Nordson EFD 741MD-SS Series Manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 752V Series Manual

Nordson EFD

Nordson EFD 741V Series User manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

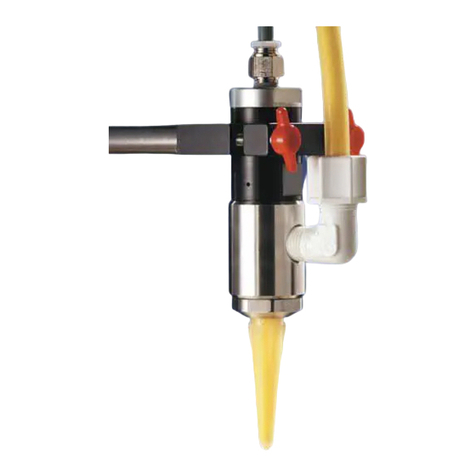

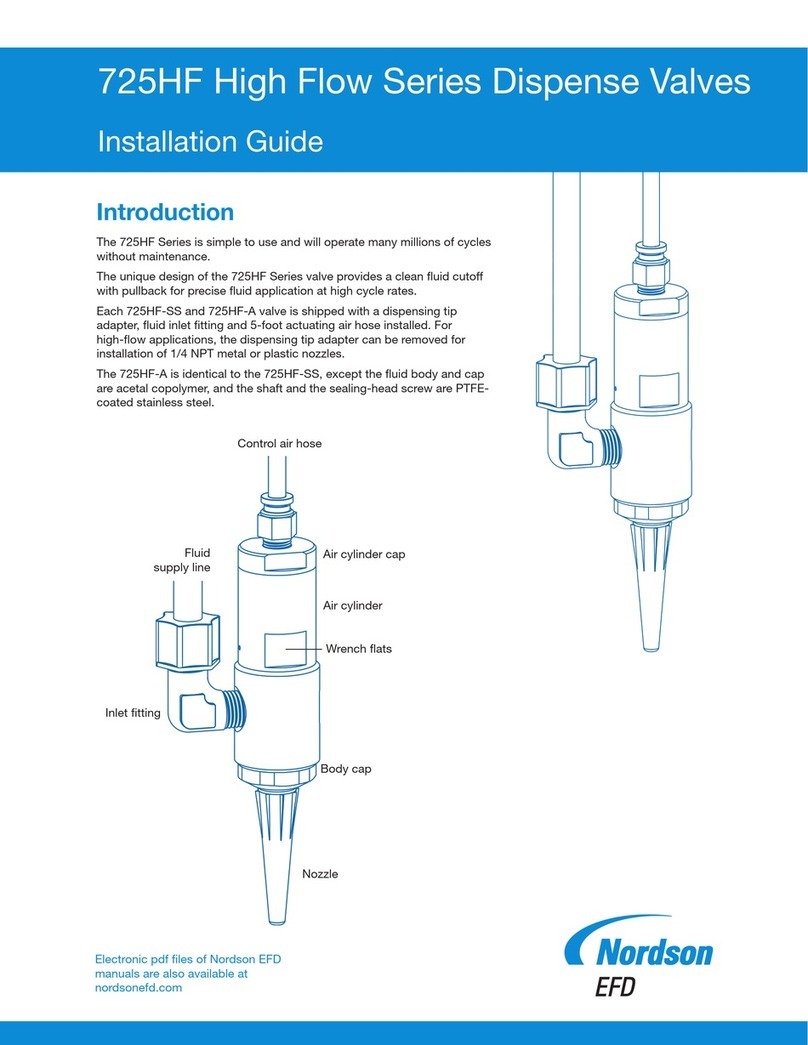

Nordson EFD 725HF Series User manual

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 752V-HL User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 781S Series User manual

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 781Mini Series User manual

Nordson EFD

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD 745NC User manual

Popular Control Unit manuals by other brands

Hills Reliance

Hills Reliance NX-EchoStream NX-1248 Installation manual and programming guide

Cegasa

Cegasa eBick MCP Series user manual

Siemens

Siemens SINUMERIK 808D operating instructions

Atlantic

Atlantic PRIMOCOSY HR BP Fitting instructions

Johnson Controls

Johnson Controls Tyco RSV-1 quick start guide

Keysight Technologies

Keysight Technologies 81610A user guide

LICHUAN

LICHUAN MC556 Instruction book

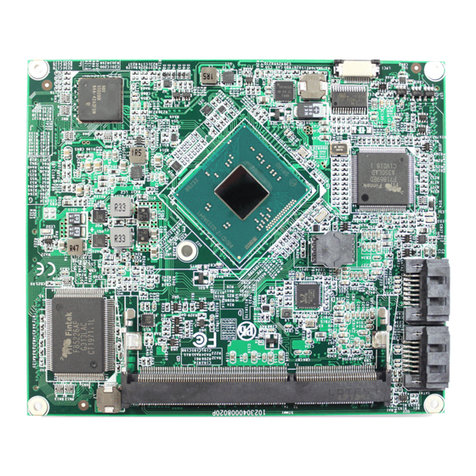

Arbor Technology

Arbor Technology EmETX-i2304 user manual

Festo

Festo CPX-E-EC Translation of the original instructions

Paradigma

Paradigma SCB-09 User and installation manual

RADEMACHER

RADEMACHER 2696 Instruction manual for the electrical connection and for commissioning

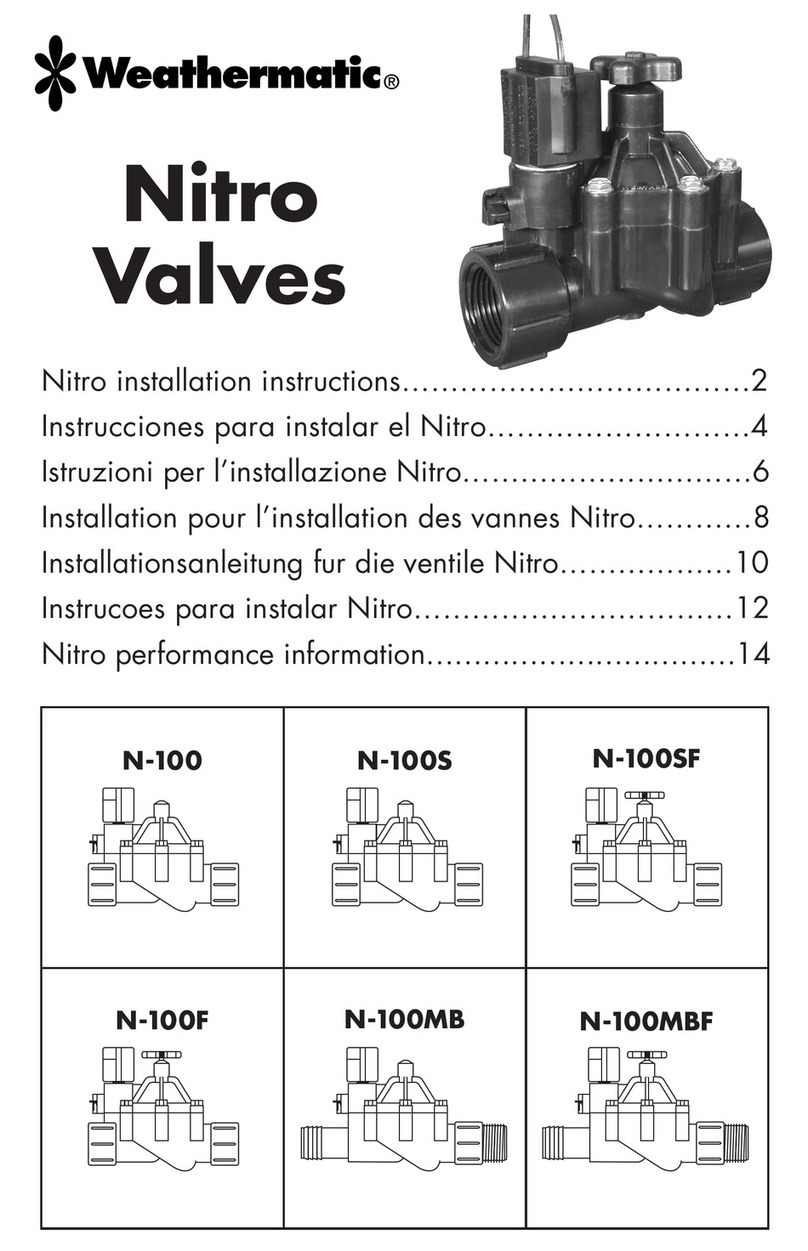

Weathermatic

Weathermatic N-100 Installation instruction guide