Nisca PR5350 User manual

DIRECT CARD PRINTER

PR5350

Service Manual

Ver. 1.0

Aug.'05

Contents

Section 1Overview

1.Outline of Equipment

1.Description of Equipment

2.Basic Specifications

2.Mechanical Operation

3.Electrical Operation

1.Electrical Block Diagram

2.Main Circuit Board

3.Interface Board

4.Operation Panel Board

5.Mechanical Actuators

Section 2Setting Up

1.Setting Up

1.Caution for setting up

2.Space for installation

3.Connection to Host Computer

2.To put aENCODER in the printer

1.Procedure to put in

Section 3Operation Panel

1.Overview

2.Description of Operation Panel

3.Internal Modes of Printer.

1.Operation of Service Mode

2.Structure of Service Mode menu

3.Description of Service Mode

4.Structure of Service Mode Menu

Section 4Maintenance

1.Maintenance List

2.Method of Maintenance

1.Cleaning Rubber Roller

2.Applying grease to Pulley Shafts etc.

Section 5Replacement and Adjustment

1.Replacing Main Board

2.Adjustment after Main Board replaced

1.Adjusting the Print Position

2.Adjustment of Print Uniformity

3.Adjustment of Print Density

4.Adjustment of Sensor Level

3.Adjusting density of LCD Display

4.Adjustment for Card Thickness

Section 6Troubleshooting

1.Troubleshooting with the display on the LCD

1.Description for the message on the LCD and meeting of recovery

2.Checking and repairing of the troubles

3.Troubles on communication with PC

2.Errors which can not be checked on the LCD panel

3.Card JAM Locations

Section 7Appendix

1.Harness Connection

2,Electric Parts Layout

3.Parts Guide

Section 1 Overview

1. 1 Outline of Equipment

1.1.1 Description of Equipment

This equipment is a full color card printer to print image, characters and protective

overlay on a plastic card based on the data supplied from personal computer.

Printing method is dye sublimation heat transfer printing for color image and heat

melted ink transfer printing system for characters (black)and protective overlay. With

standard built in Flip Turn Block, both side printing is possible in single operation.

Magnetic encoding is possible on the magnetic stripe of the card by connecting

Magnetic Encoding Unit, which is available as an optional unit. Also, as an option, Heat

Roller Unit is available for printing hologram coating and thicker protective overlay.

1.1.2 Basic Specifications

Printing method Image Area: Dye Diffusion Thermal Transfer

Character Area: Molten Type Thermal Transfer

Protective Layer: Molten Type Thermal Transfer

Printing Media PVC Card (Recommended Card by NISCA)

Size:Conform to JIS X 6301 (ISO standard CR-80)

Thickness:Conform to JIS X 6301(ISO standard CR-80)

Printing

Resolution

300dpi (11.81dots/mm)

Printing

Grayscale

Input:256 grayscale for each colors R,G and B

Output:256 grayscale control for each colors C,M and Y

Printing Size Max. 85.5mm(card longitudinal)

×54mm(card transverse direction)

Printing

Arrangement Area

Max. Entire area

Printing Speed 45seconds per card excluding communication time at the

whole area printed as mentioned above.

Supply method

and capacity

100 cards(card thickness:0.76mm);supplied automatically

Interface SCSI or USB 2.0 (Fixed in factory)

Power supply AC 100~240V 50/60Hz

Power

consumption

120W max.

Equipment

dimensions

421mm(H)×271mm(W)×331mm(D)

(excluding Stack Box)

Equipment weight

13kg:Main body

13.8kg:Including optional magnetic encoder

1.2 Mechanical Operation

This equipment consists of Card Supply Block, Flip Turn Block,

Card Ejection Block, Card Encoding Block and Card Rejection Block.

?

?Card Supply Block

Card Supply Box can contain up to 100 pcs of standard plastic cards(0.76mm

thick)so that a continuous printing of high volume card is possible.

The box is made of a transparent plastic for easy checking of the remaining card

supply and protecting the cards from dust. The card is fed from the bottom of the

pile and automatically transported in the printer. A weight plate is provided to

ensure the positive feeding of cards when the remaining cards becomes low.

Card separation is done by the gate at the entrance, which can be adjusted to

various thickness of cards.

?Card Cleaning Block

There are two rubber rollers with sticky surface to remove dust .One is for front side of a

card and the other is for back side of the card. Since this printer has this feature it is

possible to make printing process faster and clear at dual side printing.

It is necessary to clean them periodically to let them keep this performance.

See section4 for how to clean them.

?Flip Turn Block

Turns the card for both side printing. This block also serves to switch the card

path to Print Block, Eject Block and Reject Block. It is possible to rotate the this

block manually. Never touch the part besides green color part when you need to

rotate this block manually.

?Print Block

The card moves back and forth in the Print Block 5 times to be printed with 3

colors, black and overlay. Print Block consists of Card Transport Module, Print

Head Module and Ribbon Feed Module.

In the Card Transport Module, the card is transported by two pairs of capstan

rollers placed in front and behind platen roller. While printing, the nip release

mechanism works to eliminate the shock of the card entering the printing block and

provide a smooth and clear printing. Each roller is precisely driven by stepping

motor to minimize the color deviation and the side of the card is controlled to limit

skew. A high resolution (300 dpi)thermal head is used in the Print Head Module

for clear and high quality image printing. An even pressure is given to the thermal

print head by two coil spring located at both end of the head to maintain uniform

contact to the card. The thermal head is assembled in one independent unit so that

the replacement is made very easy. Also a user can replace the print head and

ribbon at front side by featuring front access system.

Ribbon Feed Module has Feed Bobbin, Transport Roller, Take-up Bobbin and

driven by each independent torque limiter so that the ribbon can be fed with

constant tension for stable printing. Take up bobbin is driven at two speeds, slow

for printing and high for non-printing, which makes the efficient operation possible.

?Card Encode Block

Magnetic Encode Unit, IC Encode Unit, etc are available for this printer as optional

unit. By mounting the Encode Unit, printing of image and characters, encoding

Magnetic (or IC )data can be processed in one operation in one equipment. As the

Encode Unit can be mounted in the Printer, it does not require additional desk space.

?Card Reject Block

If a trouble occurs while printing, the printer stops automatically. In such case, by

pressing "Clear" key, the card currently being printed will be ejected through

Reject Exit.

?Card Ejection Block

Card Ejection Block has a transparent card stack box. The printed cards are ejected

in this box and stacked (100 cards of standard thickness ).

The box has a cut out for easy removal of the printed cards.

1.3 Electrical operation

1.3.1. Electrical Block Diagram

Operation Thermal

Panel Board Head

Main Circuit Mechanical

Board Actuators

Interface Power Supply

Board Unit

Printer Unit Block Diagram

The Printer Unit is controlled and driven with the following components.

?Main Circuit Board (PBA-MAIN)

Receives commands and data from the host through SCSI interface and controls the

operation of the Printer Unit, also controls the thermal print head according to the

image data.

?Interface Board (PBA-I/F-SCSI or PBA-IF-USB)

Controls the SCSI or PARALLEL interface.

For SCSI :It has connector and terminator switch for SCSI interface and has

connector for optional units.

For USB : It has a connector for USB interface and has connector for optional

units

?Operation Panel Board (PBA-OPEPANE)

Constituted with LCD, LED, Push Buttons, and controlled by the Main Circuit

Board.

?Power Supply Unit

Supplies DC24V, and DC5V to the Printer Unit and Optional Unit.

?Thermal Head

Supplies head energy for printing the image, characters and OP (over coat).

?Mechanical Actuators

Consists of sensors and the motors to transport the cards.

1.3.2 Main Circuit Board(PBA-MAIN)

There are CPU Block, Memory Block, Actuator Control Block.

Following items are the main components:

?32 bit CPU (IC1)

32 bit single chip micro processor, activated on the clock of 12.5 MHz

?Flash Memory(IC8)

A memory of 4 M bytes for storing the firmware.

It can be downloaded through the SCSI or USB interface.

?SRAM(IC9)

1 M byte memory to be used for cash memory of CPU(IC1).

?EEPROM (IC4)

4K byte memory to record total frame number, number of errors, setting values of

the specific unit, etc.

?Serial interface driver (IC33)

Translated the signal of CPU to RS232C for communication with the built-in encoder

unit.

?SDRAM (IC14)

Memory of 16 M byte which stores the data of RGB +characters for 2 frames.

?DSP (IC3)

Digital Signal Processor works for color changing or enhance of edge of an image.

?Control IC (IC2)

A Gate array to control the printer activated on the clock of 20 MHz.

This IC controls following items by setting from CPU

>To control the transfer of the image data to DRAM and also image rotating function.

>To control the thermal head

>Interface for SCSI or USB 2.0 control IC

>To control the LCD

>To supply driving signals for PM 1-3

>To generate the control signal for DM1

>To control sensors

1.3.3 Interface Board (PBA-I/F)

Interface board applies to SCSI-2 or USB 2.0 standard.

<SCSI 2 type interface board>

There are two "half 50" pin connectors on the interface board. Also, there is a

connector for connecting the optional device.

?Serial interface driver (IC4)

Translates the signal of CPU to RS422 level for the communication with the

attached optional equipment.

?SCSI Controller (IC2)

Operates on the clock frequency (OSC1)of 20MHz and controls SCSI bus.

?SCSI terminator (IC3)

An active terminator IC supporting the SCSI specification, which terminates the

SCSI

bus by the input of the switch (SW2)located on the backside of the printer.

<USB 2.0 type interface board>

There is B type connectors on the interface board. Also, there is a connector for

connecting the optional device.

?Serial interface driver (IC2)

Translates the signal of CPU to RS422 level for the communication with the

attached optional equipment.

?USB controller (IC1)

Controls the interface USB 2.0 bus. (generated by OSC1)

1.3.4 Operation Panel Board (PBA-OPEPANE)

Operation Panel is used to indicate the current status of the Printer to the operator, to

change setting, execute printing, and clearing errors.

?LCD (IC1)

LCD panel of 16 characters * 2 lines. Displays the condition of the printer, setting and

changes of values, error messages, etc.

?LED1 -LED3

Indicate the Printer condition to operator.

?SW1 -SW3

Switches for operator to operate the Printer.

Note: Details of operating the Operation Panel is explained in Section 3,

Operation Panel.

1.3.5 Mechanical Actuators

The Printer Mechanism consists of Sensors and Motors, etc.

<Input mechanisms>

Symbol Component Function

SN1 Optical Sensor

Detection of card empty at Card Supply

Block.

SN2 Optical Sensor

Detection of card position

(Just before Cleaning Roller).

SN3 Optical Sensor

Detection of card position

(Just before Flip Turn Unit).

SN4 Optical Sensor

Detection of card position

(Just before Print Block).

SN5 Optical Sensor

Detection of card position

(to detect the leading edge of a card).

SN6 Optical Sensor

Detection of the home position of Flip Turn

unit.

SN7 Optical Sensor

Detection of the angle of Flip Turn unit.

SN8 Optical Sensor

Detection of length of ribbon fed.

(taking up side)

SN10 Optical Sensor

Detection of mark on the ribbon.

SN11 Optical Sensor

Detection of print head position.

SN12 Optical Sensor

Detection of print head position.

SN13 Micro switch Detection of open/close of Front Cover.

(with interlock function)

SN14 Micro switch Detection of open/close of Top Cover.

(with interlock function)

SN15 Optical Sensor

Detection of card position

(just before encoder )only available when Encoder

set.

SN18 Optical Sensor Detection of length of ribbon fed.

(supply side)

<Output Mechanisms>

Symbol Component Function

DM1 DC Motor Rolls up Ink Ribbon.

Moves (up/down)Thermal Head

PM1 Pulse Motor Drives rotation mechanism in Flip Turn Block.

Transports a card (Card Supply Block)

PM2 Pulse Motor Transports a card (Flip Turn Block)

PM3 Pulse Motor Transports a card (Print Block)

HFAN Fan Motor Cools Thermal Head.

DFAN Fan Motor Cools Power Supply.

Section 2 Setting Up

2. 1 Setting Up

2.1.1 Caution for setting up

Dusty place must be avoided for using this equipment because the printing system of this

printer is especially sensitive to dust. When printing on the card with magnetic stripe, do

not place the printer at near the equipment which is emitting magnetic field.

Other than above, use general caution for setting up other OA equipments and choose

proper place with proper environment. For further details, please read operation manual.

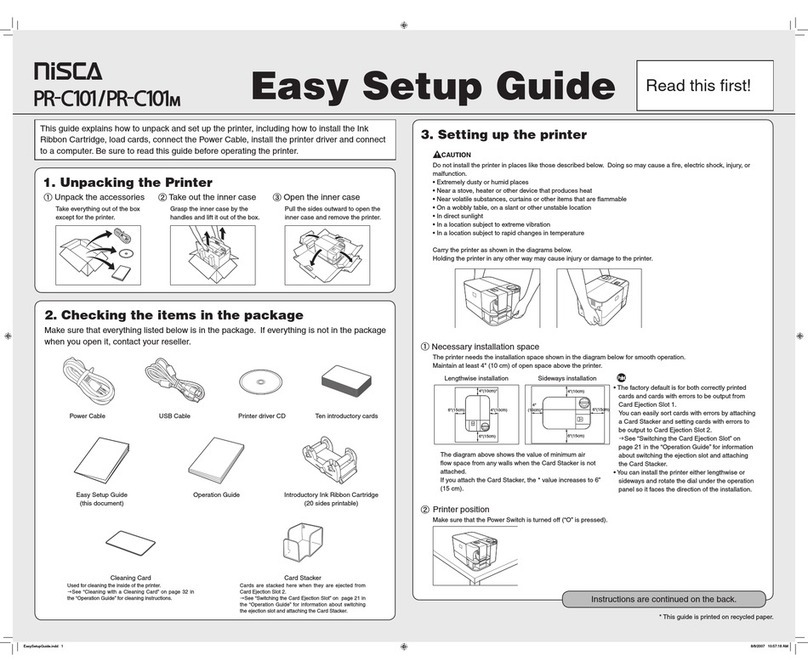

2.1.2 Space for installation

The space for the operation as

shown in the illustration should

be provided.

?At least 50 cm(20 inch)of

clearance should be kept for

the Top Cover.

?Table to place the printer

should be able to hold

minimum 14Kg(31lbs)and

have flat top and 4 rigid legs.

?It should not incline more

than 1?.

2.1.3 Connection to Host Computer with SCSI or USB

<SCSI type interface>

1)Connection of SCSI Cable

Connect the Printer, PC and Peripheral Units with SCSI Cable.

The Printer is equipped with two female connectors of 50 Pins (half type)of SCSI

specification. Use suitable SCSI cable with suitable connectors to match the PC and

Peripheral Units.

Note 1: Total length of the SCSI cable should be within 6 meters.

To ensure stable operation, within 4 meters is recommended.

Note 2: Pleaseuse the SCSI -II specification high impedance cable. In case of daisy

chain connection, operation may become unstable unless all cables are SCSI-II

specification.

Note 3: Turn OFF power switches of the Printer, PC and all units when connecting the

cable. The retaining hook should be securely latched.

Note 4: On the backside of the Printer, OPTION CONNECTOR located next to SCSI

connectors is the connector for the Optional Units of this card printer only.

Do not connect any other unit. It may cause a trouble.

Interface connectors

2)Setting internal SCSI Terminator.

The Printer has Active Terminator for SCSI-I and SCSI-II.

When using the Terminator, turn the switch at the back of the Printer ON (upper side).

(Turn OFF the power switch when operating this.)

To switch on

To switch off

Appearance of Terminator switch

3)Setting SCSI ID Number

The SCSI ID number can be freely selected from 0 to 7 through the operation panel of

the printer.

Default ID setting is 4.

Note 1: Do not set the same ID number as the PC and other peripheral units. (It may

cause a trouble.)

When setting, check the ID numbers of the other units.

Note 2: When setting the ID number, turn OFF the power switches of PC and all other

peripherals.

<USB type interface>

1)Connection of USB Cable

Connect the Printer, PC and Peripheral Units with USB 2.0 Cable.

The Printer is equipped with B type connector

Note 1: Turn OFF power switches of the Printer, PC and all units when connecting the

cable.

Note 2: On the backside of the Printer, OPTION CONNECTOR located next to USB

connector is the connector for the Optional Units of this card printer

only. Do not connect any other unit. It may cause a trouble.

2.2 Installation of the Encoder Unit

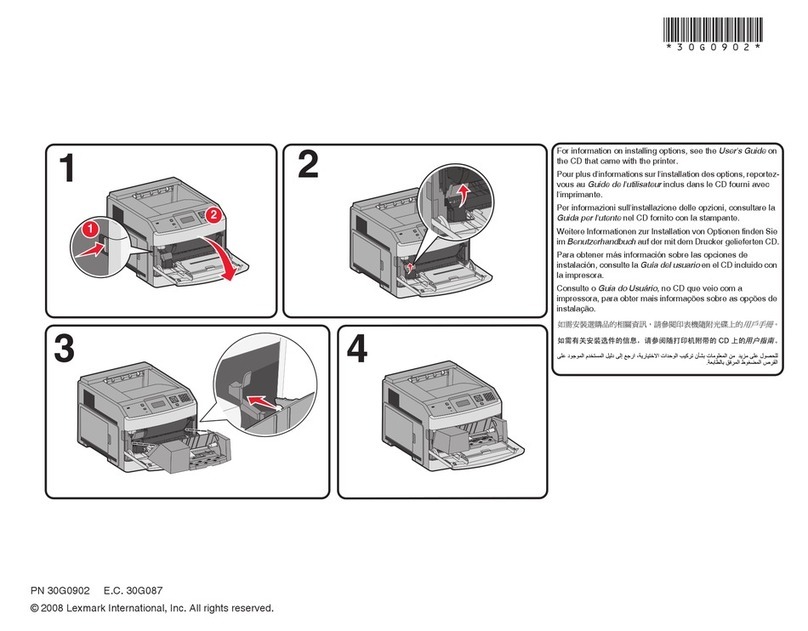

2.2.1 Installing steps

Step 1 Turn OFF the printer power source.

Step 2 Remove RIGHT-COVER. (Remove 2 x M-4 screws )

Step 3 Take the screw off to take out a slide for a card rejected .

Step 4 Insert the ENCODER into the encoder space of the printer with connecting the

two harnesses from the printer.

Step 5 Fix the ENCODR with the screw of which was removed in Step3.

Step 6 Put the small Exsit Cover on the RIGHT-COVER with two screws.

The Exit Cover and two screws are supplied with ENCODER.

Step 7 Put the RIGHT-COVER back to the printer and fix with 2 x M-4 screws

Step 3 Step 4

Step 5 Step 6

Section3OperationPanel

3.1 Overview

Operation panel of PR5300 is used as a communication interface with the operator.

The Operation Panel has functions to display the printer setting such as image memory

mode, ink ribbon selection etc and to check the condition of the printer operation such

as finding the cause of error for trouble shooting, Printer adjustment, checking condition

of operation etc as well as to show the current operating status of the printer.

3.2 Description of Operation Panel

Refer to Section 4 of the Operation Manual of PR5350.

3.3 Internal Modes of Printer

There are three Operation Panel Modes for PR5350 as following

1. Normal mode Display the current operating status, such as error, of the Printer during

the print operation. The Printer is in this mode when the power is

turned ON. Refer to Operation Manual of PR5350 for the actual operation.

2. User mode This mode is used to set the Printer conditions such as setting of

image memory, ink ribbon selection etc. Also, used to show the

information such as the ROM version etc. For the operation refer to

the Operation Manual. In this section of this booklet, print mode only

is explained.

3. Service Adjustment of the Printer, such as the print density etc, is done in this

mode mode. Also, this mode is used for analyzing the cause of troubles such

as checking the condition of sensors and operation of individual

actuators. Details of this mode is described in this section.

3.3.1 OPERATION OF SERVICE MODE

Service mode is the mode for the service person to adjust and check performance of the

printer. The image data in the printer is cleared when switched to and from the service

mode.

Switching to Service Mode

?To switch to service mode,

1. Return from the other mode to Normal Mode.

2. In the idle or error mode, keep the MENU key pressed till it becomes

Command Reception Mode. ("Input Command" appears on the LCD panel)

3. While pressing the MENU key, press EXE and CLEAR keys alternately

(about 8 times )till the display changes from "Input Command" to "Service Mode".

4. Release the MENU key.

?Moving in the Same Directory

To move in the directory, press MENU key to change the menu. MENU will change

in the set order when the key is pressed.

?Execution of a menu

See section 3.3.2 and 3.3.3 for operation of current menu.

?Moving to the Lower Layer Directory

To enter into the directory of the lower layer from the present layer, press EXE key

at the appropriate menu.

?Returning to the Upper Layer Directory

To go one layer higher than the present, switch the menu to "Return to Parent Menu"

and press EXE key.

?Returning to Normal Mode

Switch the menu to "Return to Normal Mode" and press EXE key or switch the

menu to "Return to Parent Menu" and press CLEAR key.

3.3.2 Menu Structure of Service Mode

The Menus of Service Mode are as follows. The part in rectangle will be displayed only

when the referred optional units are connected.

Service Mode SN01 02 03 04 05 ISO Track1

CLR:Back EXE Go EXE:Encode

SN06 07 08 09 10 ISO Track2

EXE:Encode

Adjustment Mode SN11 12 13 14 15 ISO Track3

EXE:sub menu EXE:Encode

Sensor Check SN16 17 18 JIS2

EXE:sub menu EXE:Encode

Actuator Check SN10 Analog Disp Return to Parent

EXE:sub menu Menu (CLR/EXE)

Eject Position Auto Adjustment

EXE:sub menu EXE:Adj Start

User Menu Config Return to Parent IC-R/W Test

EXE:sub menu Menu (CLR/EXE) EXE:Entry/Eject

Encoder Check Return to Parent

EXE:sub menu Menu (CLR/EXE)

IC-R/W Check Stack Position

EXE:sub menu

H.Roller Check Reject Position Heat Total Time

EXE:sub menu

Error Display Select Action Position Adj.

EXE:sub menu

Return to Normal Print Number Position Adj.

Mode (EXE) EXE:Test Print

Card Pass Test Sensor Adj.

EXE:Start (Auto) EXE:Start

Return to Parent Return to Parent

Menu (CLR/EXE) Menu (CLR/EXE)

Ribbon Menu Disp

Error Rate

Adjust Menu Disp Error Log Disp

Status Menu Disp Error Code rate

Return to Parent Error Log Reset

Menu (CLR/EXE)

Return to Parent

Menu (CLR/EXE)

?

?

?

?

?

?

?

?

?

?

Other manuals for PR5350

1

Table of contents

Other Nisca Printer manuals