82K Swirl Nozzle Attachments

E2001 Nordson Corporation

All rights reserved

1007839A

Issued 5/01

Manual 27-84

To order parts, call the Nordson Customer Service Center or your local

Nordson representative.

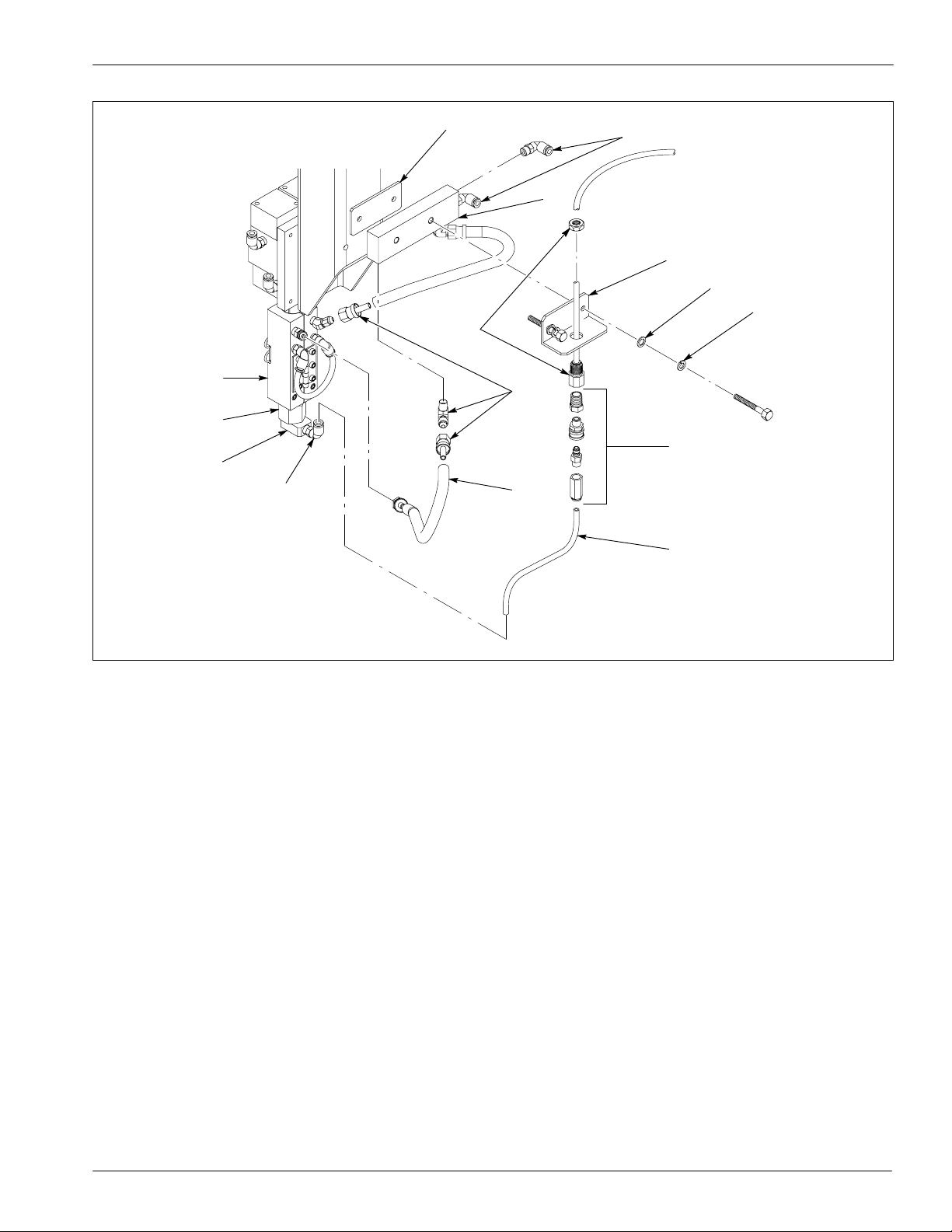

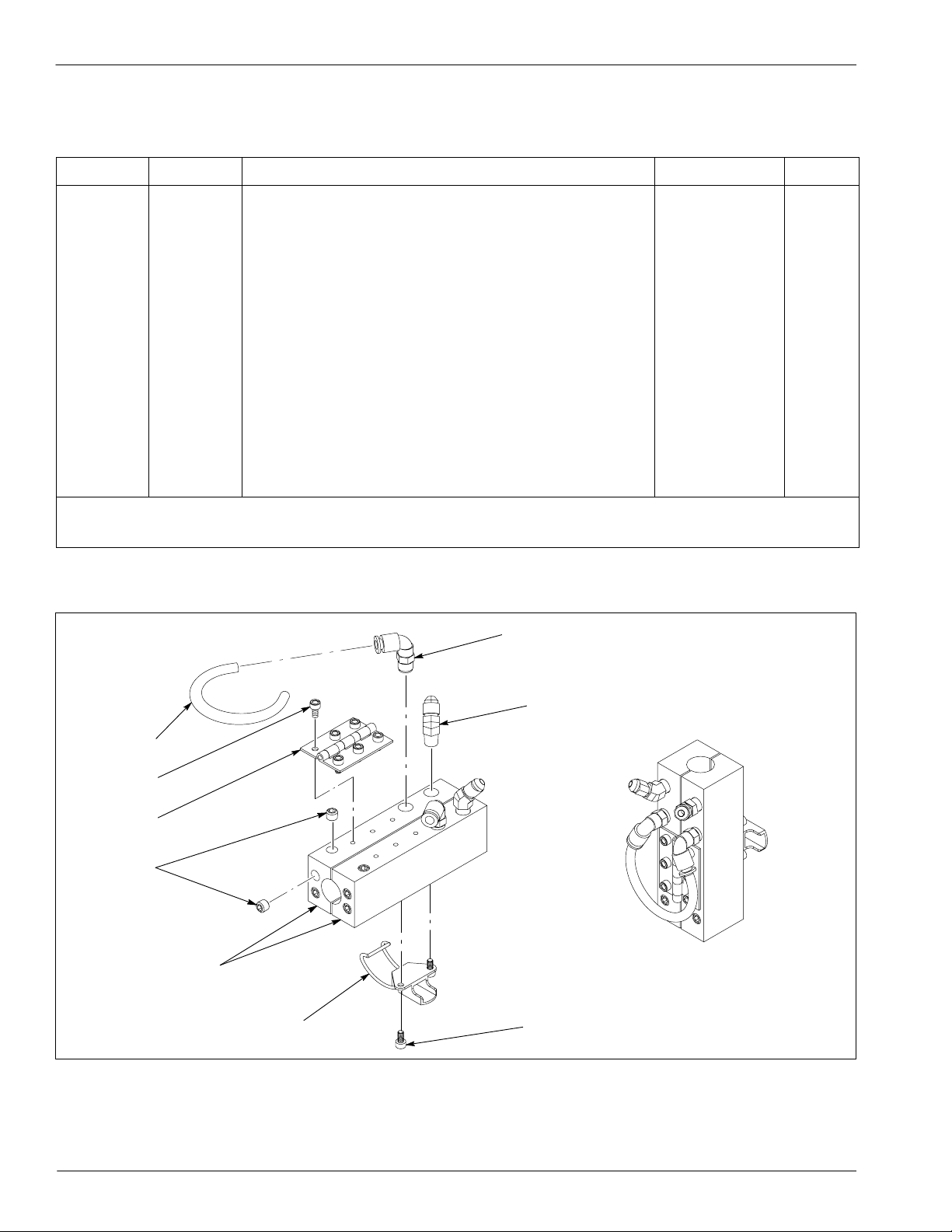

See Figure 4.

Item Part Description Quantity Note

—1005731 Assembly, mounting, temperature conditioning, 2K swirl,

supply air

1

1 1005733 SInsulator, Haysite, 1.50 x 2.75 x 0.125 in. thick 1

2 972119 SElbow, male, 1/4tube x 1/8NPT 3

3 1005734 SManifold, temperature conditioning, pneumatic swirl 1

4 1007967 SBracket, air supply, 2K swirl 1

5 983410 SWasher, flat, M6, narrow, steel, zinc 2

6 983140 SWasher, lock, E, split, 1/4, steel, nickel 2

7 972725 SConnector, bulkhead, 1/4in. tube 1

8 973372 SBushing, pipe, hydraulic, 1/4x 1/8, steel, zinc 1

9 241041 SCoupling, quick disconnect 1

10 241042 SCoupling, quick disconnect 1

11 972659 SConnector, female, 1/4tube x 1/8NPT 1

12 282286 STubing, 1/4in. OD blue urethane, 2 ft AR

13 329829 SConnector, female, 1/4in. hose, 7/16-20 barbed 4

14 1007842 SElbow, male, 37 D, 7/16-20, 1/8NPT, brass 2

15 1007966 SHose, push-lock (801), 0.25 in. ID, 2 ft AR

NS 900481 SAdhesive, pipe/thread/hydraulic sealant AR

NS 900464 SAdhesive, threadlocking AR

AR: As Required

NS: Not Shown

6. Parts

Temperature Conditioning

Mounting Assembly