Ningbo DSW PS-372 User manual

Address: Room1121 Linqiao Piazza, Ningbo City,315010, China Tel:+86(574) 27861829 27861849 Fax:+86(574)87264906

Ningbo DSW International Co.,Ltd.

OFF ON

MEMORY

OFF ON

STATUSLED

Test

LED

Alarm

LED

Status

LED

TEST STATUS ALARM

TAMP C NC NO + -

Tamper

Output Relay Output Power

SENSITIVITY

POSONIC PS-372

TEST

Test

Mode

SW

Sensitivity

VR

Tamper

SW

MIC

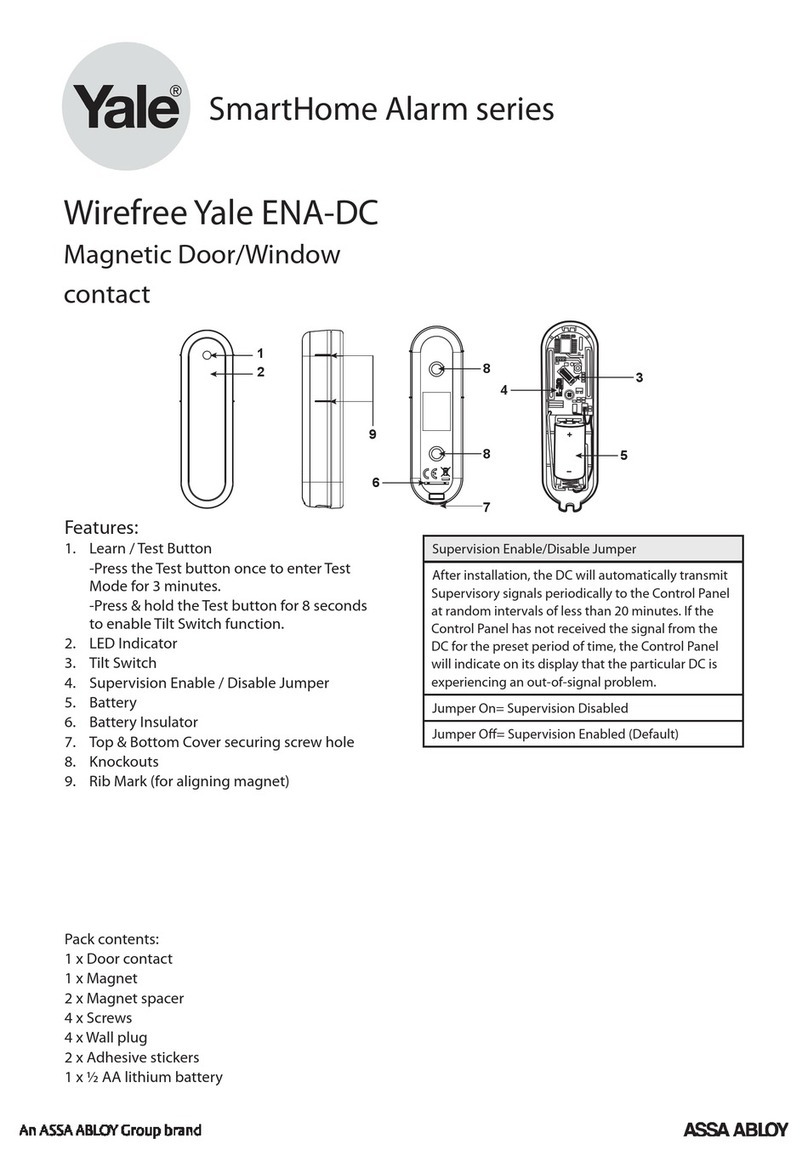

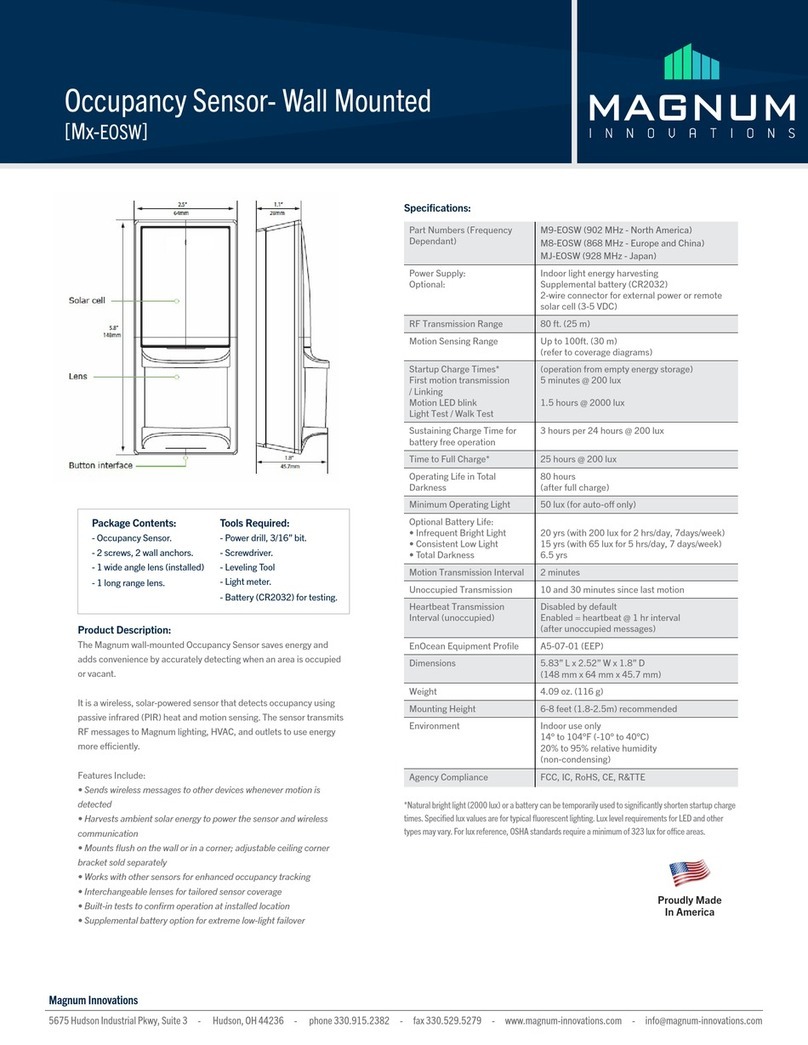

Figure 1

PS-372 Digital Glass Break Detector

Installation Manual

Thank you for selecting the PS-372 glass break detector, which is designed for

professional .security applications, with advanced techniques. Please follow the

instructions m this manual carefully to optimize use of your detector, which has

been 100% quality control tested to ensure proper operation and unit durability.

The PS-372 is a microprocessor-based glass break detector utilizing dual fi-

equency analysis to detect the common sounds of shattering glass and acoustical

shock.when a window is broken. It can analyze the frequency and wave shape of

the sound received by a condenser microphone and compare with the real glass

break data inside .its database and determine whether it is an alarm .signal. The

detector's sensitivity can be set manually so that a good balance point is reached

according to the environment condition. "The alarm LED indicating lamp on the

detector may be programmed for memory or auto reset with a configuration

jumper inside the detector.(See Fig.1). You have got PS-372, the most advanced

glass break detector available on to-day's security market.

The PS-372 will protect 3- 6mm plate glass and 6mm tempered and laminated

glass at a range of up to 8m. In order to achieve the best result, the detector

should be firmly fixed on a surface. Room acoustics will also affect the range of a

glass break detector, It is better that the acoustic environment, such as furniture

layout, during testing is same as the normal situation. It is very important that the

detection range is verified using the PS-373 tester.

1. Driven by software, 8/12 bits microprocessor, controlled DSP(8MHz)

2. High fi'equency and sound pressure detection

3. Digital RF1/EMI filtering, extremely high immunity.

4. Manual sensitivity settings to avoid false alarm.

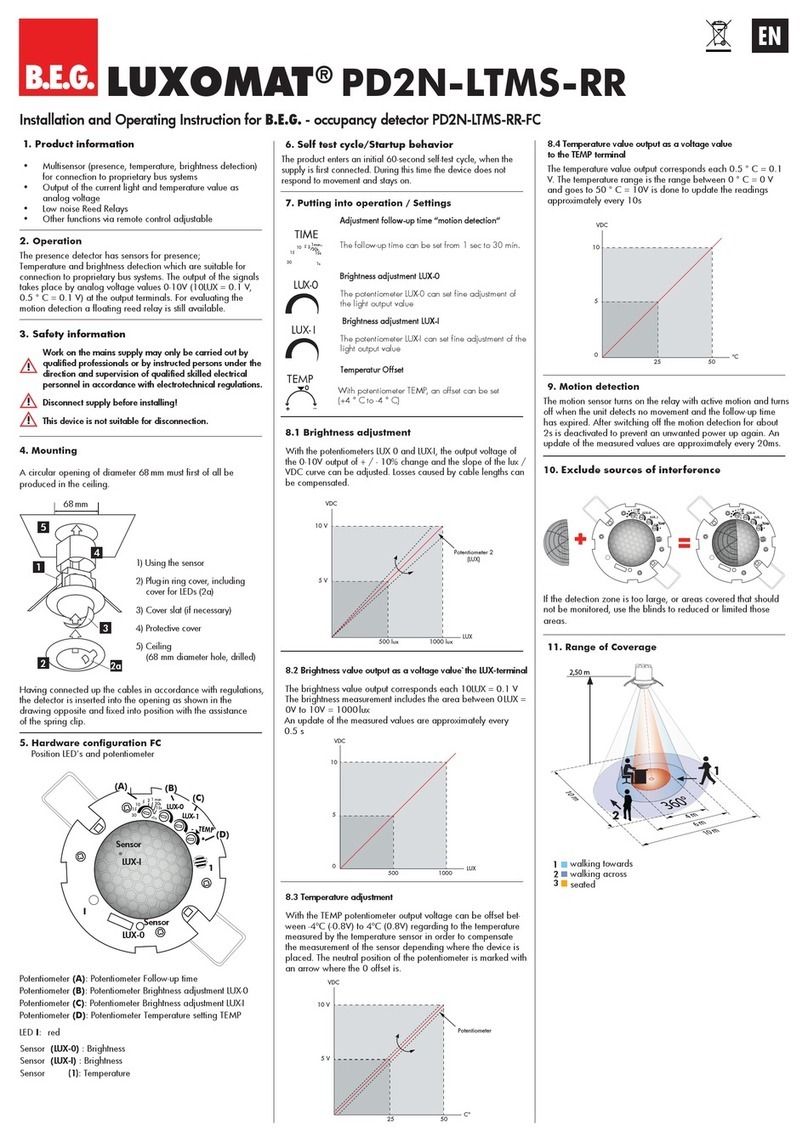

Mount the PS-372 on the ceiling or wall with the most open and direct acoustic path to the protected glass. (See Fig 2 &3). Keep an

open field between the glass break detector and points of entry (no partitions, walls, etc. between the detector and the protected glass.)

While the PS-372 may be mounted on any wall or ceiling, a 40% reduction in range is expected when mounting on the same wall as the

glass. Drapes and window coverings will affect the detection range. USe the PS-373 Glassbreak Simulator behind window coverings to

test properly. Do not mount the detector closer than 1.2m to door bells, air conditioners, air compressors, large fans, steam or air vents,

or any other sources that tend to generate noise interference. If, for any reason, the unit does not enter the Normal mode of operation

immediately following its power up sequence (see STATUS INDICATORS), verify that the TestMode Jumper/Switch is in the OFF

position and reset the device by de-powenng and reapplying power.

1. Remove the cover by pressing the opening pin(l) on the side of the detector.

2. Run the wire through one of the holes at the back or side openings of the case.

3. Connect the terminals.

4. Mount the detector in its location with a screw inserted into screw holes (2) and (3).

5. Setting of sensitivity

6. Replace the cover.

7. Test the detector.

MOUNTING LOCATION

Figure 3 (mounted on wall)Figure 2 (mounted on ceiling)

FEATURES

INTRODUCTION

INSTALLATION

APPLICATIONS

WIRING TERMINATION

-Wiring connection of the terminals is as follows:

TAMP: Connect to 24 hour zone or tamper zone of alarm control panel.

RELAY OUTPUT: NC,C is normal closed output, NO,C is nom3al opened output.

POWER SUPPLY: Connect to DC12V auxiliary output of alarm control panel.

Address: Room1121 Linqiao Piazza, Ningbo City,315010, China Tel:+86(574) 27861829 27861849 Fax:+86(574)87264906

Ningbo DSW International Co.,Ltd.

STATUS LED: ON side of lumper is shorted, tile green status LED is able. OFF side is shorted, the LED is disable. Default setting is ON.

MEMORY: ON side of jumper is shorted, the memory LED is able. The red ALARM LED will be steady ON after alarmed detection until

reset by pressing the TEST switch twice or power off. Default setting is OFF.

Use a screwdriver to turn the sensitivity adjusting VR as shown on Fig 1. Turn clockwise to increase sensitivity. Turn anti-clockx.sise to

reduce sensitivity, Do not set sensitivity any higher than necessary to protect the glass in the detector's range. Setting sensitivity higher

than needed increases the chance of false alarms without increasing protection. A correct setting is that besides enough sensitivity it

will not caused false alarm when you clap your hand near the detector.

When the correct sensitivity is found using the above procedure, determine whether the sensitivity is high enough to trigger the alarm

(red LED ON) by using PS-373 tester. If the Red LED does not come ON, the sensitivity must be increased.

When setting sensitivity make sure that the room's environment is as close as possible to what it will be when the detector is in use. For

instance, it the curtains are usually closed at night when the alam is armed, then set sensitivity with the curtain closed. If a window in

the room is left open, then set the sensitivity with v, indoor, open. The sensitivity should always be retested when the environment of the

room changes, such as when furniture is moved.

For proper testing, use the PS-373 Glass break Simulator. Press the Test Mode Switch of the detector once: the yellow Test Mode LED

will illuminate. Then move to the part of the protected surface furthest from the glass break detector to conduct the test. Press and hold

the "push" switch on the simulator until a full glass break test tone is generated. The detector's red LED should respond to this tone and

light. If the red LED does not respond to the test tone, the sensitivity should be increased(turn VR clockwise). If the detector still

responds to the simulator even the distance between them is further than the protected range, it means the sensitivity is too sensitive

and need to be reduced (turn VR anti-clockwise). Once testing is complete, press the Test Mode Switch again to exit Test Mode: the

yellow Test Mode LED will be extinguished, However, if left in Test Mode, the PS-372 will automatically exit Test Mode 5 minutes later.

Please always check whether the capacity of 9V battery inside simulator is in the enough level for testing.

Normal: Green LED lights, disable by jumper

Alarm: Red LED lights for 3 seconds. If alarm memory is set, red LED will light constantly. To clear alarm memory, press lest Button

twice or cycle power.

Test Mode: Yellow LED light

Low Voltage: Red LED flashing when supply voltage is under 11V

Regular maintenance and inspection (at least annually) by the installer and frequent testing by the user are vital to continuous

satisfactory operation of any alarm system, The installer should assume the responsibility of developing and offering a regular

maintenance program to the user, as well as acquainting the user with the proper operation and limitations of the alarm system and its

component parts. Recommendations must be included for a specific program of frequent testing (at least monthly) to insure the

system's operation at all times.

While this Glass Break Detector is a highly reliable intrusion detection device, it does not offer guaranteed protection against burglary.

Any intrusion detection device is subject to compromise or failure to warn for a variety of reasons. For example: Intruders may gain

access through unprotected openings or have the technical sophistication to bypass an alarm sensor or disconnect an alarm warning

device. This detector cannot operate properly if it is not installed in accordance with the instructions in this installation manual or the

control to which it is connected is not operative (because of lack of power, malfunction, etc.) This detector cannot sense intrusion when

the attack occurs outside of its specified protection range or if its DC electrical power source is off, missing, dead, or insufficiently

filtered. This equipment, like other electrical devices, is subject to component failure. Although this equipment is designed to last as long

as 10 years, the electronic components could fail at any time. The most common cause of an alarm system not functioning when an

intrusion occurs is inadequate maintenance. This device, and the alarm system to which it is connected, should be tested monthly to

make sure all is working properly.

JUMPER SETTING

SENSITIVITY SETTING

TESTING

LED INDICATION

MAINTENANCE

LIMITATIONS OF YOUR GLASS BREAK DETECTOR

SPECIFICATIONS

Model

Sensor

Digital Processor

Coverage Range

Type of glass protected

Sensitivity Adjust

Alarm Output

Alarm Indication

Alarm Duration

Alarm Output Rating

Tamper Output

Power Source

Circuit Protection

Mounting

Operating Temperature

Case

Dimension

Weight

PS-372

Condensed M icrophone

Microprocessor controlled

8 in

All type, rain size 900cm square

Continuously adjustable

N.O. and N.C. contact

Red LED

3 seconds

30VDC 1A

N.C. contact

11.5-16VDC, 24mA

Reverse polarity protected

Ceiling or wall mounted, near to or opposite to the glass

oo

-10 to 50 C

Fire resistance white ABS

51X99X20mm

100g

Table of contents

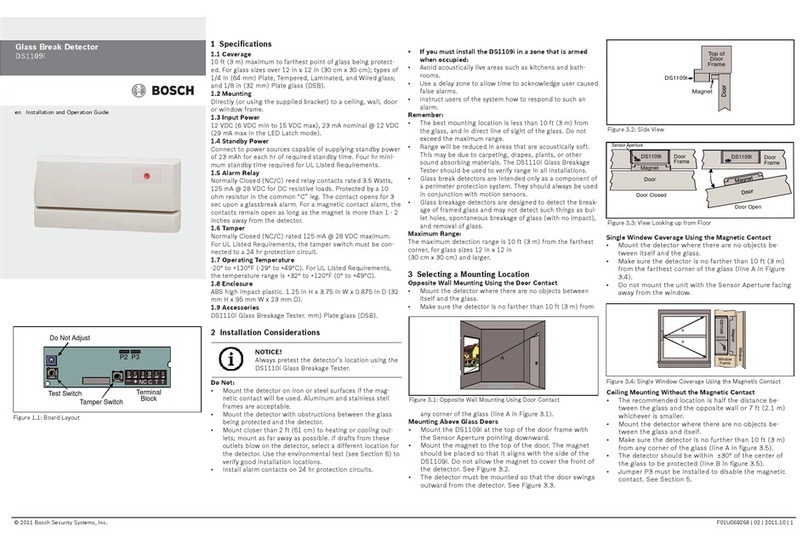

Popular Security Sensor manuals by other brands

Bacharach

Bacharach Tru Pointe 2100 Operation and maintenance guide

Interlogix

Interlogix VE1120 Series Installation sheet

Magnum Innovations

Magnum Innovations M EOSW Series manual

Rehoo

Rehoo NDC-K user manual

Optex

Optex AX-330PLUS installation instructions

Lince

Lince 9528-GOLD-TP-L Programming and operating manual

SICK

SICK Prime KTX-WP91142242 Series manual

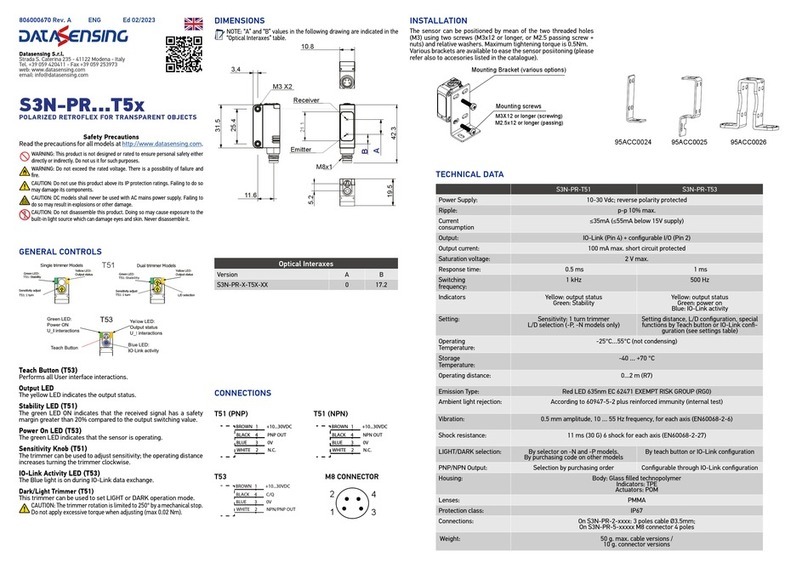

Datasensing

Datasensing S3N-PR T5 Series manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 Additional Installation, Operation and Maintenance Instructions

Niko

Niko SERVODAN user manual

Agilent Technologies

Agilent Technologies 5977C Series operating manual

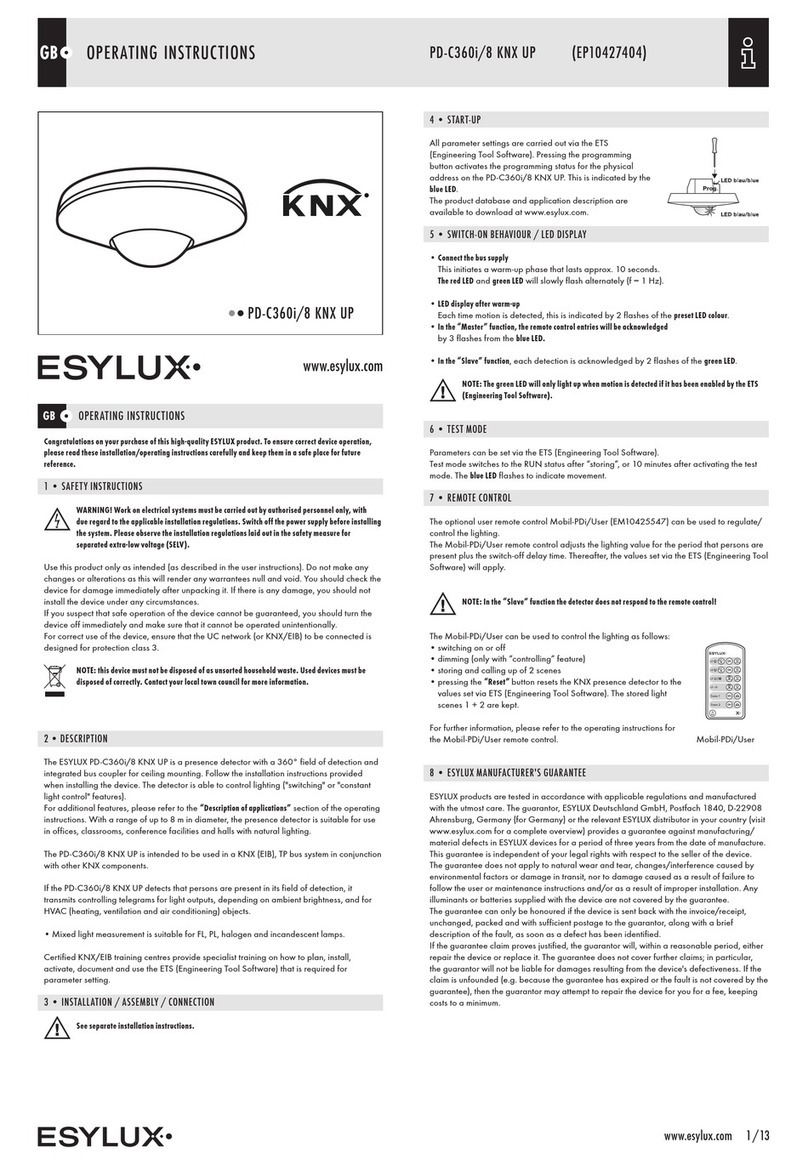

ESYLUX

ESYLUX EP10427404 operating instructions