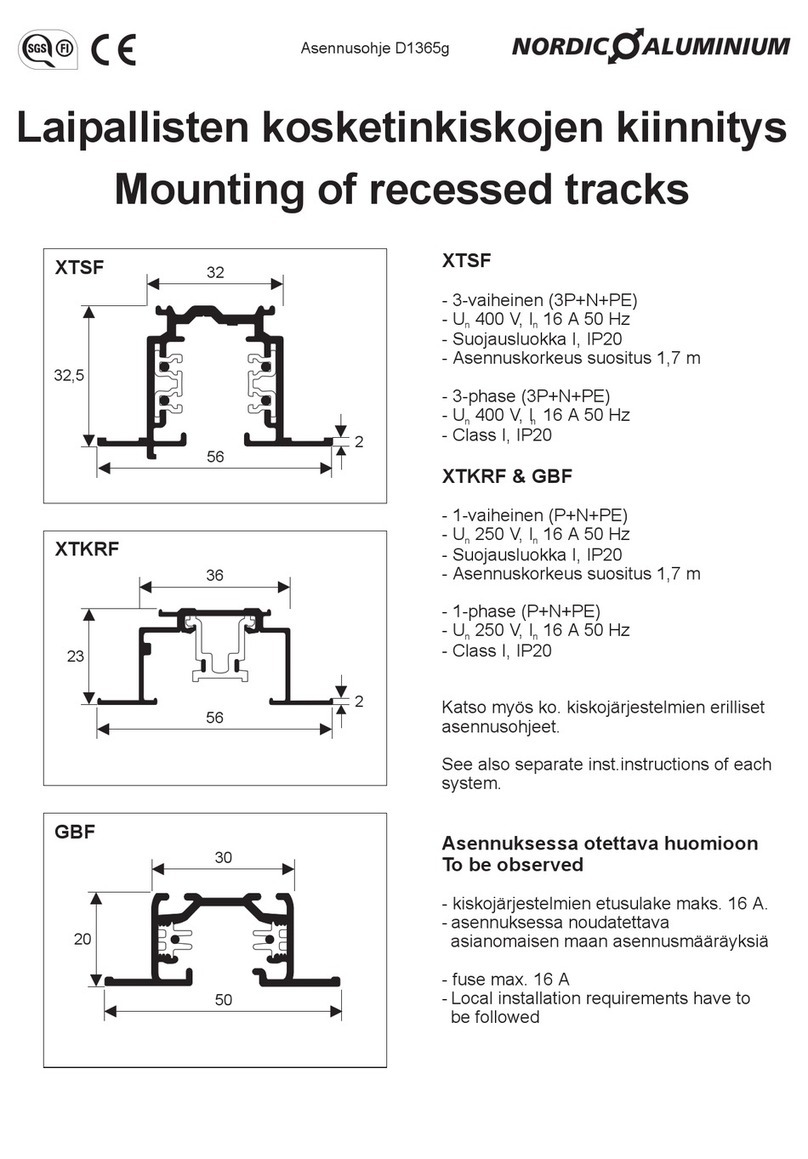

Nordic Aluminium Global trac Htek Series User manual

series

Htek

2-circuit 277V Lighting Track

with independent neutrals

INSTALLATION INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When installing or using this track system, basic safety precautions should always be

followed, including the following :

1. Read all of these installation instructions before installing the GLOBAL Htek 277V lighting

track system

2. The GLOBAL Htek 277V track system is intended for use only with GLOBAL Htek

components and fixtures marked for use with GLOBAL Htek system. To reduce risk of fire

and electric shock, do not use other components as part of this system.

3. Track installation is to only be performed by a certified electrician in accordance with the

National Electrical Code and all local codes and ordinances.

4. The GLOBAL Htek system is designed to be fed by two branch circuits rated 277VAC,

20A, eg. the system is a two-circuit / two-neutral track and care must be taken to keep

circuits designated as circuit1 and circuit2 separate.

5. Do not install the track in damp or wet locations.

6. Do not install any parts of the track system less than 8 ft above the floor.

7. Do not install any fixtures closer than six inches from combustible materials.

8. Do not use this track with a power supply cord or convenience receptacle adapter.

9. Do not install the track with electric power connected. Similarly, disconnect electricity

when installing or removing fixtures or components or changing the configuration of the

track.

10. Do not attempt to energize anything other than Lighting Track Fixtures on the track. To

reduce the risk of fire and electrical shock, do not attempt to connect power tools,

extension cords, appliances and the like to the track.

SAVE THESE INSTRUCTIONS

HTEK page 1(8)

series

Installation instructions D2427e

Htek

2-circuit 277V Lighting Track

with independent neutrals

INSTALLATION INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When installing or using this track system, basic safety precautions should always be

followed, including the following :

1. Read all of these installation instructions before installing the GLOBAL Htek 277V lighting

track system

2. The GLOBAL Htek 277V track system is intended for use only with GLOBAL Htek

components and fixtures marked for use with GLOBAL Htek system. To reduce risk of fire

and electric shock, do not use other components as part of this system.

3. Track installation is to only be performed by a certified electrician in accordance with the

National Electrical Code and all local codes and ordinances.

4. The GLOBAL Htek system is designed to be fed by two branch circuits rated 277VAC,

20A, eg. the system is a two-circuit / two-neutral track and care must be taken to keep

circuits designated as circuit1 and circuit2 separate.

5. Do not install the track in damp or wet locations.

6. Do not install any parts of the track system less than 8 ft above the floor.

7. Do not install any fixtures closer than six inches from combustible materials.

8. Do not use this track with a power supply cord or convenience receptacle adapter.

9. Do not install the track with electric power connected. Similarly, disconnect electricity

when installing or removing fixtures or components or changing the configuration of the

track.

10. Do not attempt to energize anything other than Lighting Track Fixtures on the track. To

reduce the risk of fire and electrical shock, do not attempt to connect power tools,

extension cords, appliances and the like to the track.

SAVE THESE INSTRUCTIONS

HTEK page 1(8)

series

Htek

2-circuit 277V Lighting Track

with independent neutrals

INSTALLATION INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When installing or using this track system, basic safety precautions should always be

followed, including the following :

1. Read all of these installation instructions before installing the GLOBAL Htek 277V lighting

track system

2. The GLOBAL Htek 277V track system is intended for use only with GLOBAL Htek

components and fixtures marked for use with GLOBAL Htek system. To reduce risk of fire

and electric shock, do not use other components as part of this system.

3. Track installation is to only be performed by a certified electrician in accordance with the

National Electrical Code and all local codes and ordinances.

4. The GLOBAL Htek system is designed to be fed by two branch circuits rated 277VAC,

20A, eg. the system is a two-circuit / two-neutral track and care must be taken to keep

circuits designated as circuit1 and circuit2 separate.

5. Do not install the track in damp or wet locations.

6. Do not install any parts of the track system less than 8 ft above the floor.

7. Do not install any fixtures closer than six inches from combustible materials.

8. Do not use this track with a power supply cord or convenience receptacle adapter.

9. Do not install the track with electric power connected. Similarly, disconnect electricity

when installing or removing fixtures or components or changing the configuration of the

track.

10. Do not attempt to energize anything other than Lighting Track Fixtures on the track. To

reduce the risk of fire and electrical shock, do not attempt to connect power tools,

extension cords, appliances and the like to the track.

SAVE THESE INSTRUCTIONS

HTEK page 1(8)

GES 208 (8ft)GES 208 (8ft)

oneone--circuit track, surface circuit track, surface

mountmount

GES 212 (12ft)GES 212 (12ft)

GET 304 (4ft)GET 304 (4ft)

GET 308 (8ft)

twotwo--circuit track, surface circuit track, surface

mountmount

GET 312 (12ft)GET 312 (12ft)

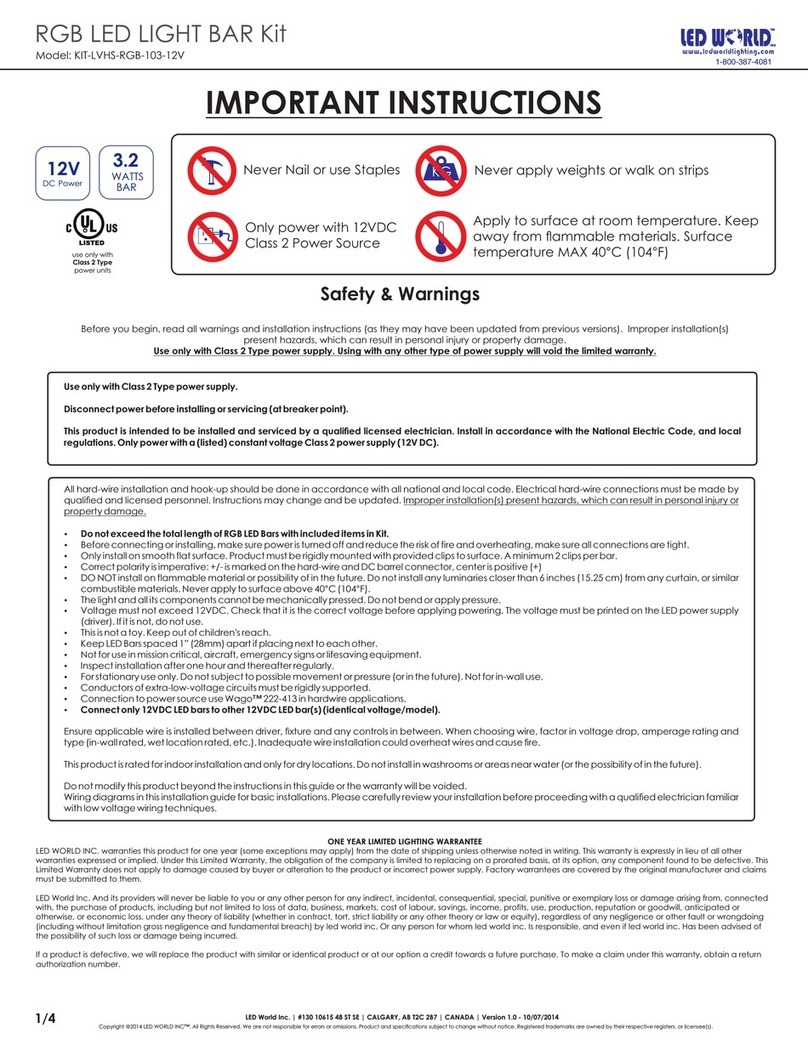

IMPORTANT SAFETY INSTRUCTIONS

Read All Instructions Before InstallationRead All Instructions Before Installation

The GLOBAL trac

eco

system is intended for use with GLOBAL trac

eco

components and fixtures marked for use with the GLOBAL trac eco

system. To reduce the risk of fire and electric shock, do not use other

components as part of this system.

Track installation is only to be performed by a certified electrician in

accordance with the National Electrical Code and all local codes and

ordinances.

Single-circuit system: The

eco

GES track system is designed to be

supplied by a single 120 volt branch circuit with a maximum capacity of

20 amps.

Two-circuit system: The

eco

GET track system is designed to be

supplied by a balanced 120/240 volt, three-wire branch circuit with a

maximum capacity of 40 amps.

Do not use this track system with a power supply cord or convenience

receptacle adapter.

Do not install any fixtures closer than six inches from combustible

materials.

Do not install the track in damp or wet locations.

Do not install the track with electric power connected. Similarly,

disconnect electricity when installing or removing fixtures or components

or changing the configuration of the track.

Do not attach anything other than UL listed lighting fixtures marked

for

for for

for

use with Nordic Aluminium GLOBAL trac

h Nordic Aluminium GLOBAL trac

h Nordic Aluminium GLOBAL trac

use w h Nordic Aluminium GLOBAL trac

eco

system only

system only system only

system only

to the track.

IMPORTANT

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

ADDING FIXTURES OR CHANGING THE TRACK

ADDING FIXTURES OR CHANGING THE TRACK ADDING FIXTURES OR CHANGING THE TRACK

ADDING FIXTURES OR CHANGING THE TRACK

CONFIGURATION

CONFIGURATIONCONFIGURATION

CONFIGURATION

INSTALLATIONINSTALLATION INSTRUCTIONSINSTRUCTIONS

eco

GLOBAL

eco

Feed and Connector Components

The GLOBAL trac

eco

system includes the following feed and connector components:

GES single-circuit GET two-circuit

system system

Live end feeds

For feeding power to surface mounted track

from the end. Typically used in conjunction

with a GES 15 Feed Canopy Cover.

Straight feed connectors

For feeding power to surface mounted track

in the middle of two runs. Typically used in

conjunction with a GES 15 Feed Canopy Cover.

Adjustable L-connectors

For connecting two lengths of track in an

L-shape. Can be field adjusted to branch

left or right. Can also be used as a feed

connector.

T-connectors

For connecting three tracks in a T-shape. The GES 40

can be field adjusted to be an inside or outside,

left or right Tee. In the case of two-circuit, the GET 39

or GET 40 must be selected for left or right Tee

connection. Can also be used as a feed connector.

X-connectors

For connecting four lengths of track in an X-shape.

Can also be used as a feed connector.

Linear coupler

For connecting two lengths of track in a linear

configuration.

Floating Feed

For feeding power to surface mounted track at any

point along the length of the track.

Surface conduit feed

For feeding track at the end with horizontal conduit run.

Compatible with 1/2 inch conduit fitting.

Flexible connector

For connecting two lengths of track at

any angle, providing the ability to also

connect two tracks at unequal elevation

or in two different planes.

Dead end cover

For all open ends of track

Nordic Aluminium Inc

4300C Bankers Circle, Doraville, GA, 30360, Tel: 770-326-3331, Fax: 770-326-3353

GES 11

GES 14

GES 34

GES 40

GES 38

GES 21

GES 67

GES 13

GES 23

GES 41

GET 11

GET 14

GET 34

GET 39

GET 40

GET 38

GET 21

GET 67

GET 13

GET 23

GES 41

1:1

1:1

1:1

1:1

1:1

track

tracktrack

track

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

D2234a

GES 204 (4ftGES 204 (4ft

GES 208 (8ft)GES 208 (8ft)

oneone--circuit track, surface circuit track, surface

mountmount

GES 212 (12ft)GES 212 (12ft)

GET 304 (4ft)GET 304 (4ft)

GET 308 (8ft)

twotwo--circuit track, surface circuit track, surface

mountmount

GET 312 (12ft)GET 312 (12ft)

IMPORTANT SAFETY INSTRUCTIONS

Read All Instructions Before InstallationRead All Instructions Before Installation

The GLOBAL trac

eco

system is intended for use with GLOBAL trac

eco

components and fixtures marked for use with the GLOBAL trac eco

system. To reduce the risk of fire and electric shock, do not use other

components as part of this system.

Track installation is only to be performed by a certified electrician in

accordance with the National Electrical Code and all local codes and

ordinances.

Single-circuit system: The

eco

GES track system is designed to be

supplied by a single 120 volt branch circuit with a maximum capacity of

20 amps.

Two-circuit system: The

eco

GET track system is designed to be

supplied by a balanced 120/240 volt, three-wire branch circuit with a

maximum capacity of 40 amps.

Do not use this track system with a power supply cord or convenience

receptacle adapter.

Do not install any fixtures closer than six inches from combustible

materials.

Do not install the track in damp or wet locations.

Do not install the track with electric power connected. Similarly,

disconnect electricity when installing or removing fixtures or components

or changing the configuration of the track.

Do not attach anything other than UL listed lighting fixtures marked

for

for for

for

use with Nordic Aluminium GLOBAL trac

h Nordic Aluminium GLOBAL trac

h Nordic Aluminium GLOBAL trac

use w h Nordic Aluminium GLOBAL trac

eco

system only

system only system only

system only

to the track.

IMPORTANT

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE WHEN

ADDING FIXTURES OR CHANGING THE TRACK

ADDING FIXTURES OR CHANGING THE TRACK ADDING FIXTURES OR CHANGING THE TRACK

ADDING FIXTURES OR CHANGING THE TRACK

CONFIGURATION

CONFIGURATIONCONFIGURATION

CONFIGURATION

INSTRUCTIONS

GLOBAL

eco

Feed and Connector Components

The GLOBAL trac

eco

system includes the following feed and connector components:

GES single-circuit GET two-circuit

system system

Live end feeds

For feeding power to surface mounted track

from the end. Typically used in conjunction

with a GES 15 Feed Canopy Cover.

Straight feed connectors

For feeding power to surface mounted track

in the middle of two runs. Typically used in

conjunction with a GES 15 Feed Canopy Cover.

Adjustable L-connectors

For connecting two lengths of track in an

L-shape. Can be field adjusted to branch

left or right. Can also be used as a feed

connector.

T-connectors

For connecting three tracks in a T-shape. The GES 40

can be field adjusted to be an inside or outside,

left or right Tee. In the case of two-circuit, the GET 39

or GET 40 must be selected for left or right Tee

connection. Can also be used as a feed connector.

X-connectors

For connecting four lengths of track in an X-shape.

Can also be used as a feed connector.

Linear coupler

For connecting two lengths of track in a linear

configuration.

Floating Feed

For feeding power to surface mounted track at any

point along the length of the track.

Surface conduit feed

For feeding track at the end with horizontal conduit run.

Compatible with 1/2 inch conduit fitting.

Flexible connector

For connecting two lengths of track at

any angle, providing the ability to also

connect two tracks at unequal elevation

or in two different planes.

Dead end cover

For all open ends of track

Nordic Aluminium Inc

4300C Bankers Circle, Doraville, GA, 30360, Tel: 770-326-3331, Fax: 770-326-3353

GES 11

GES 14

GES 34

GES 40

GES 38

GES 21

GES 67

GES 13

GES 23

GES 41

GET 11

GET 14

GET 34

GET 39

GET 40

GET 38

GET 21

GET 67

GET 13

GET 23

GES 41

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

1:1

)

HTEK page 2(8)

fixing knob

circuit selector

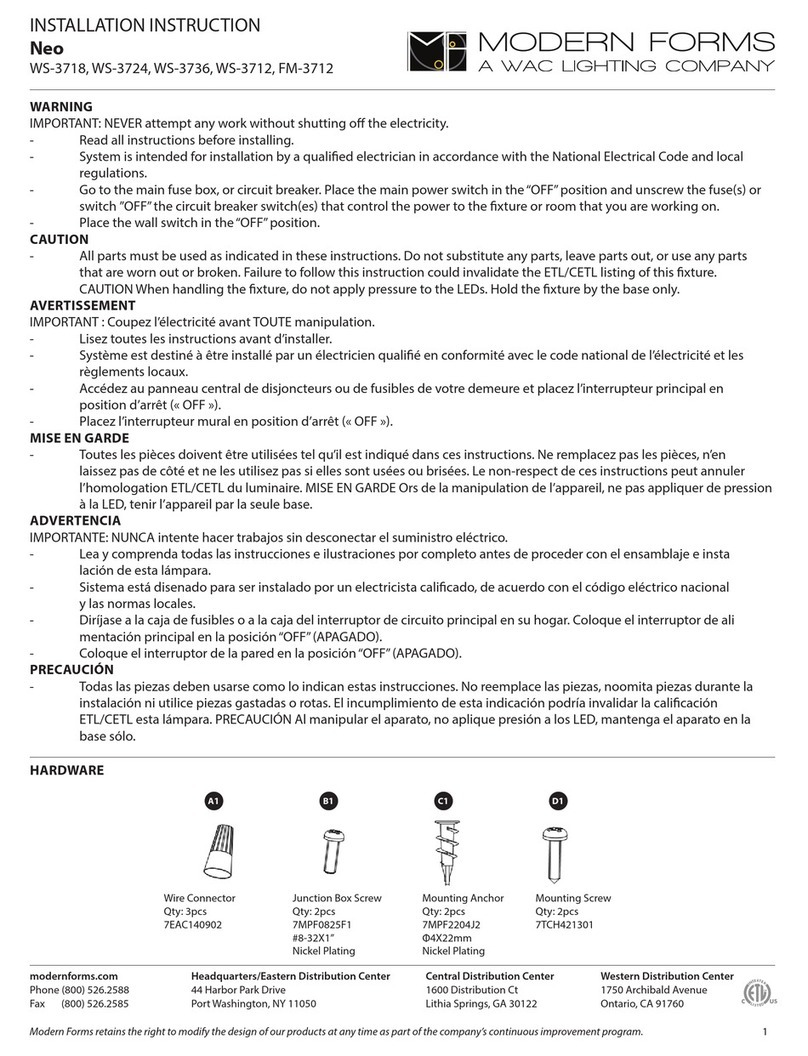

INSTALLING AND REMOVING FIXTURES

HTEK 68

polarity ridge

To reduce the risk of fire and electric shock, use only fixtures marked for use with

Nordic Aluminium HTEK system

The fixture adapter is inserted with the screws on the adapter opposite

the polarity ridge on the track

Push the adapter into the track till it snaps into place.

Turn the mechanical fixing knob clockwise.

Select the desired circuit with the circuit selector knob.

To remove the adapter from track, select 0-position (OFF) before turning

the mechanical fixing knob counterclockwise. Pull from fixing knob end.

1.

2.

3.

4.

5.

ELECTRICAL CONNECTION

277 V~ Max. 20 A/cct

Max. 20 A

Max. 20 A

L1

L2

N2

N1

L1L2

N2

N

Ground

Line2

Line1

Neutral2

Neutral1

polarity ridge

HTEK 61

rotating

NSPM1/8”-27

HTEK 68 with nipple:

HTEK 68

Switchable between circuits & on/off

Includes rotation lock.

Max. 20lbs / 1200W

rotation lock

screw

The fixture adapter is inserted with the polarity groove towards to

the polarity ridge on the track

Push the adapter into the track till it snaps into place.

Turn the mechanical fixing knob clockwise.

Select the desired circuit with the circuit selector knob (1-0-2).

To remove the adapter from track, select 0-position (OFF) before

turning the mechanical fixing knob counterclockwise. Pull first from

fixing knob end.

1.

2.

3.

4.

5.

HTEK100

HTEK 61

rotating

NSPM1/8”-27

Nipple for HTEK 100 :

rotation lock screw, (do not overtight)

Mechanical fixing knob

circuit selector

Polarity ridge

Polarity groove

Off

On

1

2

2

1

0(Off)

FEEDS

TEK 11, 12, 14, 34

39, 40, 38

STEP 1.

Remove the knock-out hole provided on the back side of the feed connector. Remove feed connector cover.

STEP 2.

Pass the supply, neutral and ground wires through the canopy cover.

STEP 3.

Attach feed connector to track (NOTE: track is polarized and feed connector will only fit one end of track). Pass wires through hole on feed and

mount track to ceiling using toggle bolts or screws.

STEP 4.

ALWAYS CONNECT GROUND WIRE TO GREEN GROUND TERMINAL. Connect live conductors to the appropriate terminal marked "L1", or

"L2". Connect neutral conductors to the appropriate terminal marked "N1" or "N2".

STEP 5.

Replace feed connector cover plate

INSTALLATION OF HTEK TRACK TO AN OUTLET BOX

Outlet Box

Outlet Box Canopy Cover

(GES 15)

N

L

1

L 2

N

2

1

Ground

HTEK page 5(8)

HTEK trac

HTEK 44, 48, 412

HTEK 11, 12, 14, 34

3

Pendant Suspension

A. Pendant wiring B. Mechanical pendant support detail

detail Outlet box

Thread:

3/8 inch - 18 IP

Thread:

3/8 inch - 18 IP

Metal

bracket Metal

bracket

2 Lock nuts 2 Lock nuts

SPXX Stem

and canopy

assembly

SP4E end feed

suspension

bracket

SP4P point

suspension

bracket

Max 4 ft interval

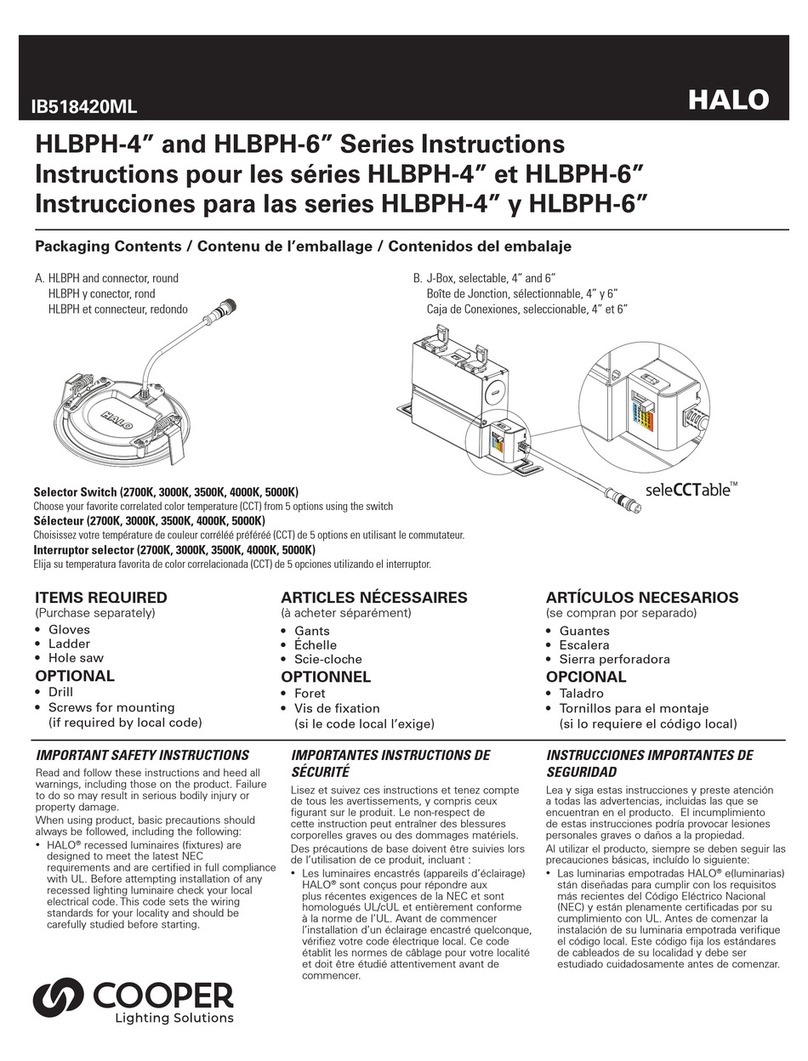

MOUNTING THE TRACK

NOTE: The track should be securely mounted at the maximum intervals of the 4ft, and must be

mounted in accordance with all applicable codes and standards.

Ceiling mounting options Instructions for each option:

A. Using the factory provided mounting holes, use appropriate screw or

toggle bolt for securing the track to the ceiling.

B. Mark the location of the centerline of the track on the ceiling. Using an

appropriate screw or toggle bolt, secure SKB mounting clips at the

correct position on ceiling. Loosen the set screw on the side of the clips

and insert the track, tightening the set screws while holding the track

position.

C. Use the SKBT 12 for securing the track to T-bar ceiling grids. Snap the

clips onto the grid in the correct locations, then insert the track,

tightening the set screws while holding the track in the position.

D. Use the SKBX 12 for T-bar grid recessed into the ceiling tile. Follow the

same procedure as C above.

SPXX Stem

and canopy

assembly

SKB 12

SKBT 12

SKBX 12

Live end feed

Electrical feed through pendant feed stem, Catalog numbers SP XX.

Secure mounting bracket to outlet box using hardware provided.

Thread one nut on upper end of feed stem. Pass required supply

wires and ground wire (by others) through second nut and through

feed stem. Attach upper threaded portion of stem to mounting

bracket and secure second nut tightly.

Loosen lock screw and slide canopy up stem, taking care not to

scratch the surface finish. Tighten canopy once in position.

Remove plastic cover from SP 4E mounting bracket. Using a sharp

knife, cut out the top protrusion to allow the feed stem to pass

through cover. Slide cover up stem while completing remaining

connections.

Pass supply and ground wires through metal bushing of SP 4E

mounting bracket. Thread bracket onto stem and tighten.

Cut out knock-out on back side of live end feed connector using a

sharp knife. Pass wires from the mounting bracket through the

knock-out and attach live end to track.

Secure mounting bracket to back of track, fastening the set screws.

Attach supply leads and ground wire to proper screw terminals in

the live end and replace the cover.

1.

2.

3.

4.

5.

6.

7.

8.

9. Slide mounting bracket cover down the stem and over the

mounting bracket.

HTEK page 6(8)

Track support using pendant stem, Catalog numbers SP XX.

Secure mounting bracket to outlet box using hardware provided or

other appropriate fasteners.

Thread one nut on upper end of feed stem. Attach upper threaded

portion of stem to mounting bracket and secure second nut tightly.

Loosen lock screw and slide canopy up stem, taking care not to

scratch the surface finish. Tighten canopy once in position.

Remove plastic cover from SP 4P mounting bracket. Using a sharp

knife, cut out the top protrusion to allow the feed stem to pass

through cover. Slide cover up stem while completing remaining

connections.

Thread SP4P metal bracket onto stem and tighten.

Secure mounting bracket to back of track, fastening the set screws.

Slide mounting bracket cover down the stem and over the

mounting bracket.

When supported by Pendant Stems the following spacings shall be

maintained:

a. Maximum 4 ft. spacing for stems maximum 39 in. long

b. Maximum 8 ft. spacing for stems maximum 24 in. long

c. Each intercept to be directly supported by Pendan Stem or one

Pendant Stem shall be provided adjacent each side of intercept

maximum 10 in. spacing from end of track.

(XX = Stem length in inches)

1.

2.

3.

4.

5.

6.

7.

8.

SKB 12

SKB 10

4

Pendant Suspension

A. Pendant wiring B. Mechanical pendant support detail

detail Outlet box

Thread:

3/8 inch - 18 IP

Thread:

3/8 inch - 18 IP

Metal

bracket Metal

bracket

2 Lock nuts 2 Lock nuts

SPXX Stem

and canopy

assembly

SP4E end feed

suspension

bracket

SP4P point

suspension

bracket

Max 4 ft interval

MOUNTING THE TRACK

NOTE: The track should be securely mounted at the maximum intervals of the 4ft, and must be

mounted in accordance with all applicable codes and standards.

Ceiling mounting options Instructions for each option:

A. Using the factory provided mounting holes, use appropriate screw or

toggle bolt for securing the track to the ceiling.

B. Mark the location of the centerline of the track on the ceiling. Using an

appropriate screw or toggle bolt, secure SKB mounting clips at the

correct position on ceiling. Loosen the set screw on the side of the clips

and insert the track, tightening the set screws while holding the track

position.

C. Use the SKBT 12 for securing the track to T-bar ceiling grids. Snap the

clips onto the grid in the correct locations, then insert the track,

tightening the set screws while holding the track in the position.

D. Use the SKBX 12 for T-bar grid recessed into the ceiling tile. Follow the

same procedure as C above.

SPXX Stem

and canopy

assembly

SKB 12

SKBT 12

SKBX 12

Electrical feed through pendant feed stem, Catalog numbers SP XX.

1. Secure mounting bracket to outlet box using hardware provided.

2. Thread one nut on upper end of feed stem. Pass required supply

wires and ground wire (by others) through second nut and through

feed stem. Attach upper threaded portion of stem to mounting

bracket and secure second nut tightly.

3. Loosen lock screw and slide canopy up stem, taking care not to

scratch the surface finish. Tighten canopy once in position.

4. Remove plastic cover from SP 4E mounting bracket. Using a sharp

knife, cut out the top protrusion to allow the feed stem to pass

through cover. Slide cover up stem while completing remaining

connections.

5. Pass supply and ground wires through metal bushing of SP 4E

mounting bracket. Thread bracket onto stem and tighten.

6. Cut out knock-out on back side of live end feed connector using a

sharp knife. Pass wires from the mounting bracket through the

knock-out and attach live end to track.

7. Secure mounting bracket to back of track, fastening the set screws.

8. Attach supply leads and ground wire to proper screw terminals in

the live end and replace the cover.

9. Slide mounting bracket cover down the stem and over the

mounting bracket.

Track support using pendant stem, Catalog numbers SP XX.

1. Secure mounting bracket to outlet box using hardware provided or

other appropriate fasteners.

2. Thread one nut on upper end of feed stem. Attach upper threaded

portion of stem to mounting bracket and secure second nut tightly.

3. Loosen lock screw and slide canopy up stem, taking care not to

scratch the surface finish. Tighten canopy once in position.

4. Remove plastic cover from SP 4P mounting bracket. Using a sharp

knife, cut out the top protrusion to allow the feed stem to pass

through cover. Slide cover up stem while completing remaining

connections.

5. Thread SP4P metal bracket onto stem and tighten.

6. Secure mounting bracket to back of track, fastening the set screws.

7. Slide mounting bracket cover down the stem and over the

mounting bracket.

(XX = Stem length in inches)

Live end feed

Max 4 ft interval Max 6”

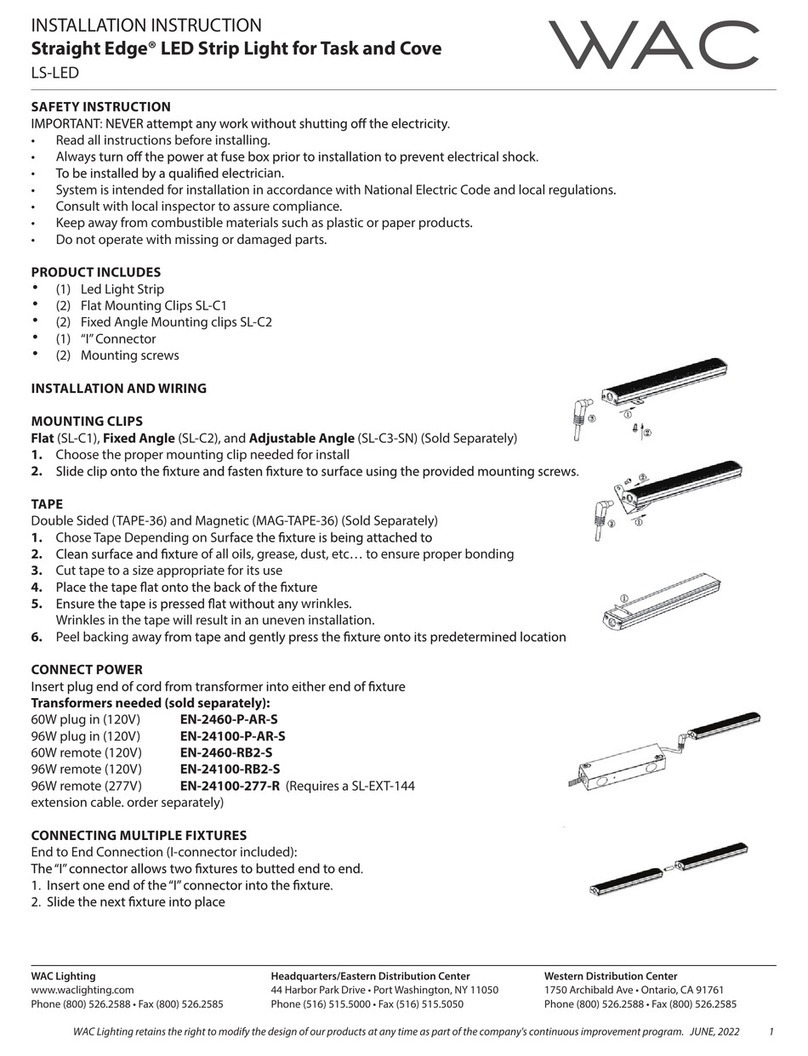

STEP 1

Carefully cut the track to length using a

hacksaw or other metal saw. Ensure that the

cut is clean and straight.

STEP 2

Insert the bending tool so that the track

conductor fits in the outermost slot at the tip

of the bending tool.

STEP 3

Rotate the bending tool 90 degrees upward.

Repeat steps 2 and 3 for all four conductors.

STEP 4

Bent conductors should look similar to the

factory finished ends, as shown.

STEP 5

Confirm correct bending by inserting the

opposite end of the tool in the end of the

track.

The standard length HTEK track is supplied with the

conductor ends factory bent to allow for proper

connection of fittings. However, the track can

easily be field cut to different lengths with a

hacksaw or a circular saw intended for cutting

aluminum. After cutting, the conductor ends must

be bent in the field with the Nordic XTSV 12

bending tool.

FIELD CUTTING OF TRACK TO LENGTH

FIELD DRILLING OF MOUNTING HOLES

1

2 3

4 5

Bending tool

XTSV 12

see NOTE

If track is field cut, it may become necessary to drill new

mounting holes. If so, use one of the off-cut pieces with

existing mounting hole as a template for new hole to be drilled.

The drill bit should be no larger than ¼ inch in diameter. The

hole should be centered in the groove in the bottom of the

track. Remove burrs after drilling. Hole location should be in

accordance with the note below.

NOTE: A single section of the track that is 4 feet or less in

length must have one mounting opening spaced a maximum

of 6 inches from each end of the track section. Additional

openings may be provided. A single section of the track that is

greater than 4 feet in length is to be provided with mounting

openings spaced a maximum of 12 inches from each end of

the track section with additional openings provided a minimum

of every 4 feet along the length of the track section.

Hole location

Max 1/4 “

HTEK page 7(8)

5

FEEDING TRACK AT A CORNER CONNECTOR

GLOBAL Htek track can be fed at the following corners and track intercept connectors

When feeding at one of the above connectors, follow the feeding instructions as shown

under ‘INSTALLATION OF GLOBAL HTEK TRACK TO AN OUTLET BOX’.

NOTE: The track is polarized, so connectors can only be installed in the track in one

direction. I, L, T, X-connectors are pre-wired, and should not be re-configured in the

field. When requiring a turn in a different direction, or if an opposite T-connector is

required, remove the cover and turn the connector as shown above.

TEK 21 Straight connector

TEK 24 Adjustable corner

Bent TEK 34

L-connector

TEK 39 T-connector

TEK 40 T-connector

L-connector

Bent TEK 39 T-connector

NOTE: Dark line

directs polarity

ridge on track.

TEK 38 X-connector

TEK 34 Bent TEK 40

T-connector TEK 14 Middle feed

INSTALLING CONNECTORS

1. Select the correct connector to fit the end of the track.

2. Align the guide lug of the connector with the groove on the

track.

3. Insert the connector into the end of the track, ensuring that

the guide lug enters the groove in the base of the track.

4. If the connection is too tight, loosen the lock screw until the

connector slides in.

5. Once the connector is correctly inserted, tighten the lock

screw.

HTEK page 4(8)

HTEK

HTEK 40 HTEK

HTEK 34

HTEK

Bent HTEK 34

Bent HTEK 39 T-connector

Bent HTEK 40

T-connector

HTEK 21

HTEK 24

6

HTEK page 3(8)

WARNING

NORDIC ALUMINIUM LIGHTING TRACK SYSTEMS

DO NOT solder connectors as this will prohibit

the adapters circuit switch to move freely from circuit to circuit.

Nordic Aluminium track adapters and accessories

are made of strong polycarbonate material.

To clean, use only a damp cloth.

DO NOT expose to any

lubricants, solvents or cleaning solutions,

as they may impair the strength of the product.

Also, when changing the location of a fixture/adapter

DO NOT slide the adapter down the track

as it will damage the connectors and cause faulty lighting.

Fixture must be taken out of track

and placed to its desired location.

Nordic Aluminium, Inc 4300C Bankers Circle, Doraville, GA 30360 Ph: 770-326-3331 Fax: 770-326-3353

Nordic Aluminium, Inc. 1075 Old Norcross Road, Suite A, Lawrenceville, GA 30045, USA

Ph: 678-407-7876, Fax: 678-407-7875

HTEK page 8 (8)

Other Nordic Aluminium Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

CircuPool

CircuPool RJ-Classic Series Installation and operation guide

Event Lighting

Event Lighting PAR4X12B2 user manual

Steren

Steren LAM-225 instruction manual

walser

walser Walimex Pro 380 Bi Color RLL-380BV instruction manual

Artecta

Artecta Aviano 20 CCT V1 user manual

Lightolier

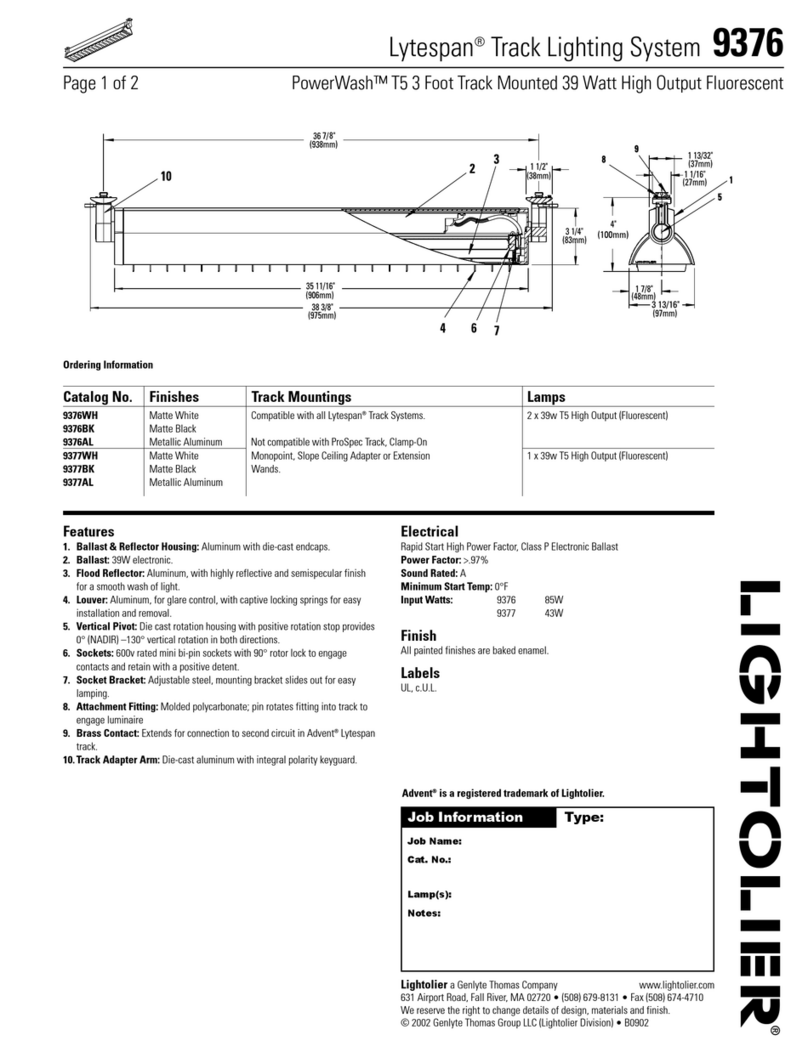

Lightolier Lytespan 9376 specification