Northern Telecom DNC-50 Operating instructions

450-1011-501

Network Operations Systems

DNC-50, DNC-100,

DNC-500

Dynamic Network Control

Systems

Maintenance and Troubleshooting Guide

Release: NSR27/28 02 Status: Standard

i

Practice 450-1011-501

Network Operations Systems

DNC-50, DNC-100, DNC-500*

Dynamic Network Control Systems

Maintenance and Troubleshooting Guide

Publication number: 450-1011-501

Product release: NSR27/28 02

Document release: Standard

Date: March 30, 1990

1989 Northern Telecom

* DNC-50, DNC-100 and DNC-500 are trademarks of Northern Telecom.

iii

Practice 450-1011-501

Table of contents

1. Introduction 1

Revision History 1

Document Release Information 2

An Overview of the Maintenance Tasks 2

How to Use this Guide 3

Getting Ready 4

2. Routine Maintenance 5

Servicing the Air Intake Filter 5

Cleaning the Tape Heads of the Cartridge Tape Units 7

3. Troubleshooting and Fault Clearing Procedures 11

Fault-Clearing Summary: Symptoms and Solutions 12

Rebooting the System 14

Using Software Reboot 14

Using the Reset Switch 15

Powering Down and Powering Up 16

Accessing the Maintenance Service in SAS 30

4. Replacing Cabinet Subassemblies 33

Removing a Fan Assembly 33

Installing the Fan Assembly 36

Replacing the Filter Door 37

1

Practice 450-1011-501

1. Introduction

This document provides on-site maintenance and troubleshooting information

for the DNC-50, DNC-100, and DNC-500 Dynamic Network Control Systems.

It is intended to support trained maintenance personnel.

The maintenance personnel may be an employee or employees of the

customer, if the customer has elected to take responsibility for on-site

maintenance. However, the maintenance personnel may also be employees of

the telephone company (if a leased system) or Northern Telecom, if a service

contract is purchased from Northern Telecom.

The procedures in this document are designed to serve all of these

arrangements. However, depending on contractual arrangements,

responsibilities for specific tasks may rest with different parties. In all cases,

the terms of your maintenance contract override any information in this

document.

Revision History

Changes to NSR27/28.02 Version (March 30, 1990)

The procedure for vacuuming the DNC cabinets has been updated.

Changes to NSR27/28 01 Version (November 10, 1989)

(a) The procedures for cleaning the Cartridge Tape Drive are expanded to

include the tape drive in the 1/4-wide tape SRU. It has a different

orientation than the tape drive in the mass storage SRUs. These

procedures are in Part 2. They are applicable to both NSR27 and 28.

Changes to NSR27 02 Version (May 12, 1989)

(a) This NTP is converted to a new document style for NSR27.

(b) The troubleshooting and fault-clearing procedures in Part 3 are

expanded from the NSR26 Standard version.

2Introduction

Practice 450-1011-501

Document Release Information

The release information for this document is found on page i. The information

includes the 10-digit identification number for the practice, plus the following

additional information:

(a) Date: This is the date the document was released for reproduction or

printing. It is not intended to be the same as the software or product

release date.

(b) Product release: This is the software or product release number

associated with the current issue of the document, plus the issue number

of document. The format is NSRaa bb, where:

•NSRaa is the Network Software Release number

•bb is a sequential issue number for the document that indicates how

many times the document has been released with the specified

software release.

(c) Document release: A rating code of Draft, Preliminary, or Standard is

assigned to the document, reflecting the current status of the document.

An Overview of the Maintenance Tasks

The tasks in this document are divided into three categories. One isRoutine

Maintenance, which documents the simple routine maintenance tasks

required by the system. Routine maintenance is always the responsibility of

the customer, regardless of whether the customer has purchased a

maintenance contract. These tasks consist of periodically cleaning the fan

filters at the bottom of the cabinets and cleaning the heads of the tape units.

The second category includes the Troubleshooting and Fault Clearing

procedures. These procedures are used to identify the source of faults and

potential solutions. The Maintenance Service of System Administrative

Services supports these procedures.

The Maintenance Service is a software program provided with the system's

base software that isolates and diagnoses faulty equipment and software.

Faulty units are automatically taken out of service by the system. The system

also provides for manually taking units out of service.

The third category is Replacing Cabinet Subassemblies. Because of the

system's modular design, most equipment can be quickly removed and

replaced by spare units. (The customer should have a spare for each type of

equipment on the site.) Except for the specific cabinet subassemblies

documented here, the equipment should be removed and replaced according to

the detailed procedures in the Installation Guide for Cabinet Systems,

450-1011-201.

Introduction 3

Practice 450-1011-501

How to Use this Guide

To simplify the use of the document and to improve its readability, the tasks

are described from the point of view of the maintenance personnel doing the

actual work. There may, however, be more than one person using the

procedures.

Also, other documents are used with this document, such as the Installation

Guide for Cabinet Systems, 450-1011-201, for removing and reinstalling

faulty equipment, and the Guide to System Administrative Services,

450-1011-301, for detailed information on how to use the system's

Maintenance Service and log messaging utility.

The maintenance personnel must either coordinate their efforts with the system

administrator, or be given access to System Administrative Services by the

system administrator.

4Introduction

Practice 450-1011-501

Getting Ready

Before starting any maintenance or troubleshooting tasks, ensure that you

have read the introduction of this document. Then, if you are going to install

or remove equipment, you should review the appropriate supporting

documents, such as the Installation Guide for Cabinet Systems,

450-1011-201, and the Guide to System Administrative Services,

450-1011-301.

Also, you should ensure that you have on hand the Site Records,

450-1011-152, so that you can make notations on the provisioning

worksheets. A list of tools is provided below for your convenience. Specific

tools required for a given procedure are noted in the procedure itself.

TOOLS:

1 hexagonal nutdriver (1/4 inches)

1 hexagonal nutdriver (3/8 inches)

1 hexagonal nutdriver (3/16 inches)

1 Allen wrench (5/64 inches)

1 small flat-blade screwdriver.

MATERIALS:

1 felt pen

1 pencil.

5

Practice 450-1011-501

2. Routine Maintenance

The system is based on solid state circuitry that requires little routine

maintenance. However, its efficient operation does depend on the periodic

cleaning or replacement of the air filter in each cabinet and the tape heads of

the cartridge tape units. Both tasks can be performed with the system fully

operational.

Servicing the Air Intake Filter

TOOLS and MATERIALS:

1 vacuum (brushless motor), - or

1 replacement air filter (part number PO642355) for each DNC cabinet

The DNC cabinets must be vacuumed to prevent the buildup of electrostatic

discharges caused by dust. Use a vacuum cleaner with an induction-wound

(brushless) motor, and with plastic or rubber attachments. (Series-wound

motors cause electromagnetic interference.) Battery operated vacuum cleaners

can suffice for small applications or areas without power. Vacuum inside or

around the DNC cabinets each time the frames’ filters are inspected, until an

appropriate vacuuming schedule is determined. Do not bump any part of the

vacuum cleaner against equipment, and especially avoid metal to metal

contact.

The air intake filter at the bottom of each cabinet should be cleaned once a

month in ordinary office environments. Inspect the filters on new systems

more frequently to determine the filter cleaning interval appropriate for your

system. Typically, only damaged filters need replacing.

To access the filter, proceed as follows:

(1) Open the front door of the cabinet. An air grill is located at the bottom of

the cabinet as shown in Fig. 2-1.

(2) Grasp the two tabs at the top of the air grill and pull the top of the grill

outward (the grill is hinged at the bottom).

(3) The filter lies just beneath the cabinet door. Pull the filter out of the

cabinet.

6Routine Maintenance

Practice 450-1011-501

Figure 2-1

The Air Intake Grill and Filter

450-0522

Filter

Air Grill

Routine Maintenance 7

Practice 450-1011-501

(4) You can now clean the filter with a vacuum or replace it with a new

filter.

(5) Insert the new or cleaned filter into the filter slot and slide it in until the

air grill can be freely closed.

(6) Close the air grill, snapping it into position.

(7) Close the cabinet door.

(8) Repeat Steps 1 to 7 for each cabinet in the system.

Cleaning the Tape Heads of the Cartridge Tape Units

Tools:

•denatured (isopropyl) alcohol

•foam or lint-free swabs, 6 in. long.

Steps:

(1) Locate the tape heads inside the SRU slot that accepts the cartridge tape.

Mass Storage and Cartridge Tape SRUs: the heads are located

inside and at the rear of the cartridge slot. See Figure 2-2.

1/4-shelf Disk/Tape SRUs: the heads are located inside and at the

top of the cartridge slot. See Figure 2-3.

(2) Dampen (don't saturate) a foam swab with denatured alcohol and wipe

the swab over the tape heads.

Use a cleaning motion at right angles to the direction of tape travel.

Avoid touching any rubber parts with the alcohol. Some deterioration of

the rubber can result.

(3) With a dry swab, wipe any excess alcohol from the tape heads, also

using a motion at right angles to the tape travel.

- CAUTION -

To ensure proper operation, carefully clean the tape heads after the

system loads for the first time, and before every tape drive session.

8Routine Maintenance

Practice 450-1011-501

Figure 2-2

Tape Head Location in the Mass Storage or Cartridge Tape SRU

Select

Fault

Tape Slot

Erase Head

Read/Write Head

Direction of Cleaning Motion

450-0097

Routine Maintenance 9

Practice 450-1011-501

Figure 2-3

Tape Head Location in the 1/4-shelf Disk/Tape SRU

450-0096c

Push this knob down

to clean the tape heads

The read/write heads are located behind

this knob, close to the back of the slot.

They are exposed slightly (for cleaning)

when this knob is pushed down.

11

Practice 450-1011-501

3. Troubleshooting and Fault

Clearing Procedures

Troubleshooting usually begins when someone, such as a user or the system

administrator, notices a symptom of a fault. It may be that a piece of

equipment is not functioning properly, an alarm has been generated, or the

system has displayed a fault message on the notification line of the terminal

screens or on the liquid crystal display (LCD) of the SASI Primary Processor.

(The Primary Processor is typically located in the first or second cabinet from

the left, as viewed from the front.)

The system administrator also has access to the system's self-diagnostics and

fault reporting software to periodically check the operating status of all shared

resource units (SRUs), remote resource units (RRUs), and program resource

units (PRUs). Units can be taken out of service manually at any time, and are

automatically taken out of service if identified as faulty by the system's

self-diagnostics.

The self-diagnostics operate under control of the Maintenance Service of

System Administrative Services. This service displays and tests the status of

resource units. On notification of a fault, the system administrator can access

this service, potentially identify and isolate the fault, and take the faulty unit

out of service. Corrective action may then be taken.

For software faults, the problem can be cleared by reloading the PRU. This

action can be performed by the system administrator using the instructions in

Part 25 of the Guide to System Administrative Services, 450-1011-301.

If the fault is hardware-related, the system administrator should contact the

appropriate maintenance personnel according to the terms of the customer's

maintenance contract or other maintenance arrangement. The maintenance

personnel are responsible for replacing faulty equipment.

In some cases, the fault may not be identified by the system's

self-diagnostics. In such a case, refer to Table 3-A for troubleshooting

procedures. If a hardware unit is faulty, remove it and install a spare

according to the procedures of the Installation Guide for Cabinet Systems,

12 Troubleshooting and Fault Clearing Procedures

Practice 450-1011-501

450-1011-201. If a cabinet subassembly is faulty, remove it and install a

spare according to Part 4 of this document.

The Installation Guide for Cabinet Systems provides procedures for installing

the following equipment:

•cabinets

•cabinet doors

•input, horizontal, and terminating jumper assemblies

•shared resource units

•LAN interface units

•the office cross-connect panel

•connections to peripheral equipment.

Fault-Clearing Summary: Symptoms and Solutions

On notification of a fault in the system, you will want to gather as much

information as possible from the person reporting it. Ask the person reporting

the fault what the symptoms are, under what conditions the fault occurs,

whether it is intermittent or ongoing, whether it can be reproduced, and any

other relevant information there may be.

You will want to contact the system administrator for any additional

information, such as reports or log messages recorded by System

Administrative Services. With this information, you can then refer to the

following procedure and Table 3-A for a summary of symptoms and solutions

for potential system faults.

The following procedure is a summary for troubleshooting hardware and

software faults in the system.

Note: The system log messages can be of use in determining the

cause of a system malfunction.

(1) Access the Maintenance menu in SAS to determine the status of each

SRU, RRU and PRU.

Note: If you cannot access the system from the administrator's

terminal, proceed to Step 8 for instructions on how to clear a major

fault.

Troubleshooting and Fault Clearing Procedures 13

Practice 450-1011-501

(2) For each device whose status is other than ‘Working’, invoke a

‘Courtesy Down’ function followed by a ‘Put Into Service’ to reboot

that device. Note the following conditions:

a) The rebooting function for software PRUs resident on an SRU may

lag behind the rebooting function of the actual hardware SRU. For

example, the SRU may indicate a ‘Working’ status before the PRU.

Allow sufficient time to complete the operation (at least five

minutes).

b) The SRU/RRU/PRU may need to be rebooted more than once to

restore the status to ‘Working’.

c) The ‘Courtesy Down’ function is not allowed for units that have

special importance within the system. If such a unit is faulty, then

the entire system must be rebooted. (See ‘Rebooting the System’,

below.) The restricted units are:

•the Primary Processor SRU and most core system PRUs

•the LANlink SRU that supports the system administrator's terminal

•the system administrator's terminal

•any PRUs resident on the Primary Processor that support the

System Administrative Services (SAS) menu functions.

(3) If an RRU continues to have a ‘Faulty’ status, replace it

Note: Before removing a SCSI (Small Computing Systems

Interface) cable from any equipment, the system must be powered

down.

(4) After replacing a faulty RRU, reboot the device using the ‘Courtesy

Down’ and ‘Put into Service’ functions.

(5) If an SRU continues to have a ‘Faulty’ status, power the system down

and replace the SRU.

- CAUTION -

You must power the system down if you intend to remove or reseat

any SRU, or if you intend to remove a SCSI (Small Computing

Systems Interface) cable from any device.

14 Troubleshooting and Fault Clearing Procedures

Practice 450-1011-501

(6) If the program resource units (PRUs) in an SRU repeatedly have a

‘Faulty’ status, power the system down and replace the SRU.

(7) After replacing an SRU, power the system up and reboot the device

using the ‘Courtesy Down’ and ‘Put into Service’ functions.

(8) If you cannot access the system from the administrator's terminal,

reinitialize the system using the backup tape (if available), or do a

complete system rebuild.

(9) If the system reinitialization does not complete successfully, power the

system down, replace the Primary Processor SRU, power the system up

again, and attempt to reload the system from the backup tape (if

available), or do a complete system rebuild.

If the system fails to reboot successfully, power the system down,

replace the Mass Storage SRU, format the disk, and again attempt to

reload or rebuild the system.

If you continue to have problems, contact Northern Telecom's customer

service center.

Rebooting the System

Rebooting the system is a last-resort method of remedying an error condition.

There are three ways to reboot a DNC:

•using the software reboot feature

•pressing the Reset button on the Primary Processor SRU (if the system

is equipped with a 68020 XP primary processor)

•powering down and then powering up again.

Using Software Reboot

If you are the superuser, you can reboot the system by using the software

reboot feature. (Only the superuser can access the Utilities Services - Main

Menu, as required by this procedure.) Take the following steps:

(1) Sign on as the superuser.

The main menu appears.

(2) Select the System Administrative Services option and press ENTER.

The System Administrative Services - Main Menu appears.

(3) Select the Utilities option and press ENTER.

The Utilities Services - Main Menu appears.

(4) Select the Helix Command Interpreter option and press ENTER.

The system prompt appears. (It is usually ‘>’.)

Other manuals for DNC-50

1

This manual suits for next models

2

Table of contents

Other Northern Telecom Control System manuals

Popular Control System manuals by other brands

Siemens

Siemens SINUMERIK 802D Short guide

Huawei

Huawei LUNA2000-100KTL-M1 user manual

Niles

Niles Intellicontrol Tabletop Remote manual

heat-timer

heat-timer SQ-Elite-8T Installation and operation instruction manual

CAME

CAME GARD 8 SERIES installation manual

Siemens

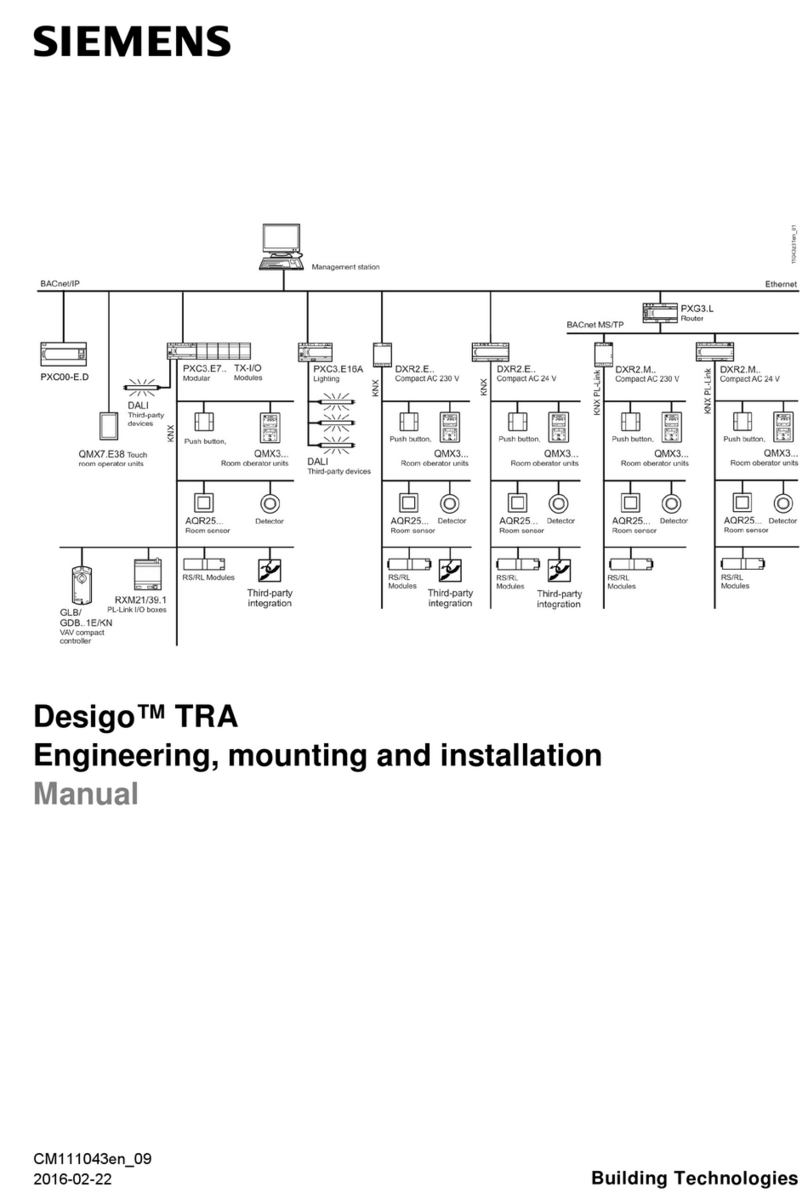

Siemens Desigo TRA Engineering, mounting and installation manual