9

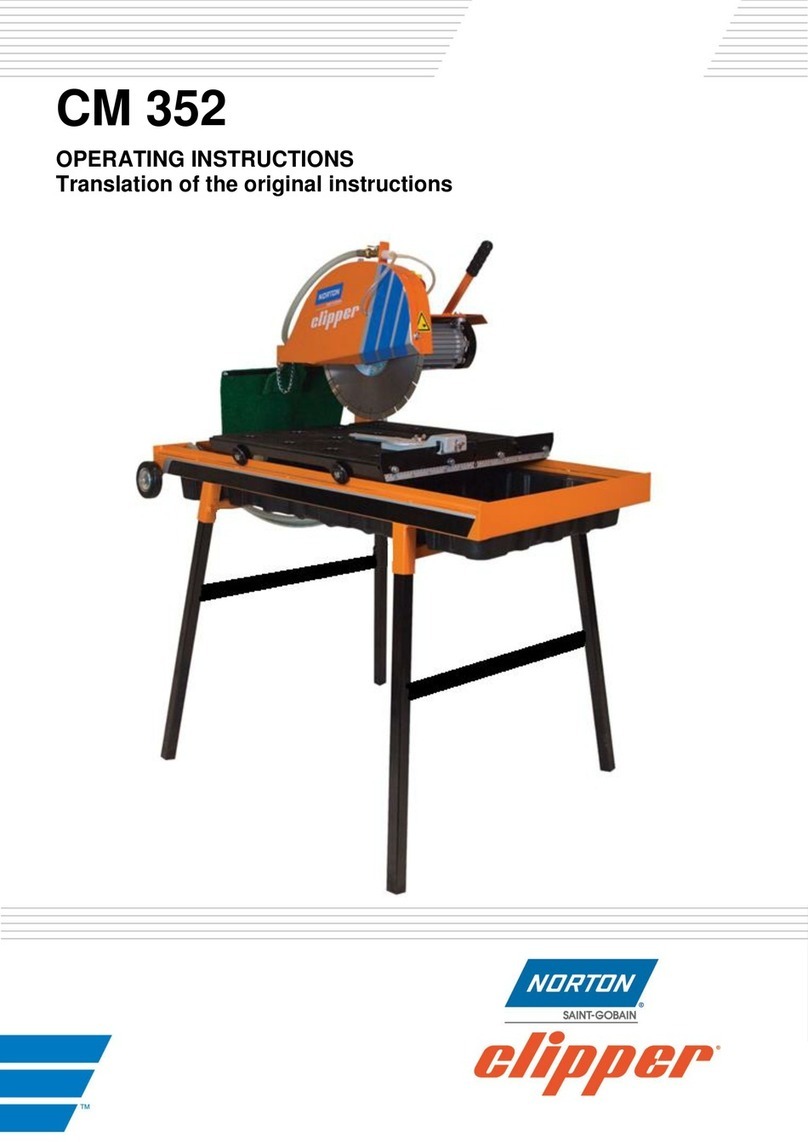

Jig-welded steel construction with 500mm-diameter blade capacity, which offers maximum operator

protection and increased visibility of the work piece.

Incorporated in the blade guard is an outer metal vent, which permits easy access to shaft for

inspection and blade replacement when motor is switched off, while fully protecting the blade when

in operation.

Down feed and cutting depth adjustment

The spring-loaded cutting head, activated by hand with the grip (7) on the blade guard or with the

foot pedal (8), ensures smooth lowering of the cutting head for shock-free penetration of the work

piece and improved control of the cutting pressure.

A crank assembly (10) in conjunction with a depth locking device on the cutting head pivoting bar

enables the operator to set the cutting head to desired maximum cutting depth. The knob (9)

enables to lock the cutting head at the right cutting depth.

Electrical Motor and switch (11)

Motor with 5,5kW. Low voltage trigger (NVR) prevents the motor to restart for example after a power

cut.

The electric motor has overload protection. Thermal overload tripping can occur for two reasons:

a. tripping under light load

If connection is incorrect

If a phase is not under load

Check the connections and the phase voltage before restarting the machine.

b. tripping under heavy load

If motor has been overloaded

The ON-OFF switch also serves as emergency stop.

2.4 Technical Data

Electric motor 5,5 kW, 400V, 3-Phase 50Hz 1490 min

-1

Electric motor protection IP54

Switch Star-triangle switch with thermal overload protection, no volt release and

emergency stop

Max. blade diameter 500 mm

Bore 25,4 mm

Cutting length mm 500 mm

Cutting depth mm 190 mm

Flange diameter 115 mm

Blade shaft speed 2062 min

-1

Machine dimensions 1400x760x1750 mm

Weight 248 kg

Max. operating weight 280 kg

Sound pressure level 85 dB (A) (following ISO EN 11201)

Sound energy level 99 dB (A) (following ISO EN 3744)