Nordson ASYMTEK DispenseJet Series User manual

DispenseJet

Series

DJ-9500

Owner’s Manual

P/N 7218010, Revision D ©2010

NOTICE

This is an Asymtek publication, which is protected by copyright. Original copyright date 2008. No part of this

document may be photocopied, reproduced, or translated to another language without the prior written consent of

Asymtek. The information contained in this publication is subject to change without notice.

Manuals on the Internet

For the convenience of Asymtek customers and field service representatives, copies of Asymtek manuals can be

downloaded from:

http://www.asymtek.com/support/tech_manuals.htm

Contact Us

Asymtek welcomes requests for information, comments, and inquiries about its products. Please contact us using the

information below:

Headquarters 2762 Loker Avenue West

Carlsbad, CA 92010-6603

USA

Toll Free: 1-800-ASYMTEK (1-800-279-6835)

Tel: +1-760-431-1919

Fax: +1-760-431-2678

Website: www.asymtek.com

Technical Support

USA: 1-800-ASYMTEK (1-800-279-6835)

Other regions:

www.asymtek.com Tech Support

Trademarks

Asymtek®, DispenseJet®, Millennium®, Century®, and Fluidmove®are registered trademarks of Asymtek.

Axiomis a trademark of Asymtek.

Microsoft®, Windows®, and Windows NT ®are registered trademarks of Microsoft Corporation.

All other brand or product names are trademarks or registered trademarks of their respective organizations.

Table of Contents i

Table of Contents

1Introduction ......................................................................................................................................... 1

Overview................................................................................................................................................ 1

Specifications ........................................................................................................................................ 4

2Safety.................................................................................................................................................... 5

Overview................................................................................................................................................ 5

Safety Warning Symbols ....................................................................................................................... 5

Safety of Personnel ............................................................................................................................... 5

Preventing Equipment and Workpiece Damage ................................................................................... 6

Material Safety ...................................................................................................................................... 6

3Theory of Operation ............................................................................................................................ 7

Overview................................................................................................................................................ 7

Adjustable Features .............................................................................................................................. 7

Fluid Pressure .......................................................................................................................... 7

Stroke Adjustment .................................................................................................................... 7

Solenoid Valve ......................................................................................................................... 7

Seat, Nozzle and Needle Assembly......................................................................................... 7

Active Nozzle............................................................................................................................ 7

Thermal Control Assembly....................................................................................................... 7

Dot and Line Parameters ......................................................................................................... 7

Body Heater ............................................................................................................................. 8

4Installation ........................................................................................................................................... 9

Overview................................................................................................................................................ 9

Safety First ............................................................................................................................................ 9

Unpacking the DJ-9500......................................................................................................................... 9

Installing the DJ-9500 Valve.................................................................................................................. 9

5Setup................................................................................................................................................... 13

Overview.............................................................................................................................................. 13

Setting Up the DJ-9500 ....................................................................................................................... 13

6Maintenance and Service ................................................................................................................. 17

Overview.............................................................................................................................................. 17

Disassembling the DJ-9500 – Wetted Parts ....................................................................................... 17

Cleaning and Inspecting the DJ-9500 – Wetted Parts ........................................................................ 19

Removing the Cup Seal ......................................................................................................... 19

Cleaning the Cup Seal ........................................................................................................... 19

Cleaning the Static Seal ......................................................................................................... 20

Removing the Static Seal ....................................................................................................... 20

Cleaning the Nozzle ............................................................................................................... 21

Assembling the DJ-9500 – Wetted Parts ............................................................................................ 23

Removing and Replacing the Needle Assembly................................................................................. 27

Lubricating the Retainer Assembly and Stroke Adjustment Assembly ............................................... 29

Removing and Replacing the Solenoid Valve or Thermal Control Assembly (TCA) .......................... 30

ii Table of Contents

7Troubleshooting ................................................................................................................................ 35

Overview.............................................................................................................................................. 35

Troubleshooting the DJ-9500 .............................................................................................................. 35

8Additional Information ...................................................................................................................... 39

Recommended Facility Items.............................................................................................................. 39

Return Material Authorization.............................................................................................................. 39

Input/Output Connection ..................................................................................................................... 40

Needle Assembly, Nozzle, and Seat Configuration ............................................................................ 41

Spares and Accessories...................................................................................................................... 44

Sample Application Settings ............................................................................................................... 46

9Illustrated Parts List.......................................................................................................................... 49

Table of Contents iii

Table of Figures

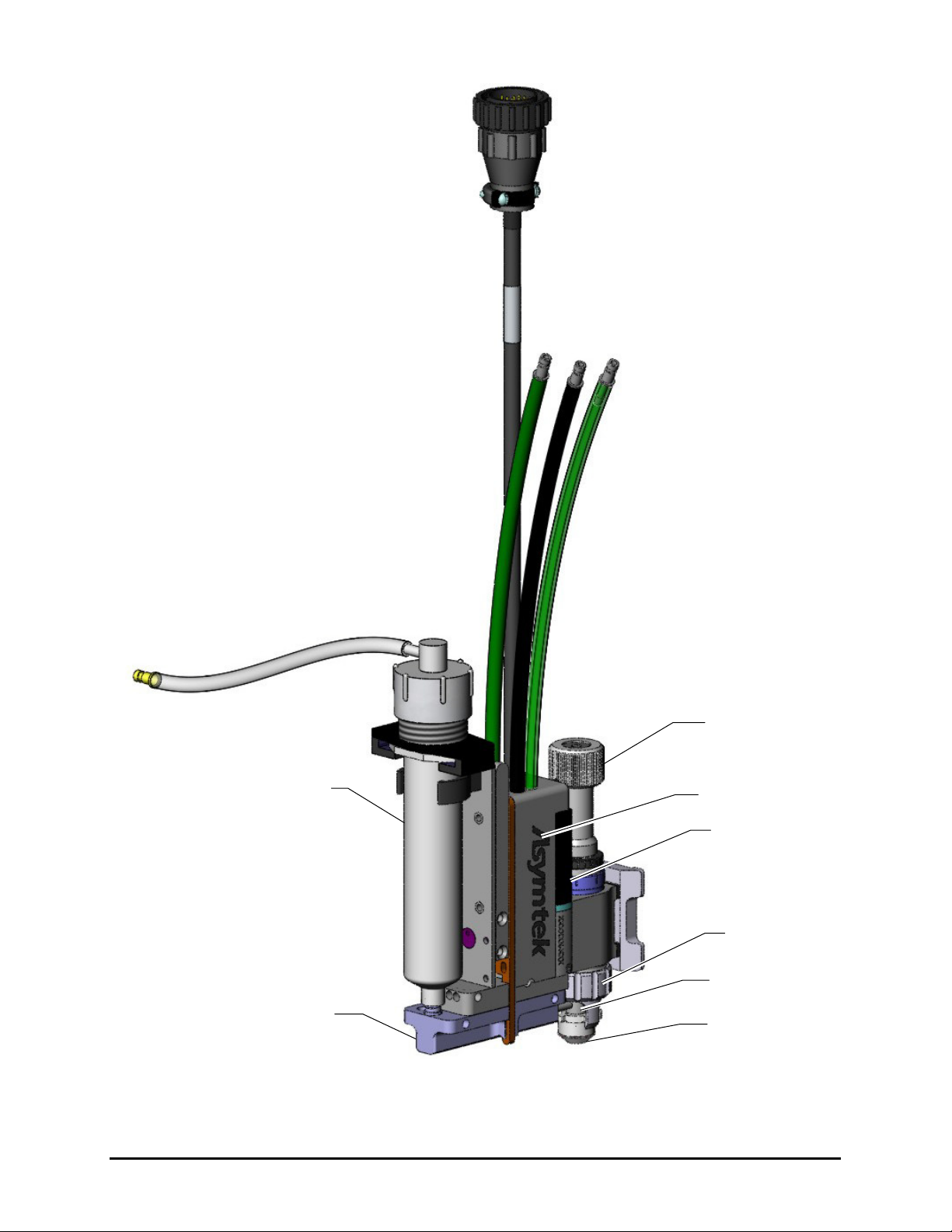

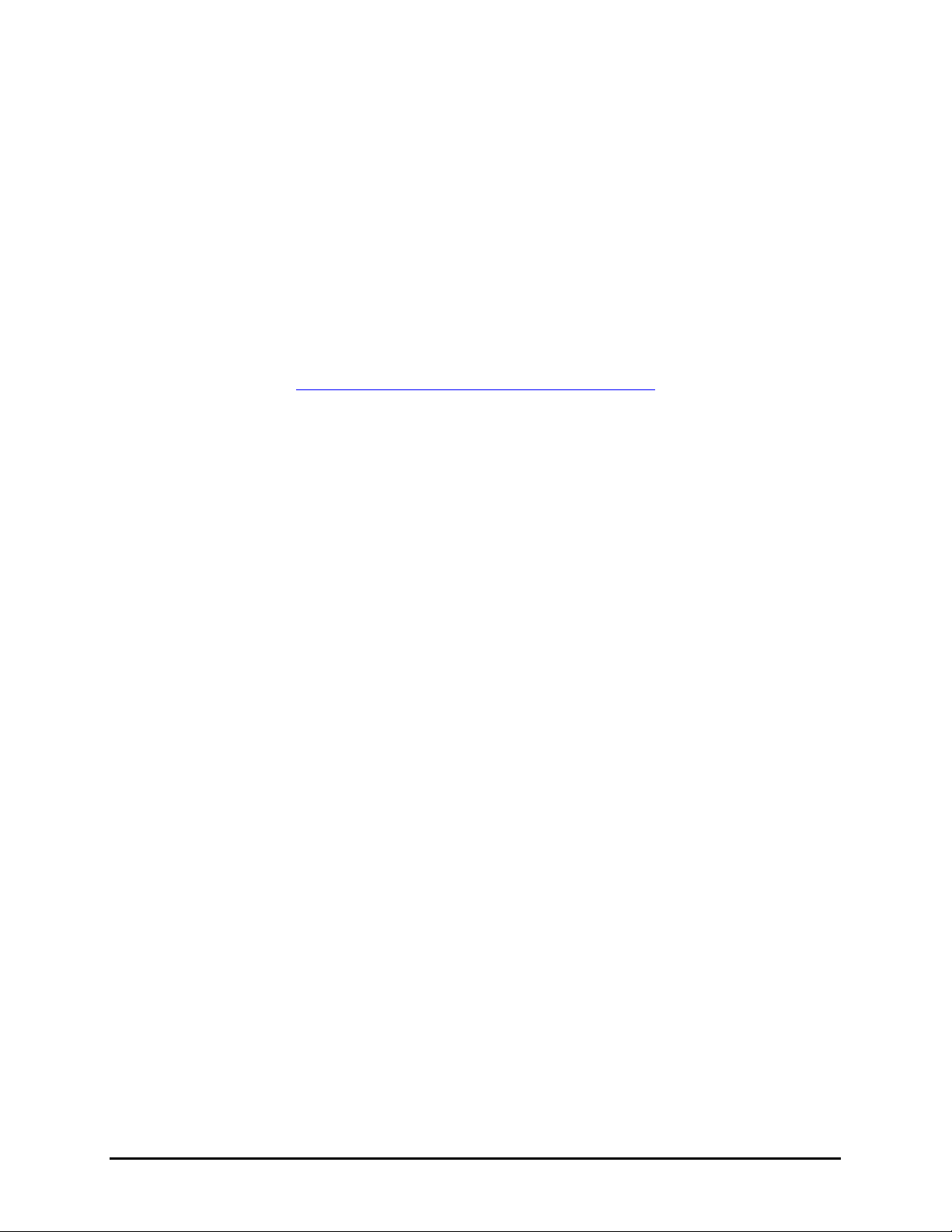

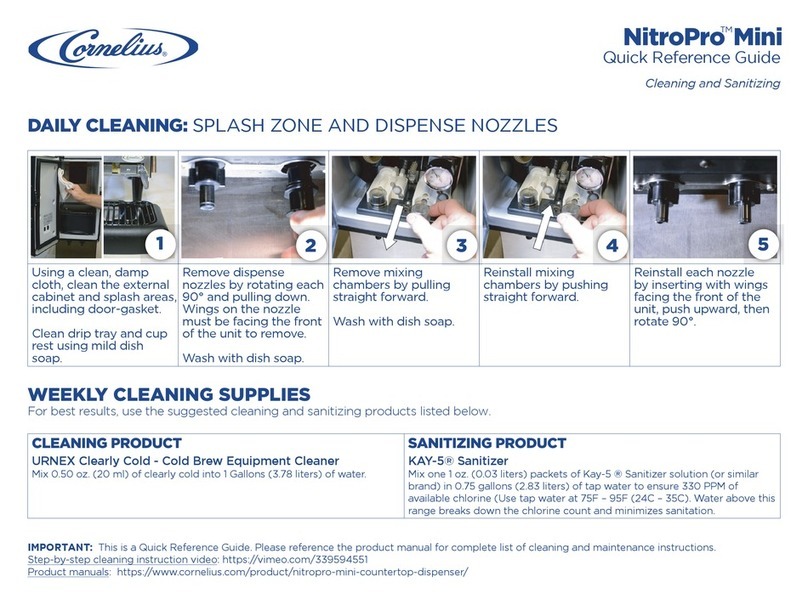

Figure 1-1 DispenseJet Series DJ-9500 (30cc Fluid Tube w/o Heat Exchanger)................................ 1

Figure 1-2 DispenseJet Series DJ-9520 (30cc Fluid Reservoir w/ Heat Exchanger) .......................... 2

Figure 1-3 DispenseJet Series DJ-9520 (6oz Fluid Tube w/ Heat Exchanger) ................................... 3

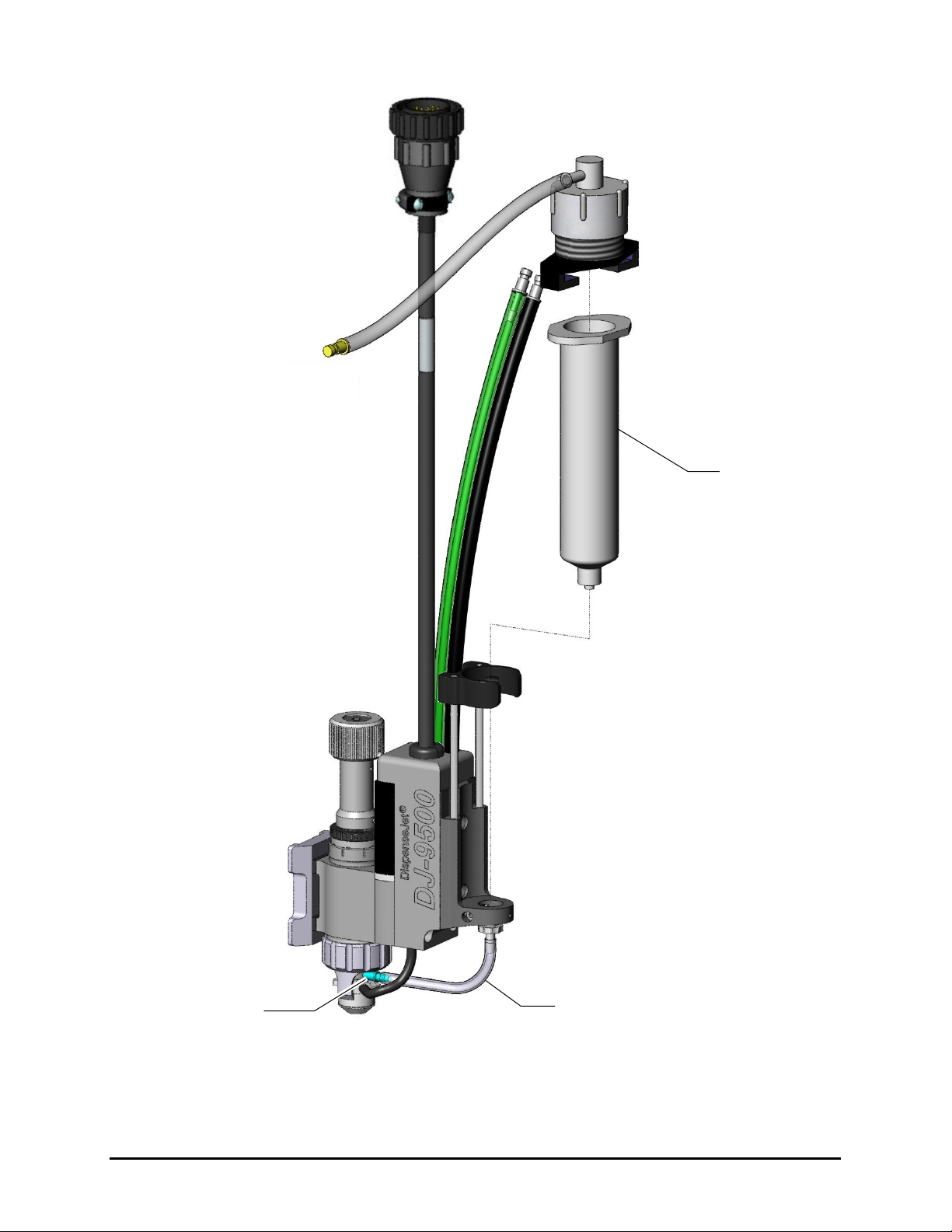

Figure 3-1 DJ-9500 Exploded View...................................................................................................... 8

Figure 4-1 Connection Diagram – Axiom X-1000............................................................................... 11

Figure 4-2 Connection Diagram – Spectrum S-900 Series................................................................ 12

Figure 5-1 Connecting the Fluid Reservoir (30cc Fluid Tube w/o Heat Exchanger).......................... 14

Figure 5-2 Connecting the Fluid Reservoir (30cc Fluid Reservoir w/ Heat Exchanger)..................... 15

Figure 5-3 Connecting the Fluid Reservoir (6oz Fluid Reservoir w/ Heat Exchanger) ...................... 16

Figure 6-1 Disassembling Wetted Parts (DJ9520 w/Cup Seal and Unitized Nozzle shown)............ 18

Figure 6-2 Removing the Seat............................................................................................................ 19

Figure 6-3 Removing the Fluid Seal ................................................................................................... 19

Figure 6-4 Cleaning the Static Seal.................................................................................................... 20

Figure 6-5 Removing the Static Seal.................................................................................................. 20

Figure 6-6 Nozzle, Seat, and O-ring Removal (Active Nozzle Pictured)............................................ 21

Figure 6-7 Inserting the Cup Seal ...................................................................................................... 23

Figure 6-8 Seal Fully Inserted ............................................................................................................ 23

Figure 6-9 Assemble the Static Seal .................................................................................................. 23

Figure 6-10 Place Static Seal on Needle ............................................................................................. 23

Figure 6-11 Seating the Static Seal...................................................................................................... 23

Figure 6-12 Stroke Adjustment Assembly Fully Opened ..................................................................... 24

Figure 6-13 Inserting the Seat .............................................................................................................. 24

Figure 6-14 Nozzle In Cavity Recess ................................................................................................... 24

Figure 6-15 TCA Placed Over Nozzle .................................................................................................. 24

Figure 6-16 Unitized Nozzle In Fluid Chamber Cavity Recess ............................................................ 25

Figure 6-17 Fluid Chamber/Unitized Nozzle Placed over Needle Assembly ....................................... 25

Figure 6-18 TCA Placed Over Unitized Nozzle .................................................................................... 25

Figure 6-19 Tightening the Collar ......................................................................................................... 25

Figure 6-20 Stroke Adjustment............................................................................................................. 26

Figure 6-21 Unscrewing the Needle Assembly .................................................................................... 27

Figure 6-22 Inserting the Needle Flange.............................................................................................. 27

Figure 6-23 Inserting the Needle .......................................................................................................... 28

Figure 6-24 Detaching the Needle from the Insertion Tool Base ......................................................... 28

Figure 6-25 Needle and Flange Fully Seated....................................................................................... 29

Figure 6-26 Loosening the Four Socket Head Screws (DJ-9500) ....................................................... 30

Figure 6-27 Loosening the Four Socket Head Screws (DJ-9520) ....................................................... 31

Figure 6-28 Pushing the Coolant Line through the Junction Box......................................................... 32

Figure 6-29 Removing the TCA Assembly ........................................................................................... 32

Figure 6-30 Attaching the TCA Assembly ............................................................................................ 32

Figure 6-31 Pulling the Coolant Line Back through the Junction Box .................................................. 32

Figure 6-32 Pressing the TCA into the Junction Box .......................................................................... 33

Figure 6-33 TCA Electrical Connectors ................................................................................................ 33

Figure 6-34 Connecting the Solenoid ................................................................................................... 33

Figure 6-35 Junction Box to Valve Body Alignment ............................................................................. 34

Figure 9-1 DJ-9500 Illustrated Parts List (Cup Seal, Standard Nozzle, and 30cc Mount) ................ 51

Figure 9-2 DJ-9520 Illustrated Parts List (Cup Seal, Unitized Nozzle, and 30cc Mount).................. 52

Figure 9-3 DJ-9520 Illustrated Parts List (Static Seal, Active Nozzle, and 6oz Mount) .................... 53

iv Table of Contents

Table of Tables

Table 6-1 Nozzle Cleaning Tools ...................................................................................................... 22

Table 7-1 DJ-9500 Troubleshooting – Symptom Based ................................................................... 35

Table 7-2 DJ-9500 Troubleshooting – Set-up Based........................................................................ 37

Table 7-3 DJ-9500 Troubleshooting – Component Based................................................................ 38

Table 8-1 Available Needle/Nozzle and Seat Sizes.......................................................................... 41

Table 8-2 DJ-9500 Spares and Accessories..................................................................................... 44

Table 8-3 DJ-9520 Spares and Accessories..................................................................................... 45

Table 8-4 Hardware Settings............................................................................................................. 46

Table 8-5 Software Settings .............................................................................................................. 46

Table 9-1 Illustrated Parts List........................................................................................................... 49

Introduction 1

1 Introduction

Overview

The DispenseJet Series DJ-9500 (Figure 1-1) is a non-contact dispenser providing high-speed delivery

and exceptional volumetric control for various fluids, including silicones, underfill, encapsulants, UV

adhesives, and silver epoxy. The DJ-9500 jets in tight spaces as small as 175 micrometers and creates

fillet wet-out widths as small as 300 micrometers on the dispensed side of the die. It dispenses fluid either

as discrete dots or as a rapid succession of dots to form a 100-micrometer diameter stream of fluid from

the nozzle. It is fully compatible with Asymtek DispenseMate, Axiom X-1000, Spectrum S-820, and

Spectrum S-900 Series Dispensing Systems.

Figure 1-1 DispenseJet Series DJ-9500 (30cc Fluid Tube w/o Heat Exchanger)

Thermal Control

Assembly

Feed Tube

Assembly

Fluid Reservoir

Fluid Chamber

Stroke Adjustment

Knob

Collar (Retainer

Assembly)

Junction Box

Solenoid

2 Introduction

Figure 1-2 DispenseJet Series DJ-9520 (30cc Fluid Reservoir w/ Heat Exchanger)

Thermal Control

Assembly

Heat Exchanger

Fluid Reservoir

Fluid Chamber

Stroke Adjustment

Knob

Collar (Retainer

Assembly)

Junction Box

Solenoid

Introduction 3

Figure 1-3 DispenseJet Series DJ-9520 (6oz Fluid Tube w/ Heat Exchanger)

Thermal Control

Assembly

Fluid Reservoir

Fluid Chamber

Stroke Adjustment

Knob

Collar (Retainer

Assembly)

Junction Box

Heat Exchanger

Solenoid

4 Introduction

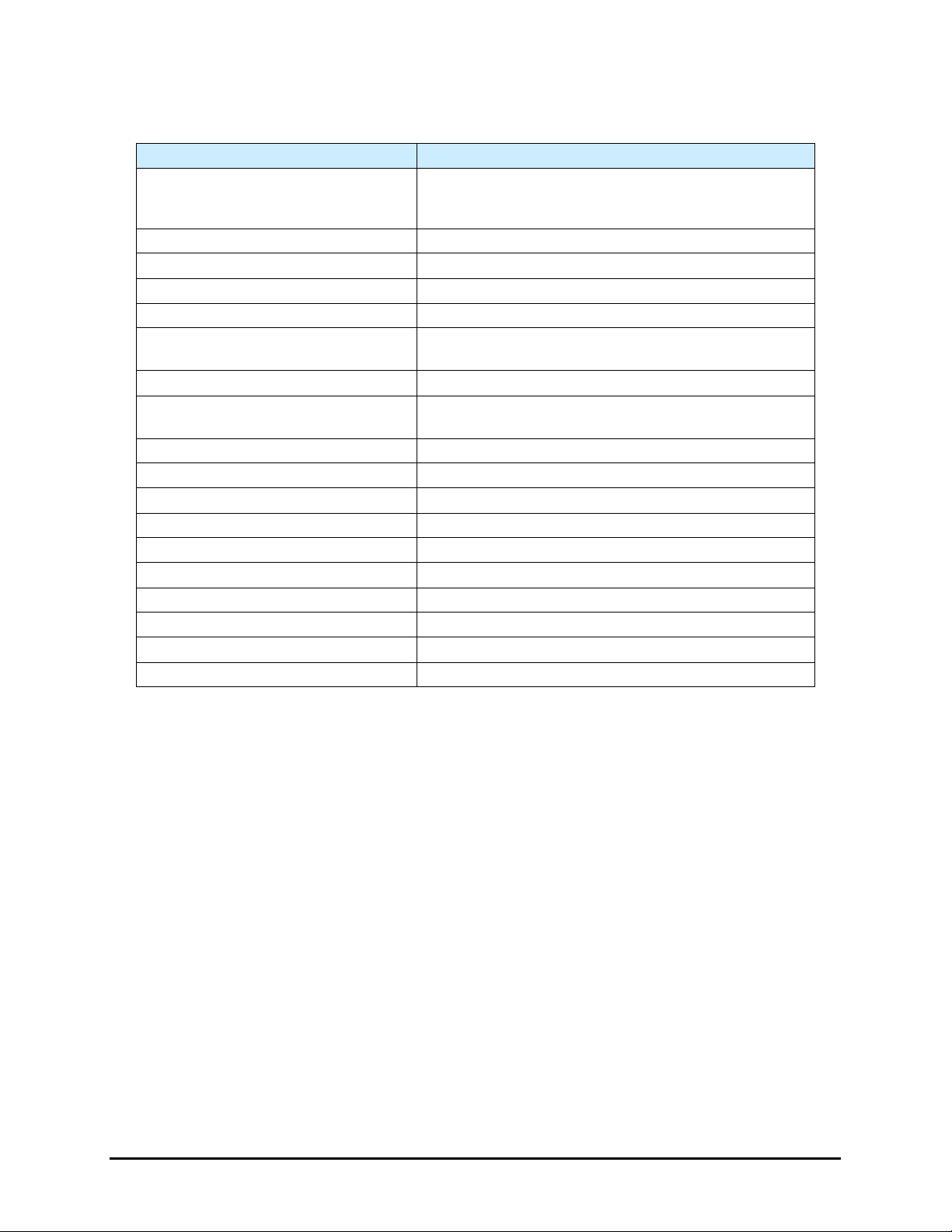

Specifications

Characteristic Specification

Size Width: 33 mm

Height: 142 mm

Depth: 100 mm (135mm w/ Body Heater)

Seat and Nozzle Carbide / Stainless Steel

Needle Assembly Carbide

Fluid Seal PEEK or Flouroloy

Fluid Chamber O-Ring Ethylene Propylene or Viton

Jet Body 6061-T6 Aluminum/Nickel Plated

NPE 303 Stainless Steel

Needle Assembly Bearings PEEK

Thermal Control Body 6061-T6 Aluminum

Nickel Plated

Feed Tube Assembly Fitting Female Luer per ANSI/HIMA MD70.1-1983

Maximum Cycle Frequency 200 Hz.

Minimum Valve Air Pressure 5.5 bar (80 psi)

Solenoid 24 VDC, 5 watts

Nozzle Heater (TCA) 24 VDC, 14.7 Watts, 40 ohms

Thermal Control RTD 100 ohm, platinum

Maximum Heater Set Point 100 °C

Body Heater Ch2 24 VDC, 50 Watts, 11.5 ohms

Body Heater Rtd 100 ohm, platinum

Max Heater Set Point 100 °C

*At Maximum Cycle Rate

NOTE Asymtek manufactures each DJ-9500 under strict manufacturing quality control

standards to ensure precise and reliable performance. To obtain maximum performance,

please read instructions carefully. Please contact Asymtek for the suitability of the

DJ-9500 technology for other applications.

Safety 5

2 Safety

Overview

Dispensing system operation involves heat, air pressure, fluid pressure, mechanical and pneumatic

devices, electrical power, and the use of hazardous materials. Refer to the safety section of your particular

dispensing system Operations Manual prior to installing and operating your DispenseJet Series DJ-9500.

Safety is considered a joint responsibility between the original equipment manufacturer (Asymtek) and

the end-user (owner). All safety precautions and practices should be in accordance with local regulations

and facility practice.

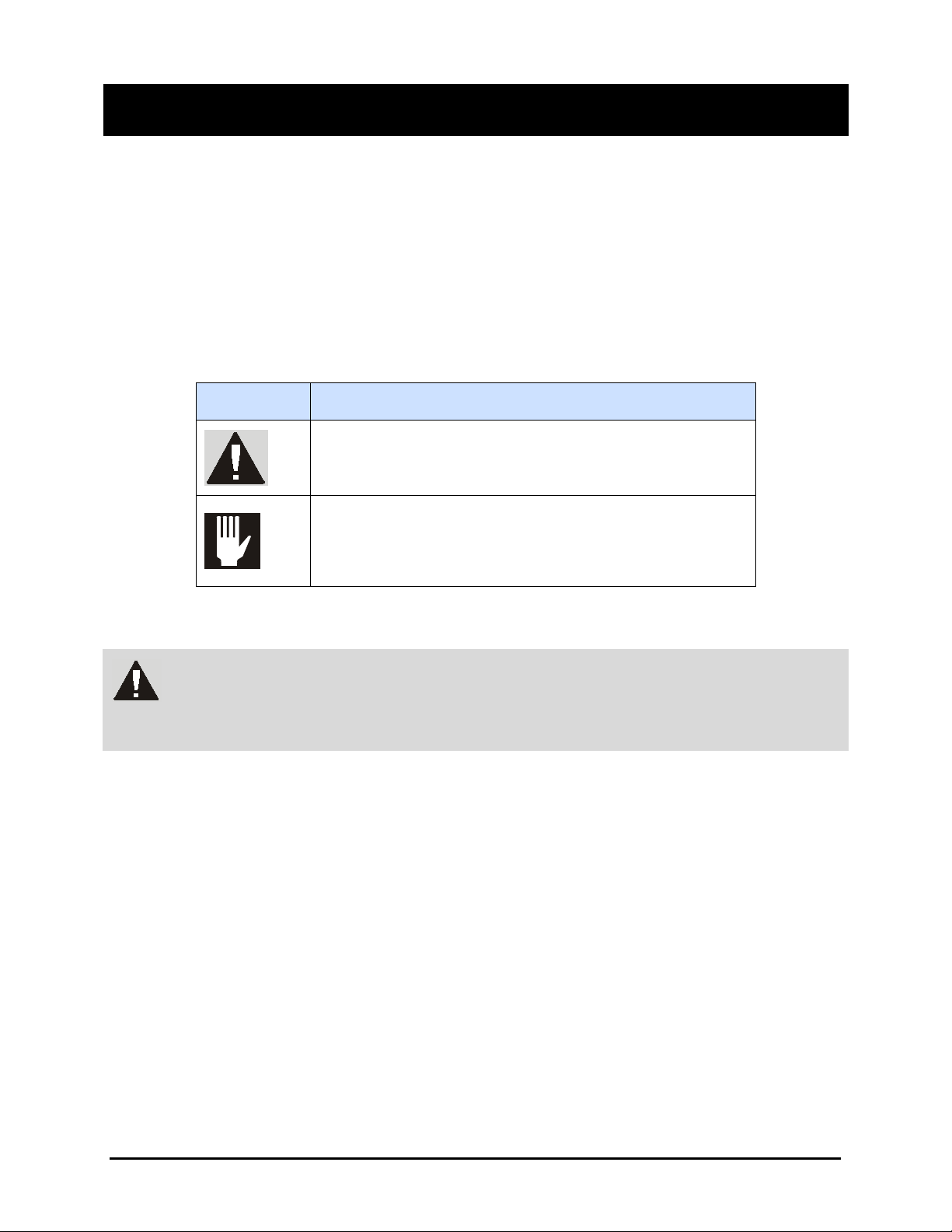

Safety Warning Symbols

Symbol Description

Personnel Safety Warning. This symbol appears in a

shaded text block to warn you about actions that could cause

personal injury or death.

Property Damage Caution. This symbol appears in a shaded

text block to warn you about actions that could cause serious

damage to the machinery, software, parts being processed,

and facilities.

Safety of Personnel

WARNING! Unsafe equipment conditions can result in personal injury or property damage.

Failure to adhere to safety warnings and precautions could result in serious bodily

harm to the user.

•Only trained personnel should be permitted to perform installation, operation, maintenance, and

troubleshooting procedures on the DispenseJet Series DJ-9500.

•Before performing maintenance or service on the DJ-9500, position it at the front of the

dispensing chamber. This will provide easy access to components and limit exposure to

hazardous areas.

•Immediately push the red Emergency Machine Off (EMO) button on your dispensing system if

personnel are in danger.

•Do not touch the moving parts while the dispensing system is operating.

•Follow Material Safety Data Sheet (MSDS) recommendations for the proper handling of

hazardous materials.

•Remove the DJ-9500 completely from the dispensing system and allow the heated parts to cool

before cleaning or performing maintenance.

•Relieve pneumatic pressure before adjusting or servicing pressurized components.

6 Safety

Preventing Equipment and Workpiece Damage

•Immediately push the EMO button on the dispensing system if the dispensing system, DJ-9500,

or a workpiece is in danger of being damaged.

•Use standard Electrostatic Discharge (ESD) precautions when working near sensitive

components. Always wear a grounding strap and connect it to the ESD ground before handling

workpieces and equipment.

•Perform all recommended DJ-9500 maintenance procedures at the suggested intervals.

•Immediately contain and clean up any caustic or conductive fluid spills as recommended in the

material manufacturer’s MSDS.

•If fluid gets into internal portions of the DJ-9500, immediately contact Asymtek Technical

Support.

•Use only replacement parts that are designed for use with the original equipment. Table 9-1

contains an illustrated parts list.

CAUTION! The DispenseJet Series DJ-9500 is a precision instrument of inherently safe

design. The use of any dispensing fluid and the related choice of solvent for

cleaning, as well as all associated safety precautions is the responsibility of the

end-user. Consult with your fluid supplier for recommendations on Personal

Protective Equipment and safety practices.

Material Safety

•Follow Material Safety Data Sheet (MSDS) recommendations for the proper handling, cleanup,

and disposal of hazardous materials.

•Know the MSDS recommendations for treatment of injury resulting from exposure to hazardous

materials.

•When working with multiple fluids, refer to the MSDS to ensure the materials are compatible.

•Always wear appropriate Personal Protective Equipment (PPE) as recommended by facility

safety practices and the material manufacturer’s MSDS.

Theory of Operation 7

3 Theory of Operation

Overview

The DJ-9500 is a normally closed, air-actuated, spring-return mechanism, which uses momentum transfer

principles to expel precise volumes of material. Pressurized air is regulated by a high-speed solenoid to

retract the Needle Assembly from the seat. Fluid, fed into the fluid chamber, flows over the seat. When

the air is exhausted, the needle travels rapidly to the closed position, displacing fluid through the seat and

nozzle in the form of a droplet. Multiple droplets fired in succession can be used to form larger dispense

volumes and lines when combined with the motion of a dispenser robot.

Adjustable Features

The following features affect performance of the DJ-9500 and are typically adjusted to fit your application.

Fluid Pressure

Fluid Pressure should be set so that fluid fills to the seat, but should not be influential in pushing the fluid

through the seat and nozzle. In general, higher fluid pressure results in a larger volume of material jetted.

Stroke Adjustment

The Stroke Adjustment controls the travel distance of the Needle Assembly. Turn counterclockwise to

increase Needle Assembly travel, turn clockwise to decrease travel. An increase of travel distance will

often result in a larger volume of material jetted.

Solenoid Valve

The Solenoid Valve controls the valve operation. When energized, it allows air in the jet air chamber to

compress a spring and thereby raise the Needle Assembly. When de-energized, the air is released and the

spring forces the piston down so that the needle tip contacts the seat. The valve ON/OFF times can be

adjusted in the Fluidmove software.

Seat, Nozzle and Needle Assembly

Seat, Nozzle and Needle Assembly geometries are typically the main factors controlling volume. Size is

determined based on the application and fluid properties. Other parameters are adjusted in accordance

with seat, nozzle and needle assembly choices. Sizes are listed in Table 8-1.

Active Nozzle

The Active Nozzle controls fluid break-off and minimizes accumulation at the nozzle tip.

Thermal Control Assembly

Fluid temperature often influences fluid viscosity and flow characteristics. The DJ-9500 is equipped with

a Thermal Control Assembly that assures a constant fluid temperature.

Dot and Line Parameters

In addition to the DJ-9500 hardware configuration and settings, Dot and Line Parameters are set in the

Fluidmove software program to control the size and quality of dots and lines dispensed. For information

on dispense parameters, refer to the Fluidmove User Guide or Online Help.

8 Theory of Operation

Body Heater

The Body Heater helps hold the DJ-9500 series assembly at constant temperature to protect it against

transient temperature fluctuation in the machine. The Heat Exchanger version will supply a fluid at a

constant temperature.

Figure 3-1 DJ-9500 Exploded View

Jet Body

Nozzle

Stroke Adjustment

Knob Assembly

Needle Assembly

Reservoir Holder

Collar

Seal

Thermal Control

Assembly (TCA)

Seat

Feed Tube

Assembly

Retainer

Fluid Chamber

O-Ring

Solenoid Valve

Fluid Reservoir

Installation 9

4 Installation

Overview

The DJ-9500 is designed for use on Asymtek DispenseMate, Axiom X 1000, Spectrum S-820, and

Spectrum S-900 Series Dispensing Systems. This section includes installation instructions applicable for

each of these systems.

This section includes the following installation instructions:

•Unpacking the DJ-9500

•Installing the DJ-9500

Safety First

Dispensing system operation involves heat, air pressure, fluid pressure, mechanical and pneumatic

devices, electrical power, and the use of hazardous materials. Refer to the Safety section of your particular

dispensing system manual prior to installing and operating your DJ-9500 Valve.

Unpacking the DJ-9500

Every care has been taken when packaging your DJ-9500. However, we recommend that you look for

obvious damage and verify contents against the packing slip.

Retain the case for storage of the DJ-9500 and accessories. Retain shipping cartons for future use.

If an item needs to be returned to Asymtek, obtain a Return Material Authorization (RMA) number

from Asymtek.

Installing the DJ-9500 Valve

If your DJ-9500 valve was factory installed, you do not need to perform this procedure.

WARNING! The procedures in this section should be performed by trained personnel only.

Tools and Materials Needed:

•4 mm hex wrench

NOTE Prior to installation, use the software or dispensing system position controls to move the

dispensing head to the front center of the dispensing area. Remove any valve currently

installed on the dispensing head. If the valve bracket installed is incompatible with the

DJ-9500, remove it and the Height Sensor (if present). Refer to the installation/removal

procedures in the applicable valve manual if necessary.

10 Installation

To install the DJ-9500:

1. Mount the DJ-9500 on the dovetail bracket and tighten with the 4-mm hex wrench.

2. Make the electrical connections according to the appropriate machine configuration shown in

Figure 4-1 and Figure 4-2.

3. Connect the pneumatic hoses as shown in Figure 4-1 and Figure 4-2. You should hear a click

when the hose is inserted properly.

The black hose connects to valve air.

The transparent green hose is used for nozzle cooling in elevated temperature

environments. Refer to the Fluidmove User Guide for software control setup of the

nozzle cooler. You can download the manual from:

http://www.asymtek.com/support/tech_manuals.htm

The green hose (if installed) is used for valve body cooling in elevated temperature

environments.

NOTE Verify that the cables and connections are secured adequately to account for the motion

of the robot.

Installation 11

Figure 4-1 Connection Diagram – Axiom X-1000

Setup 13

5 Setup

Overview

This section describes the procedures required to setup the DJ-9500 for dispensing.

NOTE Refer to the Fluidmove User Guide for detailed instructions on software configuration.

Setting Up the DJ-9500

To setup the DJ-9500:

1. Make sure the DJ-9500 is completely assembled. See Section 6 - Maintenance and Service

for complete assembly and disassembly instructions.

NOTE An optional Magnetic Low Fluid Sensor Kit is available. The DJ-9500 uses P/N

7201410 and it attaches to the syringe holder (P/N 7201394) using the two

screws provided. The DJ-9520 uses P/N MLFS and attaches directly to the

syringe.

2. Connect the Fluid Reservoir to the jet (Figure 5-1 through Figure 5-3).

3. Install the DJ-9500 as detailed in Section 4 - Installation.

4. Verify the fluid pressure is set correctly for your particular application. Adjust the Fluid

Pressure to 0-2 bar (0-40 psi), depending on the fluid viscosity.

5. Verify that “DJ-Series” is selected as the active valve configuration in the Fluidmove Setup

Valves Screen.

6. When using an Active Nozzle, verify that the Active Nozzle checkbox is selected in the

Fluidmove Valve Settings Screen.

7. If your valve has a body heater, verify the appropriate temperature control settings in the

Fluidmove Heater Control Window (Body Heater is run on the Valve 2 Heater Channel).

Allow 15 minutes for the temperature to stabilize.

WARNING! CAUTION!

Caution should be used if valve offsets are uncertain as the next step causes

automatic motion of the jet nozzle to pre-determined locations. A Valve Offsets

routine should be performed after a valve change and after a hardware change or

location adjustment.

8. Perform the appropriate Fluidmove setup routine. The setup routine purges the valve,

calibrates the nozzle to the camera offset, and verifies jet operation.

14 Setup

Figure 5-1 Connecting the Fluid Reservoir (30cc Fluid Tube w/o Heat Exchanger)

Feed Tube Assembly

Fluid Reservoir

Fluid Chamber

This manual suits for next models

2

Table of contents

Other Nordson ASYMTEK Dispenser manuals

Popular Dispenser manuals by other brands

Teal

Teal TEALwash Installation and operating instructions

BETCO

BETCO COMPASS Instructional guide

Parker

Parker SciLog LabTec Series Installation, Operation & Maintenance Instruction Manual

Nordson

Nordson freedom product manual

Cornelius

Cornelius NITROPRO MINI Quick reference guide

Animo

Animo CN5e user manual

U-Line

U-Line Rubbermaid H-3542 quick start guide

Cornelius

Cornelius Enduro-200 installation manual

Star Manufacturing

Star Manufacturing Peristaltic Heated Condiment Dispenser HPDE1 Brochure & specs

U-Line

U-Line EZ Pull Senior H-2534 quick start guide

ITALTINTO

ITALTINTO i253C user manual

U-Line

U-Line H-2895 manual