NOSHOK KING-GAGE 5900 Use and care manual

Effective: September, 2010 (replaces February, 1998) EX-1710-1

Operation/Calibration Manual

User Guide to Range Calculation, Calibration

Procedures, Zero/Span Adjustments

for Differential Pressure Transmitters

Model 5900

D/P Module

4 mA to 20 mA Pressure Transmitter

Multiple Tank Level Display

KING-GAGE, A NOSHOK Company I 1010 West Bagley Road, Berea, Ohio 44017 I Ph: 855-367-2494 I www.king-gage.com

page 2

Model 5900 D/P Module EX-1710-1

© 2010 King Engineering Corp. All rights reserved.

The information contained in this manual was accurate at

the time of release. Specifications are subject to change

without notice.

WAR RANTY—All King Engineeringproductsare guaranteed

to be free from defects in material and workmanship for

one year from the date of purchase. Any product or part

found to be defective under normal use within one year

of purchase will be repaired or replaced at no charge if

returned to the company in Berea, Ohio within ten days

of discovery of the defect. No other warranties, whether

express, implied or statutory, including the warranties of

fitness for a particular purpose or merchantability, are given

by this agreement. The exclusive remedy for nonconformity

of these goods shall be repair and/or replacement of the

nonconforming goods or parts.

Seller will not be liable for consequential damages resulting

from breach of this agreement. The term "consequential

damages" shall include but shall not be limited to damage

to all machines, equipment and goods other than the goods

sold hereby, interruption of production, loss of profits,

delays of any kind, administrative expense and overhead.

Revisions:

April, 1987 –original release

December, 1987 –revised test equipment specifications

August, 1990 –revised zero/span adjustment

August, 1991 –corrected zero/span positions (pg. 11)

September, 1994 –revised text (update model numbers)

February, 1998 –LP2 3-terminal signal connector (pg. 15)

September, 2010 –revised voltage/load capacity

page 3

Model 5900 D/P Module EX-1710-1

Table of Contents

Specifications............................................................................................. 4

Span Adjustment Range............................................................................. 4

Pressure Connections................................................................................. 5

Power Requirement ................................................................................... 5

Load Capacity at Supplied Voltage ............................................................. 5

Calibration—Zero/Span Adjustment ........................................................... 6

Low Pressure Input (for differential pressure) .............................................. 8

Calibration Test Setup (Typical) ................................................................... 9

Pressure Range Calculation ...................................................................... 10

Troubleshooting....................................................................................... 11

5900 - 1 - 2

Fittings

1= none (1/8"NPT connection)

4= Swagelok 1/4"tube ×1/8"NPT

(compatible with copper or poly tubing)

Range

0= 0–5 psid /0 –0.3 bar

1= 0–10 psid /0 –0.69 bar

2= 0–15 psid /0 –1.03 bar

3= 0–30 psid /0 –2.06 bar

4= 0–50 psid /0 –3.44 bar

Model No. Designations

page 4

Model 5900 D/P Module EX-1710-1

Application

The D/P Module is a pneumatic-to-current, differential pressure transmitter. It provides

a two-wire 4-20 mA output signal suitable for process control or tank level gauging.

Model 5900 D/P Module

This surface mount transmitter is intended for control room or other protected

locations. Modules should typically be mounted within an enclosure or cabinet.

Specifications

Pressure Ranges

0–5, 0–10, 0–15, 0–30, 0–50 psid

Output

4–20 milliamperes (mAdc)

Accuracy

± 0.20% FS (± 0.10% FS, typical)

includes non-linearity, hysteresis, non-repeatability

Repeatability

± 0.02% of calibrated span

Temperature Range (environmental)

0° F to 180° F / -18°C to 82°C operating

Compensated Temperature Range

32°F to 120°F / 0°C to 54°C

Thermal Effects

(over compensated temp. range)

less than .007° F (.011%° C) span shift—sensitivity

less than .007° F (.011%° C) span shift—zero

Power Supply Voltage

14–40 Vdc (unregulated)

Power Supply Stability

(Effect on FSO) less than 0.005% of span change in output

per volt change at input terminals

Burst Pressure

200 psi

Span Adjustment Range

Transmitter adjustment turndown is 3:1 for the 0–15, 0–30, 0–50 psid nominal ranges.

Nominal Minimum Range of Adjustment

0–5 psid 0–3 psid 0–83 in. thru 0–138 in. water / 0–2.1 m thru 0–3.5 m water

0–10 psid 0–3 psid 0–83 in. thru 0–277 in. water / 0–2.1 m thru 0–7.0 m water

0–15 psid 0–3 psid 0–83 in. thru 0–415 in. water / 0–2.1 m thru 0–10.5 m water

0–30 psid 0–10 psid 0–277 in. thru 0–830 in. water / 0–7.0 m thru 0–21.0 m water

0–50 psid 0–15 psid 0–415 in. thru 0–1384 in. water / 0–10.5 m thru 0–35.1 m water

Operating Limit (Maximum Pressure)

Pressure above 300% nominal range (overrange) will result in damage to the transmitter

(200% may cause a shift in calibration).

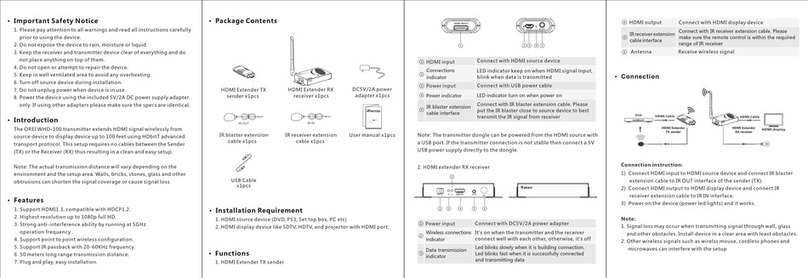

KING-

GAGE

ZERO

SPAN

+

-

D/P

MODULE

4-20 mA

Pressure

Transmitter

T

E

S

T

1 in

25 mm

7-1/8 in

181 mm

6-3/16 in

81 mm

ES

1/8 in NPT (Optional)

1/4 in Fittings

Low

Pressure

Ports

High

Pressure

Ports

4-20 mA

Output

Connection

page 5

Model 5900 D/P Module EX-1710-1

Pressure Connections

D/P Module Transmitter incorporates two (2) 1/8" NPT

ports for HIGH and LOW differential pressure inputs.

vent plug for atmospheric reference (or low pressure

input when measuring differential pressure)

connection for pressure input signal (high pressure

input when measuring differential pressure)

When application is for psig (gage pressure), the low pressure

port is not used. A vent plug should be installed in the low

pressure port to allow transmitter to reference atmosphere.

The low pressure port should never be plugged or sealed!

Signal Loop Connections

A plug-in type terminal connector is furnished for the +

Signal and −Signal inputs. Terminal block can be removed

to make the cable connections and then re-inserted into

the mating socket. Screw clamp terminals are provided

for positive (+) and negative or common (−) sides of the

signal loop.

As is typical of two-wire transmitters, all electrical power

is supplied through the signal loop wiring. Refer to the

following diagram for proper wiring of the 4–20 mA loop

circuit:

ES

1/8 in NPT (Optional)

1/4 in Fittings

Low

Pressure

Ports

High

Pressure

Ports

4-20 mA

Output

Connection

+-

+VA

VCOM

RL

KING-

GAGE

ZERO

SPAN

+

-

D/P

MODULE

4-20 mA

Pressure

Transmitter

T

E

S

T

Plug-in Power/Signal

Connector

+ Ð

2

1

4-20 mA

Output

Connection

+-

+VA

VCOM

RL

KING-

GAGE

ZERO

SPAN

+

-

D/P

MODULE

4-20 mA

Pressure

Transmitter

T

E

S

T

Plug-in Power/Signal

Connector

+ Ð

2

1

Power Requirement

The D/P transmitter requires a source of DC power (14– 40

Vdc) for operation. Minimum excitation voltage must be

no less than 14 Vdc Any receiver installed on the signal

loop (meters, data loggers, controllers, etc.) must be taken

into account when determining the required power supply

voltage to be used. The internal resistance of each device

added together represents the total “load” residing on the

signal loop circuit.

Load Capacity = (Supply Voltage −12 Volts)

(ohms) .02

Load Capacity at Supplied Voltage

KING-GAGE®tank processors and LevelBAR provide 24 Vdc

excitation to power the signal loop circuit. (If the application

requirement exceeds 700 ohms, an external power supply

of appropriate voltage will be required.)

Signal Cabling

The 4–20 mA signal loop needs to be run using twisted pair

(two conductor) cable. “Noise” or EMI (electromagnetic

interference) does not generally create a problem since it

is common to both wires in the pair and essentially cancels

itself out. In most applications, non-shielded twisted pair

instrumentation cable (20–22 awg) will be suitable for the

signal loop between the LP2 and sensor/transmitter.

20 Vdc 24 Vdc 28 Vdc 32 Vdc 36 Vdc 40 Vdc

400 ohms 600 ohms 800 ohms 1000 ohms 1200 ohms 1400 ohms

S

E

page 6

Model 5900 D/P Module EX-1710-1

Test Point Terminals (TP1, TP2)—Test meter terminals

are provided (see diagram) for measuring the output signal

without disturbing the signal loop. Do not connect any

device or meter whose internal resistance exceeds 20 ohms

across these test points. Also refer to “In-Process Zero/Span

Adjustment” in the following section.

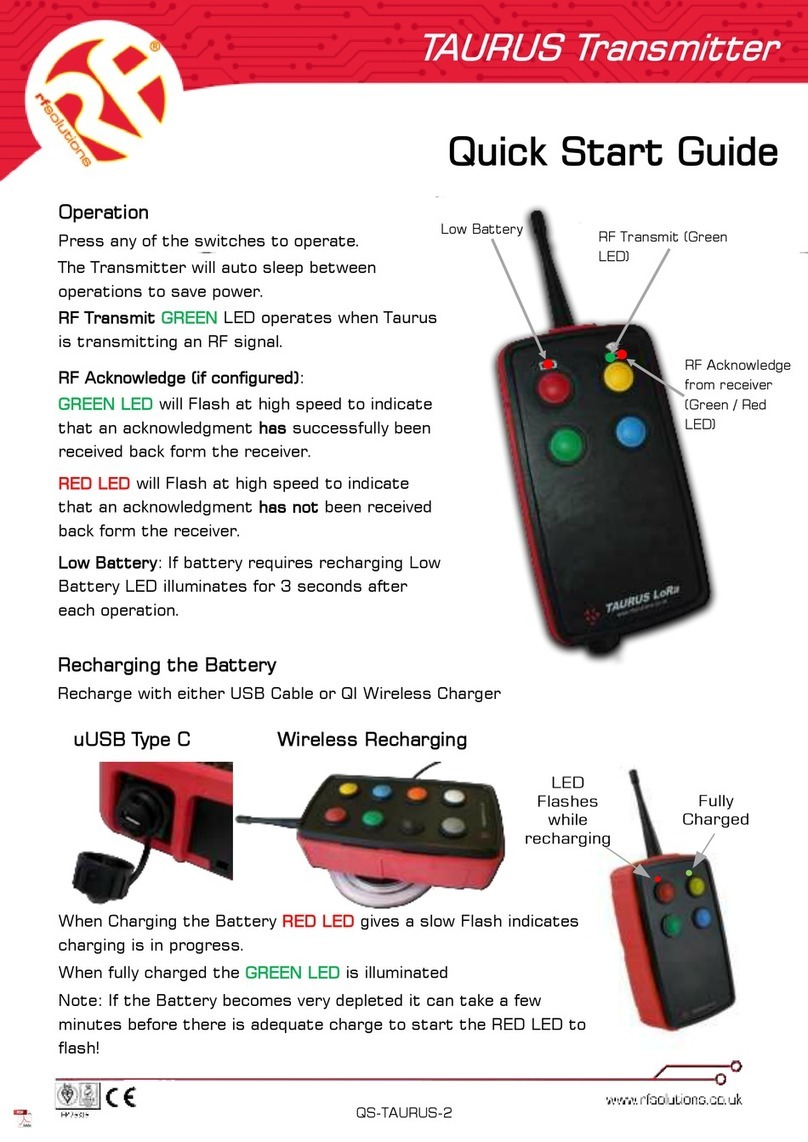

D/P Calibration

—

Zero/Span Adjustment

This procedure is intended to recalibrate the existing zero and

span output settings. It is generally recommended that the

zero output be checked at least every 12 months. Generally

speaking, slight adjustment of the zero potentiometer is all

that is needed to maintain transmitter accuracy. However,

since zero is an offset adjustment, shifting this setting

upward or downward will have some corresponding effect

on span.

Adjusting Zero Setting

Check zero by measuring the output using the meter

terminal posts (TP1 and TP2) on the transmitter board.

1. Adjust zero potentiometer as necessary to increase

output (clockwise) or decrease output (counterclock-

wise) until the signal displays as 4.00 or 4.01 mA on

the test meter.

Adjusting Span Setting

This requires applying pressure to the “S” port of the D/P

transmitter equivalent to the maximum depth (hydrostatic)

pressure. Measure the output using the meter terminal

posts on the transmitter board.

2. Adjust span potentiometer as necessary to increase

output (clockwise) or decrease output (counterclock-

wise) until the signal displays as 20.00 or 20.01 mA

on the test meter.

3. Next step is to re-check the zero output and slightly

adjust if necessary.

In-Process Zero/Span Adjustment

It is possible to make adjustments to the zero setting while

the D/P transmitter is installed at the tank. The meter terminal

posts permit in-process monitoring without disturbing the

loop wiring. Confirm that the tank is empty (or liquid level

is below sensor). Measure the transmitter output using a

milliammeter (multimeter) and adjust zero potentiometer

as required.

Using Multimeter: Set multimeter for DC current, using

mA or .001 amp scale. The internal resistance of the meter

must be 20 ohms or less since higher resistance values will

create incorrect readings. Connect the meter leads to the

TP1 and TP2 posts on the internal circuit board.

Adjusting span settings of an installed transmitter is not a

very precise method for calibration (since the hydrostatic

pressure may not be accurately determined). In-process span

adjustment is not recommended for this reason.

ON

1 2 3 4

SW 1

ZERO

SPAN

Span

Adjustment

Meter

Terminals

Zero

Adjustment

+

-

Dip Switch

Zero Adjust &

Span Adjust

Potentiometers

Maximum

25 turns

adjustment

page 7

Model 5900 D/P Module EX-1710-1

D/P Range Adjustment DIP Switch Settings

The D/P transmitter span can be adjusted from 70%

to 140% of the nominal range indicated by the model

number. (Refer to Model No. Designation on page 3.) This

is how the transmitter’s pressure range can be changed

for a specific application. When the D/P transmitter is

used with a KING-GAGE®digital tank level indicator,

the “Application Datapack” (iButton memory module) is

generally programmed with the nominal range setting. The

indicator programming will correlate the output signal to

tank capacity regardless of whether the maximum tank level

generates less than 20 mA output from the transmitter.

WHEN NOT TO CHANGE SPAN—If a KING-GAGE indicator

is part of the system, you should not have to change the

range (span) of the transmitter.

Coarse Range Setting

An initial coarse range setting is provided by the DIP switches.

Use the previously outlined Zero/Span Calibration to achieve

the final trim setting for precise 4–20 mA output over the

intended pressure range.

The DIP switches on the transmitter circuit board affect

the span (range) of the transmitter. These provide coarse

adjustment in addition to the fine span adjustment of the

potentiometer. Please refer to the individual DIP switch

positions listed for adjusting the existing setting of the

transmitter.

The four (4) switches provide 16 increments of coarse

adjustment. Prior to changing any switch setting, check

the current output of the transmitter at the desired upper

pressure value. Also note the existing switch setting.

1. Apply the desired maximum pressure to the sensing

diaphragm of the D/P transmitter (requires a pressure

test shell available from King Engineering).

2. Record the existing setting positions of the DIP

switches.

3. Adjust the potentiometer to maximum output by

turning clockwise until it “clicks”.

4. To increase the milliamp output, use a higher switch

setting arrangement; to reduce the milliamp output,

use a lower switch setting arrangement. (The goal is

to achieve a output signal value just slightly above

20 milliamps and then use the potentiometer to

trim the setting.)

5. Follow the Zero/Span Calibration procedure to check

both the zero and span output.

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

DIP Switch

Increase

Maximum mA

Output

Minimum mA

Output

Decrease

Increase

Decrease

Increase

Decrease

page 8

Model 5900 D/P Module EX-1710-1

P1

P2

Sensor

Surface of Liquid

E

S

High

Pressure

P1+ P2

Low

Pressure

P2

P1+ P2

(P1+ P2) - P2= P1

Gauge

Air Signal

S E

P1

P2

Sensor

Surface of Liquid

E

S

High

Pressure

P1+ P2

Low

Pressure

P2

P1+ P2

(P1+ P2) - P2= P1

Gauge

Air Signal

S E

Range Less Than 3.00 PSID

When the nominal 5 psid transmitter is used on an

application whose maximum pressure is less than 3.00 psid,

the full calculated range output will be less than 20 mA.

To determine the actual milliamp output of the transmitter

when the maximum applied pressure is below the lower

span limit, use the following formula:

(16 × Calculated PSID)

3.0 + 4 = mA Output

Note

The above formula may also be used for other nominal

range transmitters if maximum applied pressure will be

less than the adjustment range allows. Merely divide by

the lower span limit psid value (listed above) in place of

the “3.0” shown in the formula.

Low Pressure Input

Internal Tank Pressure or Vacuum

In a closed, pressurized or evacuated tank, it is necessary to

measure differential pressure. This is achieved by subtracting

the internal pressure condition of the tank above the surface

of the liquid from the total pressure sensed at the bottom

of the tank. When the low pressure is applied to one side

of the transmitter sensing element and the high pressure to

the other side, the internal tank pressure above the liquid

(low pressure) is balanced across the sensing element. This

is also referred to as being “equalized” (which is why we

designate the low pressure connection as “E”).

CAUTION: While the internal pressure above the liquid is

not a factor in determining range (span), there may be

instances where the sum of the liquid and internal pressure

exceeds the 150 psi burst pressure rating of the transmitter.

Also, do not subtract pressure when a vacuum condition

is present within the tank (since loss of vacuum would be

seen as an increase at the high pressure connection of the

transmitter).

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

Decrease

mA

Increase

mA

ON

1234

ON

1234

ON

1234

Coarse Setting Procedure:The number of switches in

the ON position will increase the milliamp value as each

switch controls an identical fixed resistor. To increase

milliamp output, place additional switches into the ON

position. To decrease milliamp output, move switches

to the off position.

1 2 3 4

ON

17.002

Meter

DIP Switch

1 2 3 4

ON

19.970

Meter

DIP Switch

DIP Switch—Coarse Adjustment

Coarse Range Setting—Alternate Version

Previous versions of the D/P transmitter employ similar DIP

switches, but only offer 5 increments of coarse adjustment.

With these versions, the span potentiometer offers greater

range of adjustment.

page 9

Model 5900 D/P Module EX-1710-1

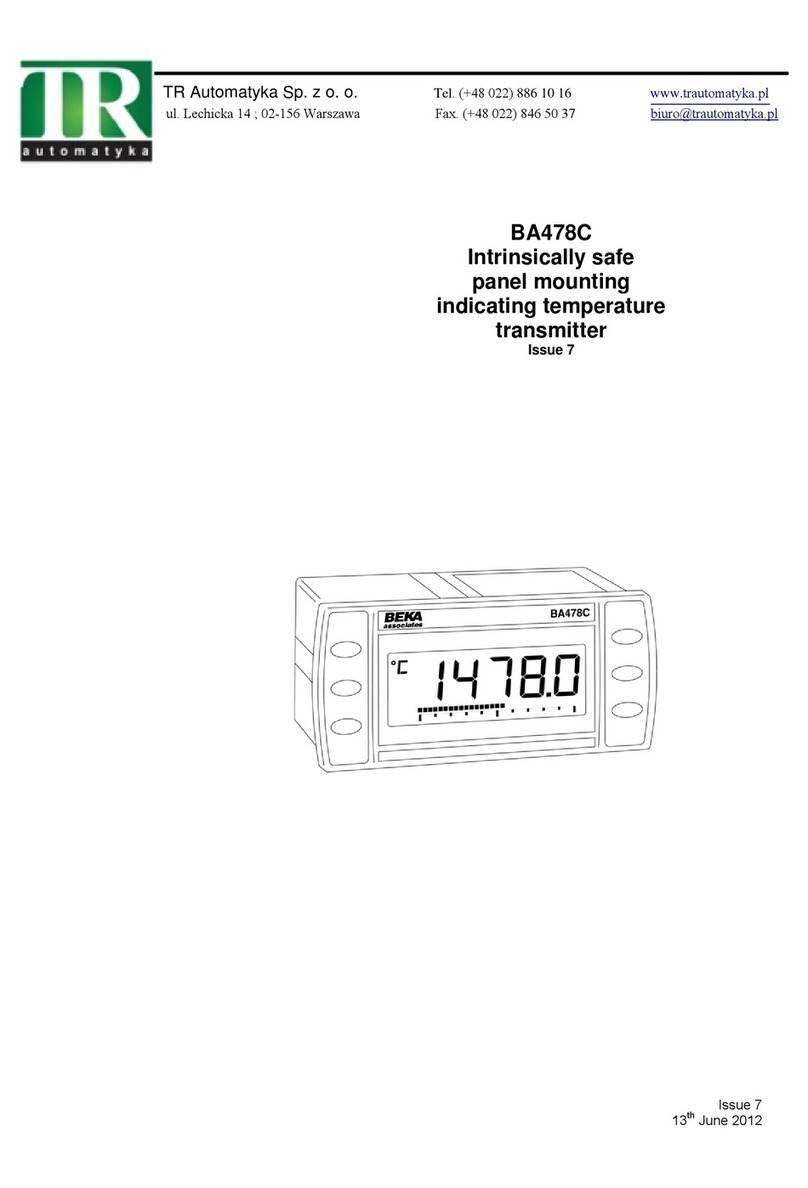

Calibration Test Setup (Typical)

This D/P transmitter has a specified accuracy of ±0.15%. To

ensure your calibration maintains this degree of accuracy,

the equipment used to check zero and span settings must

conform to the recommendation listed below. Use of

equipment with less than specified accuracy figures will not

provide acceptable results. King assumes no responsibility

for transmitter accuracy if test equipment does not meet

recommended minimum standards.

Recommended Equipment:

MILLIAMMETER; 3-1/2 digit minimum, 0.05% accuracy

(20 ohms max. internal resistance)

DC POWER SUPPLY

PRESSURE INDICATOR; PSI or IN. OF WATER

0.05% accuracy corresponding to transmitter range

5 psid nominal ±.0025 psi or .0693" of water

10 psid nominal ±.005 psi or .1385" of water

15 psid nominal ±.0075 psi or .2078" of water

30 psid nominal ±.015 psi or .4156" of water

50 psid nominal ±.025 psi or .6927" of water

NOTE—The low pressure port (“E”) of transmitter must be

vented to atmosphere during the calibration and adjustment

procedures.

0 160

Compressed

Air

Precision

Pressure

Regulator

Precision

Pressure

Indicator

S

20.00

10 A

300 mA COM

OFF VOLTS AC

VOLTS DC

300 mV DC

OHMS

AUDIO

AMPS DC

AMPS AC

Meter

4-20 mA

Output

Connection

+−

+VA

VCOM

RL

+

−

+

−

page 10

Model 5900 D/P Module EX-1710-1

Pressure Range Calculation

There are two simple equations that can be used to

determine the actual range (span) required for the

transmitter. One of these gives the range in psid and the

other in INCHES OF WATER.

(B −A) ×C

27.6807 = Range (psid)

Where . . .

A = Reserve (inches of depth from low point of tank to

sensor)

B = Full Tank (inches of depth from low point of tank to full)

C = Specific Gravity of Tank Contents

Converting LBS/GAL to Specific Gravity

If the density of the liquid is expressed as pounds per gallon

(e.g., 8.6 lbs/gal), the specific gravity can be determined

by dividing the value by 8.33 (weight of water per gallon).

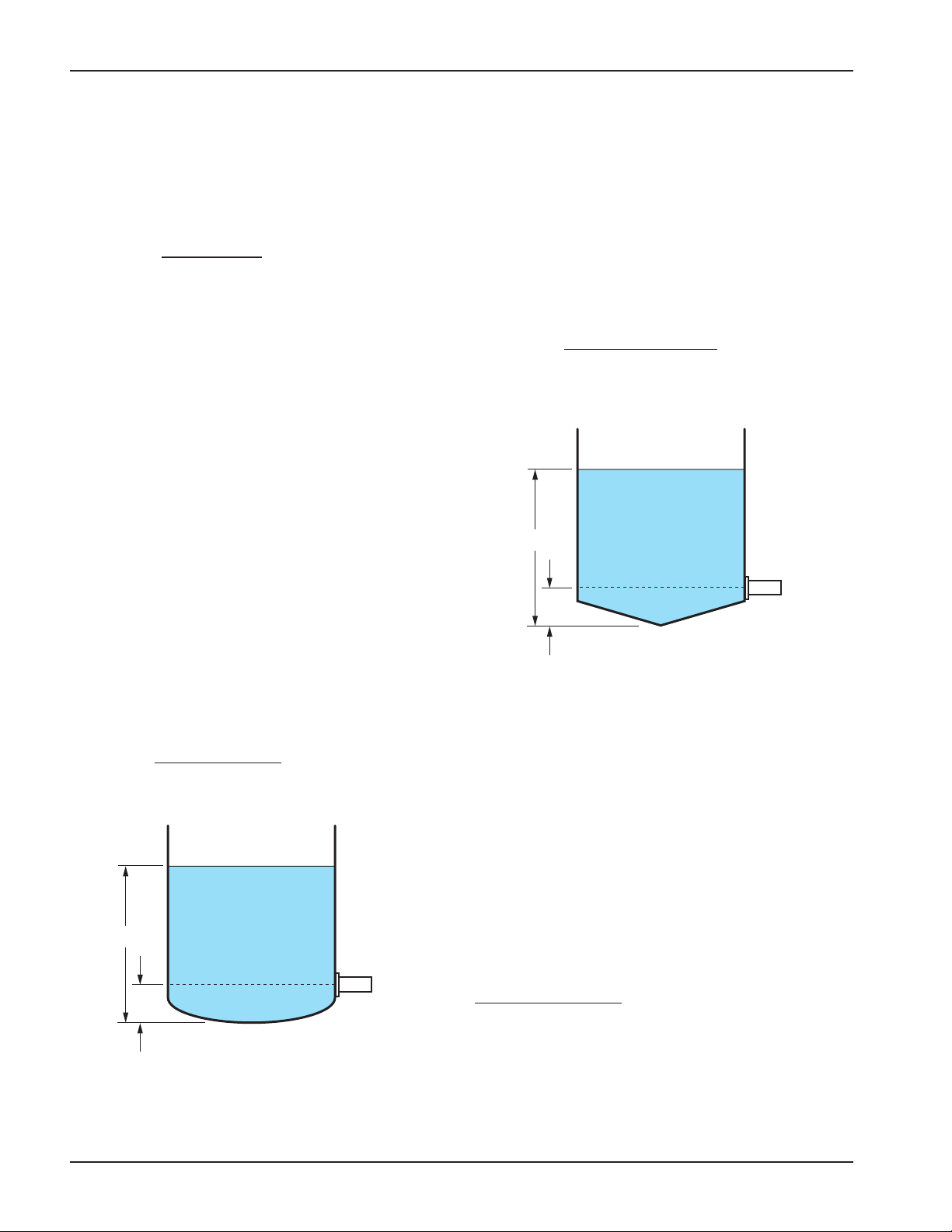

Examples—Pressure Range Calculations

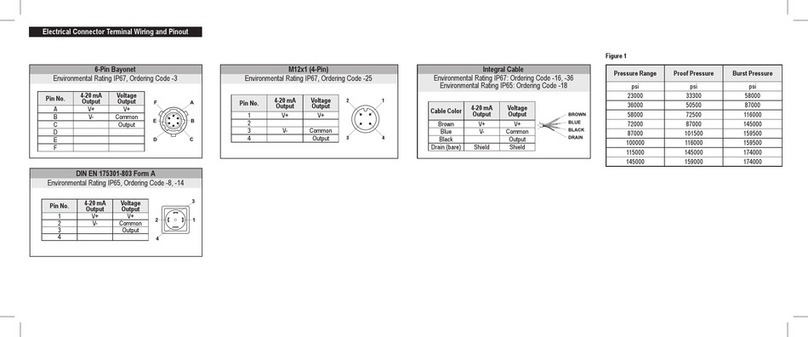

A typical tank gauging application is illustrated in Figure

1. The “reserve” represents the distance from the lowest

point on the bottom of the tank to the installed sensor.

“Full” is the level of contents at which the tank is filled

to capacity (or may be some point below the tank top, as

desired). The liquid contents in the tank is water @ 1.00

specific gravity.

C = 1.00 (Specific Gravity)

B = 382" (Full Tank)

A = 30" (Reserve)

(382 −30) × 1.00

27.6807 = 12.72 psid

(382 −30) ×1.00 = 352" water

A second tank gauging application is illustrated in Figure 2.

The “reserve” represents the distance from the lowest

point on the bottom of the tank to the installed sensor.

“Full” is the level of contents at which the tank is filled

to desired level (which is less than the actual full capacity

of the tank). The liquid contents in the tank has a specific

gravity of 1.032.

C = 1.032 (Specific Gravity)

B = 300" (Upper Level)

A = 28" (Reserve)

(300 − 28) × 1.032

27.6807 = 10.14 psid

(300 −28) × 1.032 = 281" water

NOTE—Should the calculated range exceed the upper span

limits of the transmitter, the next higher range is required.

If the calculated range falls below the lower span limits, a

lower range transmitter is required (to obtain 20 mAdc).

Figure 1

Figure 2

When Output will be Less Than 20 mA . ..

Maximum Pressure Below 3.00 PSID

When the nominal 5 psid transmitter is used on an

application whose maximum pressure is less than 3.00 psid,

the full calculated range output will be less than 20 mA.

To determine the actual milliamp output of the transmitter

when the maximum applied pressure is below the lower

span limit, use the following formula:

(16 ×Calculated PSID) + 4 = mA Output

3.0

Other Ranges

The above formula may also be used for other nominal

range transmitters if maximum applied pressure will be

less than the adjustment range allows. Merely divide by

the lower span limit PSID value (see page 4) in place of the

“3.0” shown in the formula.

A

B

Water

1.00 SP. GR.

Sensor

A

B

Milk

1.032 SP. GR.

Sensor

A

B

Water

1.00 SP. GR.

Sensor

A

B

Milk

1.032 SP. GR.

Sensor

page 11

Model 5900 D/P Module EX-1710-1

Troubleshooting

No signal

• Check that Vdc power is connected to the signal loop

circuit (V+ at transmitter + signal terminal).

• Polarity reversed- check by reversing the + and - leads

at the input terminals.

Output greater than 20.0 mA

• Check zero output of transmitter—adjust zero to 4.00

mA if necessary.

• Check span setting—adjust to 20.00 mA at nominal

range or calculated full pressure.

Maximum output less than 20.00 mA

• Check that applied pressure is within span limits

for transmitter range. (Transmitter has ±

40% span

adjustment.)

• Check span setting—adjust to 20.00 mA at nominal

range or calculated full pressure.

• Higher resistive load on signal loop may exceed voltage/

load capacity (see page 5).

Table of contents

Other NOSHOK Transmitter manuals

NOSHOK

NOSHOK 850 Series User manual

NOSHOK

NOSHOK PT40 Series User manual

NOSHOK

NOSHOK King-Gage 5800 Series Service manual

NOSHOK

NOSHOK 810 series User manual

NOSHOK

NOSHOK 800 Series User manual

NOSHOK

NOSHOK 623 Series User manual

NOSHOK

NOSHOK 204 Series User manual

NOSHOK

NOSHOK 621 Series User manual

NOSHOK

NOSHOK KING-GAGE ES2 5501 User manual

NOSHOK

NOSHOK PT41 Series User manual

Popular Transmitter manuals by other brands

Labom

Labom MiniTherm GV4730 Series operating instructions

Dräger

Dräger Polytron Transmitter IR Ex installation instructions

B-Speech

B-Speech RX2 user guide

Tactical technologies

Tactical technologies Joey Transcorder operating instructions

Dynamix

Dynamix BLUECAST-2 manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series user guide