Titan – Reassembly

STEPS DESCRIPTION IMAGE

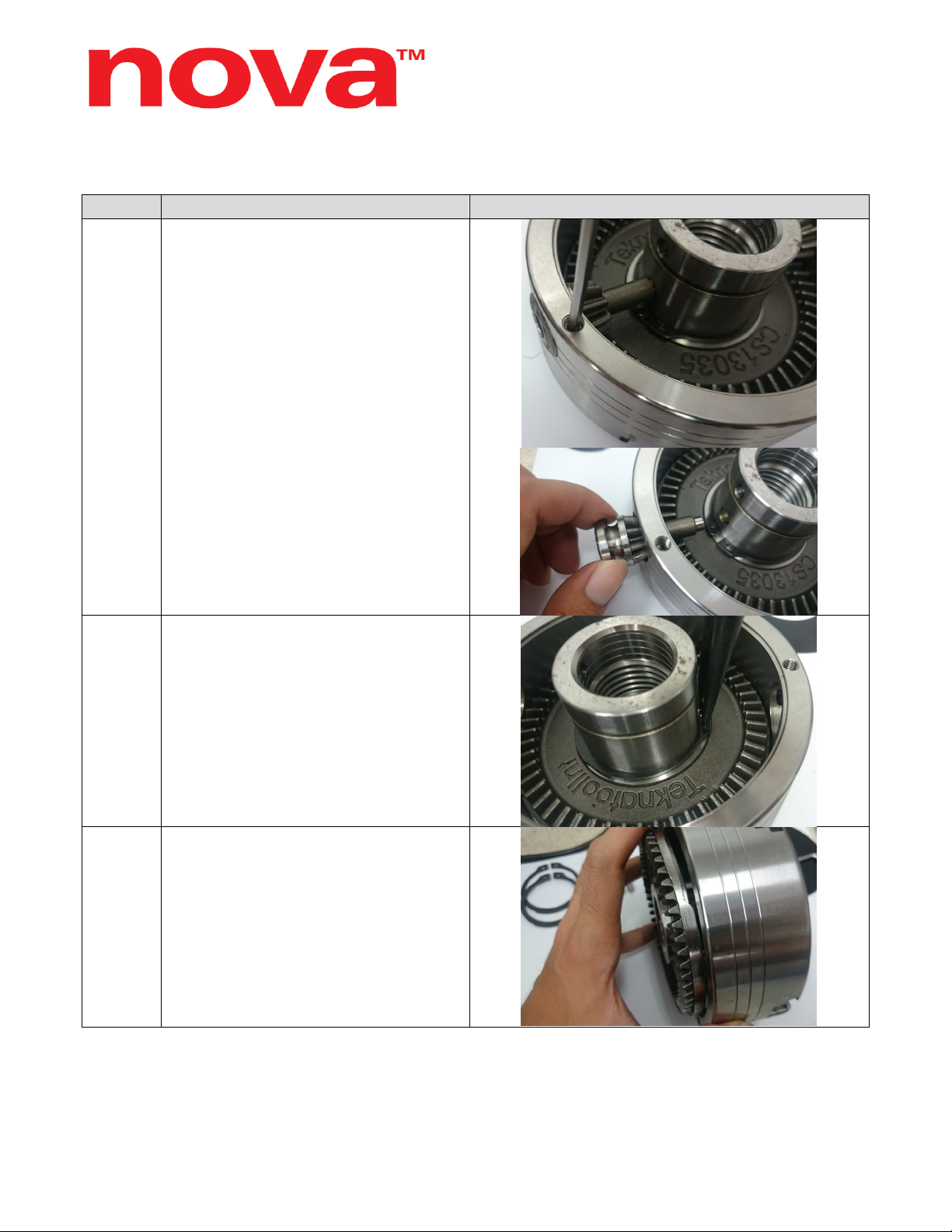

1.

Before reassembly, apply a generous

amount of lubricant where parts come

into contact.

We recommend applying the lubricant

to the inner surface of the chuck body

as well as the jaw slide slots before

assembly. Also, apply lubricant on the

spiral teeth side of the scroll ring.

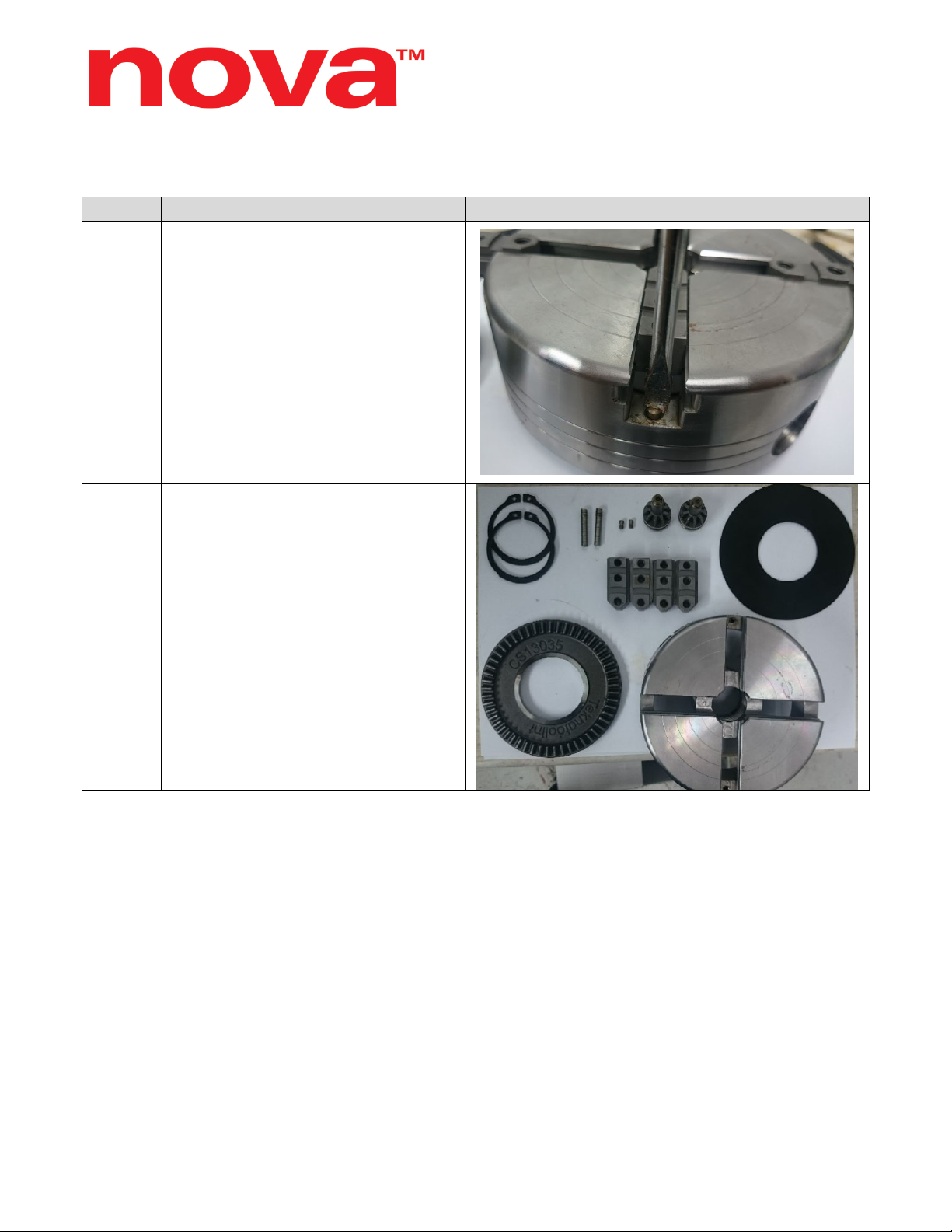

2.

Reinsert the jaw slides back into their

original slots.

Looking from the front, the jaw slide

number should be counting up from 1-

4 in the clockwise direction.

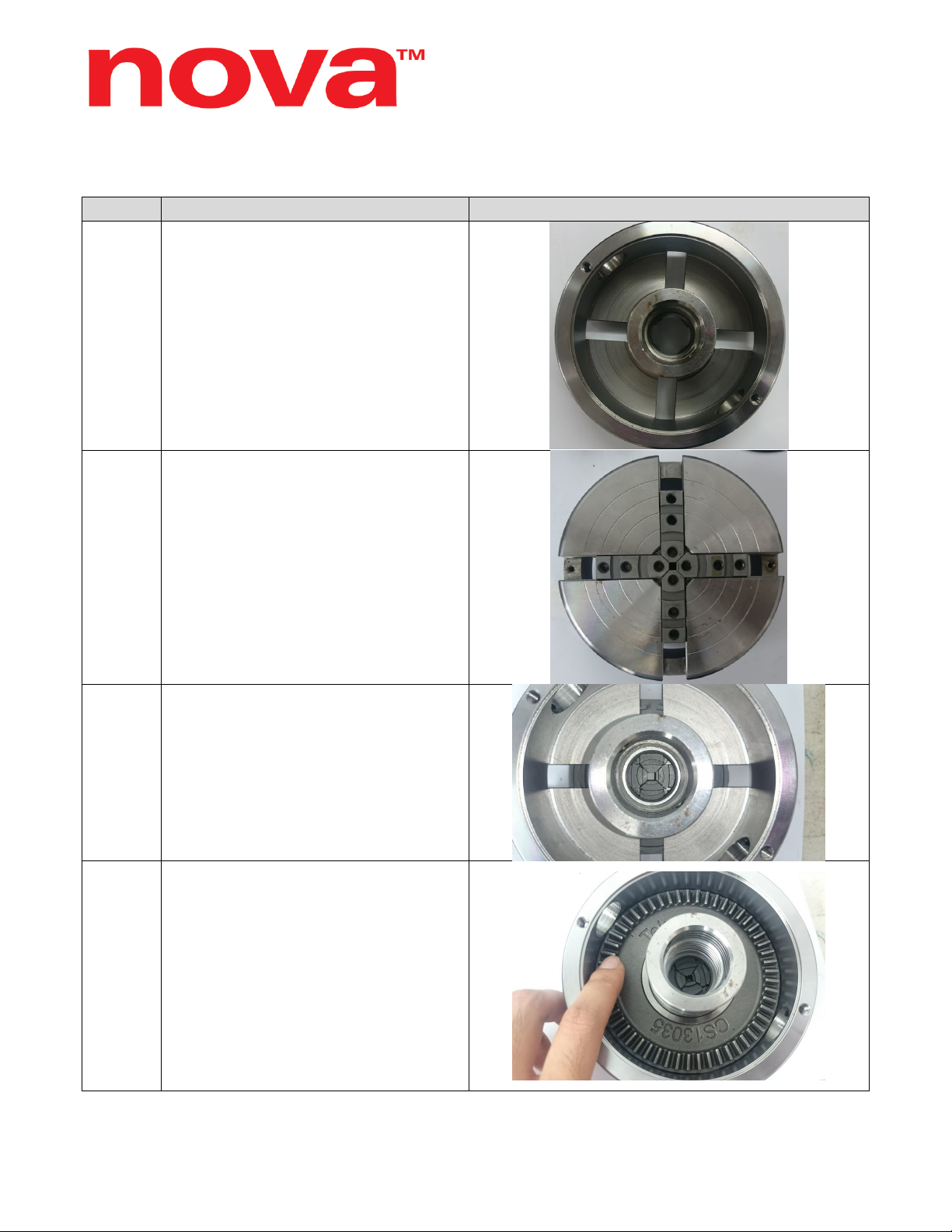

3.

Flip the chuck on its face and position

the jaw slides to form a square in the

centre as shown.

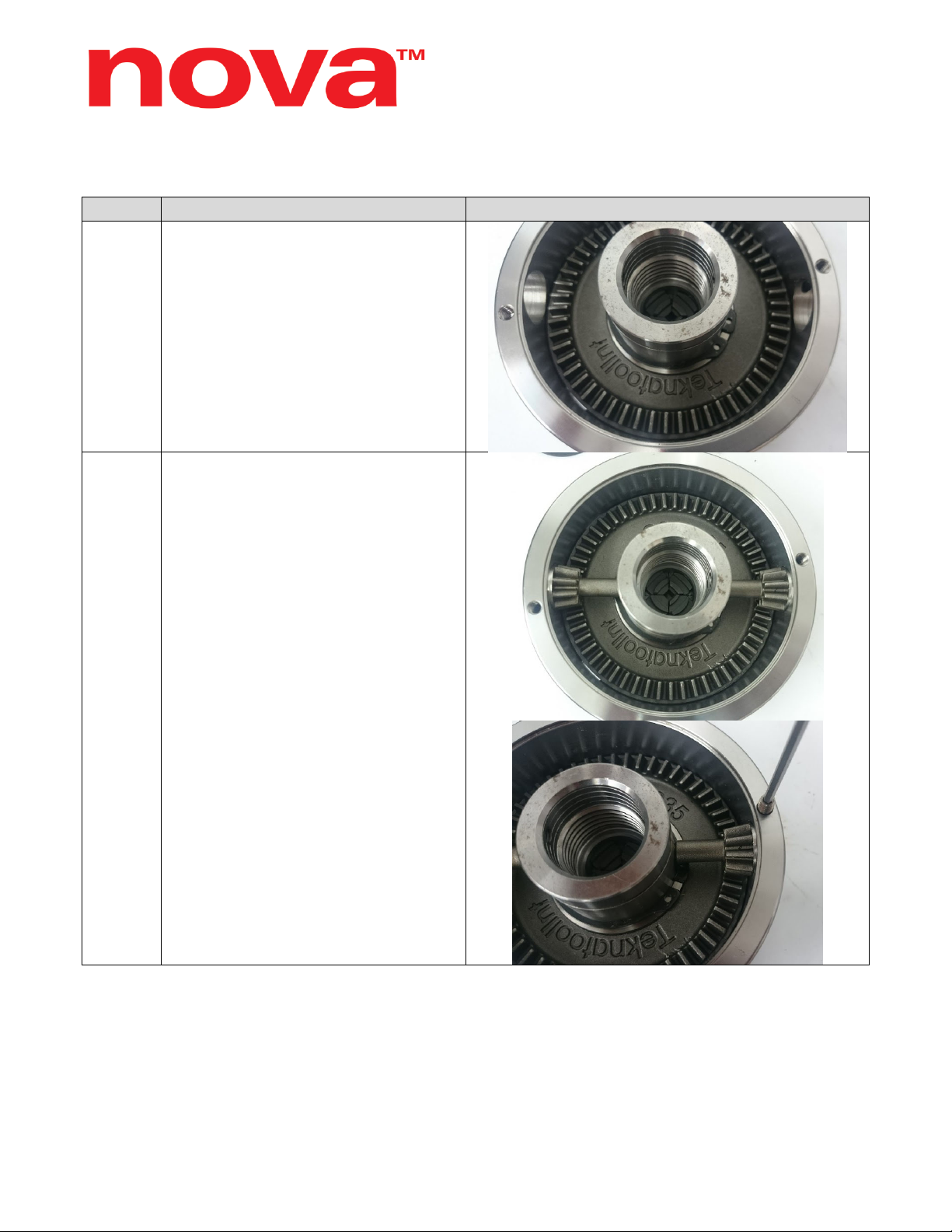

4.

Slide the scroll ring back into the

chuck body. Once it is in place, rotate

the scroll ring until it engages with the

jaw slides.

You should be able to feel the scroll

rings engage as it will drop into place,

exposing the slot where the snap ring

will fit.

Alternatively, you will see the jaw

slides move as you turn the scroll ring.

Continues to next page…

p.23