www.nordsonefd.com

[email protected] 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.781Mini Series Spray Valve

8

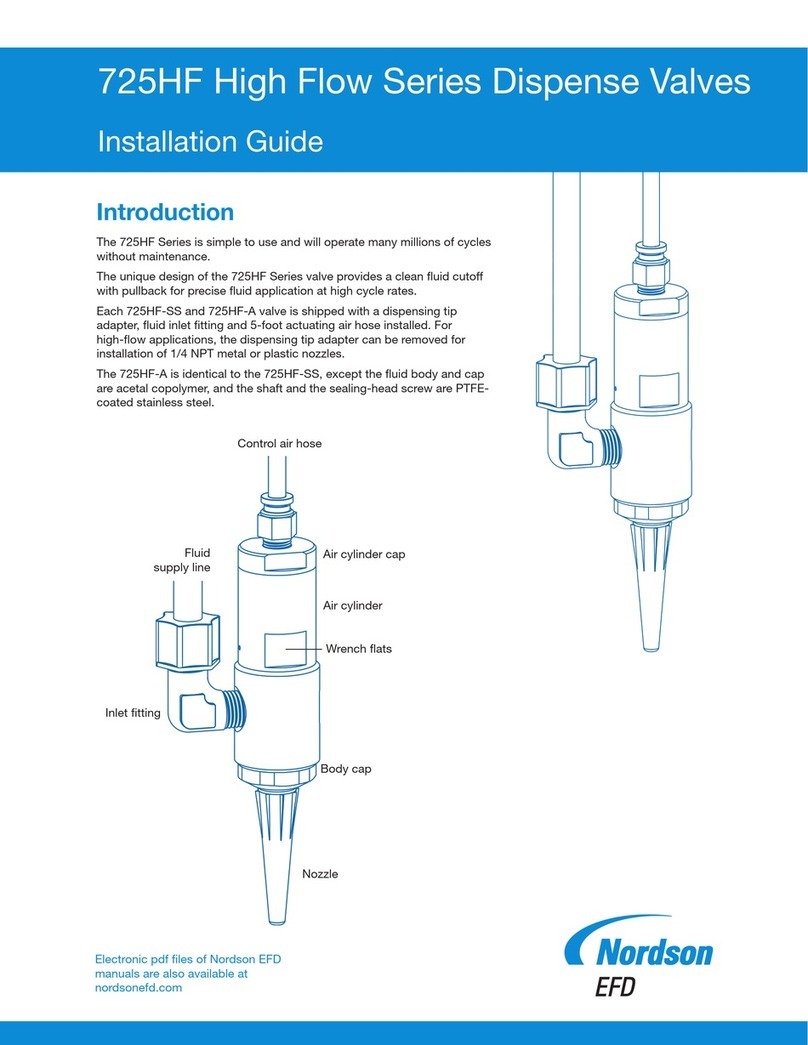

Making the System Connections

For complete installation, setup, and testing instructions, refer to the controller operating manual.

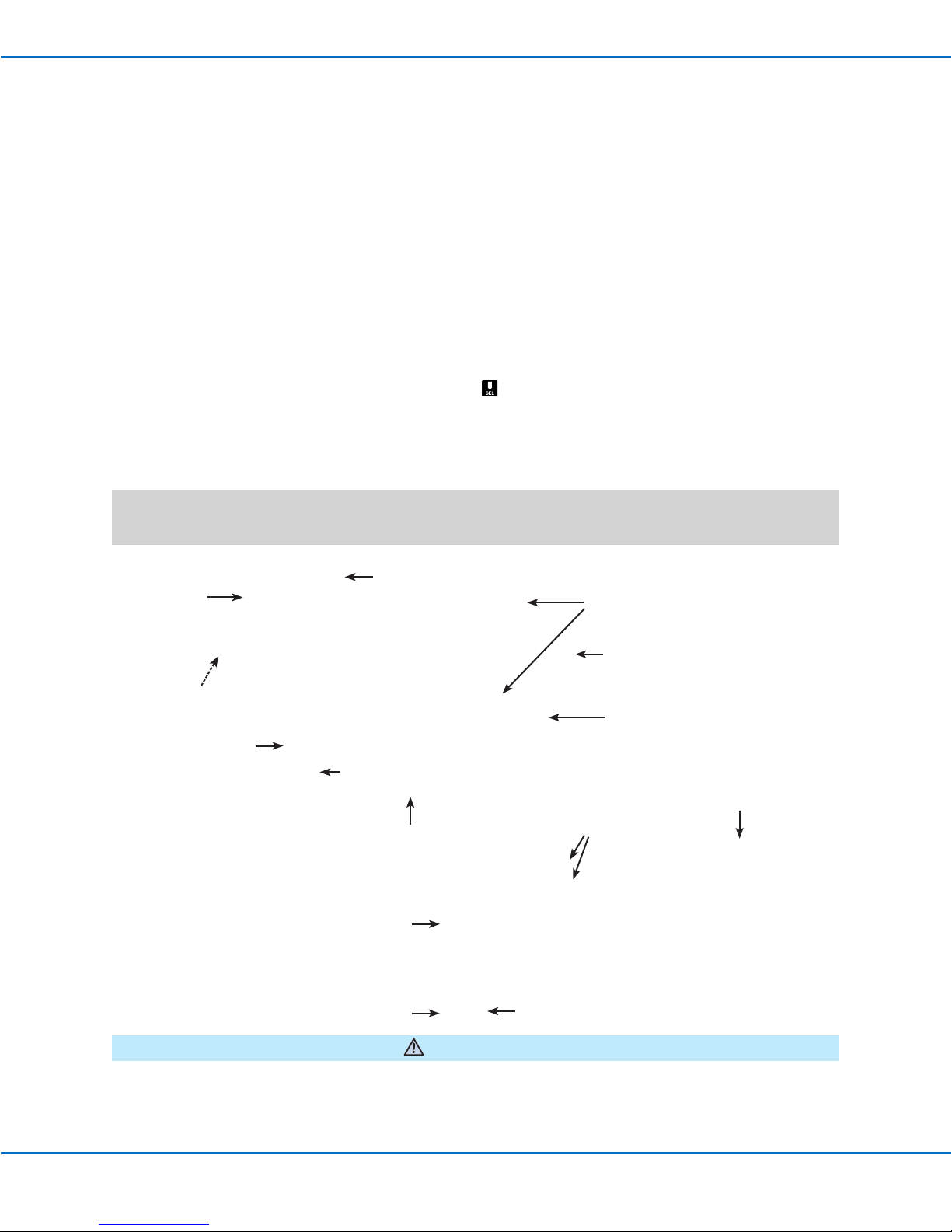

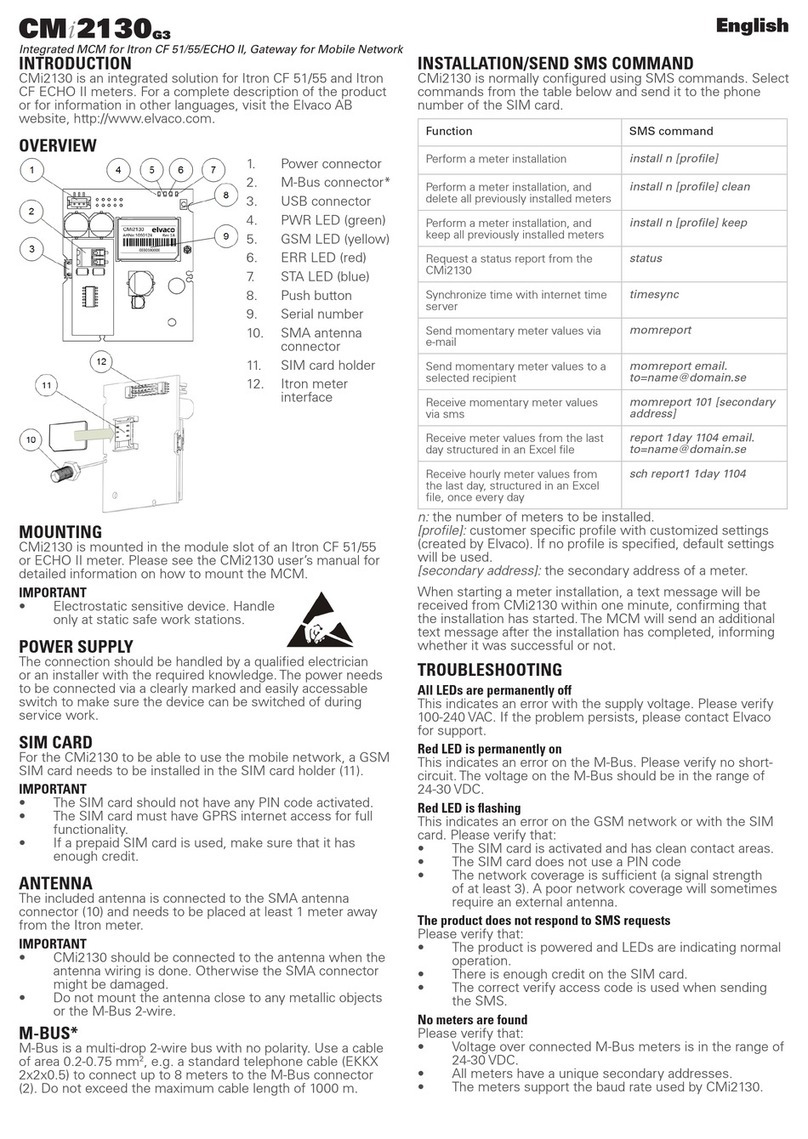

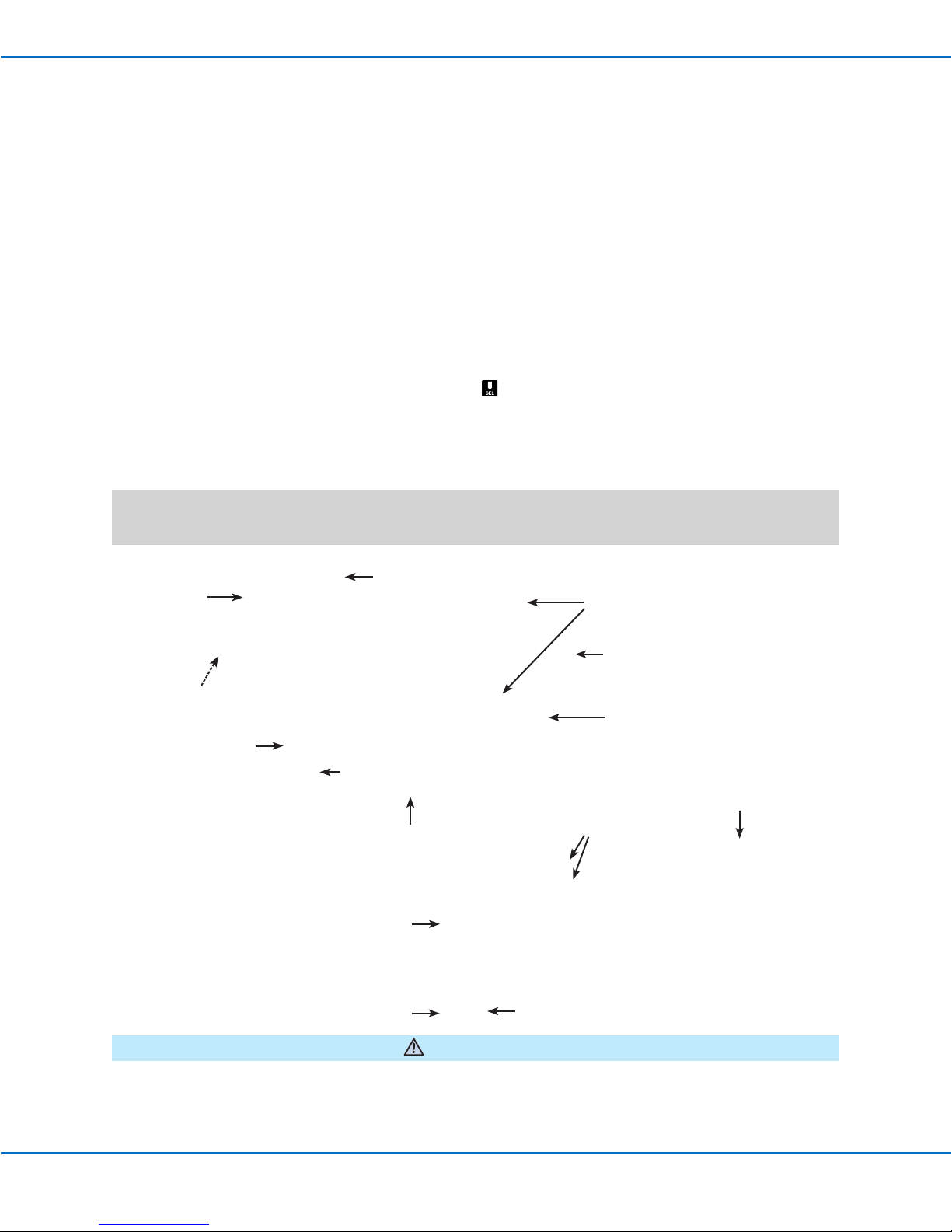

ValveMate 8040 System with a 781Mini Valve

NOTE: The area of spray coverage is determined (1) by the distance between the spray valve nozzle and the work surface and

(2) by the stroke adjustment and uid pressure. Refer to “Round Pattern Spray Area Coverage” on page 10 to determine the

distance.

Always de-pressurize the uid reservoir before opening it. To do this, slide the shutoff valve on the air line away from the reservoir.

Before opening the reservoir, check the pressure gauge to verify that pressure is zero (0). If using an EFD tank, also open the

pressure relief valve.

On all EFD cartridge reservoirs, the unique threaded design provides fail-safe air pressure release during cap removal.

CAUTION

1. Connect the valve actuating air tubing

(white) and the nozzle air tubing

(black) to the ValveMate 8040 dual

solenoid pack used to control valve

open time (white) and nozzle air

(black).

2. Connect the white male quick-

connect on the constant air line to the

white female quick-connect on the

5-micron lter / regulator.

3. Install the syringe barrel reservoir

on the uid inlet tting (for use with

Optimum® syringe barrels). For low

viscosity uids, ll the reservoir after

installing it on the uid inlet tting.

NOTE: Fill syringe barrel reservoirs no

more than 2/3full.

4. Attach the syringe barrel adapter

to the barrel reservoir using the air

interconnect coupler to connect the

adapter to the uid pressure regulator

air line.

5. Set the uid pressure regulator to

low for thin uids and higher for thick

uids.

6. Use the MODE button on the

ValveMate controller to place the

controller in the PURGE mode. In the

PURGE mode only, channels 1 and

3 can be selected independently

without nozzle air pressure.

7. Use the stroke control knob on the

781Mini valve to set the desired ow

rate. Lower strokes (< 5) will produce

smaller patterns. Check the ow rate

by actuating the controller in the TIME

OVERRIDE mode.

NOTE: Make valve stroke

adjustments only when the valve is

not cycling.

8. Set the nozzle air pressure to 0.7 bar

(10 psi) and actuate the controller.

The valve will produce a ne spray.

To change uid ow, use the stroke

control knob and / or the reservoir

pressure. To change the nozzle air,

use the nozzle air pressure regulator.

Higher pressures will provide ner

spray.

NOTE: The 5-micron lter / regulator

assembly is not included. Order

separately:

7020584: 0–100 psi lter / regulator

7020585: 0–15 psi lter / regulator

Nozzle air pressure

regulator

5-micron lter /

regulator

781Mini valve

30 cc syringe barrel

Constant air

Fluid pressure

regulator

Constant uid

pressure

Valve actuating air (white)

ValveMate 8040

Controller

Plant air

4.8–6.8 bar

(70–90 psi)

Dual solenoid pack

Nozzle air (black)

Solenoid cables

Fluid inlet tting