). Sound

signal and blinking of the display will warn the user that MC is too high.

It provides easy detection the sample that has MC significantly above others.

Alarm function is turned OFF when value of this parameter is set to .

It can be set in range from 4 to 99.9%.

- Turn off time ( ). It is possible to set the value of this

parameter in range 1 to 60 minutes. Device will turn off automatically

if it is idle for the time defined by this parameter.

- Display contrast ( ). In case that device is used in the

field at high or low temperature, readability of the display can be

low so user can adjust the value of this parameter to improve it.

BAT) 96%

T) 25ªC

AL) 30.0%

OFF

TO) 2min

CONTRAST

alarm

PAR

PAR

DVD-241/MCD-50 DVD-340

Proper placing of the meter on the surface of wooden sample means following:

- Longer side of contact plate must be parallel to wood fibers when DVD-241 and MCD-50 are used

- Wooden sample must be wider than contact plate and entire surface of contact plate must be laid on

wooden sample. To check MC in narrow wooden samples, use DVD-340.

- Contact plates of DVD-340 must be perpendicular to wood fibers when DVD-340 is used

MC 126% .

‘‘ ‘ ‘ ‘

7.1 Reset to factory calibration

After entering calibration menu, subsequent pressing on button will lead to next item ( ),

like on image bellow, which marks entering the procedure for calibration reset to factory default.

This procedure should be used in case that readings on the meter are not accurate because a user

performed user calibration earlier. It can be also done in case you are not certain wether user

calibration has been performed or not.

To reset the meter, use buttons and to select

the value ( ) then press button to confirm reset to factor y

default calibration.

C-RESET

OK

ON

OFF

PAR

C-RESET

‘ ‘ ‘

PAR

PAR

ON

OFF

7.2 User calibration of the meter

Next item in the calibration menu is user calibration. Display will show label ( ).

After item is selected, meter must be placed on wood sample with known MC while taking care

that all recommendation for accurate measurement are applied.

Use buttons and to change the values of calibration parameters of . Display will show

for example: (). One second after last press on any button, the meter will switch to display of

measured value, for example: ( ).

Calibration procedure consists of successive change of the parameter

and verification of reading until wanted value is achieved.

Press the button to accept the current calibration value as final.

In case we want to exit further calibration without making any change

of calibration, press the button to exit this procedure.

We emphasize that special attention must be paid when this

procedure is used and that user use it at his own risk!

In case that in any time user suspects that meter is making false

measurement due to user calibration, it is required to reset the device

to factory calibration defaults as described in chapter 7.1.

C-GAIN

C-GAIN

C-GAIN

GAIN)170

CAL) 13.5%

GAIN

ON

OFF

PAR

C-GAIN

‘ ‘ ‘

PAR

7. USER CALIBRATION OF DEVICE AND RESET TO FACTORY CALIBRATION

In case that, for any reason, there is a reason to doubt accuracy of measurement, user can perform

its calibration according at its sole discretion. It is possible to reset the meter to its factory calibration at

any given time.

Main goal of user calibration is that the user himself adjust device reading to match MC of the known wood

sample by changing gain factor (calibration parameter - will be discussed more in chapter 7.2)

CALIBRATION MENU ENTERING:

- Device must be in basic MC measurement mode ( ).

- Press and hold button and then simultaneously press and hold

for 5 seconds button i.e. until display shows software version

(see image).

- Press again button to see the date of software installation.

GAIN

MC 0.0%

ON

OFF

PAR

SW) 223

‘ ‘ ‘

.

‘ ‘ ‘

1

2

PAR

PAR

WOOD SPECIE WOOD SPECIE

min minmax maxaverage average

3

DENSITY (t/m ) 3

DENSITY (t/m )

Abachi (Samba)

Abura

Acacia

Afara, White

Afrormosia

Agathis

Alder

Ash

Atlas

Balau

Balsa

Beech

Beech, Chilean

Bintangor

0.25

0.6

0.45

0.41

0.6

0.49

0.46

0.5

0.35

0.52

0.4

0.7

0.52

0.32

0.66

0.52

0.75

0.6

0.82

0.85

0.88

0.8

0.6

0.55

0.62

0.55

1.0

0.64

0.71

0.8

Birch

Camphorwood

Cedar

Cherry

Chestnut

Cypress

Daru Daru

Durian

Ebony

Elm

Fir, Silver, Douglas

Hickory

Hornbeam

Iroko

0.35

0.5

0.65

0.45

0.65

0.45

0.4

0.65

0.75

0.85

0.2

0.65

0.45

0.60

0.6

0.55

0.45

0.55

0.5

0.4

0.90

0.60

0.85

0.6

0.45

0.7

0.8

0.6

WOOD SPECIE WOOD SPECIE

min minmax maxaverage average

3

DENSITY (t/m ) 3

DENSITY (t/m )

0.31

0.55

0.38

0.36

0.45

0.61

0.57

0.76

0.48

0.56

0.75

0.74

Okume

Olive Tree

Padauk

Palisander

Pear

Perupok

Pine

Pine, White, Yellow

Plum

Poplar

Pulai

Punak

Pyinkado

Ramin

Rosewood

Rubberwood

Seminai

Sequoia

Seraya

Spruce

Teak

Teak, Rhodesian

Ulin

Walnut, African

Walnut, European

Willow, White

Yew

Zebrano

0.4

0.75

0.7

0.7

0.65

0.50

0.45

0.35

0.7

0.4

0.45

0.72

0.82

0.52

0.80

0.55

0.95

0.35

0.50

0.40

0.60

0.8

0.95

0.45

0.65

0.4

0.65

0.65

WOOD SPECIE WOOD SPECIE

min minmax maxaverage average

3

DENSITY (t/m ) 3

DENSITY (t/m )

0.3

0.4

0.45

0.32

0.41

0.48

0.4

0.39

0.64

0.82

0.5

0.56

0.9

0.75

0.63

0.93

Ivory Wood, Pink

Jelutong

Juniper

Kapur

Kekatong

Kempass

Keranji

Keruing

Kranji

Kulim

Larch

Laurel, Chilean

Linden (Lime)

Magnolia

Mahogany, African

Mahogany, Sapelli

Mahogany, White

Mahogany, Philippines

Mango Wood

Maple

Meranti, Dark Red

Meranti, Light Red

Meranti, White

Merawan

Merbau

Niangon

Nyatoh (Balam)

Oak, European

0.8

0.45

0.4

0.75

0.82

0.72

0.80

0.78

0.75

0.78

0.5

0.48

0.45

0.5

0.5

0.65

0.45

0.55

0.55

0.6

0.6

0.54

0.58

0.70

0.85

0.6

0.65

0.65

MAX

HOLD

2

1. KRATKI VODI^ ZA KORI[]ENJE DODIRNOG VLAGOMERA

3

This manual suits for next models

2

Other Nigos Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

KROHNE

KROHNE OPTISONIC 7060 Electrical & mechanical installation manual

Extech Instruments

Extech Instruments LT300 user guide

Buhler

Buhler TC-Standard (+) X2 Installation and operation instructions

Precision Digital Corporation

Precision Digital Corporation PROVU PD6363 instruction manual

Tel-Atomic

Tel-Atomic SMS-102 manual

Stage6

Stage6 S6 instructions