Nordson Sealant Equipment 401 Reference guide

'LVSHQVHU

CUSTOMER PRODUCT MANUAL

COMPONENT MANUAL P/N: 744

ISSUED /201

For parts and technical support, contact Global Business Services (GBS) at

(800) 433-9319, or contact your local Nordson Sealant Equipment Representative.

This document is subject to change without notice.

Please check with customer service for the latest version.

Nordson Sealant Equipment٠Wixom, Michigan٠U.S.A

Part 7444902 2019 Nordson Corporation

Nordson Corporation welcomes requests for information, comments, and

inquiries about its products. General information about Nordson can be

found on the Internet using the following address:

http://www.nordson.com.

Notice

This is a Nordson Corporation publication which is protected by copyright.

Original copyright date 08/2016. No part of this document may be

photocopied, reproduced, or translated to another language without the

prior written consent of Nordson Corporation. The information contained

in this publication is subject to change without notice.

Trademarks

Nordson and the Nordson logo are registered trademarks of Nordson

Corporation.

All other trademarks are the property of their respective owners.

THIS PAGE HAS BEEN LEFT BLANK INTENTIONALLY.

Table of Contents i

Part 7444902

2019 Nordson Corporation

Table of Contents

Safety 1.................................................

Qualified Personnel 1...................................

Intended Use 1.........................................

Regulations and Approvals 2.............................

Personal Safety 2.......................................

High−Pressure Fluids 3..................................

Fire Safety 4...........................................

Halogenated Hydrocarbon Solvent Hazards 4..............

Action in the Event of a Malfunction 5.....................

Disposal 5.............................................

Operation 5............................................

Description 5.............................................

Consumable Items And Component Cleaning 7...............

Consumable Items 7....................................

Component Cleaning 8..................................

Electrical Connections 9.................................

Electrical Wiring 9....................................

Maintenance And Cleaning 9...............................

Operation 11..............................................

Troubleshooting 12.........................................

Repair 13.................................................

Actuator Replacement 13.................................

Ball Screw and Ball Nut Assembly Replacement 15..........

Carriage Replacement 17.................................

Coupler Replacement 18.................................

Dispense Valve Replacement 18...........................

Inlet Valve Replacement 19...............................

Metering Cylinder Replacement 20.........................

Metering Rod Replacement 22............................

Seal Cartridge Assembly Replacement 23...................

Upper Flange Replacement 24............................

Disassembly and Assembly 27...............................

Dispense Valve 28.......................................

Inlet Valve 30...........................................

Parts 32..................................................

Using the Illustrated Parts List 32..........................

3-Column Parts List 33.................................

Customer Product Manual 34.............................

401 Dispenser Parts Illustration 34.........................

401 Dispenser Parts List 35...............................

Dispense Valve Parts Illustration 36........................

Kits 40.................................................

Dispense Valve Service Kit 40...........................

Inlet Valve Service Kit 40................................

Seal Cartridge Assembly Service Kit 40...................

Specifications 41...........................................

Dimensions 42.............................................

401 Dispenser 1

Part 7444902

2019 Nordson Corporation

401 Dispenser

Safety

Read and follow these safety instructions. Task- and equipment-specific

warnings, cautions, and instructions are included in equipment

documentation where appropriate.

Make sure all equipment documentation, including these instructions, is

accessible to all persons operating or servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure that Nordson

equipment is installed, operated, and serviced by qualified personnel.

Qualified personnel are those employees or contractors who are trained

to safely perform their assigned tasks. They are familiar with all relevant

safety rules and regulations and are physically capable of performing

their assigned tasks.

Allow only qualified personnel to perform the tasks outlined in this

manual.

Intended Use

Use of Nordson equipment in ways other than those described in the

documentation supplied with the equipment may result in injury to persons

or damage to property.

Some examples of unintended use of equipment include:

Using incompatible materials

Making unauthorized modifications

Removing or bypassing safety guards or interlocks

Using incompatible or damaged parts

Using unapproved auxiliary equipment

Operating equipment in excess of maximum ratings

Only for use in automated work cells with appropriate safety guarding

and lockout devices.

401 Dispenser

2

Part 7444902 2019 Nordson Corporation

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which

it is used. Nordson equipment warranties may be voided if instructions for

installation, operation, and service are not followed.

All phases of equipment installation must comply with all federal, state, and

local codes.

Personal Safety

To prevent injury, follow these instructions.

Safety glasses are to be worn at all times while installing, servicing,

operating, or observing equipment. The sudden release of air or fluid

can cause damage to eyes.

Relieve system and material pressure before disconnecting hoses.

Do not operate equipment unless safety guards, doors, or covers are

intact and automatic interlocks are operating properly. Do not bypass or

disarm any safety devices.

Keep clear of moving equipment. Before adjusting or servicing any

moving equipment, shut off the power supply and wait until the

equipment comes to a complete stop. Lock out power and secure the

equipment to prevent unexpected movement.

Relieve (bleed off) hydraulic and pneumatic pressure before adjusting or

servicing pressurized systems or components. Disconnect, lock out, and

tag switches before servicing electrical equipment.

Operating faulty electrostatic equipment is hazardous and can cause

electrocution, fire, or explosion. Make resistance checks part of your

periodic maintenance program.

If you receive even a slight electrical shock, shut down all electrical and

electrostatic equipment immediately. Do not restart the equipment until

the problem has been identified and corrected.

Obtain and read Safety Data Sheets (SDS) for all materials used. Follow

the manufacturer’s instructions regarding the safe handling and use of

materials. Use recommended personal protection devices.

Make sure the dispensing area is adequately ventilated.

To prevent injury, be aware of less-obvious dangers in the workplace

that often cannot be completely eliminated, such as hot surfaces, sharp

edges, energized electrical circuits, and moving parts that cannot be

enclosed or otherwise guarded for practical reasons.

401 Dispenser 3

Part 7444902

2019 Nordson Corporation

High−Pressure Fluids

High pressure fluids, unless they are safely contained, are extremely

hazardous. Always relieve fluid pressure before adjusting or servicing high

pressure equipment. A jet of high−pressure fluid can cut like a knife and

cause serious bodily injury, amputation, or death. Fluids penetrating the skin

can also cause toxic poisoning. If you suffer a fluid injection injury, seek

medical care immediately.

WARNING: Any injury caused by high pressure liquid can be serious. If you

are injured or even suspect an injury:

Go to an emergency room immediately.

Tell the doctor that you suspect an injection injury.

Inform medical staff regarding the type of material dispensed.

MEDICAL ALERT − AIRLESS SPRAY WOUNDS: NOTE TO A PHYSICIAN

Injection into the skin is a serious traumatic injury. It is important to treat the

injury surgically as soon as possible. Do not delay treatment to research

toxicity. Toxicity is a concern with some exotic coatings injected directly into

the bloodstream. Consultation with a plastic surgeon or a reconstructive

hand surgeon may be advisable. The seriousness of the wound depends on

where the injury is on the body, whether the substance hit something on its

way in and deflected causing more damage, and many other variables

including skin micro−flora residing in the plant or gun which are blasted into

the wound. If the injected material contains acrylic latex and titanium dioxide

which damages the tissue’s resistance to infection, bacterial growth will

flourish. The treatment that doctors recommend for an injection injury to the

hand includes immediate decompression of the closed vascular

compartments of the hand to release the underlying tissue distended by the

injection material, judicious wound debridement, and immediate antibiotic

treatment.

401 Dispenser

4

Part 7444902 2019 Nordson Corporation

Fire Safety

To avoid a fire or explosion, follow these instructions:

Shut down all equipment immediately if you notice static sparking or

arcing. Do not restart the equipment until the cause has been identified

and corrected.

Do not smoke, weld, grind, or use open flames where flammable

materials are being used or stored.

Do not heat materials to temperatures above those recommended by

the manufacturer. Make sure heat monitoring and limiting devices are

working properly.

Provide adequate ventilation to prevent dangerous concentrations of

volatile materials or vapors. Refer to local codes or your SDS for

guidance.

Do not disconnect live electrical circuits while working with flammable

materials. Shut off power at a disconnect switch first to prevent sparking.

Know where emergency stop buttons, shutoff valves, and fire

extinguishers are located. If a fire starts in a spray booth, immediately

shut off the spray system and exhaust fans.

Shutoff electrostatic power and ground the charging system before

adjusting, cleaning, or repairing electrostatic equipment.

Clean, maintain, test, and repair equipment according to the instructions

in your equipment documentation.

Use only replacement parts that are designed for use with original

equipment. Contact your Nordson Representative for parts information

and advice.

Be sure to have a fire extinguisher on hand. Ensure ventilation is

adequate and follow all other safety guidelines as recommended by the

chemical manufacturer.

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that

contains aluminum components. Under pressure, these solvents can react

with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following

elements:

Element Symbol Prefix

Fluorine F “Fluoro−”

Chlorine Cl “Chloro−”

Bromine Br “Bromo−”

Iodine I “Iodo−”

Check your material SDS or contact your material supplier for more

information. If you must use halogenated hydrocarbon solvents, contact

your Nordson Sealant representative for information about compatible

Nordson Sealant Equipment components.

401 Dispenser 5

Part 7444902

2019 Nordson Corporation

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system

immediately and perform the following steps:

Disconnect and lock out electrical power. Close pneumatic shutoff

valves and relieve pressure.

Identify the reason for the malfunction and correct it before restarting the

equipment.

Disposal

Dispose of equipment and material used in operation and servicing

according to federal, state, and local codes.

Operation

CAUTION:

Prime/purge system prior to commencing system operation.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Description

The 401 Dispenser is a positive displacement, single−acting meter/mix/dispense system designed to

produce a variable flow, one−component material. Each meter is custom sized to provide the capacity

requirements of individual applications. A signal from the actuator opens the dispense valve. This

simultaneously sends a preset signal to the servo motor and rotates the ball screw. Rotation of the ball

screw, via the ball nut, causes the carriage to move in a downward direction. Movement of the carriage

drives the metering rod into the metering cylinder and drives the positive displacement of material. The

carriage continues to move downward until it trips the proximity sensor. At this point, the dispense valve

closes and the inlet valve opens. The servo then causes the ball screw to spin the opposite direction,

drawing the metering rod out of the metering cylinder. Once the carriage reaches a predetermined location,

the actuator stops turning, the inlet valve closes, and the system is ready for the next dispense cycle.

401 Dispenser

6

Part 7444902 2019 Nordson Corporation

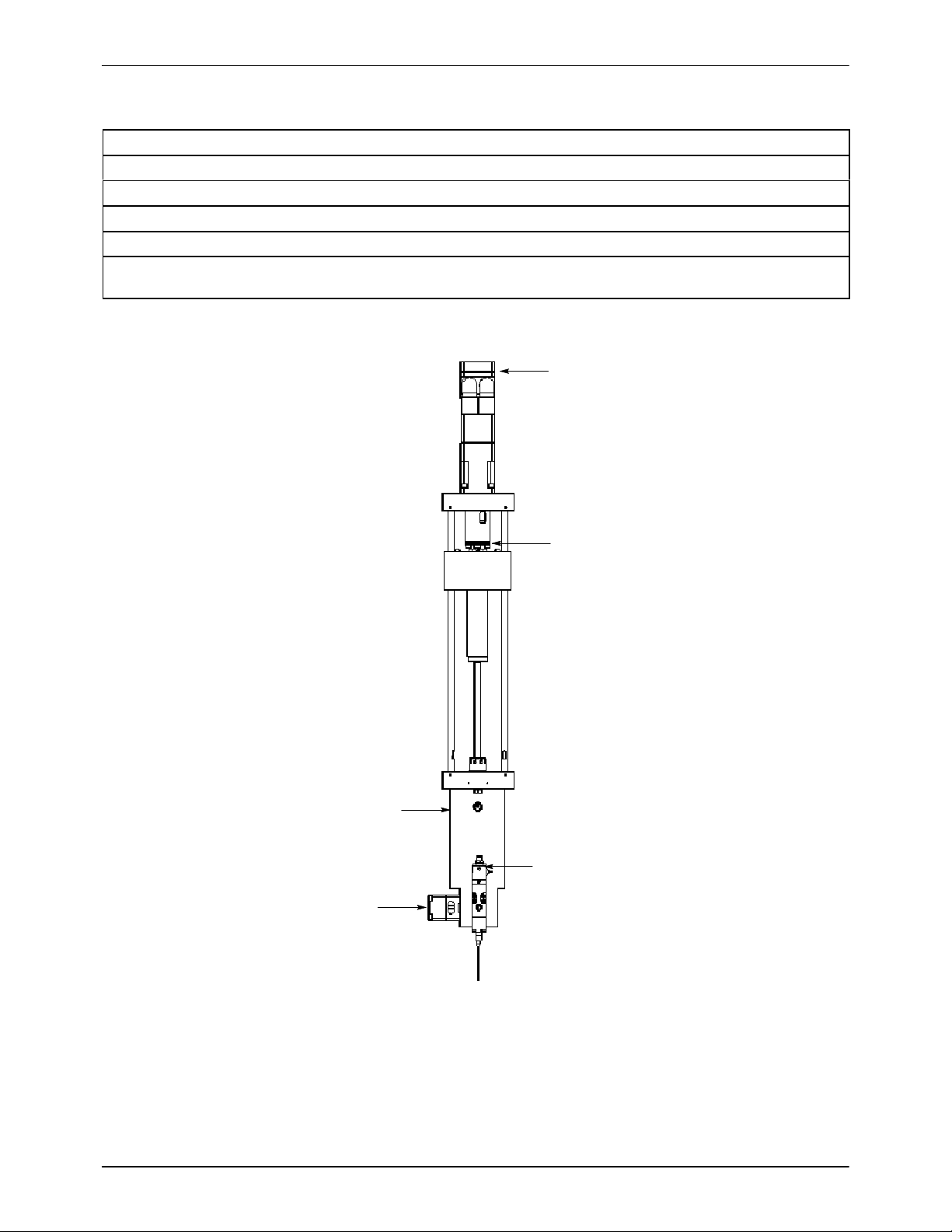

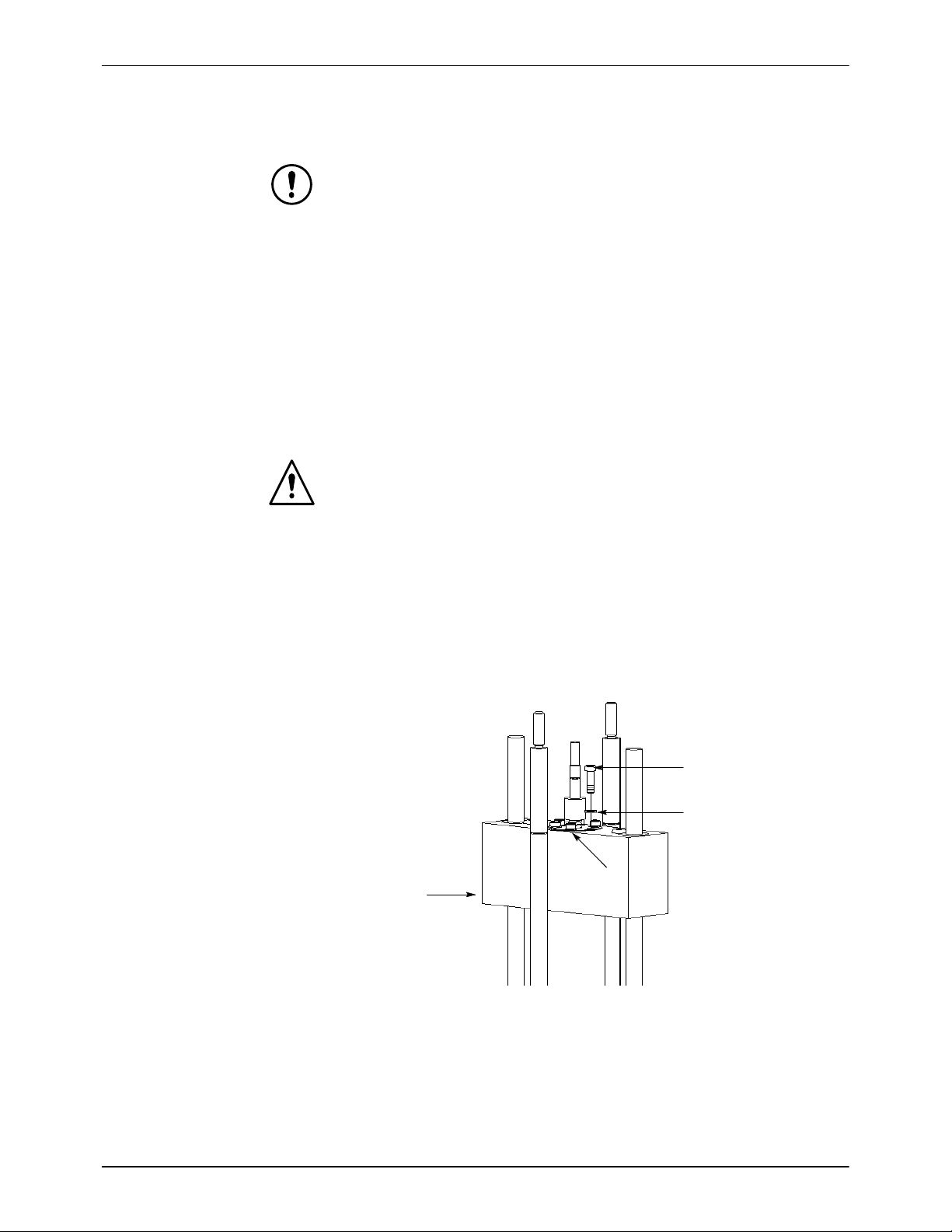

Table 1 401 Dispenser Major Components

Description

Actuator − Electric servo which facilitates metering rod movement.

Ball nut / ball screw assembly − Pneumatically driven and generates movement of metering rods.

Dispense valve − Provides complete cut−off control over the application of metered material.

Inlet valve − Accommodates the intake of material from system supply.

Metering cylinder − Houses the seal cartridge assembly and cylinder sleeve. Capable of displacing ex-

tremely small dispense volumes.

Actuator

Ball nut / ball screw assembly

Inlet valve

Dispense valve

Metering cylinder

Figure 1 401 Dispenser Major Components

401 Dispenser 7

Part 7444902

2019 Nordson Corporation

Consumable Items And Component Cleaning

Consumable Items

Table 2 Consumable Items

Item Part Application

Donnelly Bros. Inc. − All Purpose Grease

[(APG#2) (optional) (except Europe and U.K.)]

Sonneborn White Petroleum Jelly SnowwhiteN

[(optional) (Europe and U.K.)]

7426965

N/A

Applied to transducer port, gauge

port, metering rod and wearable

parts such as O−rings, seals, and

bearings.

Donnelly Bros. Inc. − All Purpose Grease

[(APG#2) (optional) (except Europe and U.K.)]

Sonneborn White Petroleum Jelly SnowwhiteN

[(optional) (Europe and U.K.)]

7426965

N/A

1) Added to bearing housing to

ensure lubrication of metering cyl-

inder wearable components.

2) Option exists to add to grease

fitting located on metering cylinder

upper bearing housing. Refer to

Maintenance, Lubrication, Meter-

ing Cylinder for additional infor-

mation.

Kendall L−247 Super Blu

[(optional) (except Europe and U.K.)]

Sonneborn White Petroleum Jelly SnowwhiteN

[(optional) (Europe and U.K.)]

7437105

N/A

Used for bearings and ball screw.

Loctite242 N/A Apply when assembly drawing re-

quires. Used for locking fasteners.

Loctite248 N/A Apply when assembly drawing re-

quires. Used for locking fasteners.

Loctite577 7438517 Used for fluid section thread seal-

ant. Used for all air fittings.

Permabond003907−000001 Apply when assembly drawing re-

quires. Used for locking fasteners.

PTFE thread seal tape N/A Pneumatic section thread sealer.

Used for all air fittings.

Seal Sav’r Oil (optional) 7428656 Added to oil reservoir to ensure

lubrication of metering cylinder

wearable components.

401 Dispenser

8

Part 7444902 2019 Nordson Corporation

Component Cleaning

The tools shown in Table 3 are utilized to clean and service various system

components.

WARNING:

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve material pressure prior to servicing system components.

Relieve system air pressure prior to servicing system components.

Disconnect and lock out power to the 401 Dispenser prior to servicing

system components.

CAUTION:

Do not allow any lubricants to enter fluid passageways during repair.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Table 3 Cleaning Tools and Chemicals

Tool Name Type Part Number

Nylon and / or soft plastic bristle brushes Cleaning tools −

Plastic pick Metering cylinder and valve cleaning / re-

build tool 7439868

401 Dispenser 9

Part 7444902

2019 Nordson Corporation

Electrical Connections

Electrical Wiring

Refer to System Manual wiring schematic for 401 Dispenser wiring

information.

Maintenance And Cleaning

WARNING:

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve material pressure prior to servicing system components.

Relieve system air pressure prior to servicing system components.

Disconnect and lock out power to the 401 Dispenser prior to servicing

system components.

CAUTION:

Do not allow any lubricants to enter fluid passageways during repair.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Refer to the Quick Start Guide for additional operating instructions.

NOTE:

The frequencies listed are only guidelines. It’s recommended to inspect

components weekly. It may be necessary to adjust frequencies due to

the facility environment, process parameters, material being applied, or

experience.

Always listen for air leaks, keep your work area clean of material, and

check with the material supplier for specific cleaning procedures for the

material being utilized.

401 Dispenser

10

Part 7444902 2019 Nordson Corporation

Table 4 Preventative Maintenance Schedule

Component Task Completion Time Frequency

Weekly Monthly Yearly Cycles

Actuator Inspect for loose

connections. In-

spect actuator rod

for damage.

Inspect: 10 Min.

Replace: 30−45 Min. ●

Air fittings and

tubing Inspect for air

leaks. 5 Min. ●

Ball screw

Check for damage

and replace dam-

aged components.

Lubricate ball

screw with Kendall

L−247 Super

Blu.

Inspect: 5 Min.

Apply Grease: 10 Min.

Replace: 30 − 60 Min. ●

Inlet/dispense

valves

Check for leakage

at the weep holes.

Use service kit, if

necessary.

Inspect 5 Min

Replace: 30 − 60 Min. ●

Material fittings

and hoses Check for material

leaks. 5 Min. ●

Material manifold

Check for leakage

and tighten any

loose valve

mounting screws.

Replace if neces-

sary.

Inspect: 5 Min.

Tighten: 5 Min.

Replace: 30 − 60 Min.

●

Metering cylinder

Inspect for leaks

and to damage re-

garding interior

sealing surfaces.

Replace metering

cylinder, if neces-

sary.

Inspect: 15−30 Min.

Replace: 2 −3 Hrs. ●

Metering rod

Inspect for dam-

age to surface of

rod. Prevent any

bypassed or

leaked material

from leaking onto

the rod.

Inspect: 10 Min.

Replace: 30 Min. ●

Pressure

transducer Check for material

leaks. 5 Min. ●

Seal cartridge

wet cups Keep wet cups ¾

full with Seal Sav’r

oil. Inspect: 5 Min.

Replace: Up to 30 Min. ●

401 Dispenser 11

Part 7444902

2019 Nordson Corporation

Operation

WARNING:

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve material pressure prior to servicing system components.

Relieve system air pressure prior to servicing system components.

Disconnect and lock out power to the 401 Dispenser prior to servicing

system components.

CAUTION:

Do not allow any lubricants to enter fluid passageways during repair.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Refer to the Quick Start Guide for additional operating instructions.

401 Dispenser

12

Part 7444902 2019 Nordson Corporation

Troubleshooting

WARNING:

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve material pressure prior to servicing system components.

Relieve system air pressure prior to servicing system components.

Disconnect and lock out power to the 401 Dispenser prior to servicing

system components.

CAUTION:

Do not allow any lubricants to enter fluid passageways during repair.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

NOTE: These troubleshooting procedures cover only the most common

problems. If you cannot solve a problem with the information provided here,

contact your local Nordson Representative for assistance.

Problem Possible Cause Corrective Action

Meter will not cycle

Blocked material path Ensure material is passing through all hoses.

Dispense valve not

opening

Ensure air is on. Inspect dispense valve for binding.

Inspect dispense valve piston for binding. Inspect

dispense valve wearable components for wear or

damage. Ensure there is sufficient air pressure. Ensure

dispense valve solenoid is functioning properly. Check

for material hardening.

Actuator not cycling Ensure power and controller connections are properly

fastened. Be sure there is sufficient power to cycle the

actuator shaft. Reference equipment literature provided

with the System Manual.

Pressure transducer

reading low pressure

Inspect pressure transducer calibration. Inspect position

of the pressure transducer to ensure the part was

installed properly. Ensure the pressure transducer is

properly functioning.

Supply equipment not

cycling Ensure there is sufficient air pressure. Reference supply

equipment literature.

Meter Leakage

Loose fitting Isolate leak(s) and tighten fitting(s).

Material metering

portion failure Ensure all fittings are properly tightened.

Valve seal failure Inspect and replace seal(s) and/or other valve wearable

components.

401 Dispenser 13

Part 7444902

2019 Nordson Corporation

Repair WARNING:

Allow only qualified personnel to perform the following tasks. Follow the

safety instructions in this document and all other related documentation.

Relieve material pressure prior to servicing system components.

Relieve system air pressure prior to servicing system components.

Disconnect and lock out power to the 401 Dispenser to servicing system

components.

CAUTION:

Do not allow any lubricants to enter fluid passageways during repair.

Relieve air and material pressure when equipment is not in use for

prolonged periods of time. Do not allow pressure to remain static when

equipment is idle as this may cause material to pack and harden.

Apply thread locker strictly in accordance to the replacement procedures

detailed in this section.

Actuator Replacement

See Figures 2 and 3.

WARNING:

Relieve system air and material pressure before making any repairs.

Failure to observe this warning may result in serious personal injury.

Disconnect and lock out power to the meter prior to servicing system

components.

1. Disconnect actuator cables.

2. Remove all guards from the meter.

3. Remove the lower coupler socket head cap screw (1). See Figure 2.

NOTE:

Utilize upper flange access hole to remove lower coupler socket head

cap screw.

Rotate the ball screw until the coupler socket head cap screw aligns with

the upper flange access hole.

401 Dispenser

14

Part 7444902 2019 Nordson Corporation

1Upper flange

Figure 2 Coupler Socket Head Cap Screw

4. Remove socket head cap screw (5) and washer (4) securing actuator (1)

to upper flange (4). See Figure 3.

5. Separate actuator (1) from upper flange (3). See Figure 3.

NOTE: The actuator (1) is removed with the coupler (2) attached. See

Figure 3.

6. Remove the coupler (2) from actuator (1). See Figure 3.

1

2

3

4

5

Figure 3 Actuator Replacement

401 Dispenser 15

Part 7444902

2019 Nordson Corporation

7. Installation of the actuator is in the reverse order of removal. Note the

following:

CAUTION:

Apply Loctite 242 or 248, or equivalent thread locker, to socket head cap

screws securing actuator to upper flange.

Allow Loctite 242 or 248, or equivalent thread locker, to fully cure prior to

utilizing system.

Tighten actuator−to−upper flange socket head cap screws to 2.4 Nm

(20.8 in.−lb).

Hand tighten coupler socket head cap screw until it is snug.

Ball Screw and Ball Nut Assembly Replacement

See Figures 4 and 5.

WARNING:

Relieve system air and material pressure before making any repairs.

Failure to observe this warning may result in serious personal injury.

Disconnect and lock out power to the meter prior to servicing system

components.

1. Remove upper flange. Refer to Repair, Upper Flange Replacement for

upper flange replacement procedure.

2. Remove socket head cap screw (1) and washer (2) securing ball nut (3)

to carriage (4). See Figure 4.

1

2

3

4

Figure 4 Ball Screw Replacement

Table of contents

Other Nordson Sealant Equipment Dispenser manuals