4

REPAIR

Only professionally trained and specifically authorized individuals are permitted to repair or modify any part of the stacker.

Any changes to installed switches and safety devices by the operator are strictly prohibited.

IMPORTANT: All spare parts from the manufacturer are inspected by Quality Assurance Authorities. To ensure the safety

and reliability of the stacker’s operation, only manufacturer approved spare parts may be used. Replaced parts, including

oils and fuels, must be disposed of in accordance with environmental protection regulations.

DANGER AREA

The “danger area” refers to the area where the stacker is working or lifting, causing a potentially dangerous situation for

persons or property in that the area.

Unauthorized persons must keep away from the danger area. In situations with potential danger to

others, the operator must give a warning notice. If the danger area isn’t vacated as requested, the operator must stop

using the stacker immediately.

WORKING IN HAZARDOUS ENVIRONMENTS

A stacker operating in an area where there is a hazard risk, or in any other high-risk area, should be specially equipped

for use in that environment.

This stacker is not equipped for hazardous situations.

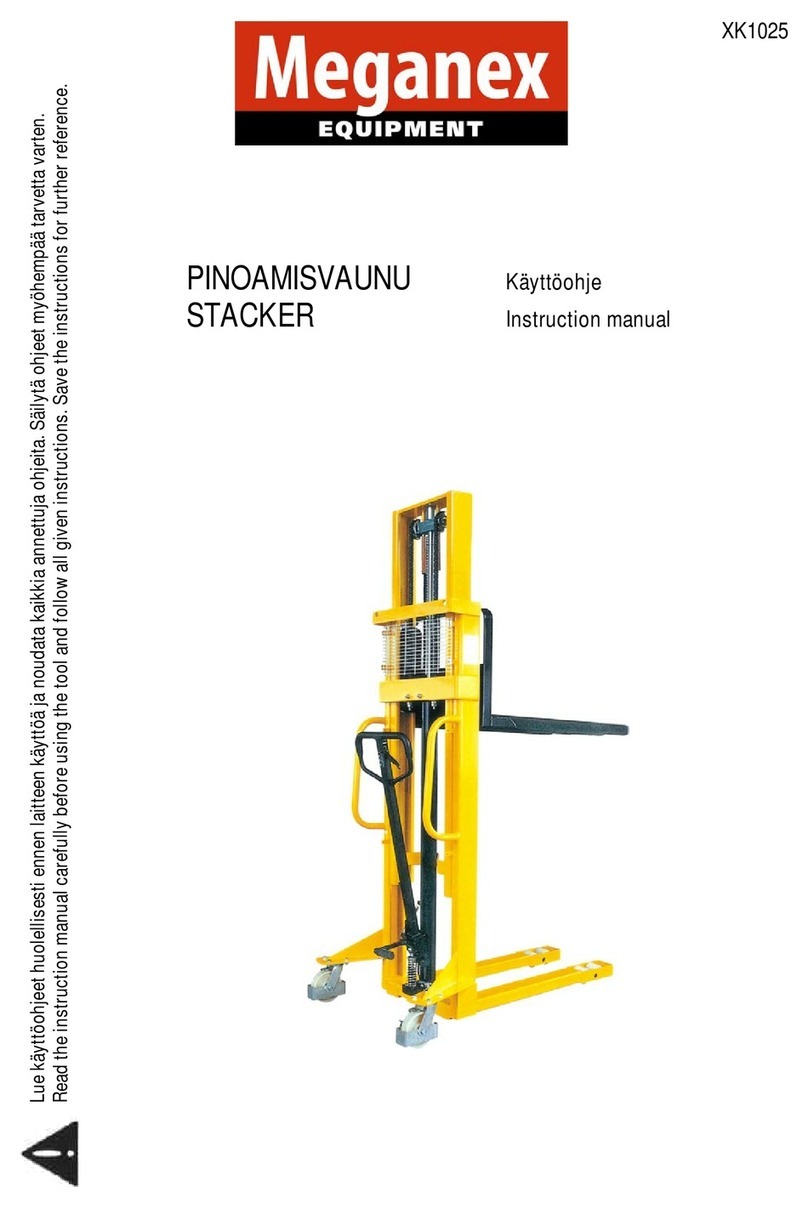

SAFETY DEVICES AND WARNING SIGNS

Special attention should be given to safety devices, warning signs, and warning notices within these Operating

Instructions and on the stacker itself.

The stacker should always be driven with the forks at a height of 12 inches (300 mm) or less except when

placing or removing a load!

DRIVING IN PUBLIC AREAS

The stacker should not be driven on public roads.

DISTANCE BETWEEN VEHICLES

Bear in mind that the material handling vehicle in front of you may brake suddenly; therefore, keep a reasonable distance

when operating this stacker.

PASSENGERS

Passengers should not ride on the stacker unless it is indicated as permissible on the stacker.

CLEARANCE HEIGHT

The stacker cannot be used where the overhead clearance height is less than the height of the load or the mast.

USE IN ELEVATORS AND ON LOADING PLATFORMS

This stacker may only be driven into an elevator or loading platform if it has been authorized. The operator must confirm

that the elevator or loading platform has adequate load capacity to support the weight of the operator, stacker, load and

other contents of the elevator or loading platform before entering the elevator or loading platform. Cargo should be placed

properly inside the elevator to avoid touching the elevator walls. Passengers must enter the elevator only after proper

parking of the stacker, and should depart from the elevator before moving the stacker.

DRIVING LANES AND WORK AREAS

Only lanes and routes that are specially allocated for stacker traffic may be used. Unauthorized persons should stay away

from work areas. Loads must only be stored in places specially provided for this purpose.

OPERATOR CONDUCT

Driving speeds must be applicable for conditions. Low speed is mandatory when turning, navigating narrow aisles,

passing through doors, or driving with a blocked field of vision. The operator must be able to measure the braking distance

to the front of the stacker by sight and control his stacker at all times. Sudden braking (except in emergency), quick

U-turns, and passing other trucks in dangerous or blind spots is prohibited. Operator should stay within the operator’s area

during operation.

VISIBILITY

The operator must have clear visibility in the driving direction the stacker is traveling. If cargo obstructs your line of sight,

operating in reverse is recommended. If operating in reverse isn’t suitable, another person must walk ahead of the stacker

to give guidance and warning.

NEGOTIATING SLOPES AND INCLINES