niu N-GT User manual

V1.0.0

1

N-GT Scooter

Dual batteries + Fast Charger

Service Manual

e13*168/2013*00546*00

Jiangsu Niu Electric Technology Co. Ltd

V1.0.0

2

Foreword

Key points in maintenance of Niu NGT are described in this maintenance manual.

Preparations in the maintenance manual include notes to all operations. Please read the manual

carefully before operating.

Key points in the inspection and adjustment, includingmaintenance methods for scooter safety and

component performance that are applied from regular examinations, are described.

Chapters are edited with disassembly diagrams, system figures and instructions about the

maintenance and failurediagnosis.

Note:

Modifications of scooter version or structure as well as photos, pictures or instructions in the manual

are referred to physical objects without further notice.

Maintenance Information

The maintenance and reparation information contained in this manual is for technical specialists only.

Maintenance or reparation performed by those who are not trained properly and provided with

appropriate tools and equipment may cause injuries to themselves or others and also lead to

damages or unsafe conditions of the scooter.

The proper maintenance and reparation procedures, some of which require special tools and

equipment, are described in this manual. The risks in terms of personal safety and scooter operation

safety, which may be resulted from the use of components, maintenance procedures or tools not

recommended by Niu must be verified.

Please make replacement with original electric components made by Niu or equivalents that have

corresponding part numbers. We strongly recommend you not to use inferior components.

Customer Safety Notice

The proper maintenance is crucial for customer safety and scooter reliability.Any errors or omissions

in scooter maintenance may result in operating malfunctions, scooter damages or injuries.

Improper maintenance or reparation may lead to unsafe conditions under which serious injuries or

even death of your customers or other people may be incurred.

Please carefully follow the procedures and cautions in this manual and other maintenance materials.

Personal Safety Notice

This manual is used only by professional maintenance technicians, and the warning information

about multiple basic workshop safety operation procedures (such as the procedure that requires

gloves when working on hot components) is n=ot set forth herein. We recommend you not to carry

out procedures specified in this manual without readiness if you have not received the workshop

safety trainingor grasped the knowledge about maintenance safety specifications.

The followingare listed as several most importance general notes to maintenance safety. However,

we are unable to set forth the warning for each of risks that may arise from maintenance and

reparation procedures. You have to determine at your discretion whether a detail task should be

implemented.

Failure to properly follow relevant instructions and notes may result in serious injuries or even death.

Please carefully follow procedures and notes in this manual.

V1.0.0

3

Importance Safety Notes

Make sure that you have completely understood basic workshop operation safety procedures and

taken on proper protective clothes and are provided with safety equipment. Extra attention should be

paid to the followingin the implementation of a maintenance task:

•Read all the relevant instructions before operation, and make sure that you have necessary tools,

spare parts, components and skills to implement a maintenance task safely and completely.

•There are high-voltage circuits in the scooter system, which can cause electric shock. It must be

verified that your maintenance site, tools, protective equipment and operation procedures are in

compliance with the insulation requirement.

•Eyes should be protected with proper safety glasses, goggles or masks in operations such as

hammering, drilling, polishing or prying or working around high-pressure air or fluid tanks, springs

or other energy storage components. Eye protection devices should be worn as long as there are

suspicious conditions.

•Other protection devices such as gloves or safety shoes are used where necessary. Gloves should

be worn before handling of a hot or sharp component that may cause serious burns or cuts or

grasping of any things that may cause injuries.

•Measures should be taken to protect you and others once a scooter is lifted. Make sure that the

scooter is always supported stably when being lifted with a crane or jacks. Please use jack mounts.

•The hot motor after driving for a long time may cause burns. Waitfor the motor to cool down

before working on it.

•Moving parts can cause injuries. Make sure that your hands, fingers and clothes are not

obstructive.

•Components must be cleaned with non-flammable solvents instead of the gasoline.

•All components related to a storage battery should be away from cigarettes, sparks and flames.

V1.0.0

4

Contents

Foreword 2

Maintenance Rules and Important notes 5

Cable connector inspection 6

Scooter Identification 7

Specifications 8

Part Names 11

Parts Removal and Installation Procedure 17

Front Wheel 41

Front Fork 43

Steering Handlebar 45

Rear Wheel/ Rear Suspension 47

Brake System 50

Lithium battery/charger 57

BCS and Fast Charger 65

Electrical System

Electronic components 66

Diagnostic Code 110

Regular Maintenance Checklist 130

V1.0.0

5

Maintenance Rules

1. Metric tools should be made as available as possible in the maintenance of the scooter. Use of

improper tools may damage the scooter.

2 Clean off the dirt outside parts or assemblies of the chassis or braking system before guard

removal from the scooter or opening for maintenance.

3 Please clean parts and blow them with an air compressor after removal and before measurement

of the wearing value.

4 Rubber parts that have become aged or deteriorated are very easy to be damaged by the solvent

or oil. They should be checked or replaced if necessary before reassembly.

5. Multiple assemblies should be loosenedin the sequence from outside to inside and beginning with

small ones.

6. Complex assemblies should be stored in a proper installation sequencefor further assembling.

7 Extra attention should be paid to important fitting positions before disassembling. Parts that are no

longer to be used should be replacedbefore disassembly.

8 The bolt or screw length varies with assemblies and guards. Bolts or screws must be installedat

correct positions. A bolt can be placed into a bolt hole for fitness in case of confusion

9 The oil seal should be installed by lubricant applicationinto the oil seal groove, and should be

checked for smoothness, smoothness and damages before installation.

10 The spherical bearings (on the front wheel-hub or rear wheel motor) should be removed by

holding one or two bearing races (the inner and outer races) with tools. The bearing may be

damaged in removal if the force is applied only to one race (the inner or outer race) and thus must be

replaced.

Important notes

1.Please use originalparts made by Niu. Use of components that are not in compliance with design

specificationsby Niu Company may cause damages to the scooter.

2.Maintenance operations can be performed only with metric tools. The metric bolts, nuts and

screws can not be interchanged with British fasteners.

3.The replacement with new washers, O rings, split pins and lock shims should be made for

reassembly.

4.Bolts or nuts should be tightened by beginning with large-diameter bolts or inward bolts and then

gradually tightening to specified torques diagonally, unless otherwise indicated.

5.Clean components that have been removed with the detergent solution.All the sliding faces

should be lubricated before assembling.

6.Check all components for the proper installation and operating after assembly.

7.Remove the dirt and oil stains before measurement. Apply recommended lubricants to sections to

be lubricated during assembly.

8.Apply the lubricant to part surfaces to avoid rusting and dust accumulation, if the engine and

transmission systems need to be stored for a long time after disassembling.

V1.0.0

6

Cable connector inspection

•Loose cables constitute a risk to electric safety. Cables should be checked after their clamping to

ensure electric safety.

•Bending of cable clamps towards welding points is not allowed.

•Cables are bound at designated positions.

•Cable placement at the scooter frame end or a sharp angle is not allowed.

•Cable placement at the bolt or screw end is not allowed.

•Cable placement should be made away from thermal sources or positions where cables may be

stuck in moving.

•The cable placement along stem handles should not be made too tight or loose and should not

interfere with adjacent parts at any steering positions.

•Cables should be placed smoothly without being twisted or tied.

•Verify whether the connector shroud is damaged or the connector is excessively open before

connecting.

•Please protect the cable at a sharp angle or turning position with adhesive tapes or a hose.

•Cables should be bound reliably with adhesive tapes after reparation.

•Controlling cables should not be bent or twisted. The controlling would not be flexible if controlling

cables were damaged.

V1.0.0

7

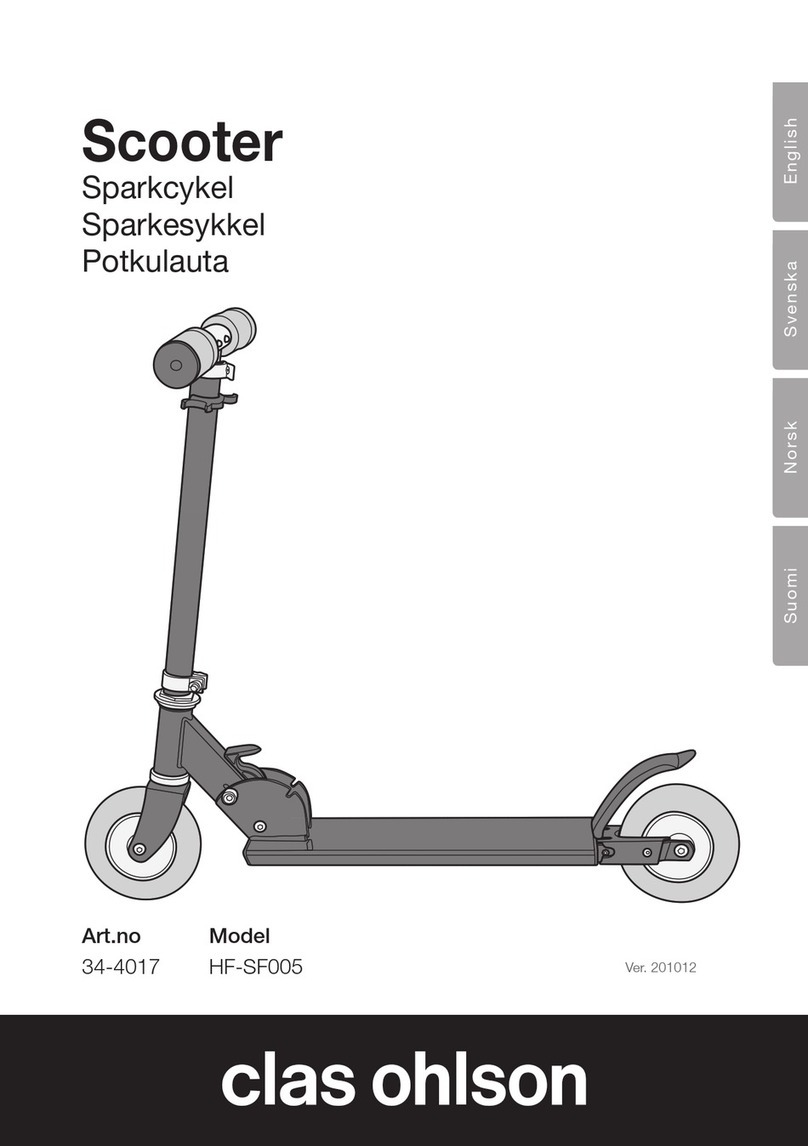

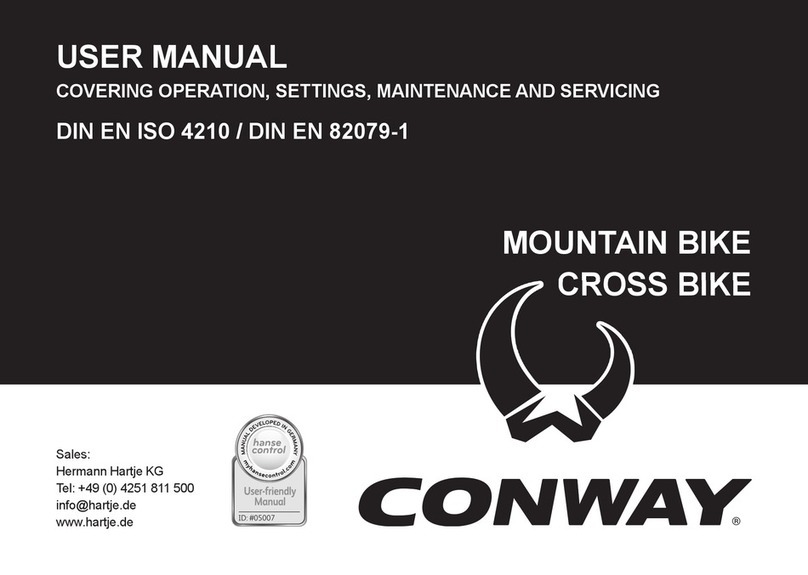

Scooter Identification

•Vehicle serial number (SN) is in the user manual

•The scooter frame identification code (VIN) is made on the rear frame at rear seat cask.

The motor code is made at left side of the wheel-hub motor.

V1.0.0

8

Overall specifications:

EU approval number: e13*168/2013*00546*00

Item Specifications

Dimensions

Length ×width ×height 1815×725×1185 mm

Wheelbase 1290mm

Complete vehicle kerb mass 90Kg

Ground clearance of the

seat cushion 740mm

Ground clearance 140mm

Scooter frame Type of the scooter frame The pedal type made with combined

welding of panels and pipes

Specifications of the front

tire 90/90-12 44J

Type of the front rim MT2.15X12 aluminum alloy

Air pressure of the front tire 200KPa

Specification of the rear tire 120/70-12 56J

Type of the rear wheel MT3.50X12 wheel-hub motor

Air pressure of the rear tire 225KPa

Suspension

Front shock absorber Telescopic type with 31mm dual

hydraulics

Rear shock absorber Telescopic type with dual hydraulic

springs

Brake

Type of the front brake Single sided hydraulic brake with dual

pistons

Type of the rear brake Opposed sided hydraulic brake with

dual pistons

CBS Division of brake force: Front: 30%

Rear: 70%

V1.0.0

9

Specifications of the motor controller system

Item Specifications

Motor

Motor type Brushless permanent-magnet motor

Controller type FOC vector control

Rated voltage DC60V

Rated power 3000W

Maximum motor power 3500W at 639min-1

Maximum motor torque 52N.M at 630min-1

Controller

Rated voltage DC60V

Rated output power 2500W

Maximum input current 70A

Maximum output current 280A

Specifications of the battery/charger

Item Specifications

Propulsion Battery

Type Packed lithium battery

Number of Cells 2*(17*10)=340(2 in parallel)

Rated voltage 60V DC

Rated capacity 2*35Ah

Mass 2*11KG=22KG

Environmental Propulsion

Performance Energy Consumption 35Wh/KM

Electric Range 134KM

Fast Charger Output voltage 35-84V DC

Max Output current 12A

V1.0.0

10

Specifications of the braking system

Item Standard value (mm) Minimum Thickness(mm)

Diameter of the front brake disc φ220mm -

Thickness of the front brake disc 4.0 3.0

Thickness of the front brake pad 4.0 3.0

brake fluid DOT3 or DOT4

Diameter of the rear brake disc φ180mm -

Thickness of the rear brake disc 3.5 2.5

Thickness of the rear brake pad 4.5 3.0

brake fluid DOT3 or DOT4

Specifications of the Lighting/Display/switch

Electric system

Item Specifications

Front headlight 12V LED

Turn signal lamp 12V LED

Rear tail lamp 12V LED

Brake lamp 12V LED

Display 12V LCD display

Central control unit(ECU) 12V

USB charging interface 5V

V1.0.0

11

Part Names

Scooter body

Windshield

Front Neck Cover

Front Panel

Front Fender

Front Left/Right

Panel

Left/RightSide

Panel

Left/RightCentral

Cover

Rear

Fender

Rear

Left/Right

Handrail

Saddle

Front Central

Cover

Rear Central

Cover

Left/Right

Body Panel

Battery Cover

Footrest

Headlight

Tail light

V1.0.0

12

Parts Removal and Installation Procedure

Procedures for removal and installation of scooter body panels are described in this section.

The ignition switch and main switch (if applicable)must be turned to OFF before disconnection or

connection of electric units, when the storage battery has been installed onto the scooter.

Note

•Do not damage scooter body coverages in disassembling/assembling.

•Do not damage hooks and claws on scooter body coverages in disassembling/assembling.

•Align the embedded panels and covers on scooter coverages with their respective grooves.

•Hooks and claws at various sections should be installed properly during assembly.

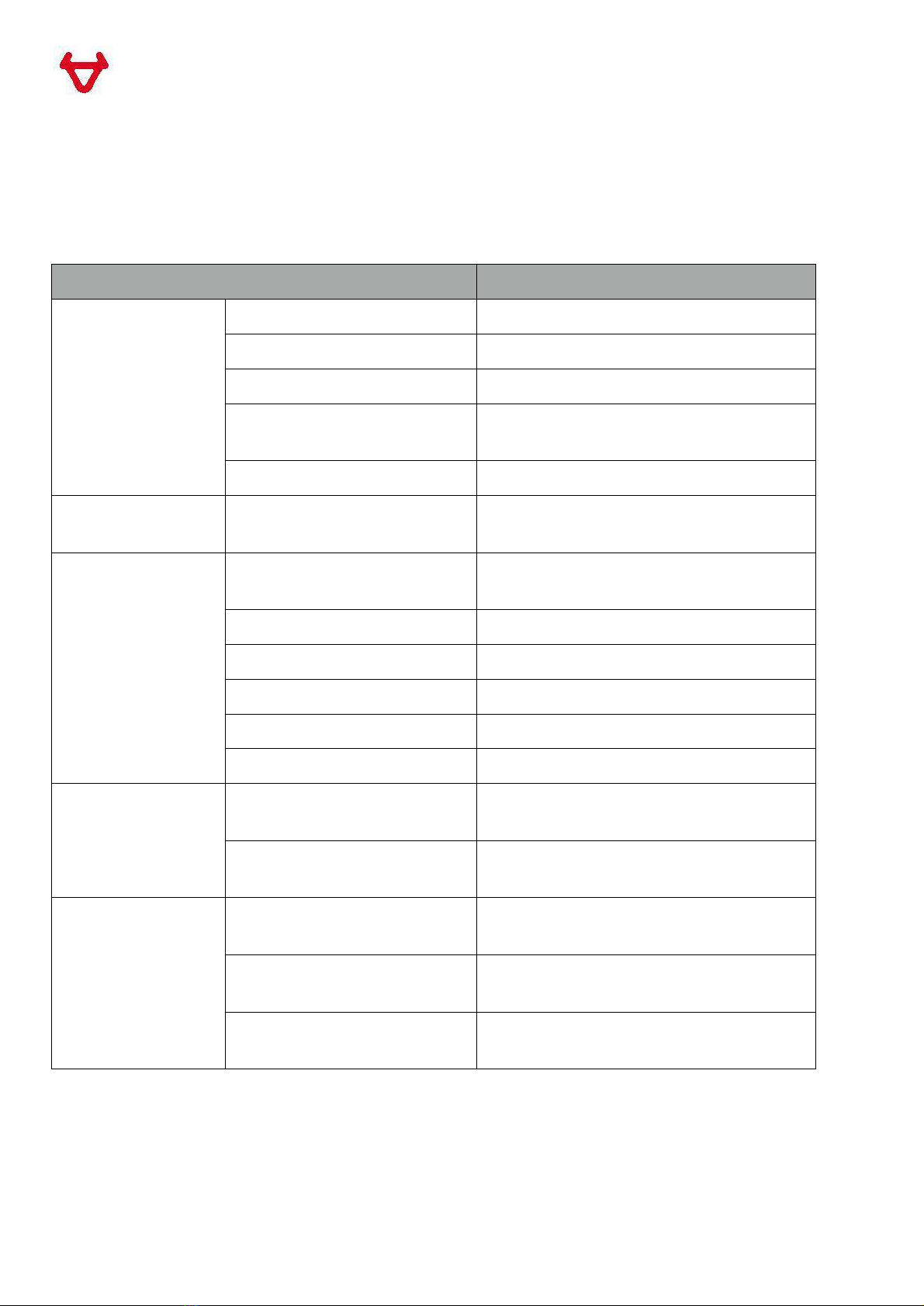

Section 1. Windshield

1.1 Unscrew two screws on the Windshield

(earlier models may have 3 screws)

Section 2. Front Neck Cover

2.1 Remove two Front Central Cover

Rubber Plugs and unscrew two screws

inside

2.2 Remove Front Neck Cover by lifting it

at front

V1.0.0

13

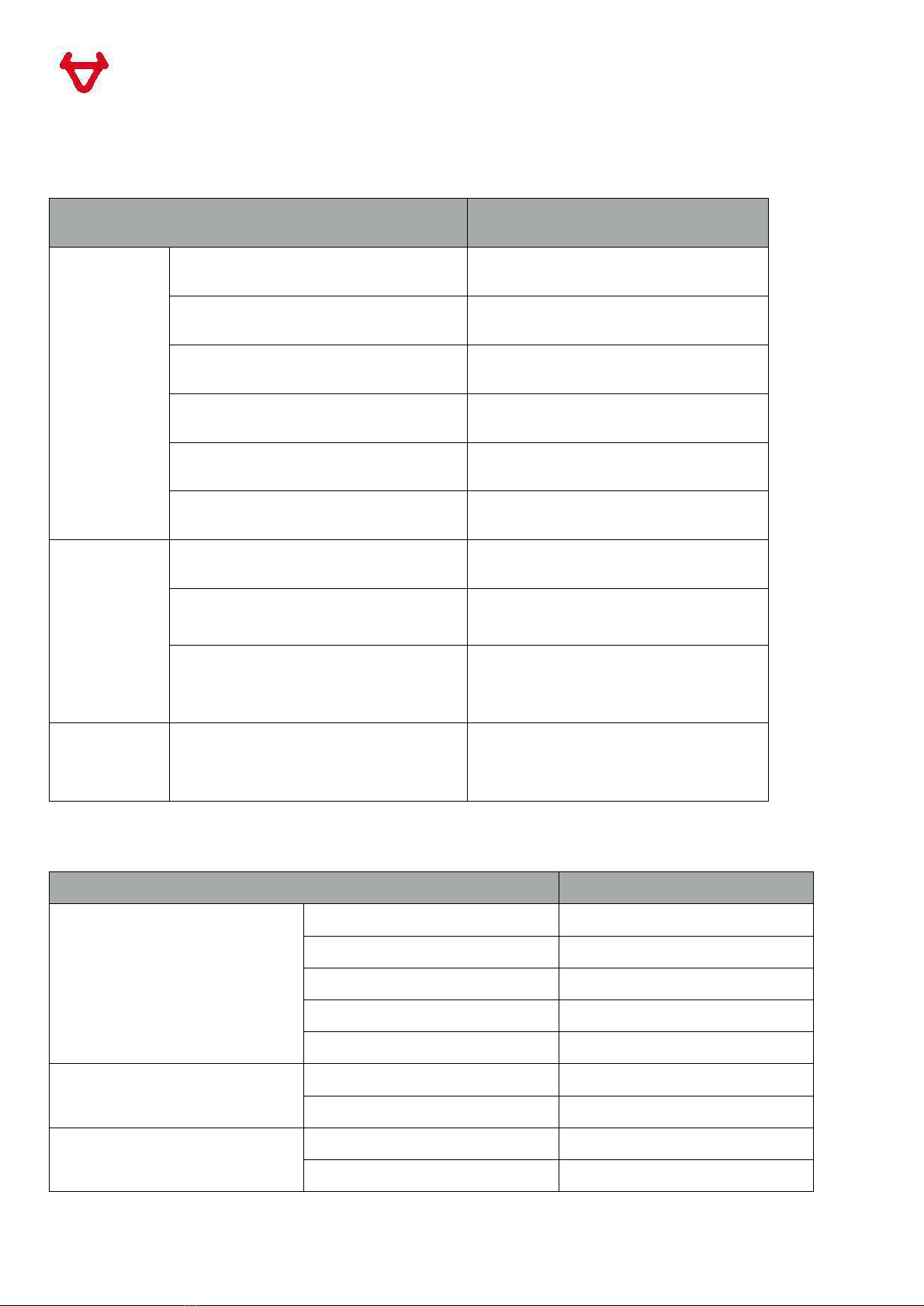

Section 3. Front Panel

3.1 Unscrew two screws on the top of Front

Panel

3.2 Take out two Push-in Rivets from the

bottom of Front Panel

3.3 Remove Front Panel by pushing it

upward

V1.0.0

14

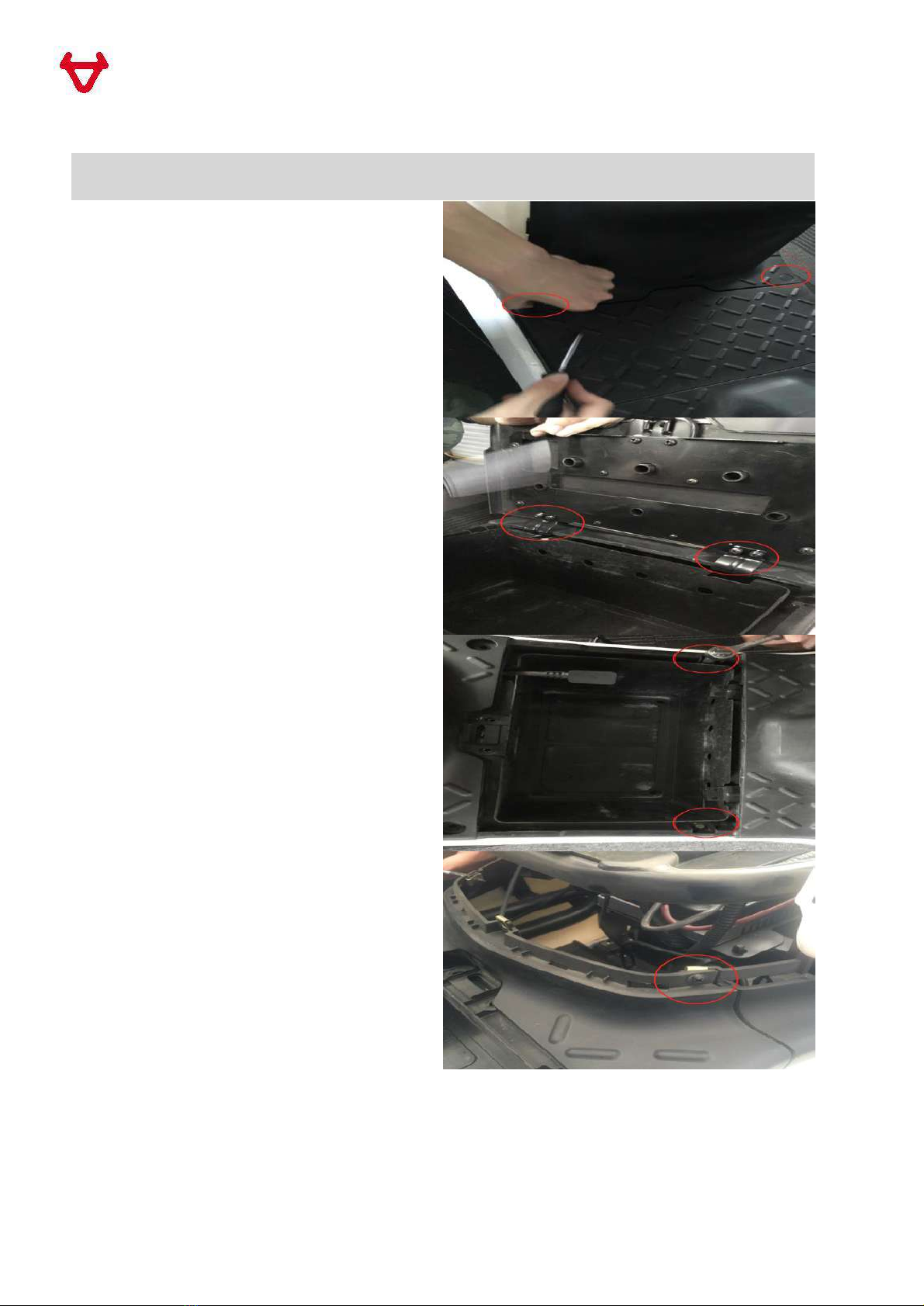

Section 4. Under Seat Storage Compartment

4.1 Unscrew four screws in the Under Seat

Storage Compartment

4.2 Lift up the Under Seat Storage

Compartment, disconnect the two

connectors

4.3 Pull Battery Compartment Lock cable

out

V1.0.0

15

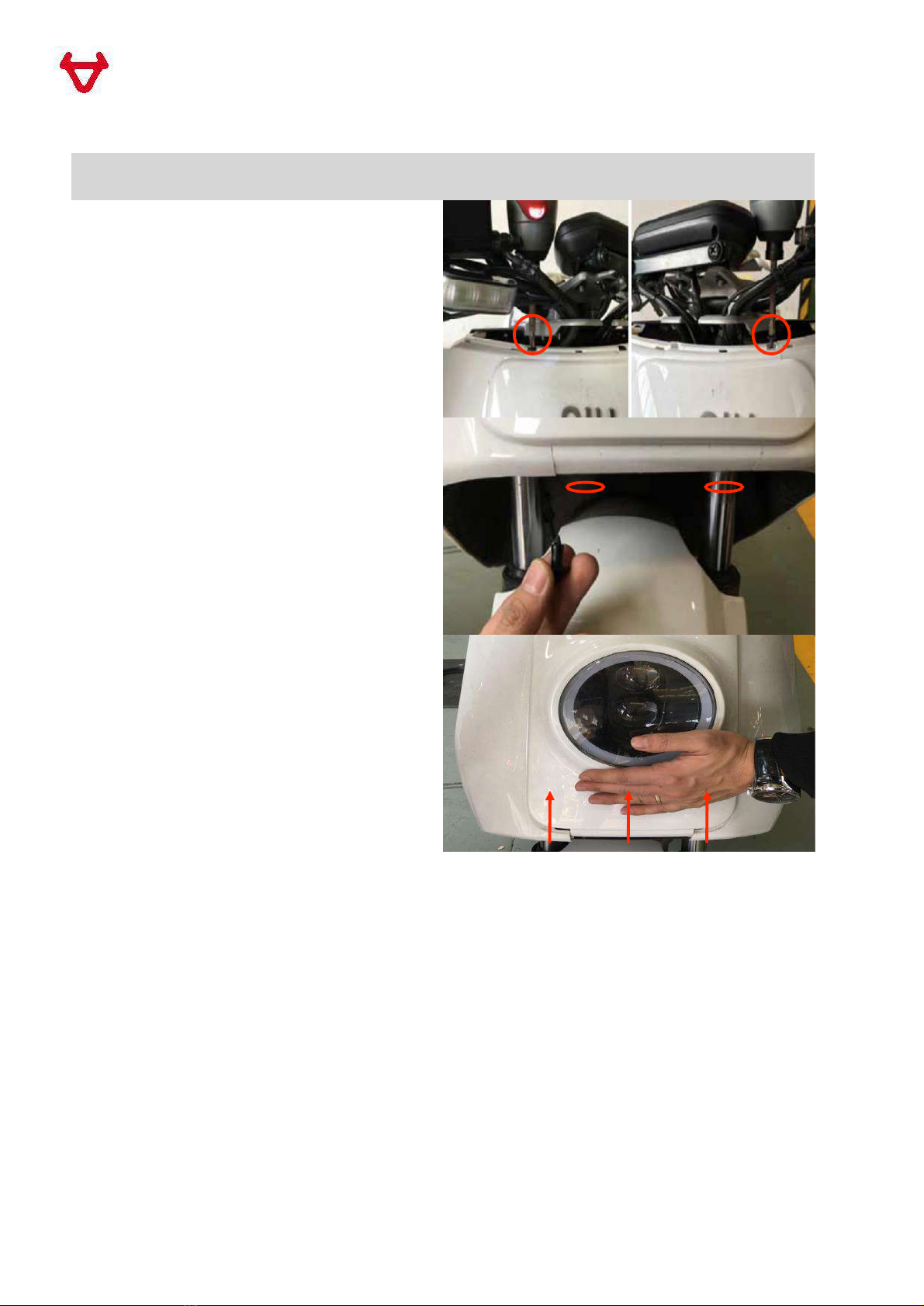

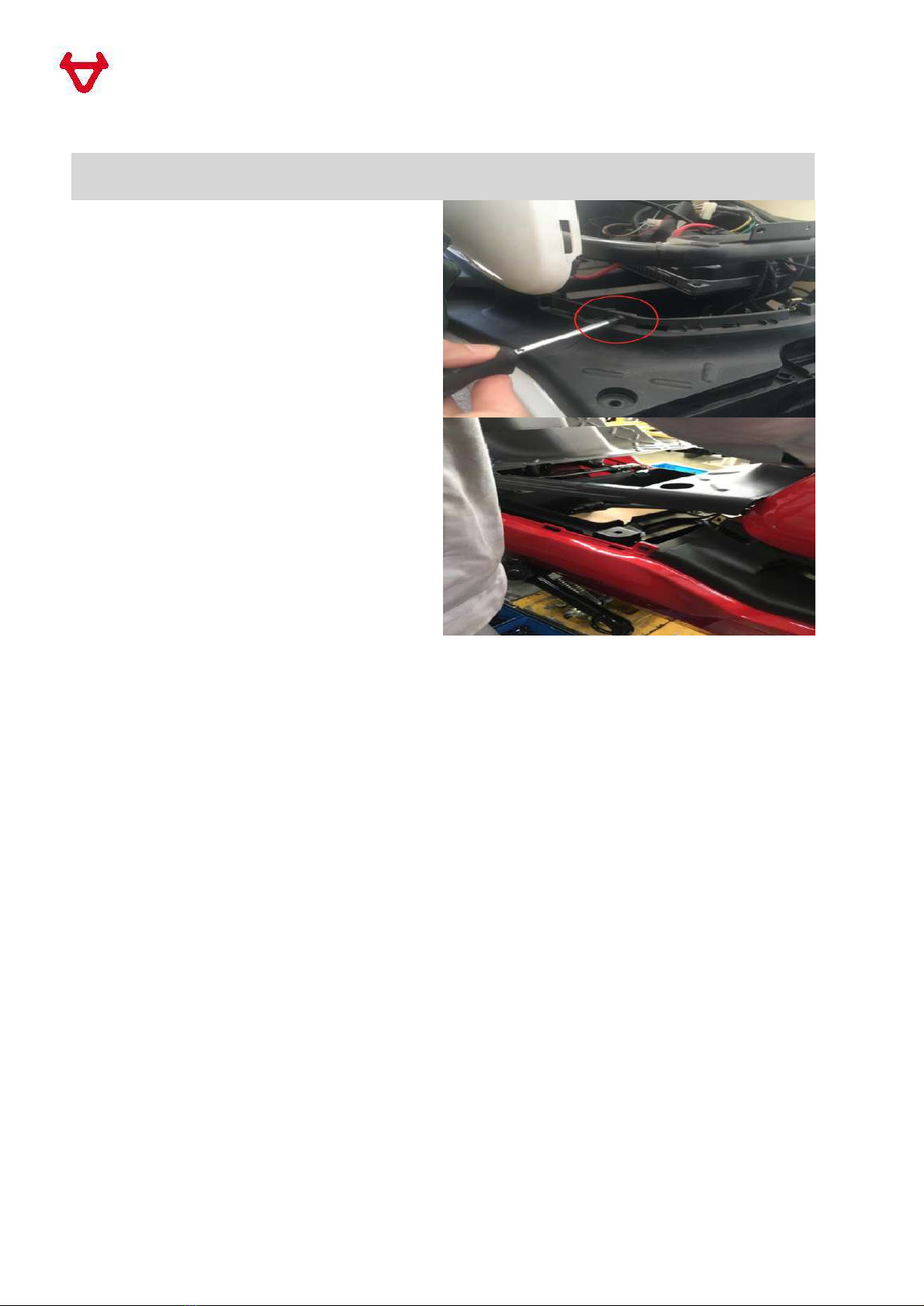

Section 5. Rear Central Cover

5.1 Unscrew the left side screw

5.2 Unscrew the right side screw

5.3 Pull out the rubber cover and unscrew

the screw

5.4 Pull out Rear Central Cover carefully

V1.0.0

16

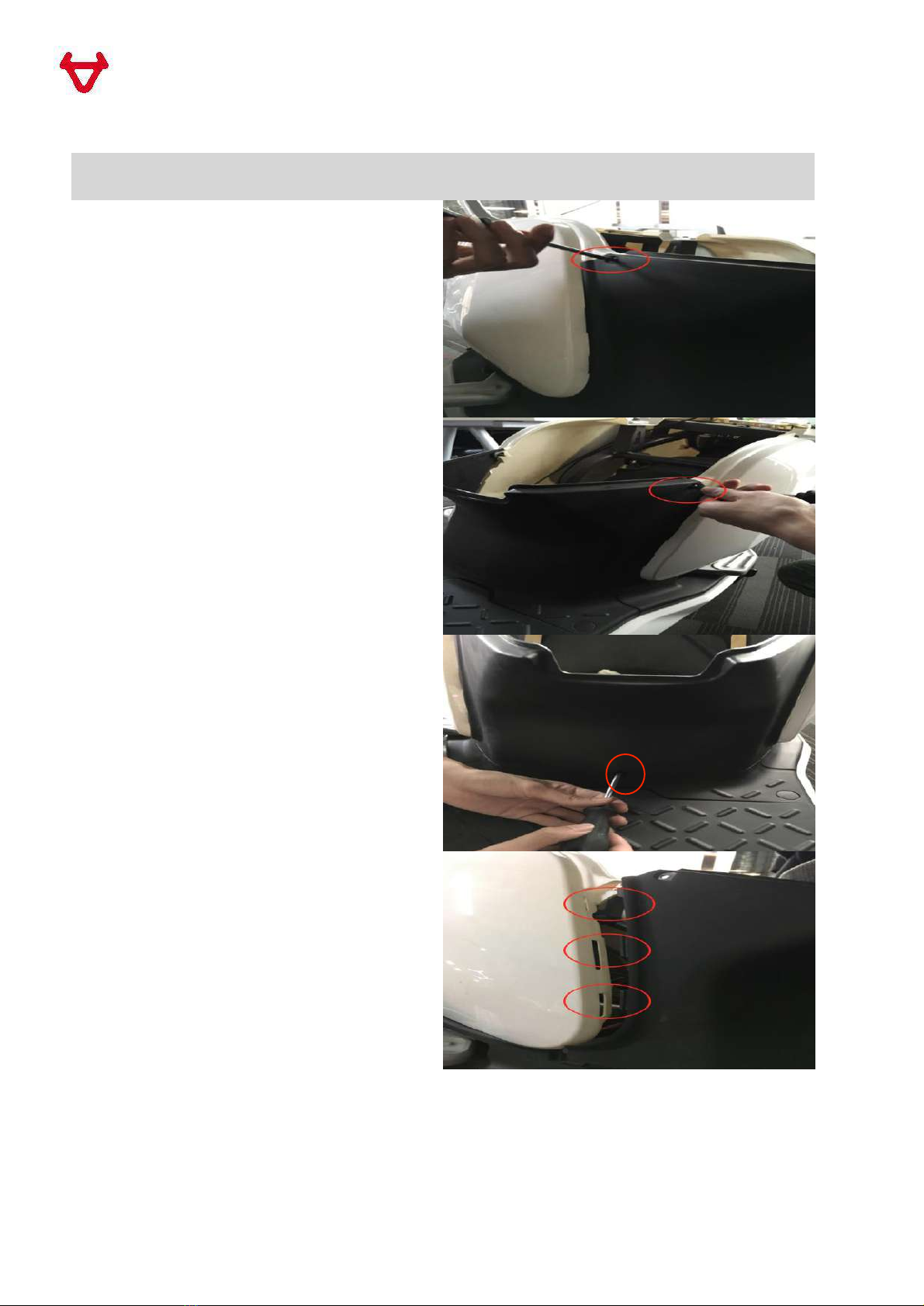

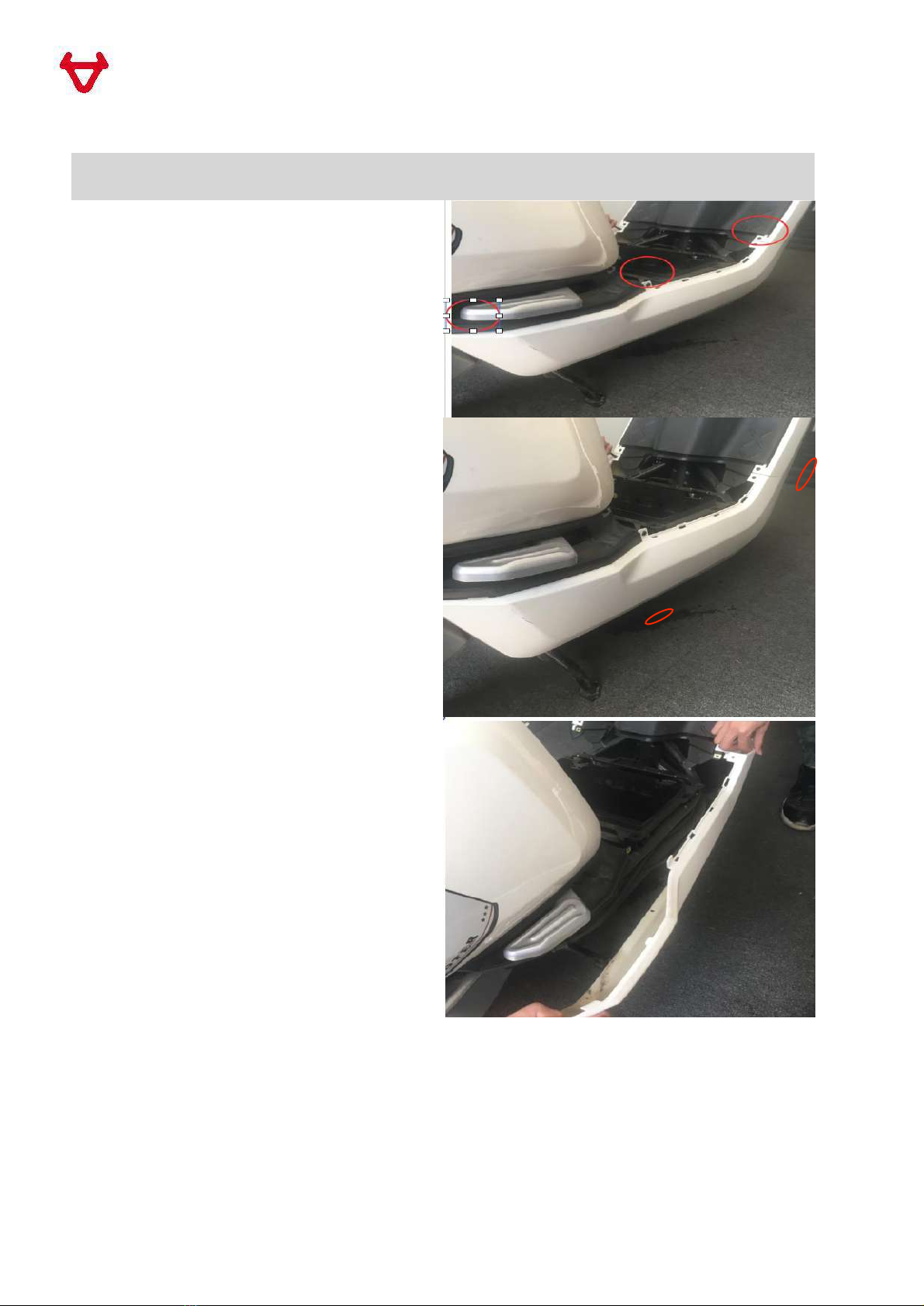

Section 6. Battery Compartment Cover and Footrest

6.1 Pull out the footrest plug and unscrew

two hexagon flange bolt

6.2 Unscrew four cross recessed pan head

tapping screws and remove Battery

Compartment Cover

6.3 Unscrew two hexagon flange bolts

6.4 Unscrew right side screw

V1.0.0

17

Section 6. Battery Compartment Cover and Footrest

6.5 Unscrew left side screw

6.6 Pull out the Footrest

V1.0.0

18

Section 7. Side Panel

7.1 Unscrew left side screw

7.2 Unscrew two screws in dark side

7.3 Pull out the whole side panel

V1.0.0

19

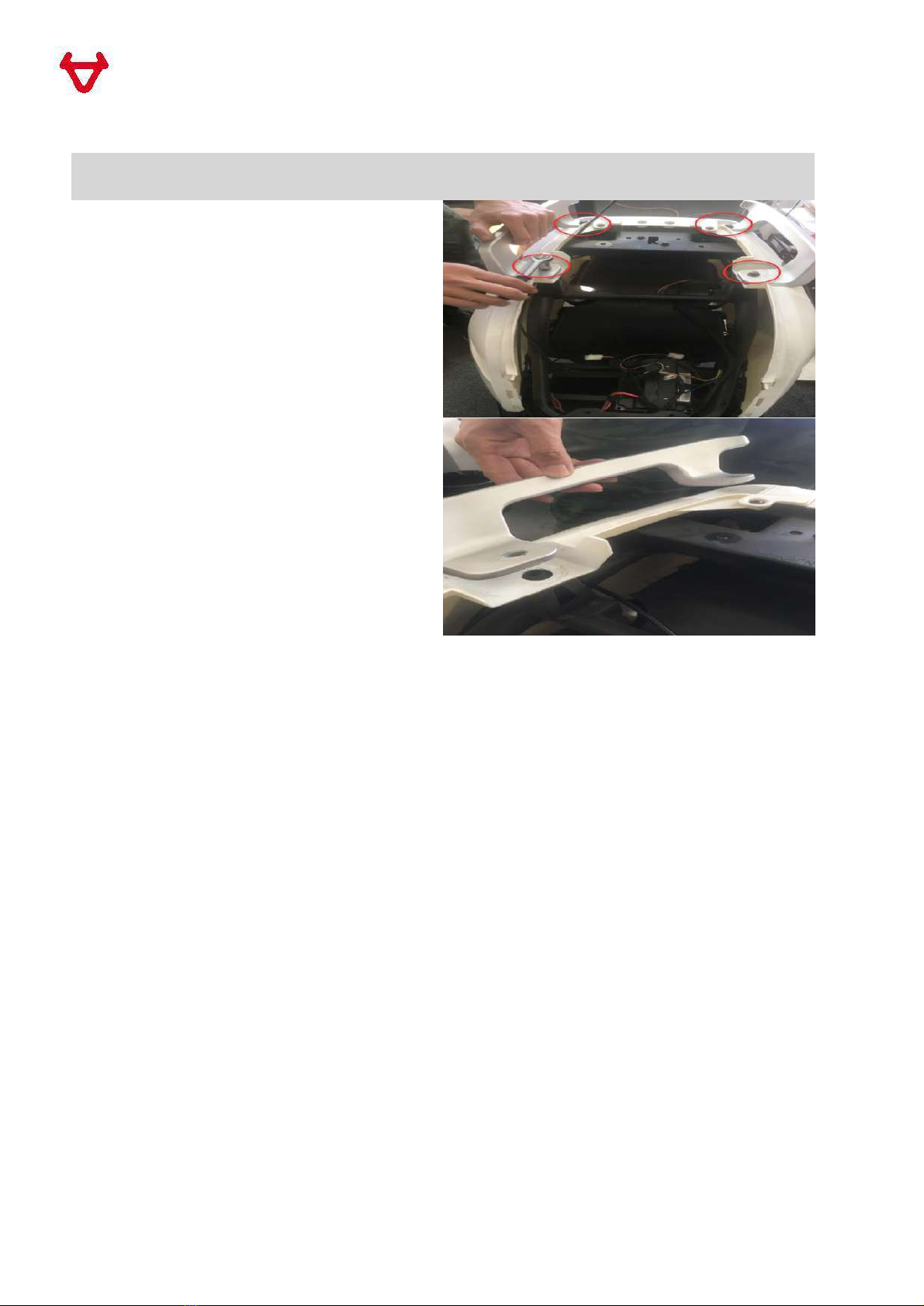

Section 8. Handrail

8.1 Remove four Hexagon flange bolts

marked in the guide photo

8.2 Pull out the Handrail

V1.0.0

20

Section 9. End cap and Body Cover

9.1 Unscrew four cross recessed medium

pan head bolts

9.2 Unscrew Cross recessed pan head

tapping screw

9.3 Unscrew two cross recessed pan head

tapping screws

9.4 Pull out the whole body panel

Table of contents

Other niu Scooter manuals