Nordson EFD 741V Series User manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

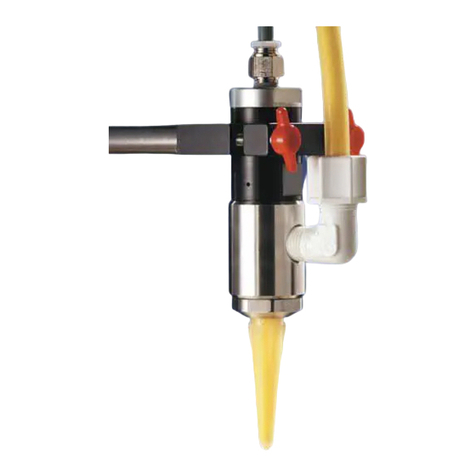

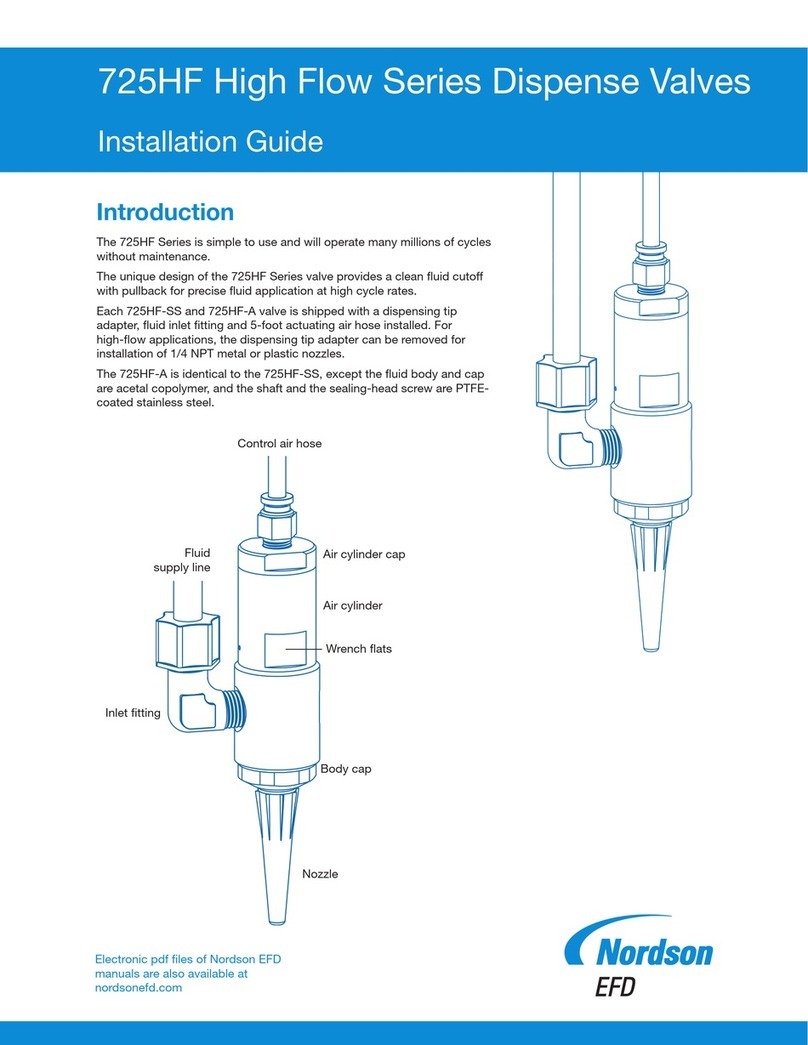

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 752V Series Manual

Nordson EFD

Nordson EFD 752V-HL User manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

Nordson EFD 745NC User manual

Nordson EFD

Nordson EFD 725HF Series User manual

Nordson EFD

Nordson EFD 741MD-SS Series Manual

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 782RA Manual

Nordson EFD

Nordson EFD 781S Series User manual

Popular Control Unit manuals by other brands

Infiltrator

Infiltrator AQUAworx IPC Panel installation manual

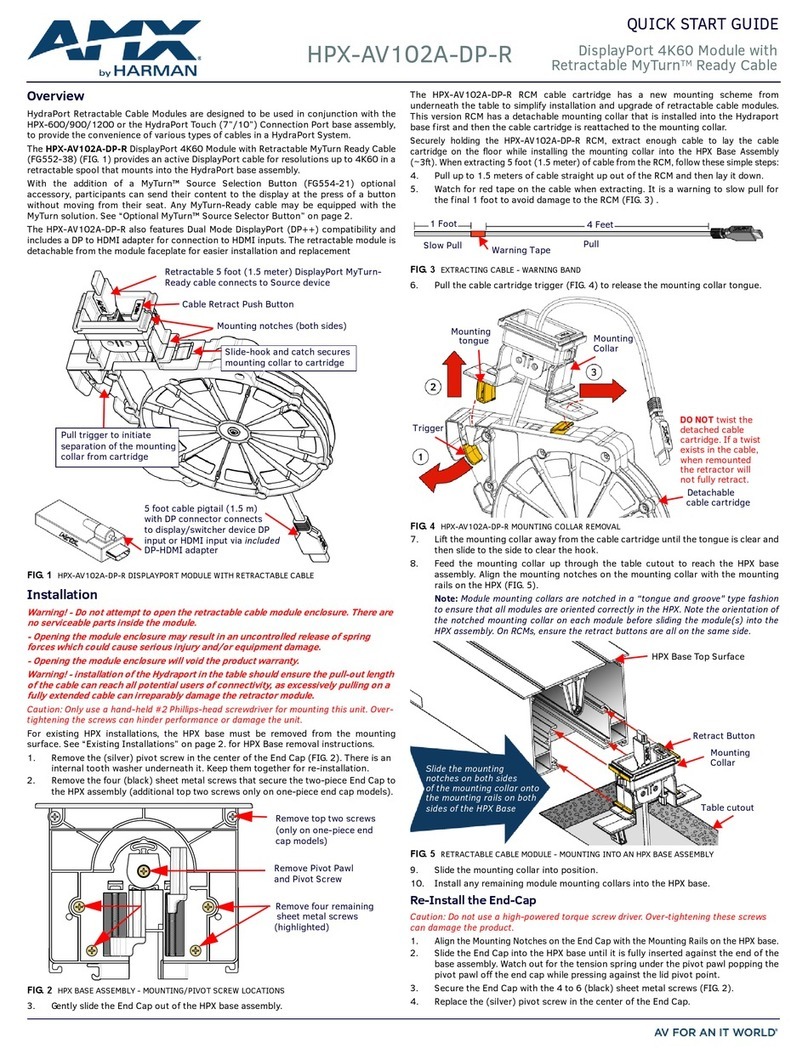

Harman

Harman AMX HPX-AV102A-DP-R quick start guide

Leadshine

Leadshine DM322E user manual

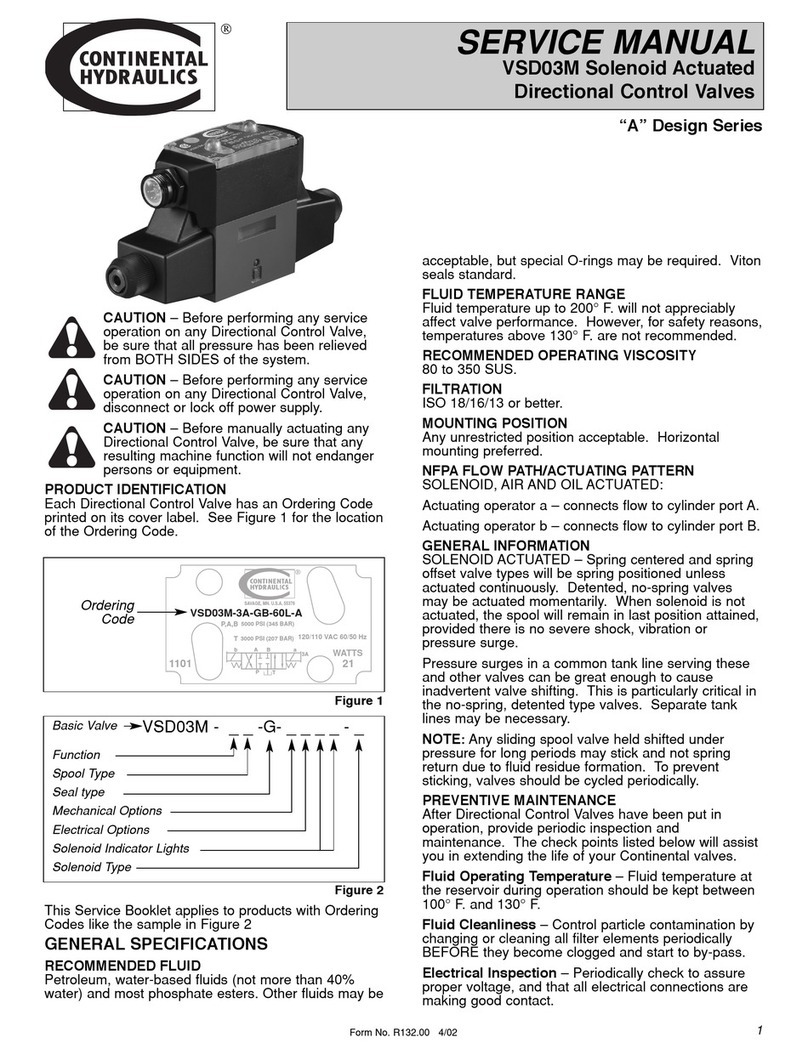

Continental Hydraulics

Continental Hydraulics A Series Service manual

GF

GF 546 instruction manual

Homematic IP

Homematic IP HmIP-CCU3 Mounting instruction and operating manual