Converting an FP-200 Extrusion Gun to an FP-200 Swirl Gun

2

Part 237494_02

E2012 Nordson Corporation

Preparing to Convert an FP-200 Gun

WARNING! Hot! Ris of burns! Hot applicator parts, splashed hot melt

material, and hot gun surfaces can cause severe burns. Wear long-sleeved,

heat-protective clothing, safety goggles, and heat-protective gloves. Hot

melt material may be released forcefully.

WARNING: Ris of burns. System or material pressurized. Air trapped in

hoses and guns can spit out molten adhesive that can cause severe burns.

Failure to relieve hydraulic pressure can result in serious burns. Relieve

hydraulic pressure when instructed to do so.

WARNING! Even when switched off, Nordson applicators, hoses, and guns

contain electrical potentials that can cause death. Disconnect and loc out

line voltage to the applicator when instructed to do so.

1. Relieve hydraulic pressure (refer to the Relieving ydraulic Pressure

procedure in the FP-200 gun product manual).

2. Switch the applicator circuit brea er to the OFF position.

3. Disconnect and loc out electrical power to the applicator.

4. Shut off the air supply to the gun.

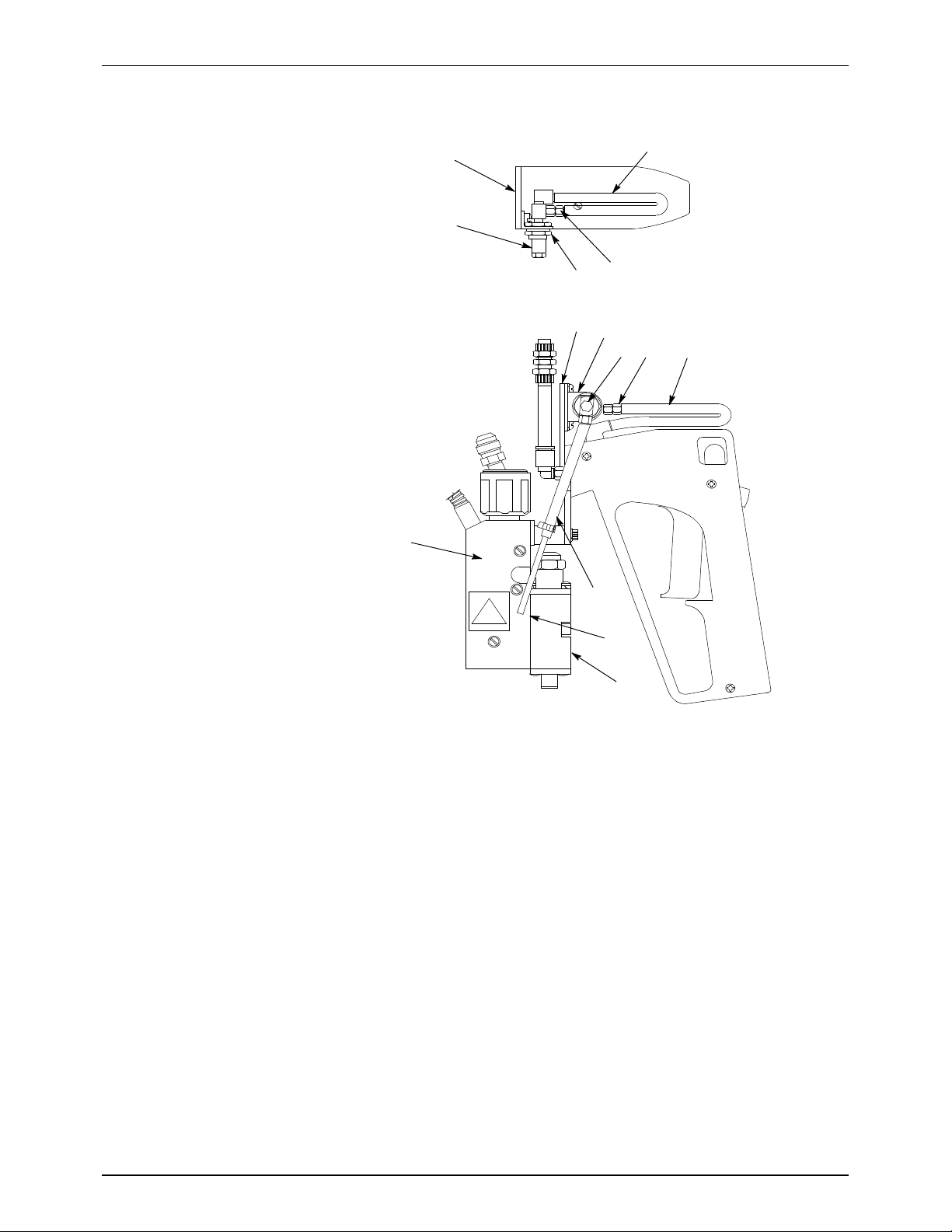

5. Remove the heat shield from the existing gun as follows:

a. Remove the auxiliary guide handle.

b. Disconnect the extrusion air line from the service bloc .

c. Remove the heat shield.

d. Reconnect the extrusion air line. Do not reinstall the auxiliary guide

handle.

6. Remove the existing gun from the suspension system by disconnecting

the hose hydraulically and electrically and by disconnecting the air line.