Nordson EFD 781S Series User manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 781Mini Series User manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 741MD-SS Series Manual

Nordson EFD

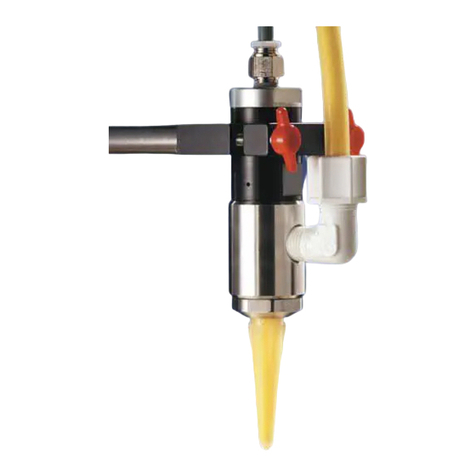

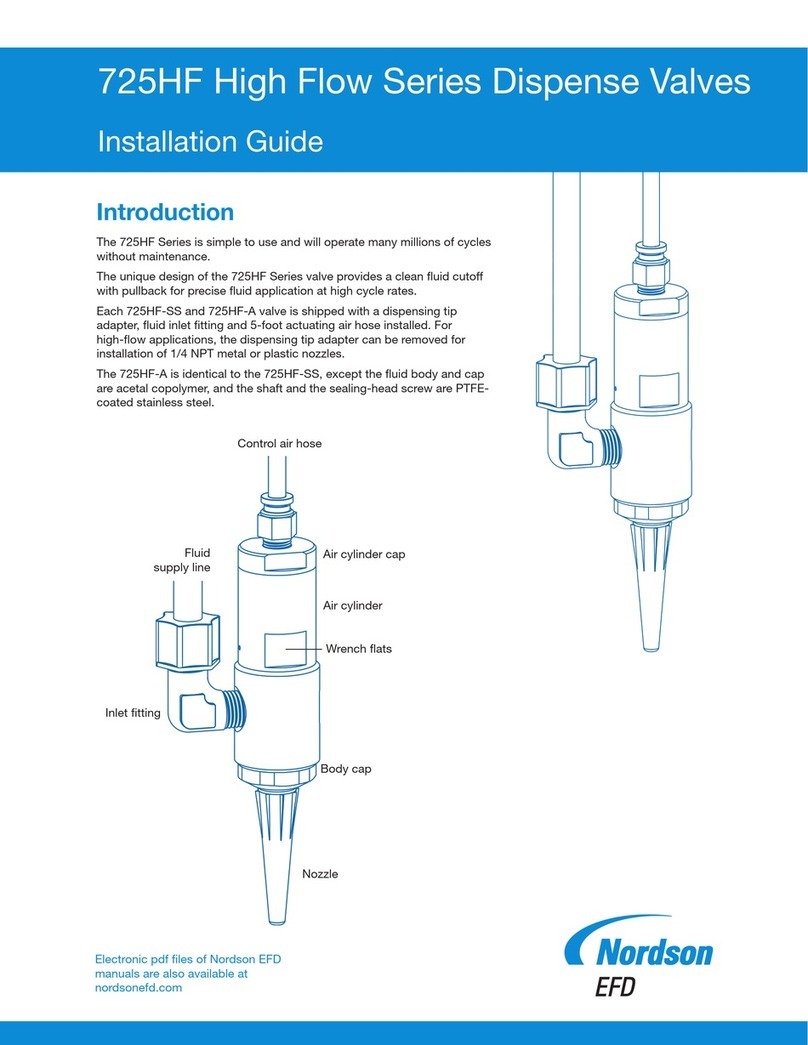

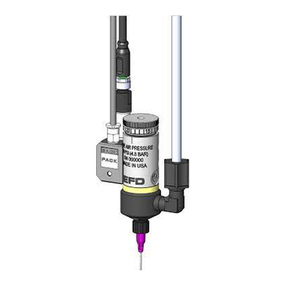

Nordson EFD 725HF Series User manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD 745NC User manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Nordson EFD

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 752V-HL User manual

Nordson EFD

Nordson EFD 741V Series User manual

Nordson EFD

Nordson EFD 752V Series Manual

Popular Control Unit manuals by other brands

Marsupial

Marsupial Eurorack Assembly instructions

Bray

Bray 940 Series Installation, operation and maintenance manual

Global Fire Equipment

Global Fire Equipment ZMU Programming manual

Siemens

Siemens SIMOCODE pro 3UF7400-1AA00-0 operating instructions

bsw

bsw BADU BNR 200 S Original operating manual

DVS

DVS EC Automatic user manual