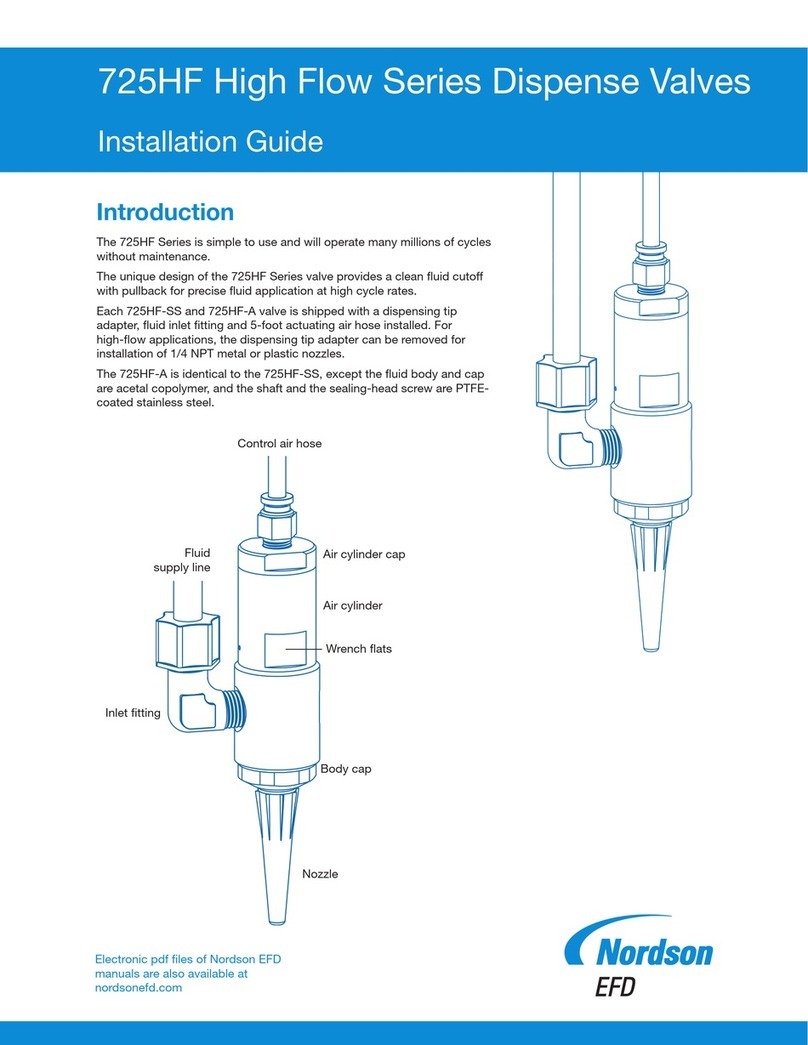

Nordson EFD 725HF-SS Manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD 741V Series User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 752V-HL User manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Nordson EFD

Nordson EFD 781Mini Series User manual

Nordson EFD

Nordson EFD 745NC User manual

Nordson EFD

Nordson EFD 782RA Manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD 752V Series Manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 741MD-SS Series Manual

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 725HF Series User manual

Popular Control Unit manuals by other brands

Cabletron Systems

Cabletron Systems SmartSwitch 9500 Hardware and installation guide

SEW-Eurodrive

SEW-Eurodrive Movidrive MDX61B manual

McQuay

McQuay OM 1057 Operation manual

Cosmo

Cosmo CFWME Installation and operating manual

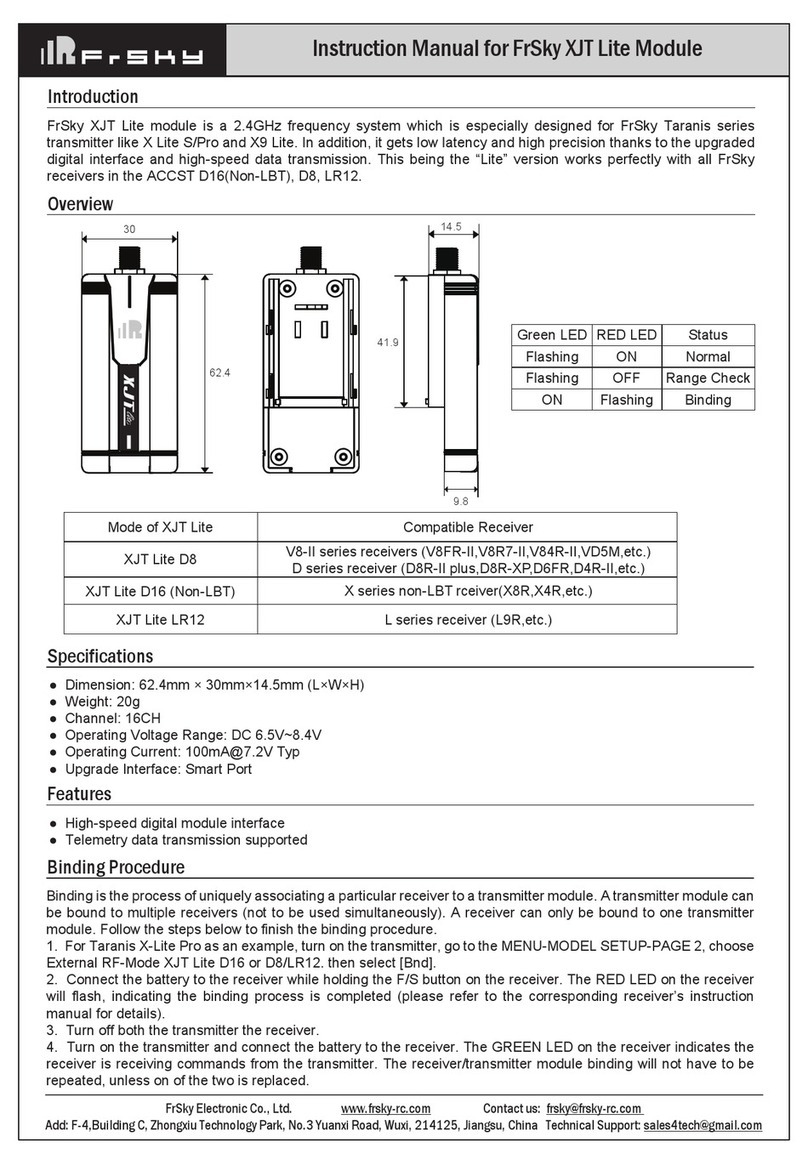

FrSky

FrSky XJT Lite D8 instruction manual

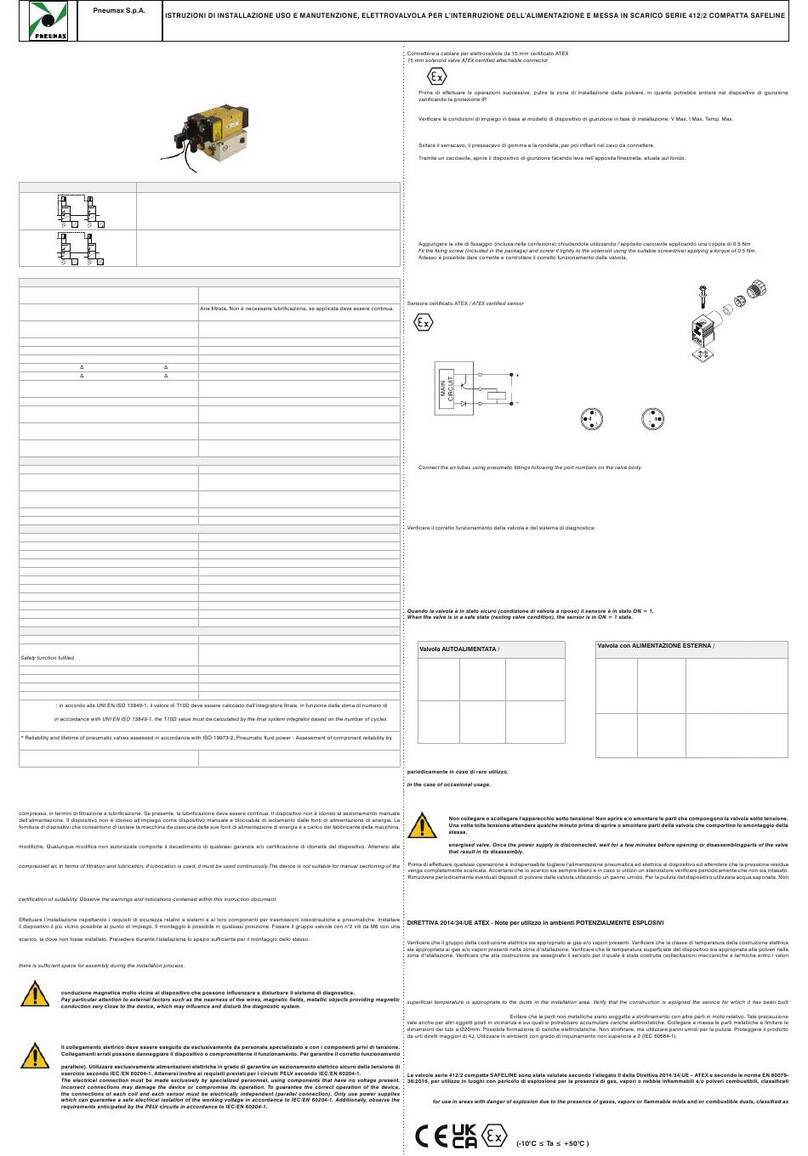

Pneumax

Pneumax 2 SAFELI 412/2 Series Installation, Use and Maintenance Instruction