Nova Electronics MR210AU User manual

1/2-Axes Motor Control Unit

MR210AU / MR220AU

User’s Manual

2004-02-18 Ver. 1.0

2007-04-04 Ver. 1.1

2008-12-12 Ver. 3.3

2010-06-30 Ver. 3.4

NOVA electronics

- i -

Caution

Introduction

Thank you for purchasing MR210AU/MR220AU motion control unit.

■ Checking the contents

When you unpack the package, check for the following accessories. If something is missing or broken, contact the place of

purchase.

Model MR210AU MR220AU

Accessories

MR210AU

RS232CCable

USBCable

24V Power Connector (CN1)

20P MIL Connector (CN3)

16P MIL Connector (CN4)

User’s Manual

(withCD-ROM)

1

1

1

1

1

1

1

MR220AU

RS232C Cable

USBCable

24V Power Connector (CN1)

20P MIL Connector (CN3)

16P MIL Connector (CN4,5)

User’s Manual

(withCD-ROM)

1

1

1

1

1

2

1

:This mark indicates the user that improper use may cause death or injury of the user or people in the

vicinity or material damages.

:This mark indicates the user that improper use may cause damage to the equipment or the loss of valuable

data.

■ General Safety Instructions

Do not use the equipment in locations subject to oil fumes. Do not disassemble, repair or modify the

equipment. Otherwise, fire or electric shock may result and cause death or serious injury.

Prior to use, read this operation manual carefully to fully understand for correct use and follow all the

instructions given in this manual. We shall be exempted from taking responsibility and held harmless for

damage or losses incurred by the user if the user fails to observe the instructions.

Use the following environmental conditions.

Ambient Temperature 0~45℃

Humidity 20~90%(no condensation)

Floating dust Not to be excessive

Corrosive gases None

Electric supply source DC24V ±10%

Caution

Warning

Warning

Caution

- ii -

Caution

■ Handling Precautions

●When connecting the power cable or connection cable, turn off the equipment power. Otherwise, breakdown or operation

error may result.

●Do not disassemble, repair or modify the equipment.

●When using the provided software, connect a cable first and then turn on power and start the software.

●When using serial communication instead of the provided software, refer to serial communication commands book.

●RS232C and USB cables are prepared as communication cables. MR210AU/MR220AU can connect with the USB cable;

however, it can select only one cable either RS232C or USB. Otherwise, it does not work correctly. When connecting the

cable, turn off the equipment power.

Information in this manual is subject to change without notice.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

- iii -

1.Outline ...........................................................................1

2.Setup Operating Program...........................................4

2.1 Operating Program Installation................................................................................................................. 4

2.1.1 Operating Program Installation ...........................................................................................................................4

2.1.2 Uninstallation ........................................................................................................................................................7

2.2 Setup with USB cable................................................................................................................................8

2.2.1 USB device driver installation .............................................................................................................................8

2.2.2 Check Operating Program Start-up....................................................................................................................8

2.3 Setup with RS232C cable ......................................................................................................................... 9

3.Driving Mode and Parameters Configuration ........10

3.1 Mode Setting ............................................................................................................................................ 10

3.2 Parameter Setting .................................................................................................................................... 14

3.3 Home Search Mode Setting.................................................................................................................... 18

3.3.1 The Description of Home Search Operation .................................................................................................. 18

3.3.2 Home Search Mode Setting ............................................................................................................................. 19

3.3.3 Example for Home Search Mode Setting ....................................................................................................... 22

4.Driving Program .........................................................25

4.1 Driving program commands.................................................................................................................... 25

4.2 Input/Output Ports.................................................................................................................................... 30

5.Driving by parallel I/F ................................................31

5.1 Home Search Execution.......................................................................................................................... 31

5.2 Index Driving............................................................................................................................................. 31

5.3 Scan Driving ............................................................................................................................................. 32

5.4 Continuous Driving .................................................................................................................................. 33

5.5 Program Driving ....................................................................................................................................... 33

6.Operation by PC ........................................................34

6.1 Start Operating Program ......................................................................................................................... 34

6.2 Main Screen.............................................................................................................................................. 35

6.3 Parameter / Mode Screen....................................................................................................................... 39

6.3.1 Mode Tab............................................................................................................................................................ 39

6.3.2 Parameter Tab ................................................................................................................................................... 40

6.3.3 Home Search Mode Tab ................................................................................................................................... 41

6.4 Program Edit Screen ............................................................................................................................... 42

6.5 Input/Output Screen................................................................................................................................. 44

- iv -

6.6 Error List.................................................................................................................................................... 45

7.Remote Box Operations ...........................................46

7.1 Data Edit Operation ................................................................................................................................. 48

7.1.1 Register Select .................................................................................................................................................. 48

7.1.2 Register Configuration ...................................................................................................................................... 48

7.1.3 Writing of Driving Programs ............................................................................................................................. 49

7.1.4 Writing of Driving Mode and Parameters........................................................................................................ 51

7.1.5 One Command Execution ................................................................................................................................52

7.2 Drive Operation ........................................................................................................................................ 52

7.2.1 Home Search..................................................................................................................................................... 52

7.2.2 Jog Feed ............................................................................................................................................................ 53

7.2.3 Program Execution............................................................................................................................................ 53

7.2.4 Current Position Writing.................................................................................................................................... 54

8.Input/Output Signal Connection...............................55

8.1 CN1 Power Connector............................................................................................................................. 55

8.2 CN2 RS232C Serial I/F Connector ........................................................................................................ 55

8.3 CN3 Parallel I/F Connector..................................................................................................................... 56

8.4 CN4, 5 Axis I/O Connector...................................................................................................................... 59

9.Package Dimensions.................................................61

10. Specifications ..........................................................62

- 1 -

1. Outline

MR210AU/220AU is a motion control unit which can control one or two axes of either stepper motor or pulse type servo drives

for position and speed controls. A built-in EEPROM can program driving parameter values and position data of up to 64 steps for

each axis. MR210AU controls 1-axis and MR220AU controls 2-axes.

Model Axes Serial Communication Port

MR210AU 1 equipped with RS-232C, USB.

MR220AU 2 equipped with RS-232C, USB.

Fig.1.1 shows the MR210AU/220AU basic circuit block diagram.

A 2-axes motion control IC “MCX302” is equipped with acceleration/deceleration drive pulse oscillation of up to 4MHz and a

position counter.

Driving pulse output to a motor driver is differential line-drive output, which can connect to the motor driver of either photo

coupler input or differential line receiver input.

Sensor input is insulated by photo coupler, which can input over run limits, a home, an in-position and alarm signal from a servo

motor driver.

Serial communication port has two interfaces, RS232C and USB. Connect the serial communication port and PC or a remote box

(option), then set data such as driving parameter mode, position data and program data. In addition, serial communication

commands are prepared so that the user can freely control the axis by programming on Windows.

Parallel interface port performs actual drive activation, stop, position and program selection, which connects to a PLC or switches.

Si ngl e C hi p

Microcomput er

Line- Driver

AM26C31

Output Buffer

TD62083A

Photo Coupler

X- A x is I / F

Y- A xi s I /F

DC 2 4V

P o we r

Fig.1.1 MR210AU/220AU Circuit Block Diagram

T89C51ED2

Photo

Output Buffer

TD62083A

+Direction

-Direction

Ge n er a l Ou t pu t

+Direction Limit

- D i re c ti on Li m it

Servo Positioning

Se rv o A l er m

Encoder Z-Phase

Home

Ne a r Ho m e

MAX232C

Parallel

I/ F

I/ F

RS -2 3 2C

MCX302

XOUT0

XL MT +

XL M T-

XSTOP0

XS TO P 1

XS TO P 2

XINPOS

X A LA RM

TX

RX

RE SE T

HO M E

STROBE

X

Y

REG0~5

MODE0~1

XDRIVE

YDRIVE

CN1

CN2

CN3

Open

CN4

Y - Ax i s I/ O S i gn a l

(SameasX-Axis)

2- Ax es M ot i o n

Control IC

TLP281

Co llec tor

XE R RO R

YE R RO R

EEPROM

FT

232

R

CN6

USB I/F

TLP281

CN5

[Note1] MR210AU does not have CN5.

N o te 1

注1

XP + P/ N

XP-P/N

Built-in

Cou pler

Inp ut

Pu lse Output

P ulse Outpu t

C om p le ti o n

- 2 -

■ Appearance

Fig.1.2 shows the appearance of the MR220AU, its package dimensions are 90mm (H)×36mm (W)×60mm (D). Input/output

connectors are placed on front panel and rear panel is equipped with DIN rail installing hook.

■ Operational Procedures

MR210AU/220AU operations are performed by following procedures (1)~(4).

(1) Operating Program Installation

Operating program is the tool to write driving parameter mode or driving programs from PC to MR210AU/220AU, which the user

can install from the accessory CD-ROM. See chapter 2.

(2) Setting of Driving Parameter Mode and Program

Connect PC and MR210AU/220AU with the cable that comes with the package, then set driving parameter mode and programs by

the operating program installed in step (1). These setting data will be written in a built-in EEPROM.

In addition, driving parameter mode and programs can be set through the optional remote box (MR200RB), which connects to the

RS232C port of the motor control unit.

MR220AU

X

Y

PI/F

24VDC

USB

RS232C

RS- 232C Cable / USB Cable (included)

CN1 Power Source DC24V In

p

ut

CN2 Serial Communication RS232C

CN6 Serial Communication USB

CN3 Parallel I/F

CN4 X-Axis In

p

ut/Out

p

ut

CN5

Y

-Axis In

p

ut/Out

p

ut

36m

m

90m

m

60m

m

MR220AU

X

Y

PI/F

24VDC

USB

RS232C

The cable comes with MR200RB.

REG DATA

X

Y

XY

REG

WRT

+

-

MR200RB

REMOTE BOX

X

Y

EXC

DP

DP

01234

56789

RST

HOME

+-

SPDSET

PRG STOP

Fi

g

.1.2 MR220AU Appearance

- 3 -

(3) Connection of Motor Driver and Sensor

Connect a motor driver to a driving pulse signal and input from a sensor to over limit signals or a home signal of each axis.

In-position and alarm input signals are prepared for the servo motor.

See chapter 8 for more details on input/output signals and connection examples of a motor driver or a sensor.

(4) Drive Activation

There are four methods to activate MR210AU/220AU as follows (a. ~ d.).

a. Activation from Parallel I/F

The method to activate by connecting a PLC or switches to parallel I/F connector. See chapter 5.

b. Activation from PC

Connect PC with the communication cable and start the operating program, the user can perform manual operations such as jog

feed of each axis, home search and program execution from main operational panel. See chapter 6.

c. Activation from Remote Box

Connect with the cable that comes with a remote box, the user can perform jog feed, home search and program execution by drive

operation of the remote box. See chapter 7.

d. Control by Serial Communications

MR210AU/220AU has serial communication commands (separate book). Connect MR210AU/220AU and your PC or a PLC with

the USB or RS232C cable, the user can control axes on your own program.

Fi

g

.1.3 Connection Example of Axis I/O Si

g

nals

X-Axis

Motor

EC

+Direction Driving Pulse

-

Direction Driving Pulse

In-position

Alerm

EC-Z

XLMT+

XLMT-

Motor Driver

XP+P/N

XP-P/N

XINPOS

XALARM

XEC-Z

MR220A

CN4

+Limit

-Limit

Home

XSTOP0

XSTOP1

Stepping / Servo Motor

- 4 -

2. Setup Operating Program

The operating program is the tool to write driving parameter mode or driving programs from PC to MR210AU/220AU. The

accessory CD-ROM contains the operating program, which is composed of three directories as follows:

・InstMS Folder -------- Installer for OS before Windows XP.

・MRPRG Folder -------- MR210AU/220AU Operating program

・Driver Folder ------- USB device driver

The latest version is available on our web site: http://www.novaelec.co.jp/eng/index.html .

First install the operating program from MR200 Series CD-ROM according to chapter 2.1. Then, to make connection with the

motor control unit, if using USB communication, follow steps in chapter 2.2. If using RS232C communication, follow steps in

chapter 2.3.

2.1 Operating Program Installation

2.1.1 Operating Program Installation

(1) Insert MR200 Series CD-ROM into the CD drive.

[Note] Do not connect MR210AU/220AU and your PC at this time. Although the user can install while being connected, if using

the USB cable, operating system will ask for the driver in the first connection. In this case, the user should install the USB device

driver in advance according to chapter 2.2.1.

(2) Windows 2000 users: double-click the installer to build on your hard disc.

Windows 2000 users ------ Execute InstMsiW.exe in InstMS folder.

Windows XP users don't need to do anything for this step.

(3) Double-click MR220A.msi program file in MRPRG folder. In a while, setup screen will be invoked and then installation will

start. Follow the on-screen instructions below.

(4) When the Setup Wizard appears, click Next.

- 5 -

(5) On the Select Installation Folder screen, click Next, which uses the default settings.

(6) On the Confirm Installation screen, click Next.

(7)On the user’s account control, click “Yes”.

* Only on Windows 7.

- 6 -

(8) MR220A is now installed.

(9) When the installation is complete, the Installation Complete screen appears. Click Close to complete setup.

- 7 -

2.1.2 Uninstallation

Usually this removal process is not needed. Please follow these steps when updating the operating program to the latest version or

removing from your hard disc.

(1)To uninstall the program, use “Add/Remove Programs” utility in the Windows Control Panel.

Or on windows 7, use” Program”, “Program and function” and “Uninstallation or change of program”.

(2) Select the “MR220A” program from the list, then click Add/Remove button.

The operating program will be uninstalled.

(3) On the user’s account control, click” Yes”.

* Only on Windows 7.

(4) Select “MR220A” program from the list , then click Remove button.

The operating program will be uninstalled

*On Windows 7, unistallation of “MR220A” is operated automatically.

- 8 -

2.2 Setup with USB cable

2.2.1 USB device driver installation

Connect the motor control unit and PC with the USB cable, then turn on both equipment power. If this is first connection with the

USB cable, new hardware will be detected. Insert MR200 Series CD-ROM into the CD drive and install USB device driver. Please

specify the folders “\driver” which is downloaded in the CD-ROM.

After installation, verify it using Windows Device Manager as follows:

Click Control Panel →System →Hardware tab →Device Manager, if USB device driver (“USB to Serial port”) is found under

Ports (COM & LPT) (Please note listed below.), the installation is successfully completed.

[Note1] Installation Wizard appears twice.

[Note2] USB driver installation is needed once every

unit. For example, if 3 units are connected to

PC, USB driver should be installed three times.

2.2.2 Check Operating Program Start-up

According to chapter 6.1, check the operating program properly starts when connecting to the motor control unit.

When the operating program is first started

after installation, it may be offline mode

even though the cable is connected. In this case,

click Option menu on the upper left of the main

window, then check (V) COM option connected

with the motor control unit, then exit the operating

program and restart it.

[Note] The COM number using with USB connecting,

click Control Panel →System →Hardware tab

→Device Manager, the user can find it after

USB device driver name (“USB to Serial Port”)

under Ports (COM & LPT).

- 9 -

2.3 Setup with RS232C cable

(1) Connect the motor control unit and PC with the RS232C cable.

(2) Turn on both equipment power.

(3) Start the operating program from Start menu.

On the Start menu, point to Programs, then click Motion Controller →MR220A →MR220A.

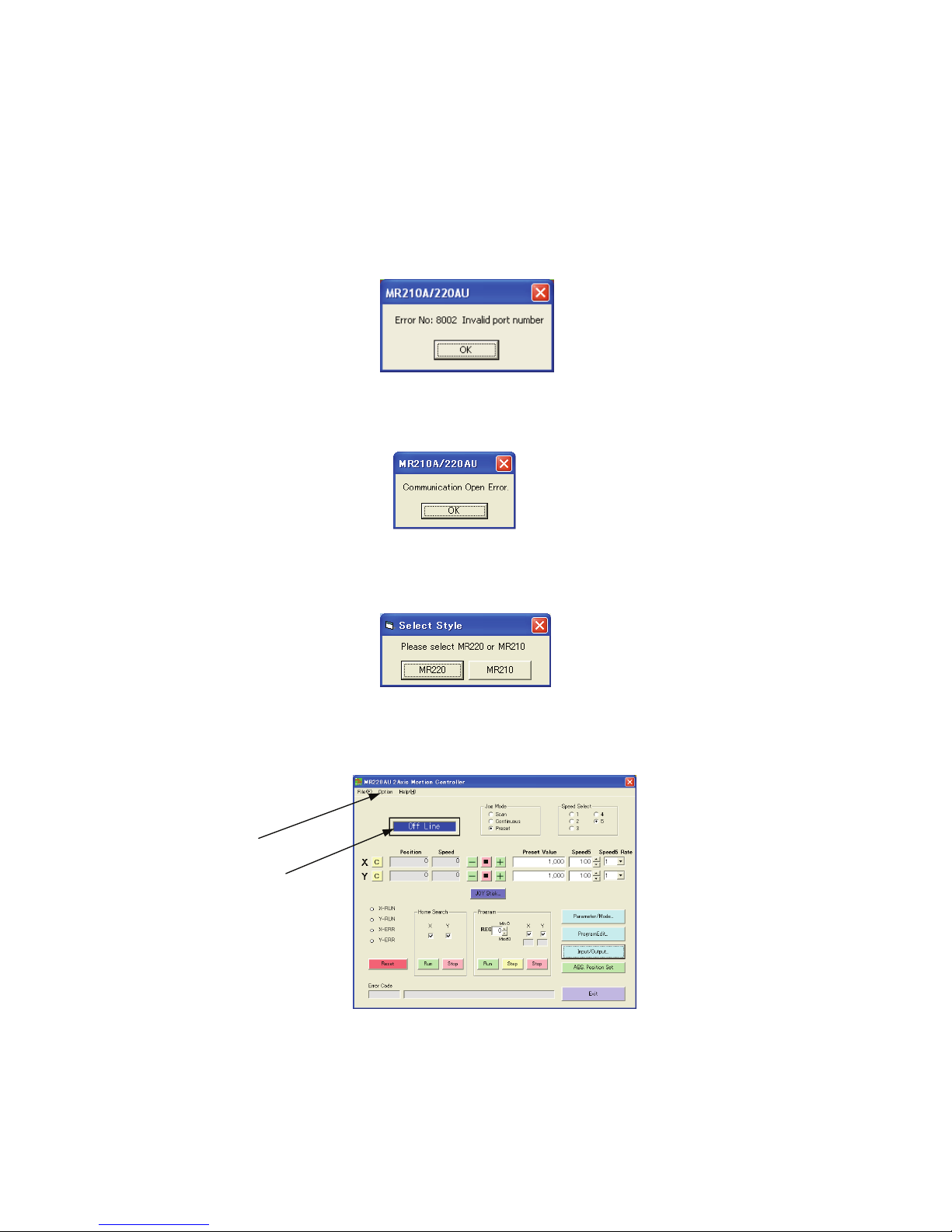

(4) In the first connection, the following error message appears.

After clicking OK, communication open error message appears.

Click OK.

(5) Select Style dialog box appears, click the type MR220AU or MR210AU which the user uses.

(6) The operating program is invoked in offline mode.

Click Option menu, then check (V) the COM port connected with the RS232C cable.

(7) Exit the operating program once and restart it. Make sure that the operating program is invoked in online mode.

O

p

tion

Off Line Mode Display

- 10 -

3. Driving Mode and Parameters Configuration

To operate MR210AU/220AU, it is first necessary to configure driving mode and parameters for MR210AU/220AU based on the

user system. Connect MR210AU/MR220AU and PC with the RS232C or USB cable and start the operating program on Windows,

the user can configure driving mode and parameters in Mode / Parameter screen.

In addition, driving mode and parameters can be configured using an optional remote box (MR200RB), which connects to the

RS232C port of the motor control unit. See chapter 7 for details on how to configure by the remote box.

■ Start Operating Program

Connect MR210AU/220AU and PC with the cable and then start the operating program. (See chapter 6.1 for details on how to

start the operating program.) When the main screen appears, click Parameter / Mode button. Parameter / Mode screen appears.

Parameter / Mode screen has three tabs: Mode, Parameter and Home Search Mode. Hereinafter describe how to configure in each

tab based on the user system.

3.1 Mode Setting

Click Mode tab to change Mode screen if not displayed. MR210AU has X-axis only.

■ Limit Stop Mode and Logical Level

Selects either instant stop or deceleration stop for driving when a limit signal becomes active, and specify a logical level either hi

or low.

Display Option Default

Limit Stop Mode

Limit Active Level

Instant (Instant stop) / Slow (Deceleration stop)

Low (GEX Short-circuited) / High (Open)

Instant

Low

Main Screen Parameter / Mode screen

Limit Stop Mode and Logical Level

Servo Inposition Enable and Logical Level

Servo Alarm Enable and Logical Level

Driving End Pulse

Deceleration Value Selecting

Software Limit

Power On Home Search Start

Power On Program Start

Click

- 11 -

Over limit input signals (nLMT+/-) for +/- direction of each axis are the #12, #13 pins in CN4, 5 connectors (See chapter 8.).

Limit Stop Mode selects either Instant Stop or Deceleration Stop for when this over limit input signal becomes active. Besides,

Limit Active Level specifies the logical level for active. To make active for when the over limit input signal and GEX are

short-circuited, set low to the logical level and to make active for when it is open, set high to the logical level.

■ Servo Inposition Enable and Logical Level

Selects action for an inposition input signal from a servo motor driver.

Display Option Default

Servo Inposition Enable

Servo Inposition Level

Disable / Enable

Low (GEX Short-circuited) / High (Open)

Disable

Low

Inposition input signals (nINPOS) of each axis are the #6 pins in CN4, 5 connectors (See chapter 8.).

When Servo Inposition Enable selects Enable, after output of driving pulses, driving will terminate after checking the inposition

input signal (nINPOS) becomes active. While the program is running, after execution of drive commands (ABS, INC), next

register will be performed after checking the inposition input signal becomes active.

Logical level (Servo Inposition Level) selects for active either when the inposition input signal (nINPOS) is open or when the

inposition input signal is short-circuited with GEX. When selecting open for active, set high and when selecting GEX

Short-circuited for active, set low.

If the inposition input signal (nINPOS) is not used like in the case of a stepping motor, set default values.

■ Servo Alarm Enable and Logical Level

Selects action for an alarm input signal from a servo motor driver.

Display Option Default

Servo Alarm Enable

Servo Alarm Level

Disable / Enable

Low (GEX Short-circuited) / High (Open)

Disable

Low

Servo alarm input signals (nALARM) of each axis are the #7 pins in CN4, 5 connectors (See chapter 8.).

When Servo Alarm Enable is enabled and when the servo alarm input signal (nALARM) becomes active during driving, pulse

output of its axis immediately stops and then turn on the nERROR output signal.

Logical level (Servo Alarm Level) selects for active either when the servo alarm input signal is open or when the servo alarm input

signal is short-circuited with GEX. When selecting open for active, set high and when selecting GEX Short-circuited for active,

set low. To clear an error after the error occurs, make the servo alarm input signal inactive and then reset the motor control unit.

If the servo alarm input signal (nALARM) is not used, set default values.

■ Driving End Pulse

Outputs End Pulse from the nDRIVE/END signal of the parallel I/F connector at the end of driving.

Display Option Default

End Pulse Disable / Enable Disable

DRIVE/END output signals of X and Y axes are #14, 15 pins in CN3 of the parallel I/F connector (See chapter 8.).

When driving end pulse (END Pulse) is disabled, the nDRIVE/END signal will be ON during drive of each axis or execution of

the program, and will be OFF at the end of driving.

When enabled, the nDRIVE/END signal will be OFF during index driving of ABS, INC, which are specified as End Pulse Enable

in commands, or home search driving. And ON pulses will be output for the period of the End Pulse Width, which is specified by

the parameter, at the end of driving. While executing the program, ON pulses are also output after execution of ABS, INC, HOM

commands which are specified as End Pulse Enable in commands.

- 12 -

■ Deceleration Value Selecting

Selects either acceleration value (symmetry acceleration/deceleration) or deceleration value individually (non-symmetry

acceleration/deceleration) as a deceleration speed at deceleration in trapezoidal driving.

Display Option Default

Deceleration Value Accel (Acceleration) / Decel (Deceleration) Accel

MR210AU/220AU can perform not only symmetry

acceleration/deceleration driving where the

acceleration and the deceleration are same but also

non-symmetry acceleration/deceleration driving

where the acceleration and the deceleration are

different. When selecting Accel (Acceleration), the

acceleration parameter is used as a deceleration speed

at deceleration and driving becomes symmetry

trapezoidal. When selecting Decel (Deceleration), the deceleration parameter is used as a deceleration speed and driving

becomes non-symmetry trapezoidal.

[Note] Please note that the following (1), (2) for when non-symmetry trapezoidal acceleration/deceleration driving is performed.

(1) In the case of acceleration > deceleration, the following condition is applied to the ratio of the acceleration and the

deceleration.

For instance, if driving speed V = 100kps, deceleration D must be greater than 1/40 of acceleration A. The value must not be less

than 1/40 of the acceleration.

(2) If acceleration > deceleration, the greater the ratio of acceleration A to deceleration D becomes, the greater the number of creep

pulses (outputs of specified driving pulses are not completed at deceleration of index driving even if the speed reaches the

initial-speed and remaining driving pulses are output at initial-speed.) becomes. Approximately maximum of 10 pulses when

A/D=10 times.

■ Software Limit

Selects either Disable or Enable for software limit.

Display Option Default

Soft Ware Limit Disable / Enable Disable

Software Limit is the over run limit function which can internally set as position data; it differs from hardware limit signal input

such as an external sensor. Software limit can be set as parameters for + and – direction respectively. When selecting enable, and

when the position counter is over the software limit + to – range during driving, decelerating stop will be performed. This error

condition will be cleared if the user drives in the opposite direction and sets the position counter back within a software limit

range.

[For reference] While a home search is running, the software limit does not function even if enabled.

■ Power On Home Search Start

Selects either Disable or Enable for automatic home search at power-on.

Display Option Default

Power On Home Search Start Disable / Enable Disable

Power On Home Search Start is the function to automatically perform home search when the power is on or motor control unit is

reset.

Acceleration Rate

Symmetry Trapezoidal Driving Non- Symmetry Trapezoidal Driving

Same as Acceleration Rate

Time

Speed Acceleration Deceleration

Deceleration Rate

Acceleration Deceleration

Speed

Time

Acceleration Rate

D>A

×

V

4

×1 0

6

D

:

Deceleration rate (pps/sec)

A

:

Acceleration rate (pps/sec)

V

:

Drive speed (pps)

- 13 -

■ Power On Program Start

Selects either Disable or Enable for automatic program start at power-on.

Display Option Default

Power On Program Start Disable / Enable Disable

Power On Program Start is the function to perform automatically the registered program from REG00 when the power is on or

motor control unit is reset. If Power On Home Search Start is also enabled, the program will be performed after completion of

home search operation.

[Note]

(1) When using Power On Program Start, write timer command to REG00 in advance, then make sure that next command is

operated after passing the specified period. In addition, it recommends to embed home search command into the program.

(2) Do not release Power On Program Start or Power On Home Search Start during driving. Make sure to first stop driving in main

screen (click STOP button) and then disable them in parameter/mode screen in advance.

(3) Do not alter the program or mode/parameters while executing the program by Power On Program Start. Make sure to first stop

in main screen (click STOP button) in advance.

- 14 -

3.2 Parameter Setting

Click Parameter tab to change Parameter screen if not displayed. MR210AU has X-axis only.

Speed Multiplier

Acceleration Rate

Deceleration Rate

Start Speed

Drive Speed 1~4

Post Timer 1~3

Home Search Low Speed

Home Search High Speed

Home Search Offset

Software Limit +

Software Limit -

Driving End Pulse Width

Pulse Scale Numeration

Pulse Scale Denomination

■ Speed Multiplier

Speed Multiplier is the parameter which decides the multiplication of the speed parameter such as drive speed or

acceleration/deceleration speed.

Display Setting Range Default

Speed multiplier 1 ~500 10

Speed parameters such as drive speed, start speed and acceleration/deceleration speed can be set within the range from 1 to 8,000.

If the user sets the larger value than that, the speed multiplier must be raised. When raising the speed multiplier, the user can drive

at high-speed but speed resolution becomes rough. Set the minimum value which covers the range of drive speed.

■ Acceleration Rate

Acceleration Rate is the parameter used as acceleration rate at acceleration in acceleration driving. When setting Deceleration

Value to Accel (default value) in mode setting, this acceleration rate will also be used at deceleration.

Display Setting Range Default

Acceleration Rate 1 ~8000 400

If the value for acceleration rate is A, actual acceleration rate is

as follows:

Acceleration Rate (pps/sec) =A ×125 ×Speed

Multiplier

To perform acceleration driving, as shown in the diagram, four

parameters: initial speed, drive speed, acceleration rate and

deceleration rate must be set. However, if performing symmetry

trapezoidal driving, no need to set deceleration rate.

For instance, if the initial speed 500pps is raised up to 20,000pps in 0.3 seconds, speed parameter should be set as follows:

Acceleration Rate (pps/sec) =(20,000 -500)/0.3 =65,000 (pps/sec)

Speed Parameter required for Trapezoidal Driving

Drive Speed

Initial Speed

Acceleration Rate

Deceleration Rate

Time

Speed

- 15 -

If speed multiplier is 10,

Setting value for acceleration rate A =65,000/( 125×10 ) =52

Setting value for start speed SV =500/10 =50

Setting value for drive speed V =20,000/10 =2,000

■ Deceleration Rate

Deceleration Rate is the parameter used as deceleration rate at deceleration in acceleration driving.

Display Setting Range Default

Deceleration Rate 1 ~8000 400

If the value for deceleration rate is D, actual deceleration rate will be as follows:

Deceleration Rate (pps/sec) =D ×125 ×Speed Multiplier

In default mode setting, Deceleration Value is set to Accel, therefore, acceleration rate is also used at deceleration and driving

becomes symmetry trapezoidal. If the user wants to perform non-symmetry trapezoidal driving, change Deceleration Value to

Decel in mode setting and set this deceleration rate.

■ Start Speed

This is the speed at the start of acceleration/deceleration driving and at the end of driving.

Display Setting Range Default

Start Speed 1 ~8000 50

Actual start speed is the value which multiplies the start speed value by speed multiplier.

Start Speed (pps) =SV ×Speed Multiplier

When drive speed is larger than this start speed, acceleration/deceleration driving is performed. In this case, the parameter of

acceleration/deceleration rate must be set. When drive speed is smaller than the start speed, constant speed driving starts instead of

acceleration/deceleration. Home search at high-speed is as well.

■ Drive Speed 1~4

Drive speed is the speed of constant speed period in acceleration/deceleration driving.

Display Setting Range Default

Drive Speed 1

Drive Speed 2

Drive Speed 3

Drive Speed 4

1 ~8000

1 ~8000

1 ~8000

1 ~8000

10

100

1000

8000

Each axis can set four types of drive speed. The user selects one drive speed from four types for driving.

Actual drive speed is the value which multiplies the drive speed value by speed multiplier.

Drive Speed (pps)=V ×Speed Multiplier

When drive speed is larger than the start speed, acceleration/deceleration driving is performed. In this case, the parameter of

acceleration/deceleration rate must be set. When drive speed is smaller than the start speed, constant speed driving starts instead of

acceleration/deceleration.

■ Post Timer 1~3

Post timer is the waiting time until next command starts after execution of drive commands such as ABS, INC for program

operation. Three types of post timer can be registered.

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

PowerPlus Energy

PowerPlus Energy PowerLink Installation and operation manual

Emerson

Emerson Fisher CCV-N instruction manual

Ambient

Ambient PowerSlot manual

SMC Networks

SMC Networks VND Series Operation manual

Jung

Jung TK SV STG 60 REG Product information

Sun Microsystems

Sun Microsystems Ultra 2 UltraSPARC-II Upgrade