- 4 -

VN-OMA0013-D

Warning

Warning

Warning

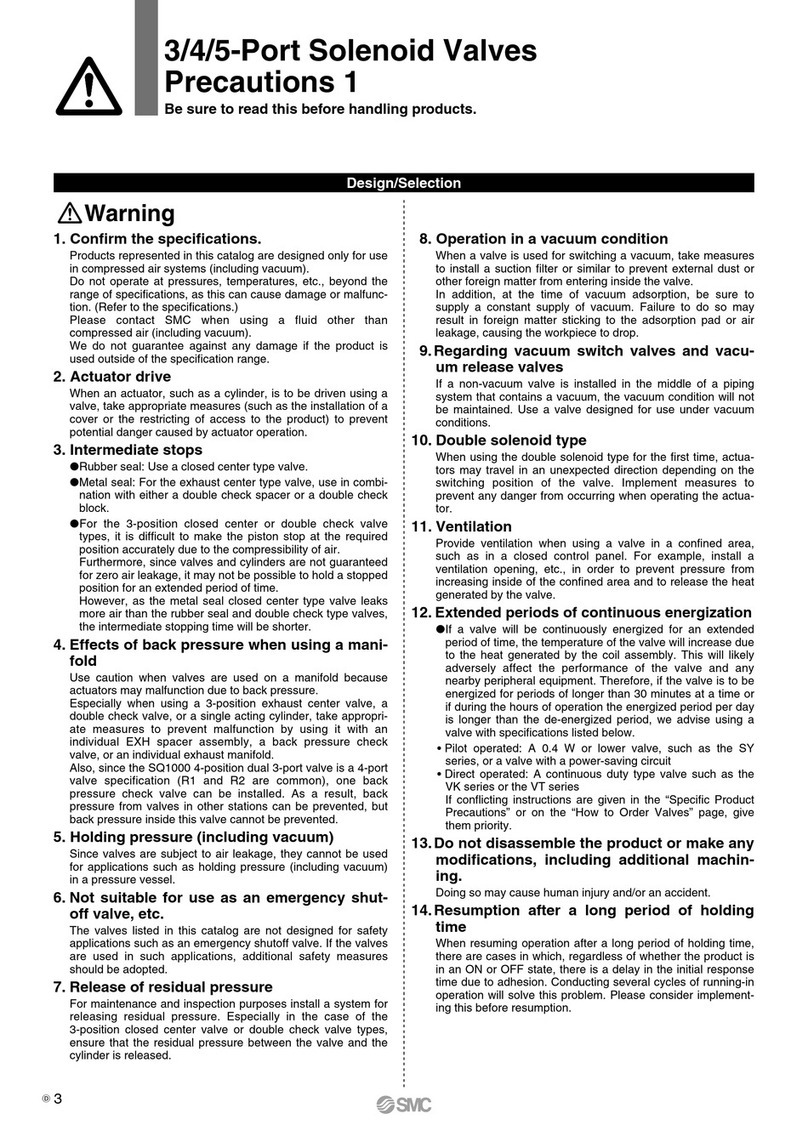

Design

1. Cannot be used as an emergency shutoff

valve, etc.

The valves presented in this catalog are not designee for safety

applications such as an e ergency shutoff valve. If the valves

are used in this type of syste , other reliable safety assurance

easures should also be adopted.

2. Ensure sufficient space for maintenance ac-

tivities.

When installing the products, allow access for aintenance.

3. iquid rings

In cases with a flowing liquid, provide a by-pass valve in the

syste to prevent the liquid fro entering the liquid seal circuit.

4. Actuator drive

When an actuator, such as a cylinder, is to be driven using a

valve, take appropriate easures to prevent potential danger

caused by actuator operation.

5. Pressure (including vacuum) holding

It is not usable for an application such as holding the pressure

(including vacuu ) inside of a pressure vessel because leakage

is entailed in a valve.

6. When an impact, such as water hammer, etc.,

caused by the rapid pressure fluctuation is

applied, the valve may be damaged. Give an

attention to it.

Selection

1. Confirm the specifications.

Give careful consideration to the operating conditions such as

the application, fluid and environ ent, and use within the

specified operating ranges in this catalog.

2. Fluids

1) Type of fluids

Before using a fluid, confir whether it is co patible with the

aterials fro each odel by referring to the fluids listed in

the catalog.

If there is so ething you do not know, please contact SMC.

2) Corrosive gas

Cannot be used since it will lead to cracks by stress corrosion

or result in other incidents.

3) When a bronze body is used, then depending on water quality,

corrosion and internal leakage ay occur. If such abnor ali-

ties occur, exchange the product for a stainless steel body.

3. Fluid quality

The use of a fluid that contains foreign atter can cause prob-

le s such as alfunction and seal failure by pro oting wear of

the valve seat, and by transfor ation of valve ele ent, etc.

Install a suitable filter (strainer) i ediately upstrea fro the

valve. As a general rule, use 80 to 100 esh.

When used to supply water to boilers, substances such as

calciu and agnesiu which generate hard scale and sludge

are included. Since this scale and sludge can cause the valve to

alfunction, install water softening equip ent, and a filter

(strainer) directly upstrea fro the valve to re ove these

substances.

4. Air quality

1) Use clean air.

Do not use co pressed air that contains che icals, synthetic

oils including organic solvents, salt or corrosive gases, etc.,

as it can cause da age or alfunction.

2) Install air filters.

Install air filters close to valves at their upstrea side. A

filtration degree of 5μ or less should be selected.

3) Install an aftercooler or air dryer, etc.

Co pressed air that contains excessive drainage ay cause

alfunction of valves and other pneu atic equip ent. To

prevent this, install an aftercooler or air dryer, etc.

4) If excessive carbon powder is generated, eliminate it by

installing mist separators at the upstream side of valves.

If excessive carbon powder is generated by the co pressor,

it ay adhere to the inside of the valves and cause

alfunction.

Refer to SMC’s Best Pneu atics catalog for further details on

co pressed air quality.

5. Ambient environment

Use within the operable a bient te perature range. Confir

the co patibility between the product’s co position aterials

and the a bient at osphere. Be certain that the fluid used does

not touch the external surface of the product.

6. ow temperature operation

1) The valve can be used in an a bient te perature of -5

o

C.

However, take easures to prevent freezing or solidification

of i purities, etc.

2) When using valves for water application in cold cli ates, take

appropriate counter easures to prevent the water fro free-

zing in tubing after cutting the water supply fro the pu p, by

draining the water, etc. Installation of a dryer, heat retaining of

the body is reco ended to prevent a freezing condition in

which the dew point te perature is high and the a bient

te perature is low, and the high flow runs.

7. Do not disassemble the product or make any

modifications, including additional machining.

It ay cause hu an injury and/or an accident.

Mounting

1. If air leakage increases or equipment does not

operated properly, stop operation.

After ounting is co pleted, confir that it has been done

correctly by perfor ing a suitable function test.

body only. They can cause the coil to burn out.

2. Secure with brackets, except in the case of

steel piping and copper fittings.

3. Avoid sources of vibration, or adjust the arm

from the body to the minimum length so that

resonance will not occur.

4. Painting and coating

Warnings or specifications printed or labeled on the product

should not be erased, re oved or covered up.

VND Series

Valves for Fluid Control

Precautions 1