VERS. 04.04.2019 MAN CM 352 EN

9

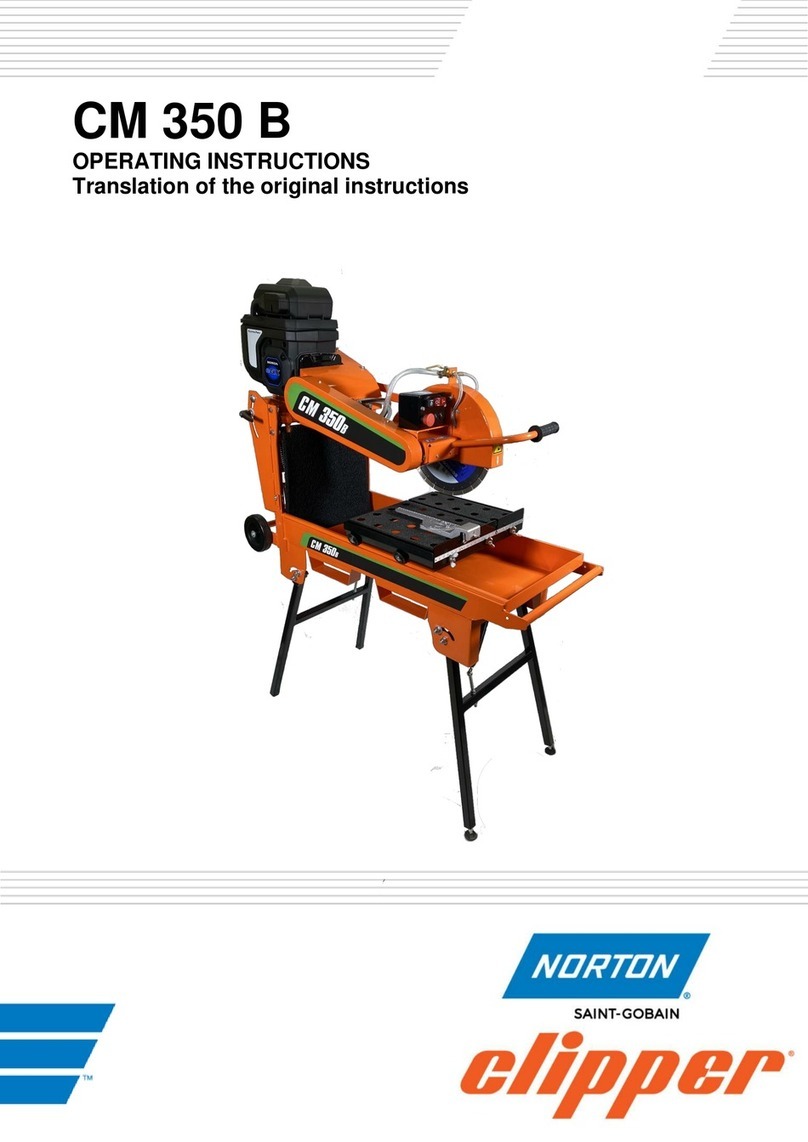

Frame and feet (1)

The frame is made of a jig-welded reinforced steel construction to ensure perfect rigidity. The machine is

mounted on four removable legs 4 locked with screws and equipped of wheels for transportation.

Cutting head (2)

The pivot is jig-machined with precision. A spring system brings the blade automatically in the up position.

The cutting head can be tilted to 45° for bevels cuts. Straight-through cutting can be made by means of a

locking device.

Blade guard (3)

Jig-welded steel construction with 350mm-diameter blade capacity, which offers maximum operator

protection and increased visibility of the work piece.

Incorporated in the blade guard is an outer metal cover, which can be easily removed to allow easy access

to shaft for inspection and blade replacement when motor is switched off, while fully protecting the blade

when in operation. The rotation of the disc is indicated by an arrow on the sidewall of the blade guard.

Electric motor and switch (4)

Electric motor 2.2kW 230V or 1.8kW 115V with an overload protection. Low voltage trigger (NVR) built in

the switch prevents the motor to restart for example after a power cut. Thermal overload tripping can occur

for two reasons:

tripping under light load if connection is incorrect

tripping under heavy load if motor has been overloaded.

The ON-OFF switch also serves as emergency stop.

Conveyor cart (5)

Steel welded construction with a stop material. The guide system of the conveyor cart permits precise cuts.

The guide-a-cut and the large surface of the conveyor cart provide precise positioning of the material.

Water cooling system (6)

The coolant system comprises:

A powerful, submersible electric water pump.

Plastic suction pipe delivering the water from the water pan to the cutting head.

A water tray placed on two adjustable supports.

A water-tap, fitted to the blade guard, permitting controlled water flow.

Two water nozzles located on the blade guard ensure adequate flow of water to both sides of the cutting

blade.

A water splash guard, fixed to head axle restricts water spray and minimises water loss.

Attention: The water pump must never run without water.