1/4˝ of insulation from the end of wire, sliding the bare end of

the wire under the clamping plate screw.

3. Set the address on the modules per the job drawing. Use the

rotary code switches to set the address of the first module (be-

tween 01 and 154).

In Class B operation, the remaining modules

are automatically assigned to the next five

higher addresses. For example, if the base ad-

dress switch is set to 28, the next five modules

will be addressed to 29, 30, 31, 32 and 33.

The module is shipped in Class B position,

remove shunts for Class A. When operating in

Class A, alternate modules are paired together

(+0/+1, +2/+3, +4/+5), resulting in a

total of three modules. For example, if the base address switch

is set to 28, then 30 and 32 will be automatically assigned to the

modules while 29, 31 and 33 are available to be used for other

modules on the SLC. For Class A and B operation, DO NOT set the

lowest address above 154, as the other modules will be assigned

to nonexistent addresses.

NOTE: The XP6-MA must have power cycled for shunt changes

to take effect.

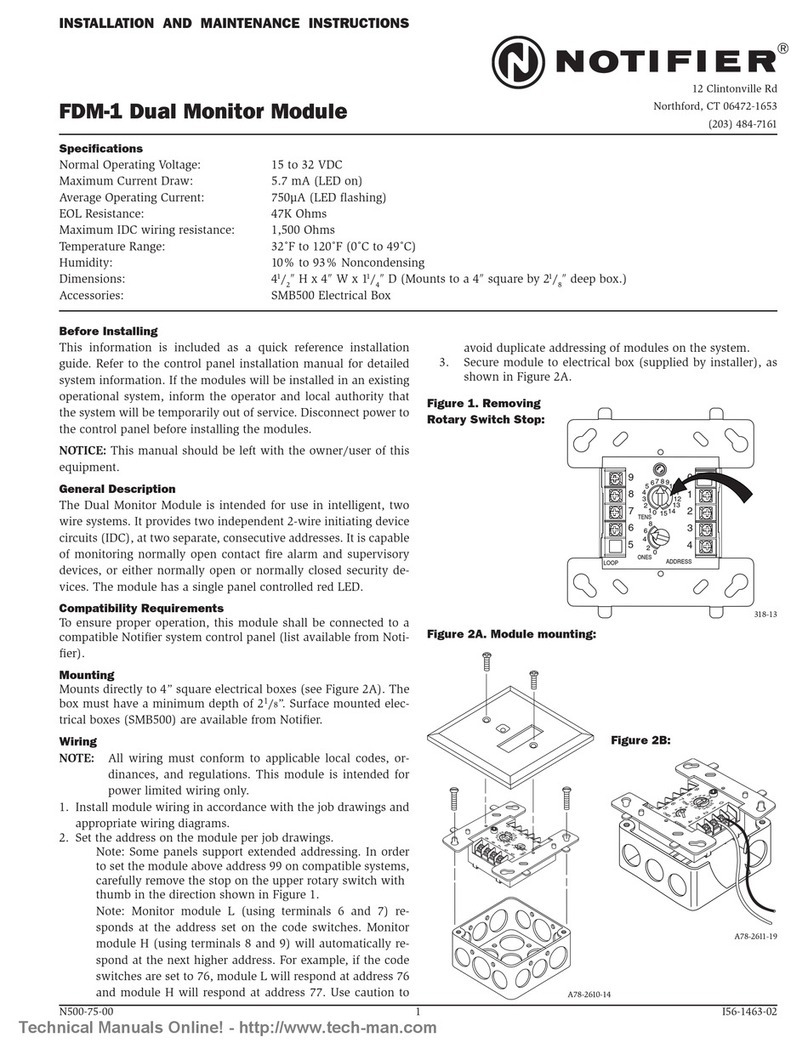

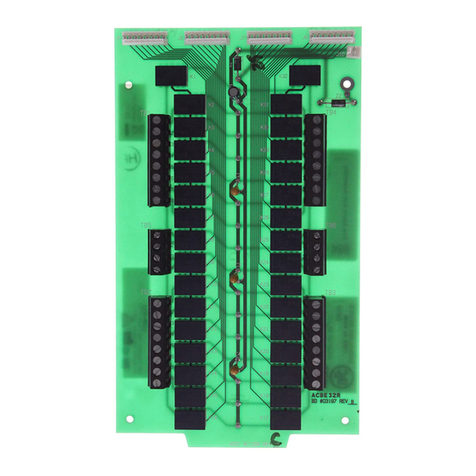

NOTE: Some panels support extended addressing. In order to set

the module above address 99 on compatible systems, carefully

remove the stop on the upper rotary switch (see Figure 7). If the

panel does not support extended addressing, do not set the lowest

address above 94.

4. A shunt is provided to disable a maximum of two unused modules

in Class B operation and Class A operation. Modules are disabled

from the highest address and work downward. If two modules

are disabled, the lowest four addresses will be functional, while

the highest two will be disabled. For example, in Class B opera-

tion, if the shunt for Address Disable is placed on “two” and the

base switch is set to 28, the modules will be assigned to 28, 29,

30 and 31 while disabling the highest two positions.

NOTE: Place unused shunts on single pin to store on board for

future use.

NOTE: Power must not be applied to the unit when changing

functionality on the shunts.

WIRING NOTES

Power-limited circuits must employ type FPL, FPLR, or FPLP

cable as required by Article 760 of the NEC.

All wiring must be in accordance with the NEC, NFPA 72 and

all other applicable codes and standards. All external power

supplies must be power limited with battery back-up. All ex-

ternal power supplies and detectors must be UL listed for fire

protection signaling applications.

PROGRAMMING

The XP6-MA module operates with the following Fire Alarm

Control Panels:

• AM2020/AFP1010 • System 5000 with AIM-200

• AFP-200 • AFC-600

• AFP-300/AFP-400 • NFS-640 (ONYX™ Series System)

• NFS-3030

The modules are programmed as devices in each system according

to the programming instructions in the appropriate FACP manual.

•

•

N500-80-00 3 I56-1806-006

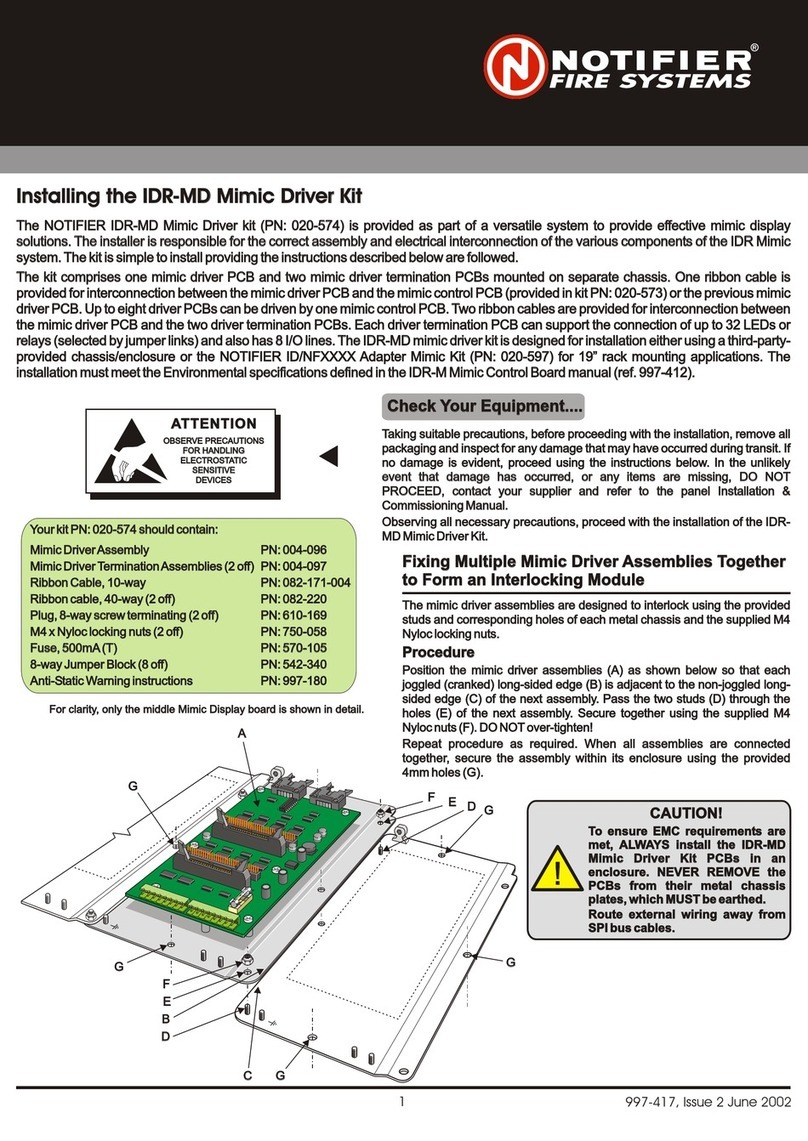

Step 1: Insert the bottom of the XP6-MA module down into a

rear slot on the chassis.

Step 2: Carefully swing the upper edge of the board back

towards the back of the chassis until it touches

the two standoffs.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instruc-

tions in this manual.

The steps in Figures 6a and 6b describe and illustrate module in-

stallation when the rear chassis position and the position in front

of it will be filled. Front position installation is possible only if

the rear position is filled with an XP module.

Figure 6a. Installation of XP6-MA module in a rear

chassis position, method two:

C0225-00

Step 1: Insert the bottom edge of the XP6-MA module down into

a rear slot of the chassis.

Step 2: Carefully swing the upper edge of the board towards the

back of the chassis until it touches the short standoff

attached to the chassis.

Step 3: Align the long standoff with the short standoff and tighten.

Figure 6b. Installation of XP6-MA module in front

chassis position:

C0226-00

Step 1: Insert the bottom edge of the XP6-MA module down

into a front slot of the chassis.

Step 2: Carefully swing the upper edge of the board

towards the back of the chassis until it touches the 1

1/4”

(31.75mm) standoffs installed on the rear module.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the

instructions in this manual.

WIRING

NOTE: All wiring must conform to applicable local codes,

ordinances, and regulations.

1. Install module wiring in accordance with the job drawings and

appropriate wiring diagrams.

2. All wiring to the XP6-MA is done via terminal blocks. In order

to properly make electrical connections strip approximately

TENS

0

78

6

5

4

3

21

910

11

12

13

14

15

Figure 7.

C0227-00