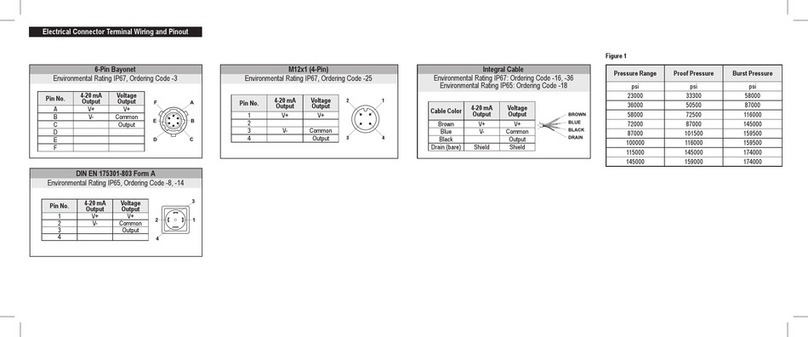

Mating connection cable assemblies are available as an accessory part

from NOSHOK. Refer to Electrical Connector Terminal Wiring and Pinout

for additional detail.

A pressure snubber may be installed to eliminate damaging hammer

effects. Water and conventional cleaning detergents are acceptable

cleaning agents. Cleaning with unsuitable cleaning agents may damage

the instrument or the product label. Do not use any aggressive chemical

agents or abrasive cloths or sponges.

Transmitter should be electrically common with earth via the process

connection.

• Refer to Power Supply Requirements and Ratings.

• Refer to Electrical Connector Terminal Wiring and Pinout.

• Refer to product technical specication for allowable minimum and

maximum temperature and pressure conditions.

General Operation

Pressure spikes in excess of the rated overpressure capability of the

transmitter may cause irreversible electrical and/or mechanical damage

to the pressure measuring and containing elements. Fluid hammer and

surges can destroy any pressure transmitter and must always be avoided.

Maintenance and Service

NOSHOK PT40 pressure transmitters are precisely calibrated, and

temperature compensated at the factory to ensure long and stable

performance.

The NOSHOK PT40 is capable of being eld adjusted for zero offset and

span by removing the top cap and adjusting the potentiometers. This

product is maintenance-free. Repairs should only be carried out by the

manufacturer.

Additional Notes

Any electrical device may be susceptible to damage when exposed to

static electrical charges. To avoid damage to the transmitter, observe the

following:

• The circuitry of the NOSHOK PT40 pressure transmitters is designed

to minimize the effect of electromagnetic and radio frequency interference.

To minimize susceptibility to noise, avoid running the termination

wiring in a conduit which contains high current AC power cables.

• Where possible avoid running the termination wiring near inductive

equipment.

NOTE: The shield and drain wire in the cable (if supplied) is not

connected to the transmitter body and is not a suitable ground.

4 mA to 20 mA output only

Vmin = 10V + (.020 x RL)

RL = RS + RW

RL = Loop resistance (ohms)

RS = Sense resistance (ohms)

RW = Wire resistance (ohms)

Load Limitations

4 mA to 20 mA Output

3-Wire Voltage Output

V+ = Supply voltage

V- = 4 mA to 20 mA signal

Output = Voltage Output signal

Common = Supply voltage return/ground

Output Signal Min

Supply

Max

Supply

Max Current

Consumption

4 mA to 20 mA 10 Vdc 30 Vdc 25 mA

0 Vdc to 5 Vdc 10 Vdc 30 Vdc 8 mA

1 Vdc to 5 Vdc 10 Vdc 30 Vdc 8 mA

0 Vdc to 10 Vdc 14 Vdc 30 Vdc 8 mA

Power Supply Requirements And Ratings

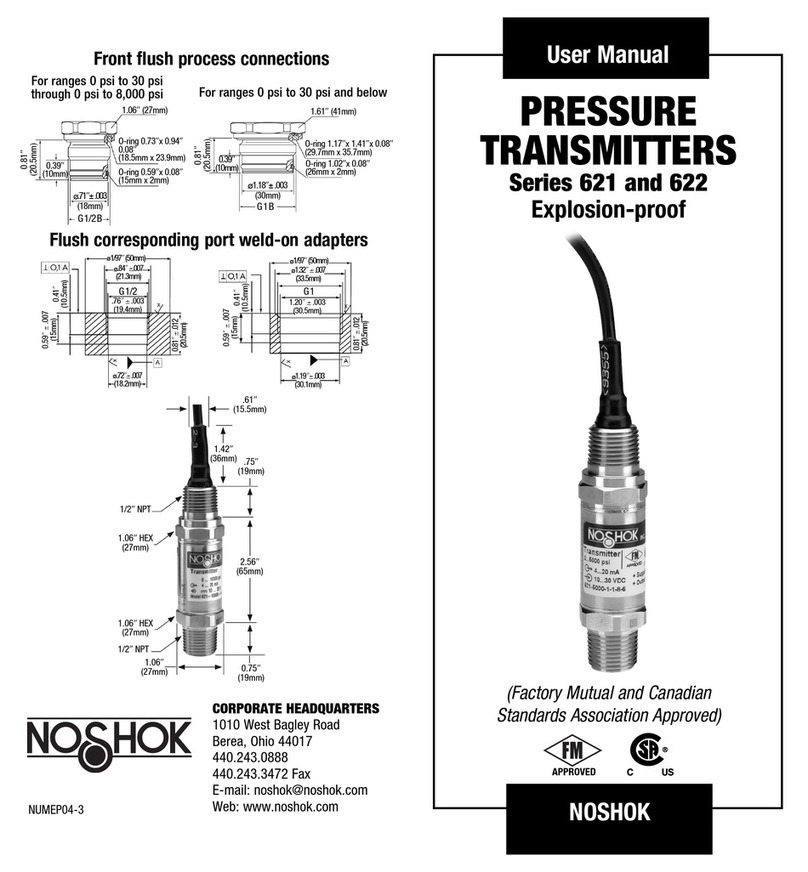

PT40 Series

High Accuracy Fixed Range Transmitter

General Description

NOSHOK PT40 pressure transmitters are high performance instruments

intended for use in industrial applications where the process media is

compatible with the 316 Stainless Steel wetted parts and system tem-

peratures and pressure are within the limits specied herein.

Installation

NOSHOK PT40 pressure transmitters require no special mounting

hardware and can be mounted in any orientation with negligible

position error.

Although the units can withstand considerable vibration without damage

or signicant output effects, it is always good practice to mount the

transmitter where there is minimum vibration. Refer to product

specication for allowable shock and vibration conditions.

For units with NPT type pressure ttings apply sealing tape or an

equivalent sealant to the threads before installing.

When installing or removing the unit apply a wrench to the hex wrench

ats, located above the pressure tting. A 27 mm wrench can be used on

the wrench ats of the hex.

WARNING

Please read the entire user manual for safe use of product.

NOTE: If NOSHOK PT40 High Accuracy pressure transmitters are used in a manner

not specified in this manual, the protection provided by the equipment may be impaired.

NOTE: The safety of the system is the responsibility of the assembler of the system.

See www.noshok.com for further product detail and documentation.

User Manual

1010 West Bagley Road • Berea, Ohio 44017

440-243-0888 • Fax 440-243-3472

Technical Specications Related To Safety

See product label for specic product input (voltage), output

(voltage or current), and pressure ranges.

Temperature

Ranges

Compensated

32 °F to 176 °F (0 °C to 80 °C)

Media -22 °F to 212 °F (-30 °C to 100 °C)

Ambient -4 °F to 176 °F (-20 °C to 80 °C)

Storage -40 °F to 212 °F (-40 °C to 100 °C)

Compensated

Temperature Error 0.20% of span / 10 K

Proof Pressure

< 300 psi: 3 times full scale

300 - 10,000 psi: 2 times full

> 10,000 psi: 1.5 times full scale

Burst Pressure

< 300 psi: 5 times full scale

300 - 10,000 psi: 4 times full

> 10,000 psi: 3 times full scale

Ingress Protection

Ratings

IP65 to IP67 Depending on Electrical

Connection (Refer to Electrical Connector

Terminal Wiring and Pinout)

Shock 1,000 g’s according to IEC 60068-2-27

Vibration 20 g’s according to IEC 60068-2-6

PT40UM-23

Uncertainty

±0.29% of span, optional ±0.19% of span,

including non-linearity best t straight line,

hysteresis, and non-repeatability per IEC

61298-2 at reference conditions

• Non-Linearity 0.25%, 0.125%

• Hysteresis 0.10%

• Non-repeatability 0.10%

Uncertainty = (Non-linearity)2+(Hysteresis)2+(Non-repeatability)2

√