©NOUVAG AG • 31886 • V20230412 • All rights reserved.

MANUFACTURER AND SERVICE POINTS

A complete list of NOUVAG certified service points are found on the NOUVAG

website: Nouvag.com > Service

POST MARKET SURVEILLANCE

In the event of incidents related to the use of the medical device,

please contact immediately the manufacturer by email

To provide adequate information, please compile the incident question-

naire at the web address

Nouvag.com > Contact us > Incident questionnaire.

Switzerland

NOUVAGAG

St. Gallerstrasse 25

9403 Goldach

Phone +41 71 846 66 00

www.nouvag.com

Germany

NOUVAGGmbH

Schulthaissstrasse 15

78462 Konstanz

Phone +49 7531 1290 - 0

www.nouvag.com

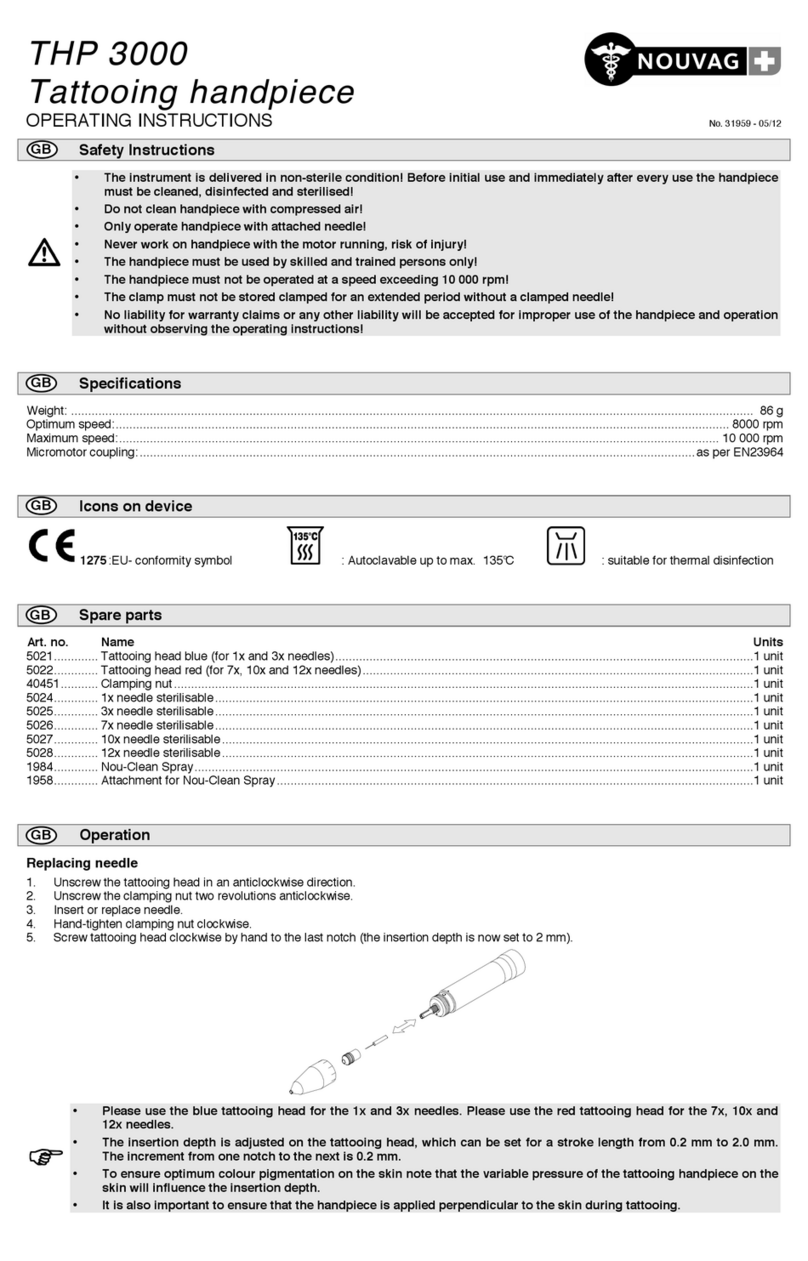

Cleaning Mechanical cleaning

. After pre-cleaning place the micro saw and its accessories in the strainer

basket.

. Mechanical cleaning is only successful if the pre-cleaning, described above,

is adhered to!

. Cleaning is done using the Vario TD programme in the cleaning and dis-

infection unit (CDU). For the cleaning process it is advisable to use DI

water (fully desalinated water).

. After completingthe cleaning programme (inc. Thermal disinfection)check

the micro saw, the nut and the cooling clip for visible contamination in

grooves and gaps. Repeat the cleaning cycle, if necessary.

Automatic cleaning process (Vario TD programme)

. Pre-clean with cold water for minutes.

. Empty

. Clean for minutes at °C with . % alkaline or at

°C with . % enzymatic cleaner.

. Empty

. Neutralise with cold water for minutes.

. Empty

. Inter-rinse for minutes with cold water.

. Empty

Disinfection Mechanical disinfection

The cleaning/disinfection unit has a thermal disinfection programme which

follows after the cleaning. When performing mechanical thermal disinfec-

tion, give due consideration to the national requirements relating to the A

value (see DINENISO-). We recommend an A value of . for the

instrument. Disinfection must be carried out with DI water.

Warning

When inadequately rinsed or exposed to the disin-

fectant or detergent for too long, the instrument can

corrode. Please see the corresponding detergent and

disinfectant’s package insert for dwell times.

Drying Mechanical drying

Dry the micro saw using the cleaning/disinfection unit’s (CDU) drying cycle. If

required, manual drying can also be achieved by using a lint-free cloth. When

drying manually, take particular care with the grooves and gaps of the instru-

ment. Then spray the instrument again with Lubrifluid.

Every CDU must provide a corresponding drying procedure through the

manufacturer (see ISO-). Please follow the corresponding CDU-manu-

facturer’s directions and operating instructions.

Manual drying

Set up the micro saw in an upright position without the

nut and the cooling clip attached.

Dry the instrument for at least minutes. Then spray

it with Lubrifluid. Afterwards reassemble the nut and

the cooling clip back onto the instrument.

Manual

cleaning and

disinfection

. Immerse the micro saw handpiece after pre-cleaning for minutes in a bath with enzymatic

cleaner. Clean accessories such as e.g. the cooling clip and the nut for minutes in an ultra-

sonic bath. Follow the instructions of the manufacturer of the detergent.

. Perform a complete post-clean of the product under running drinking water, using a soft brush.

Intensely rinse, if there is any cavities and lumens existing, with a water pressure gun (or simi-

lar) for at least seconds.

. To remove the detergent, rinse the products under running city water (drinking quality) for at least

seconds.

Warning

Do not clean micro saw (hand-

piece) in an ultrasonic bath!

Manual

disinfection

After cleaning, immerse the products for minutes in a bath with a suitable disinfectant. It must be ensured that all surfaces are com-

pletely wetted with the disinfectant. Follow the manufacturers instructions of the disinfectant. After disinfection thoroughly rinse all

products with deionised water to remove the disinfectant ( >min.).

Manual

drying

Set up the micro saw handpiece vertically, separated from the cooling clip, to make sure the outflow of water is favored. Dry products

with a lint-free paper towel. Then dry with suitable compressed air in accordance with the RKI recommendation. Pay particular atten-

tion to the drying of hard to reach areas.

Inspection and

care

. First unscrew the union nut and remove the cooling clip.

. Perform a visual inspection for damage, corrosion and wear.

. Spray the handpiece for cleaning and care. NOUVAG recommends the use

of Lubrifluid. Attach the blue spray adapter to the spray can and spray

the handpiece from the coupling side for about seconds until only

clear liquid flows out of the electronic motor.

. Then wipe with a damp cloth (observe the instructions for use of the prod-

uct).

. After spraying the handpiece, re-install the cooling clip on the handpiece

and screw the union nut onto the collet chuck.

Sterilisation Sterilisation of the micro saw handpiece is performed with a fractionated pre-vacuum steam sterilisation technique (in accordance with

DINEN / DINEN) giving due consideration to the respective national requirements. Minimum requirements:

. Pre-vacuum phases:

. Sterilisation temperature: minimum °C – maximum °C

. Holding time: At least minutes (full cycle)

. Drying time: At least minutes

When sterilising several products during one sterilisation cycle, do not exceed the maximum steriliser load (see manufacturer’s details).

A drying cycle must be added in the case of autoclaves without a vacuum function. After sterilisation an immaculate sterilisation result

must be detected by examining the appropriate indications. According to the Robert-Koch Institute preparation ends with the document-

ed release for use of the medical device. If the sterilised micro-pencil saw is not used immediately after sterilisation, it must be labelled

with the sterilisation date on the packaging.

Storage Storing the sterile packaging

The sterilised product must be stored away from dust, humidity and contami-

nation. During storage, direct sunlight should be safely avoided. After the

expiry date has passed, do not use the product any longer.

Handling the sterile packaging

Before taking out the product, check for the packaging

to be intact. When taking out the product, follow the

respective aseptic procedures.

Information for

validating the

preparation

The above preparation process has been verified by a validated procedure. The following materials and machines were used:

. Alkaline cleaner: Neodisher®Mediclean; Chemische Fabrik Dr. Weigert GmbH & Co. KG

. Enzymatic cleaner: Neodisher®MediZyme; Chemische Fabrik Dr. Weigert GmbH & Co. KG

. Cleaning and disinfection unit: Miele G CD

. Rack trolley: Miele E

. Strainer basket/flush socket bar: mach (NOUVAG REF )

. Autoclave: Selectomat -HP (MMM)

. Sterile packaging: Sterisheet ; Broemeda Amcor Flexibles GmbH

Chemicals and machines other than those mentioned can also be used. In such a case consult the manufacturers or suppliers to find out

whether their products confer the same performance as the products that the procedure was validated with. If you should opt for a dif-

ferent procedure for reprocessing to the one given above, you are required to correspondingly establish the suitability

PROBLEM CAUSE SOLUTION

Motor is running but

saw is not moving

Saw handpiece is not

correctly coupled with

motor

Press saw handpiece firmly

against the motor until it snaps

into place. Check seat with coun-

termovement.

Saw blade is not

moving regularly

Saw blade is not cor-

rectly clamped

Clamp saw blade correctly and

tighten nut with the jaw spanner.

ACCESSORIES AND SPARE PARTSMALFUNCTIONS AND TROUBLESHOOTING

INFORMATION ON DISPOSAL

When disposing of the device, device components and accessories, the

regulations issued by the legislator must be followed.

When discarding the device components and accessories, please comply

with the issued statutory regulations.

REF DESCRIPTION QUANTITY

Jaw spanner

Lubricant spray LUBRIFLUID

Cooling clip

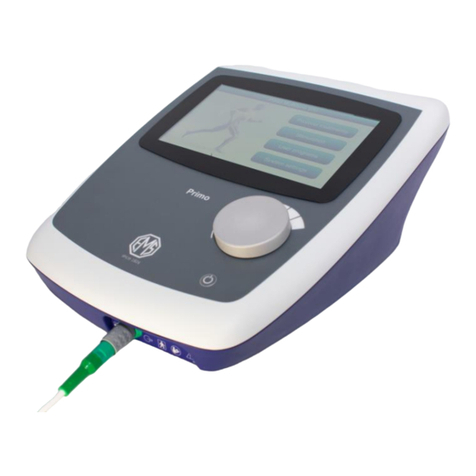

TECHNICAL DATA

REF nou

Weight g

Torque max. Ncm

Speed max. ’ rpm

Oscillation angle saw blade °

Transmission ratio :

Coupling to motor ISO

Clamping depth saw blade shank mm

Thickness saw blade , mm

There is no experience available from conducting other sterilisation procedures such as plasma sterilisation, low temperature sterilisation procedure, etc. Users

bear full responsibility if they use a procedure which differs from the validated sterilisation procedure described!

Please also comply with the applicable legislation in your country and the medical practice or hospital’s hygiene rules. This especially applies to the varying

requirements for an effective inactivation of prions.