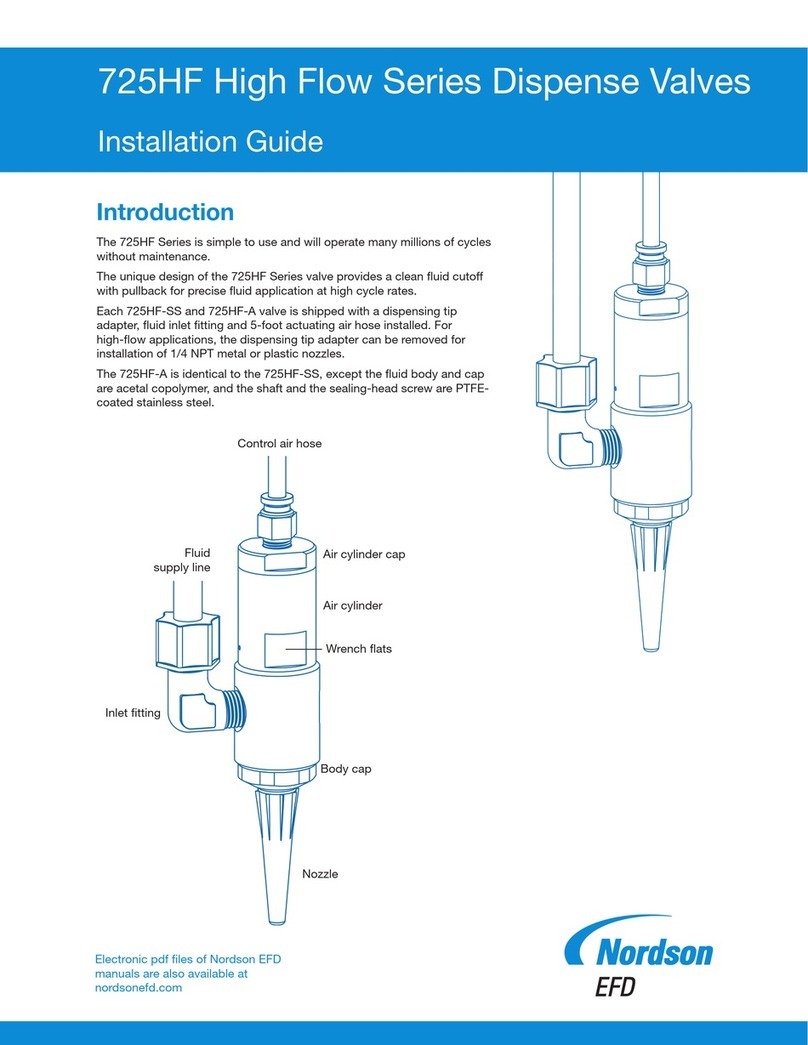

Nordson EFD 725HF-SS Manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 781Mini Series User manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD 781S Series User manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD 752V Series Manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

Nordson EFD 782RA Manual

Nordson EFD

Nordson EFD 752V-HL User manual

Nordson EFD

Nordson EFD 745NC User manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 741V Series User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

Nordson EFD 725HF Series User manual

Nordson EFD

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Popular Control Unit manuals by other brands

DAV TECH

DAV TECH DAV 150 Installation and maintenance guide

Toa

Toa AT-4012B-EB installation manual

Lindpointner

Lindpointner geba tronic Cody Light HF 1/1 manual

schmersal

schmersal Elan SRB 201ZH X3 operating instructions

aci

aci ANALOG RESCALING Series Installation & operation instructions

Allmess

Allmess ITRON EquaScan pMIURF Assembly and Programming Instructions